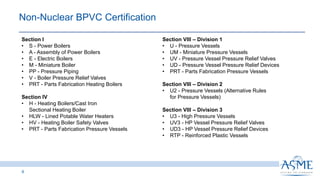

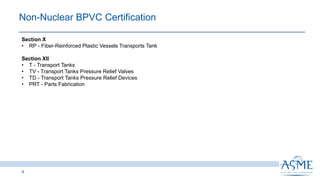

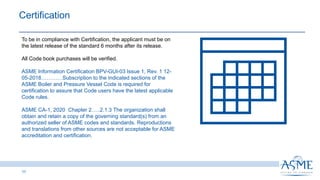

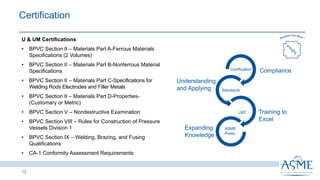

This document provides an overview and summary of the 2021 ASME Boiler & Pressure Vessel Code. It discusses that the Code includes standards for industrial and residential boilers, pressure vessels, and other pressure equipment. It also describes the Code development process, certification process, and highlights some of the key sections of the Code related to boilers, pressure vessels, and transport tanks.