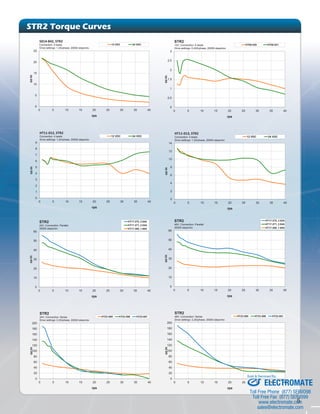

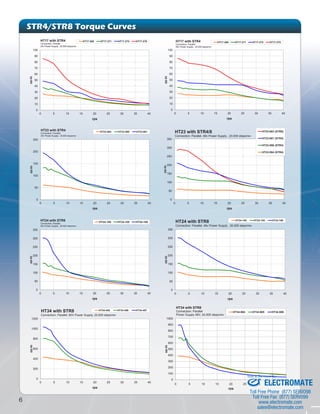

The document describes Applied Motion's STR series of stepper motor drives, including the STR2, STR4, and STR8 models. The drives can be configured using dip switches or rotary switches to select motor type, current settings, resolution, and other parameters. They provide constant current control, various protective features, and accept step and direction or CW/CCW pulse inputs. Specifications and performance curves for the drives with different stepper motors are also provided.