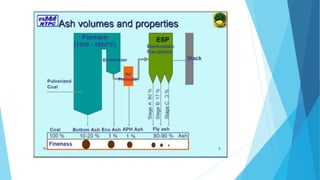

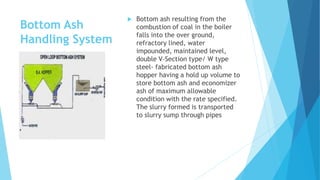

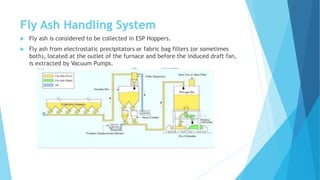

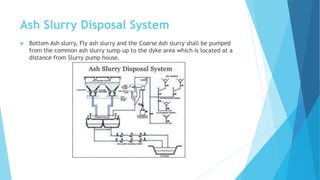

The document outlines the components and functions of an ash handling system in thermal power plants, detailing types of ash such as bottom ash, coarse ash, and fly ash. It describes the processes for handling, transporting, and utilizing ash, including its use in concrete production and soil stabilization. The document emphasizes the necessity for an efficient ash handling system due to the significant amount of ash produced as a byproduct of coal combustion.