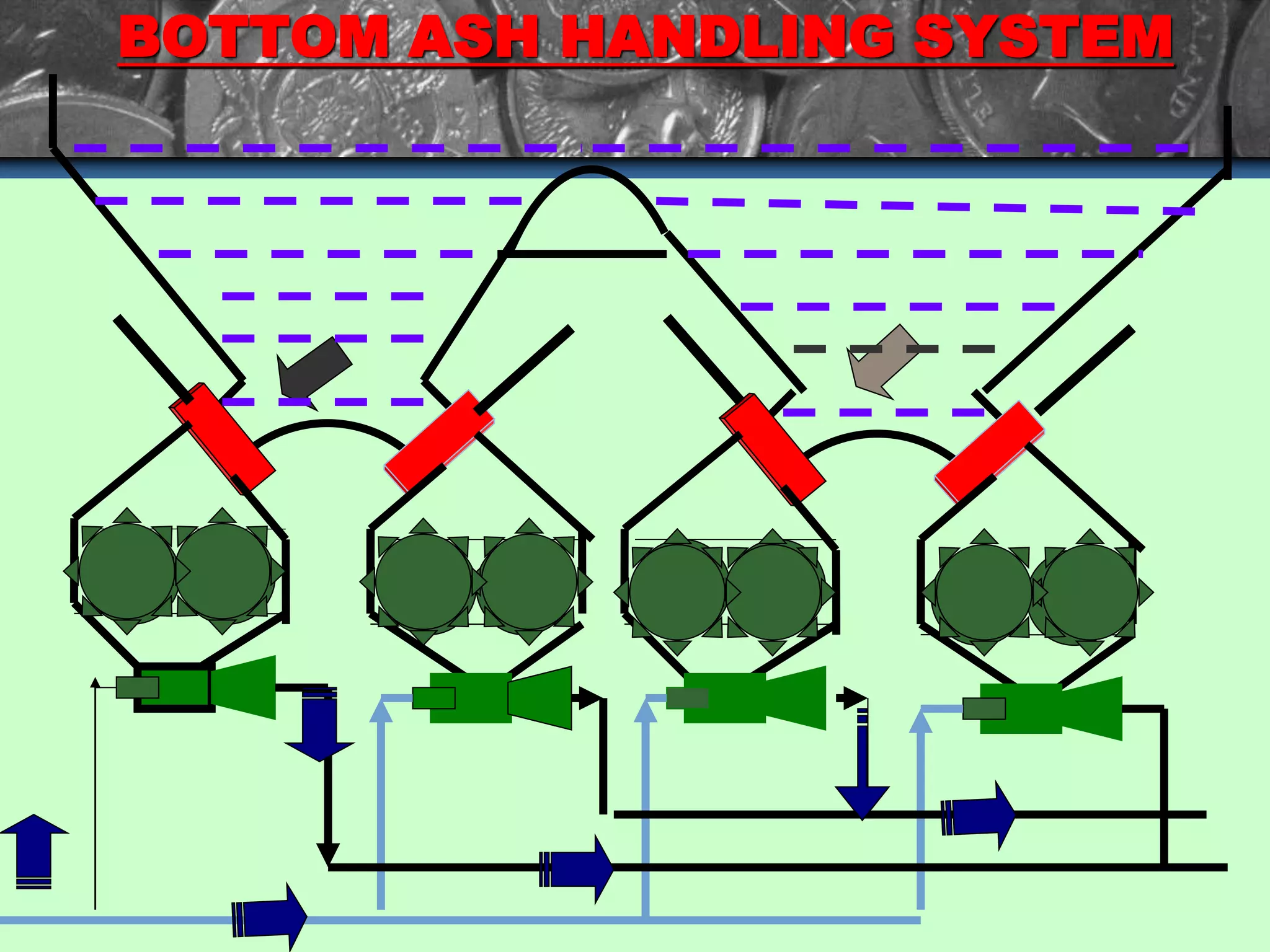

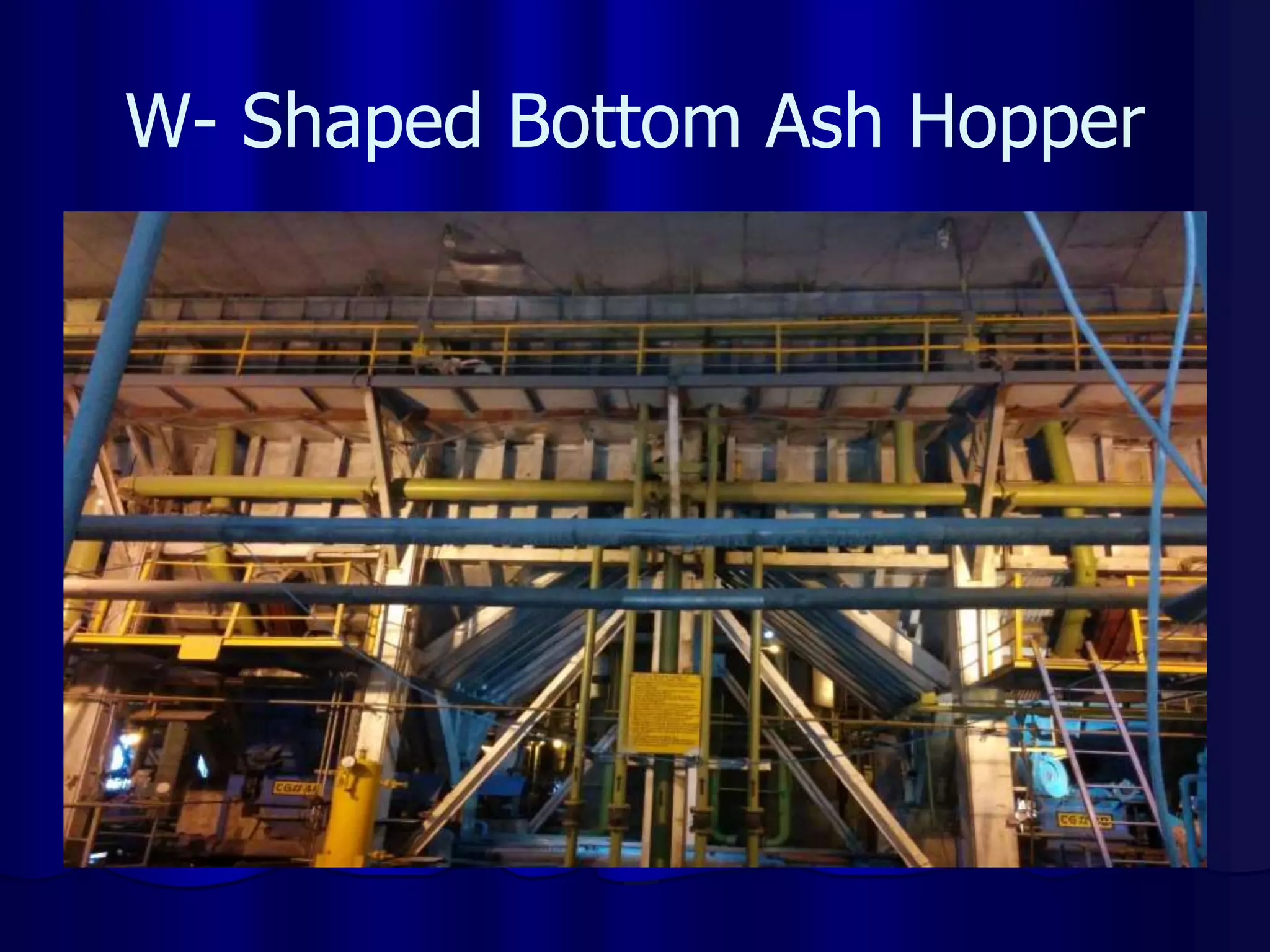

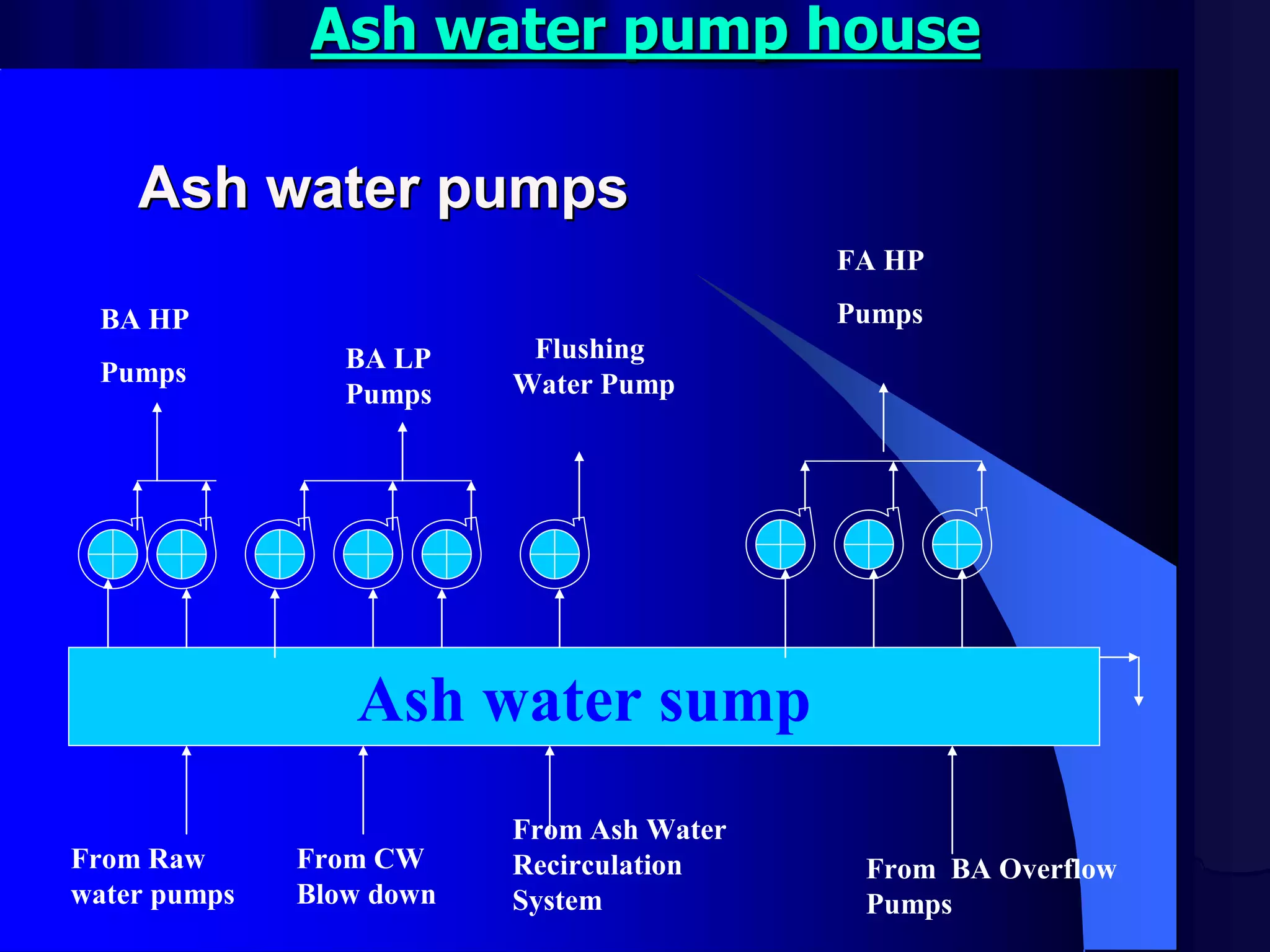

The document provides an overview of the ash handling system at a power plant, including bottom ash, fly ash, and slurry handling systems. It describes the different types of ash generated and their quantities. The bottom ash system uses intermittent water-impounded hoppers and jet pumps to remove ash from the bottom of boilers. The fly ash system can operate in either wet or dry mode to transport ash from electrostatic precipitators to storage via slurry trenches or pressurized pipes. Ash water is used throughout the systems and is pumped from a central ash water pump house. Ash slurry is transported via pipelines to the large ash dyke area for disposal and storage.