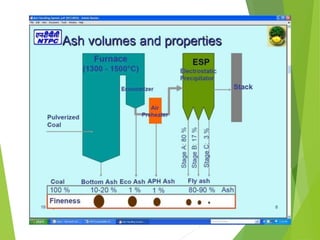

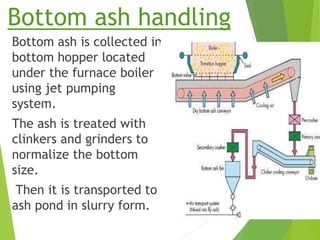

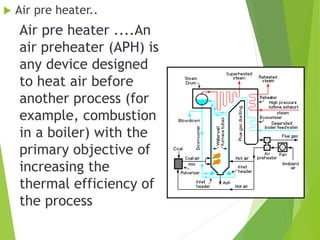

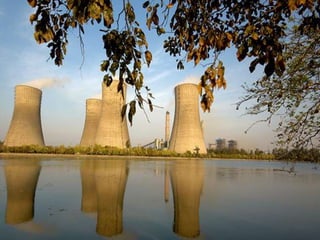

The document discusses the ash handling system at NTPC Dadri power plant. It has three types of ash handling systems: bottom ash, air preheater ash, and fly ash. Bottom ash is collected in hoppers under the furnace and transported to ash ponds in slurry form after grinding. Fly ash is captured by the air preheater, economizer, and ESP and stored in silos. The ashes are then mixed with water to form slurry and pumped via pipelines to the ash disposal site. Proper ash handling is required as thermal power plants produce a large amount of ash as a byproduct of coal combustion.