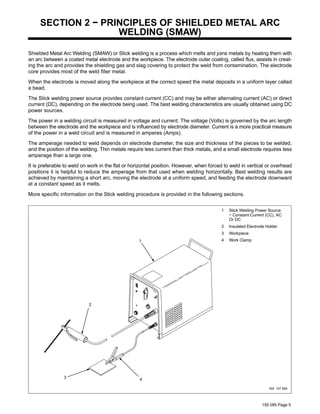

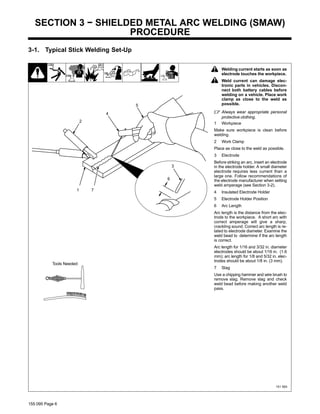

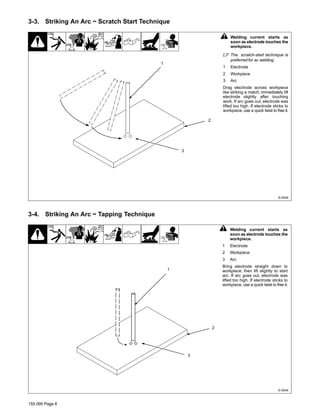

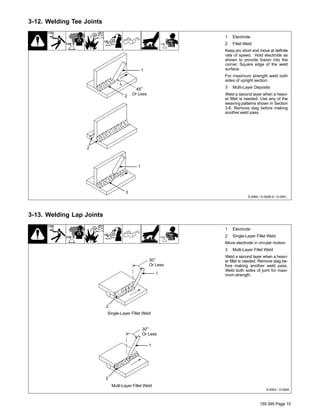

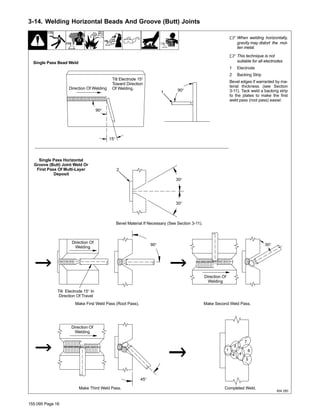

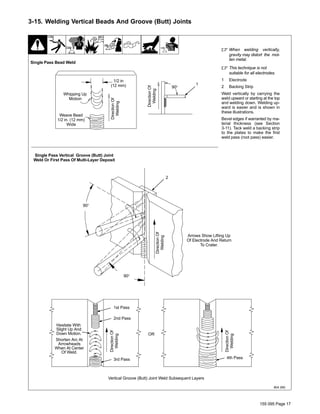

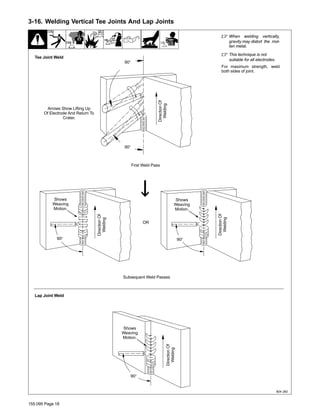

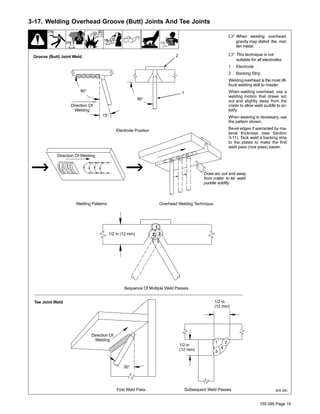

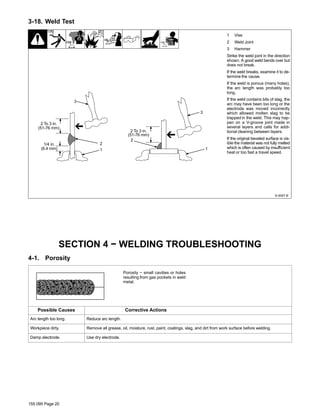

This document provides guidelines for shielded metal arc welding (SMAW). It discusses safety precautions, principles of SMAW, procedures for SMAW, welding joints, troubleshooting common issues, and contains sections on safety, principles, procedures, and troubleshooting. The document aims to educate welders on how to safely and properly perform SMAW.