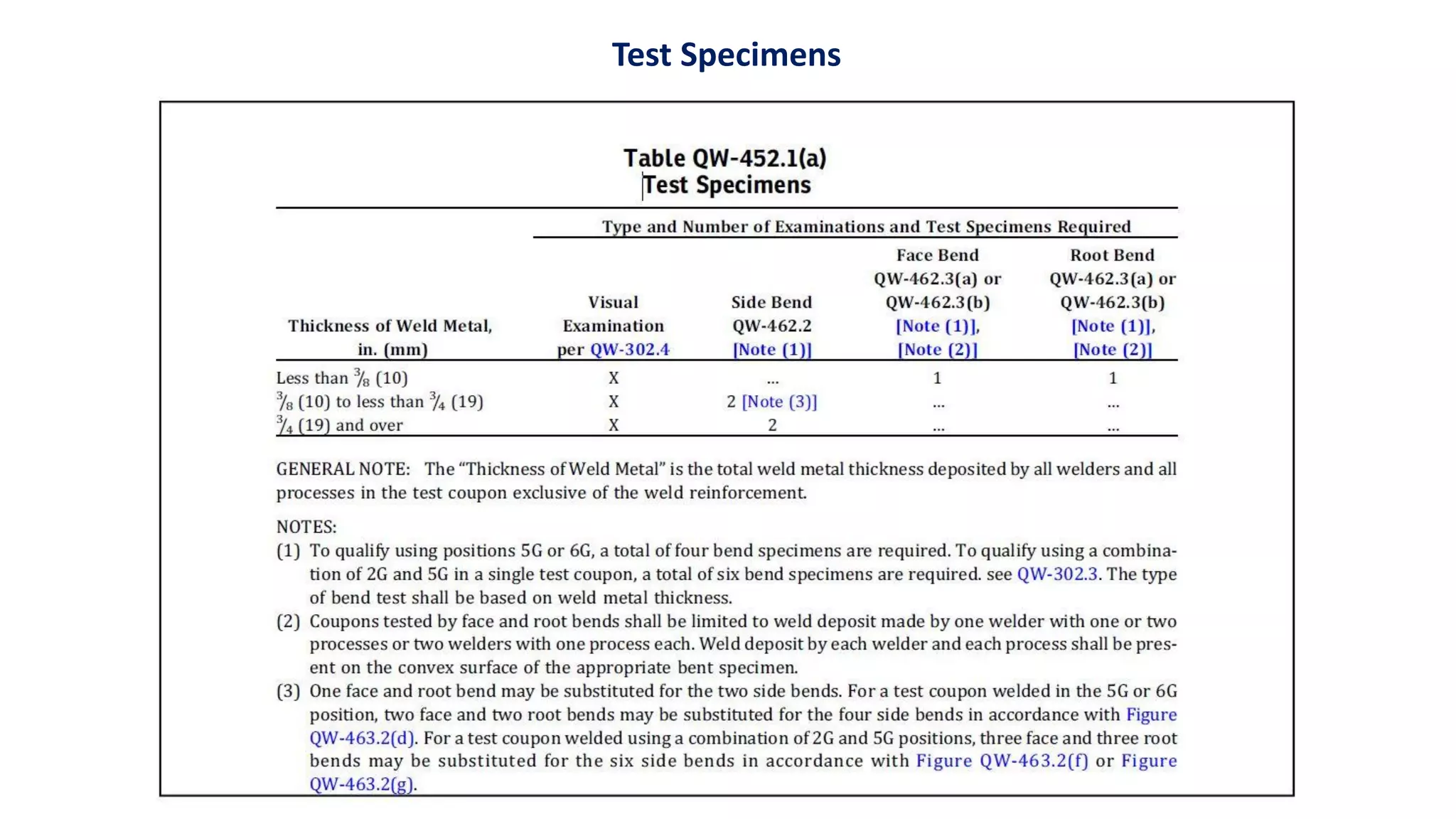

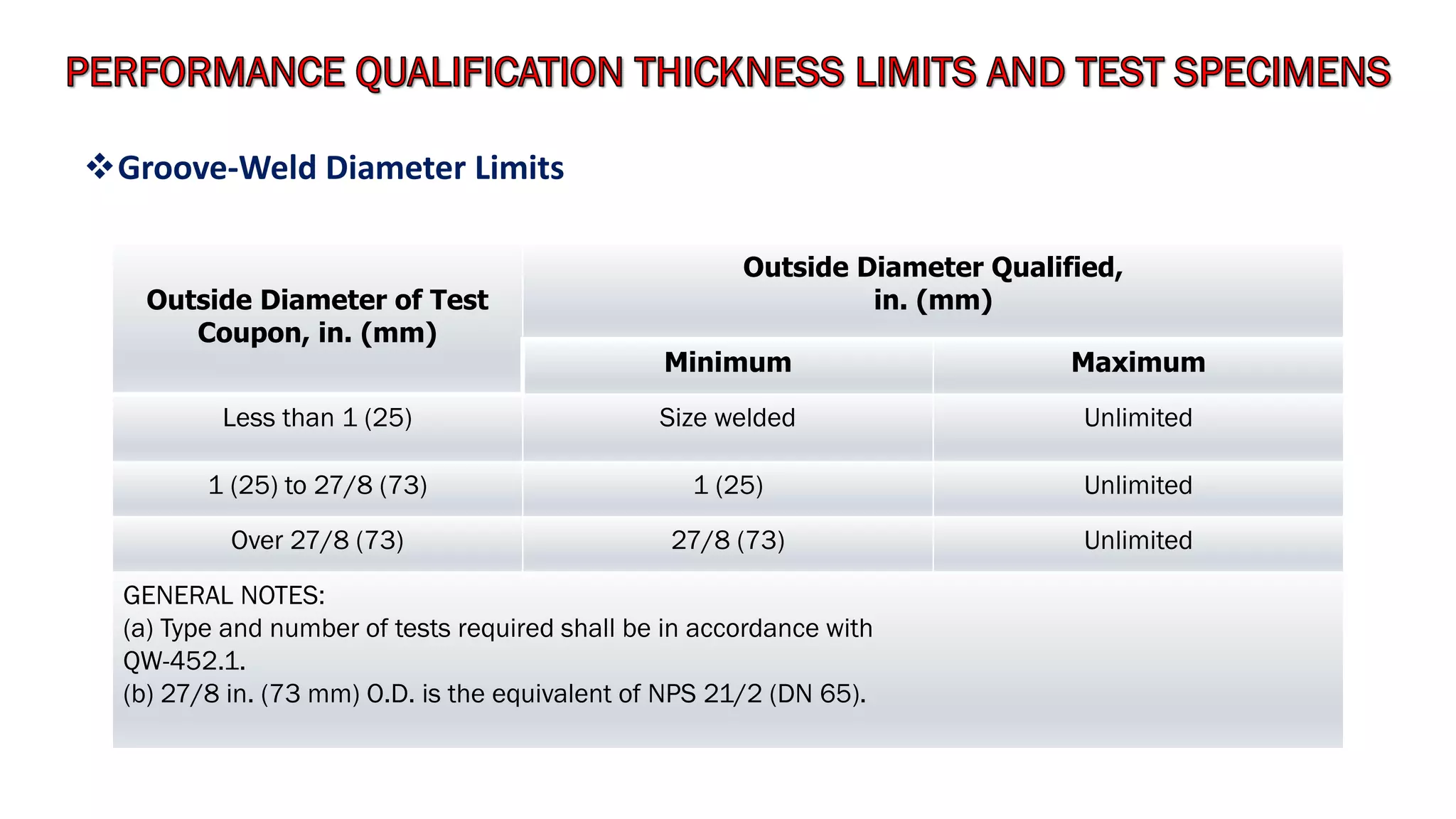

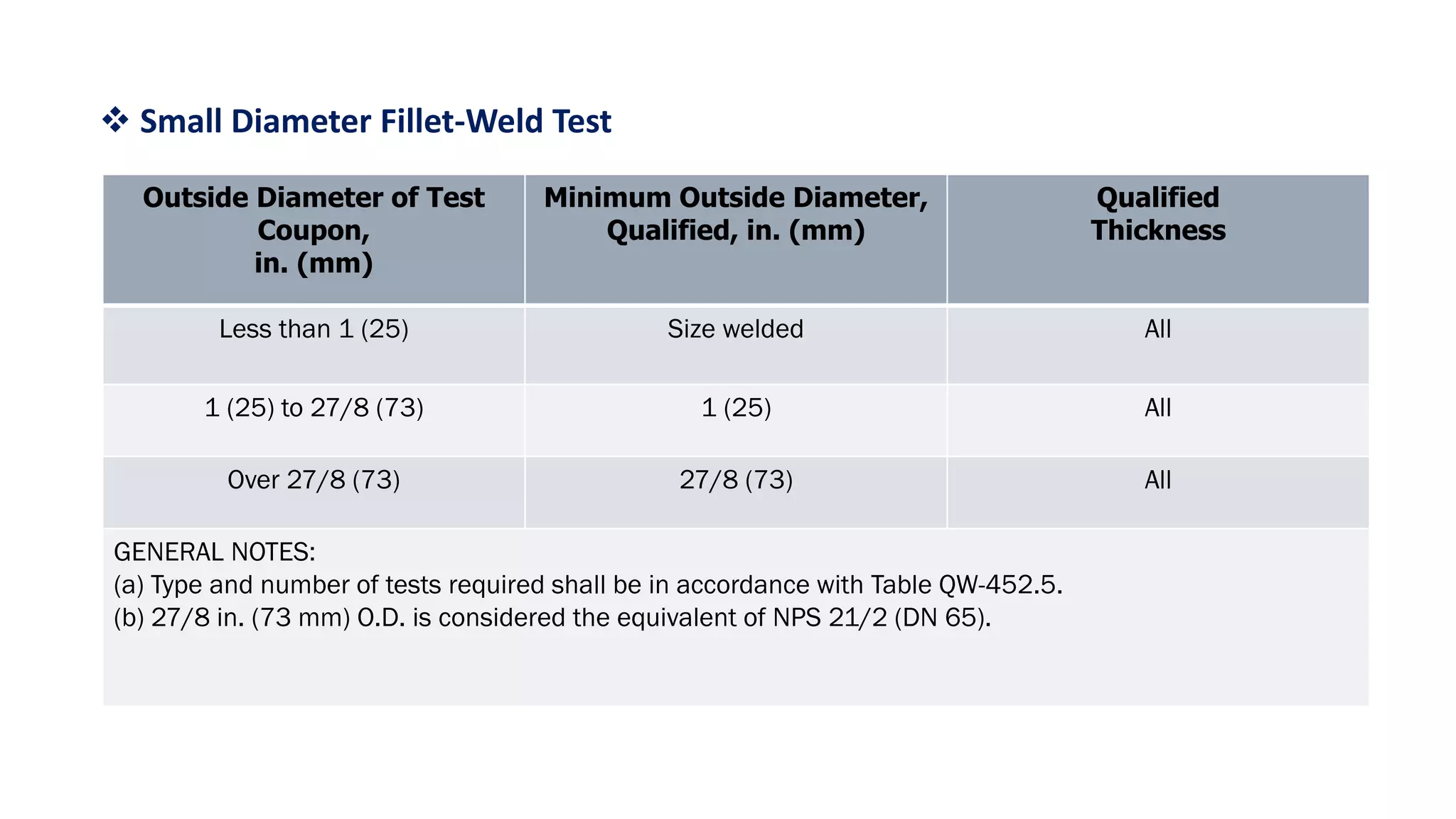

The document discusses guidelines for qualifying welders for groove and fillet welding based on test specimens. It provides tables outlining the minimum and maximum outside diameters and thicknesses welders can be qualified for depending on the size of test coupons used. Notes further explain that welders can be qualified for multiple processes and thicknesses based on different test coupons. The thickness qualified is determined individually for each welder, process, and set of variables when more than one is used for a test coupon.

![Thickness, t , of Weld Metal in

the Coupon, in. (mm)

[Note (1)] and [Note (2)]

Thickness of Weld

Metal Qualified

[Note (3)]

All 2t

1/2 (13) and over with a

minimum of three layers

Maximum to be

welded

NOTES:

(1) When more than one welder, process, or set of essential variables

is used during welding of a test coupon, the thickness, t ,

of the weld metal in the coupon deposited by each welder, for

each process, and with each set of essential variables shall be

determined and used individually in the “Thickness, t , of Weld

Metal in the Coupon” column to determine the “Thickness of

Weld Metal Qualified.”

(2) Two or more pipe test coupons with different weld metal

thickness may be used to determine the weld metal thickness

qualified and that thickness may be applied to production

welds to the smallest diameter for which the welder is qualified

in accordance with Table QW-452.3.

(3) Thickness of test coupon of 3/4 in. (19 mm) or over shall be

used for qualifying a combination of three or more welders

each of whom may use the same or a different welding process.

Thickness of Weld Metal Qualified](https://image.slidesharecdn.com/importantqualificationrangesmustknowaboutwelderperformance-200514091635/75/Important-qualification-ranges-must-know-about-welder-performance-4-2048.jpg)