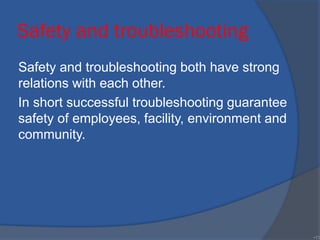

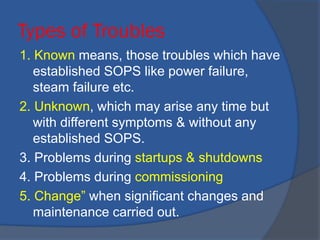

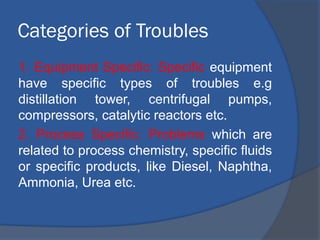

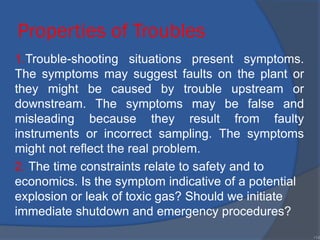

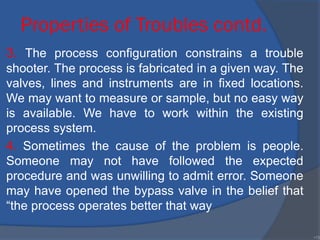

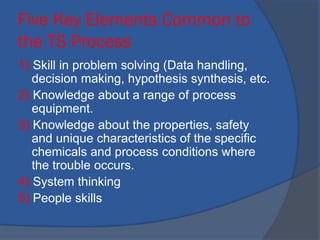

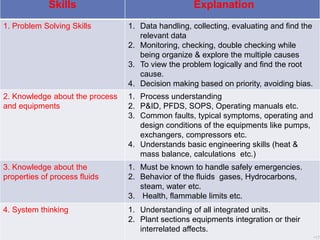

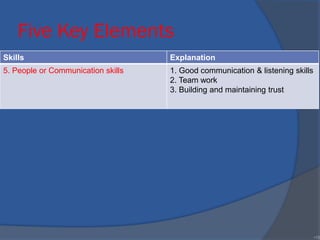

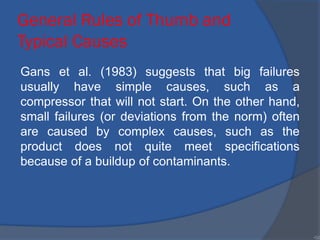

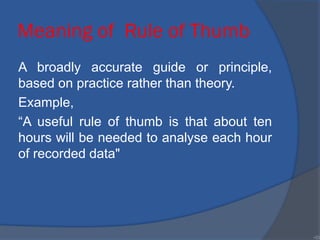

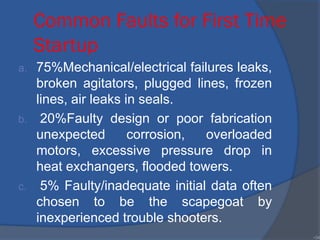

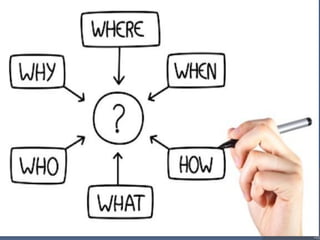

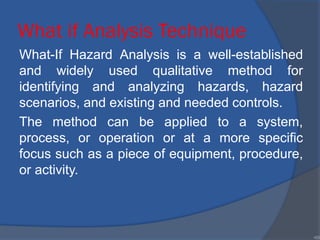

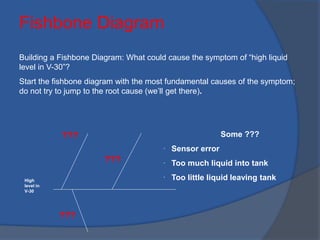

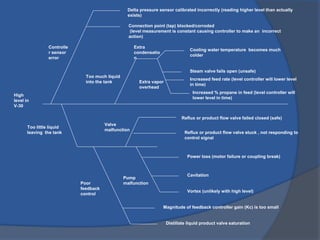

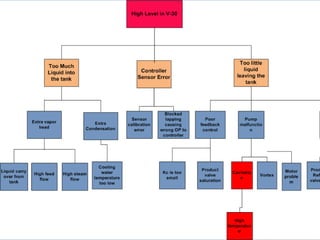

The document discusses troubleshooting processes in process operations, highlighting its importance, methodologies, and skills required for effective problem-solving in oil refineries. It outlines a systematic approach consisting of seven key steps and emphasizes the need for effective communication, data handling, and safety in troubleshooting. The document also covers different types of troubles, their causes, guidelines for successful troubleshooting, and various techniques to analyze and resolve issues.

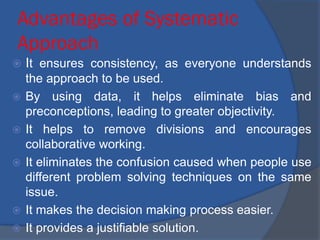

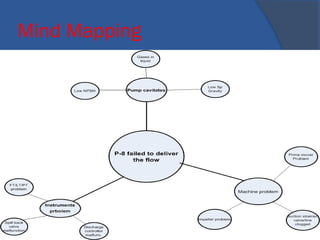

![Mind Mapping

A mind map is a diagram used to visually

organize information. A mind map is

hierarchical and shows relationships among

pieces of the whole.[1] It is often created

around a single concept, drawn as an image

in the center of a blank page, to which

associated representations of ideas such as

images, words and parts of words are added.

Major ideas are connected directly to the

central concept, and other ideas branch out

from those major ideas.

•73](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-73-320.jpg)

![Centrifugal Pumps TS Rules

of Thumb

Symptoms Control measures

No liquid

delivery

instrument error/not primed/ cavitation/supply tank

empty

Liquid

flowrate low

instrument error/ cavitation/ non-condensibles in

liquid/ inlet strainer clogged.

Intermittent

operation

[cavitation]*/ not primed/ non-condensibles in

liquid

Discharge

pressure low

instrument error/ noncondensibles in liquid/ speed

too low/ wrong direction of rotation

Power

demand

excessive

Speed too high/ density liquid high/ required

system head lower than expected/ viscosity high

•92](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-92-320.jpg)

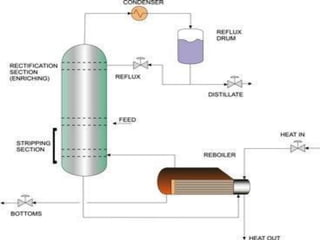

![Rules of thumb for Distillation

Column

Symptoms Causes

bottoms pressure>design High level in column, instrument faults, low

boiling rate of liquid

DT across column<design Feed and reflux composition change,

leakage from feed and product

exchangers, steam to reboiler stops or

restricted

Dp across the column<design instrument fault/ [low boilup rate], dry

trays/ low feedrate/ feed temperature too

high.

Feed flowrate<design instrument fault/ pump problems, filter

plugged/ column pressure>design/ feed

location higher than design.

Temperature of feed>design instrument fault/ preheater fouled/ feed

flowrate low/ heating medium

temperature<design

Temperature of bottoms<design instrument fault/ [low boilup]* loss of•99](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-99-320.jpg)

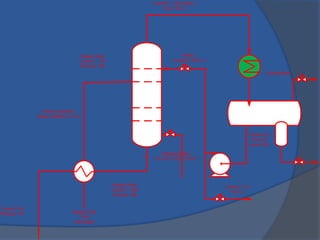

![Rules of thumb for Distillation

Column

Symptoms Causes

Temperature of

bottoms>design

Instrument fault/ [column pressure>design]*/ high boilup/

overhead condenser vent plugged/ insufficient condensing

Temperature at

top>design

Instrument fault/ bottom temperature>design/ reflux too low/

distillate feed forward too high/ column pressure high/ [flooding

Temperature at

top>design and

overhead composition

contaminated with too

many heavies”

vapor bypassing caused by excessive vapor velocities (high

boilup) or not enough liquid on tray or packing, or downcomers

not sealed, or sieve holes corroded larger than design and tray

weeps/ reflux too low/ feed contains excessive heavies

Temperature at

top<design

instrument fault/ control temperature too low/ [low boilup]

•100](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-100-320.jpg)

![Rules of thumb for Distillation

Column

All temperatures falling

simultaneously

low boilup pressure rising

Overhead off spec Poor tray or packing efficiency/ [maldistribution]*/ not

enough trays or packing/ loss of efficiency/ high

concentration of non-condensibles/ missing tray/ collapsed

tray/ liquid entrainment/ liquid bypass and weeping/ liquid

or gas maldistribution

Overhead contaminated

with heavies and excessive

reflux rate and high boilup

rate

inadequate gas-liquid contact/ insufficient liquid

disengagement from vapor/ presence of non-condensibles

in feed. “Overhead and bottoms off spec and decreases

across column in both DT and Dp

Overhead and bottoms off

spec

Bypass open on reflux control valve, poor stripping, low

flow of stripping agent

Overhead and bottoms off

spec, decrease in DT

across column and

Poor tray or packing efficiency/ [maldistribution]*/ not

enough trays or packing/ loss of efficiency/ high

concentration of non-condensibles/ missing tray/ collapsed•101](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-101-320.jpg)

![Control Valve Faults

Symptoms Causes

Leaks Erosion/ corrosion/ gaskets, packing or bolts at temperatures, pressures

and fluids that differ from design

Can’t control

low flowrate

miscalibration/ buildup of rust, scale, dirt/[faulty design]*.

Can’t stop

flow

miscalibration/ damaged seat or plug

Excessive

flow

miscalibration/ damaged seat or plug

Slow

response

Restricted air to actuator/ dirty air filters. “Noise”: cavitation/

compressible flow

Poor valve

action

Dirt in instrument air/ sticky valve stem/ packing gland too tight/ faulty

valve positioner

Cycling Stiction. [Faulty design]*: valve stem at design flowrate is not at

midrange. [Stiction]* is the sticking and friction related to valve

movement and measured as the difference between the driving values

needed to overcome static friction upscale and downscale. Likely cause

•105](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-105-320.jpg)

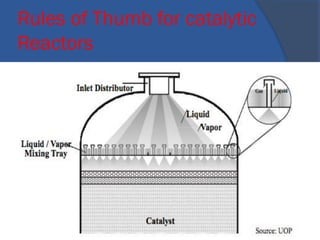

![Rules of Thumb for catalytic

ReactorsSymptoms Causes

DP

higher>design

catalyst degradation/ instrument error/ high gas flow/ sudden coking/

problem left in from construction or revamp, internal damage

Rapid decline in

conversion

unfavorable shift in equilibrium at operating temperature, for

exothermic reactions/ [sintering]*/ [agglomeration], poisons in feed,

temperature runaway

Gradual decline

in conversion

Sample error/ analysis error/ temperature sensor error/ [catalyst

activity lost]*/ [maldistribution]*/ [unacceptable temperature profiles]*/

[inadequate heat transfer]*/ wrong locations of feed, discharge or

recycle lines/ faulty design of feed and discharge ports/ wrong

internal baffles and internals/ faulty bed-voidage profiles

Temperature

runaways

Change in feed composition, furnace controlled firing, uncontrolled

reactions. feed temperature too high/ [temperature hot spot]*/ cooling

water too hot, failure of cooling media

Local high

temperature/hot

spot

[misdistribution of gas flow]*/ instrument error/ extraneous feed

component that reacts exothermically

•116](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-116-320.jpg)

![Catalytic Reactors

Local low temperature

within the bed

[maldistribution of gas flow]*/ instrument error/ extraneous

feed component that reacts endothermically

Exit gas temperature too

high

instrument error/ control-system malfunction/ fouled reactor

coolant tubes.

Temperature varies axially

across bed

[maldistribution}

Symptom: Soon after startup, temperature of tubewall near top>usual and increasing

and perhaps Dp increase and less conversion than expected or operating

temperatures>usual to obtain expected conversion

Cause: inadequate catalyst regeneration/ contamination in feed; for steam reforming

sulfur concentration>specifications/ wrong feed composition; for steam reforming:

steam/CH4<7 to 10

•117](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-117-320.jpg)

![Startup after Catalyst

Replacement/Regeneration

Symptoms Causes

conversions<standard Reduction faulty, bad batch of catalyst/

preconditioning of catalyst faulty/ temperature and

pressures incorrectly set/ instrument error for

pressure or temperature

poor selectivity bad batch of catalyst/ preconditioning of catalyst

faulty/ temperature and pressures incorrectly set/

instrument error for pressure or temperature

Dp<expected and

conversion<standard

maldistribution and axial variation in temperature/

larger size catalyst.

conversion<standard and Dp

increasing

maldistribution and axial temperatures different]*/

feed precursors present for polymerization or coking

Dp for this batch of

catalyst>previous batch

catalyst fines produced during loading/ poor loading

conversion<specifications per

unit mass of catalyst and more

side reactions

maldistribution/ faulty inlet distributor/ faulty exit

distributor

•118](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-118-320.jpg)

![Startup after Catalyst

Replacement/Regeneration

increased side reactions and

conversion<specification

Catalyst loading not the same in all tubes.

Active species volatized [regeneration faulty]*/ faulty catalyst design for typical

reaction temperature/ [hot spots]*.

Agglomeration of packing or

catalyst particles

[temperature hot spots

Carbon buildup inadequate regeneration]*/ [excessive carbon formed]*.

[Catalyst selectivity changes]*: [poisoned catalyst]*/

feed contaminants/ change in feed/ change in

temperature settings

Catalyst activity lost carbon buildup]*/[regeneration faulty]*/ [sintered

catalyst]*/ excessive regeneration temperature/

[poisoned catalyst]*/ [loss of surface area]*/

[agglomeration]*/ [active species volatized

Excessive carbon formed operating intensity above usual/ feed changes/

temperature hot spots. •119](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-119-320.jpg)

![Rules of Thumb for reactors

Symptoms Causes

Dust or corrosive

products from

upstream processes

in-line filters not working or not installed/ dust in the atmosphere

brought in with air/ air filters not working or not installed.

Loss of surface area [sintered catalyst]*/ [carbon buildup]*/ [agglomeration

Maldistribution faulty flow-distributor design/ plugging of flow distributors with fine

solids, sticky byproducts or trace polymers/ [sintered catalyst

particles]*/ [agglomeration of packing or catalyst particles]*/ fluid

feed velocity too high/ faulty loading of catalyst bed/ incorrect flow

collector at outlet.

Poisoned catalyst Poisons in feed/ flowrate of “counterpoison” insufficient/ poison

formed from unwanted reactions.

Reactor instability Control fault/ poor controller tuning/ wrong type of control/

insufficient heat transfer area/ feed temperature exceeds

threshold/ coolant temperature exceeds threshold/ coolant

flowrate<threshold/ tube diameter too large

•120](https://image.slidesharecdn.com/opt-converted-180918172427/85/Process-Troubleshooting-120-320.jpg)