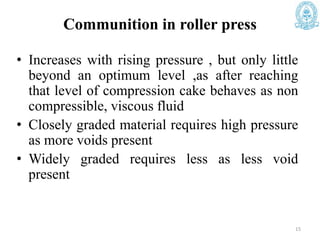

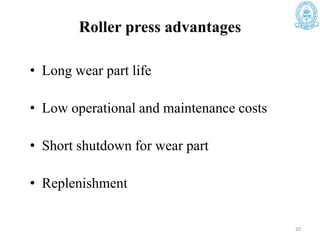

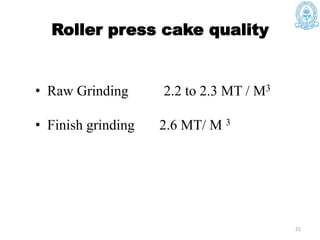

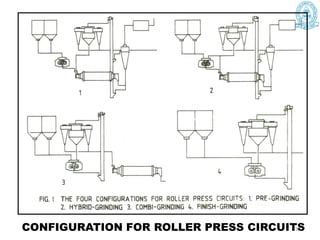

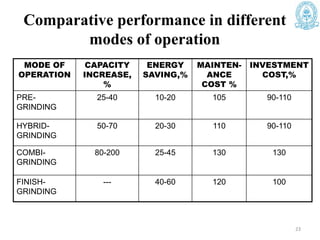

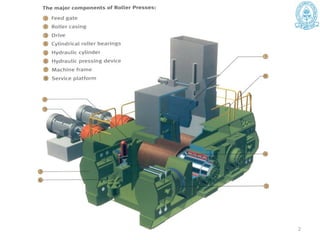

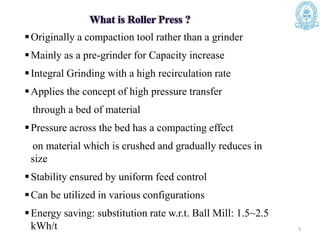

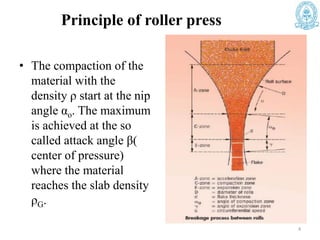

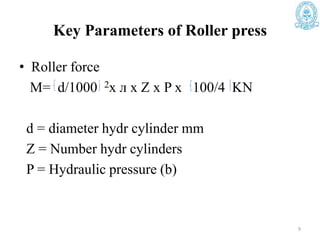

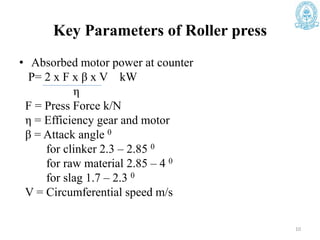

The document outlines the concept and operational principles of roller presses, highlighting their role in grinding and pyro-processing. It details specifications, key parameters, and advantages of roller presses, including energy savings and enhanced grinding efficiency. Additionally, it compares different modes of operation regarding capacity increase, energy savings, and maintenance costs.

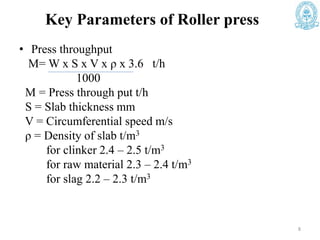

![Circulating load factor [-]

Roller speed [m/s]

Stable operation

unstable operation

Maximize absorbed power by increasing circulating load close to

point of unstable operation

Maximizing Absorbed Power

11](https://image.slidesharecdn.com/rollerpress-240627044630-ba7018f5/85/Roller-Press-pdf-Srinivas-nerella-HPGR-pdf-11-320.jpg)