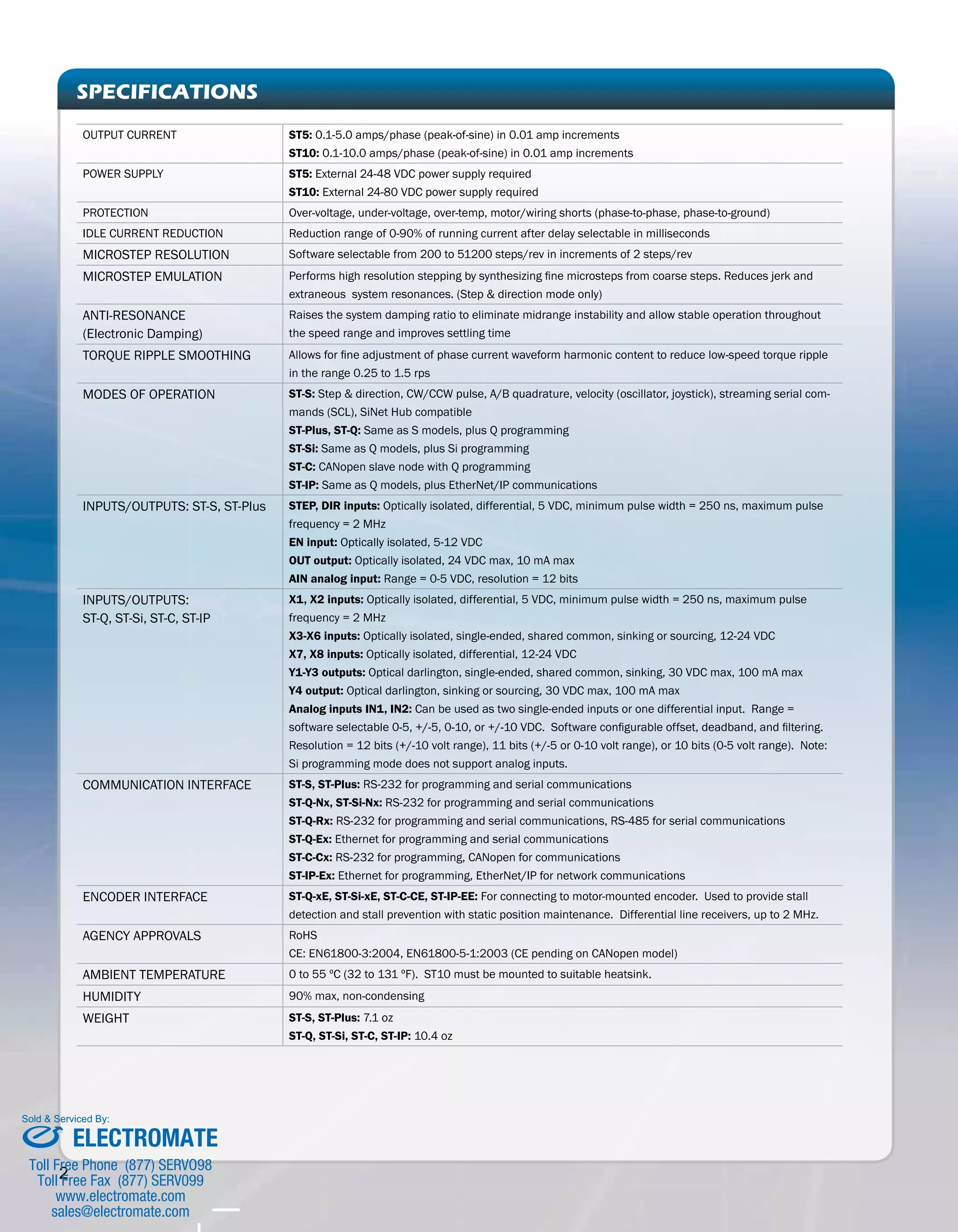

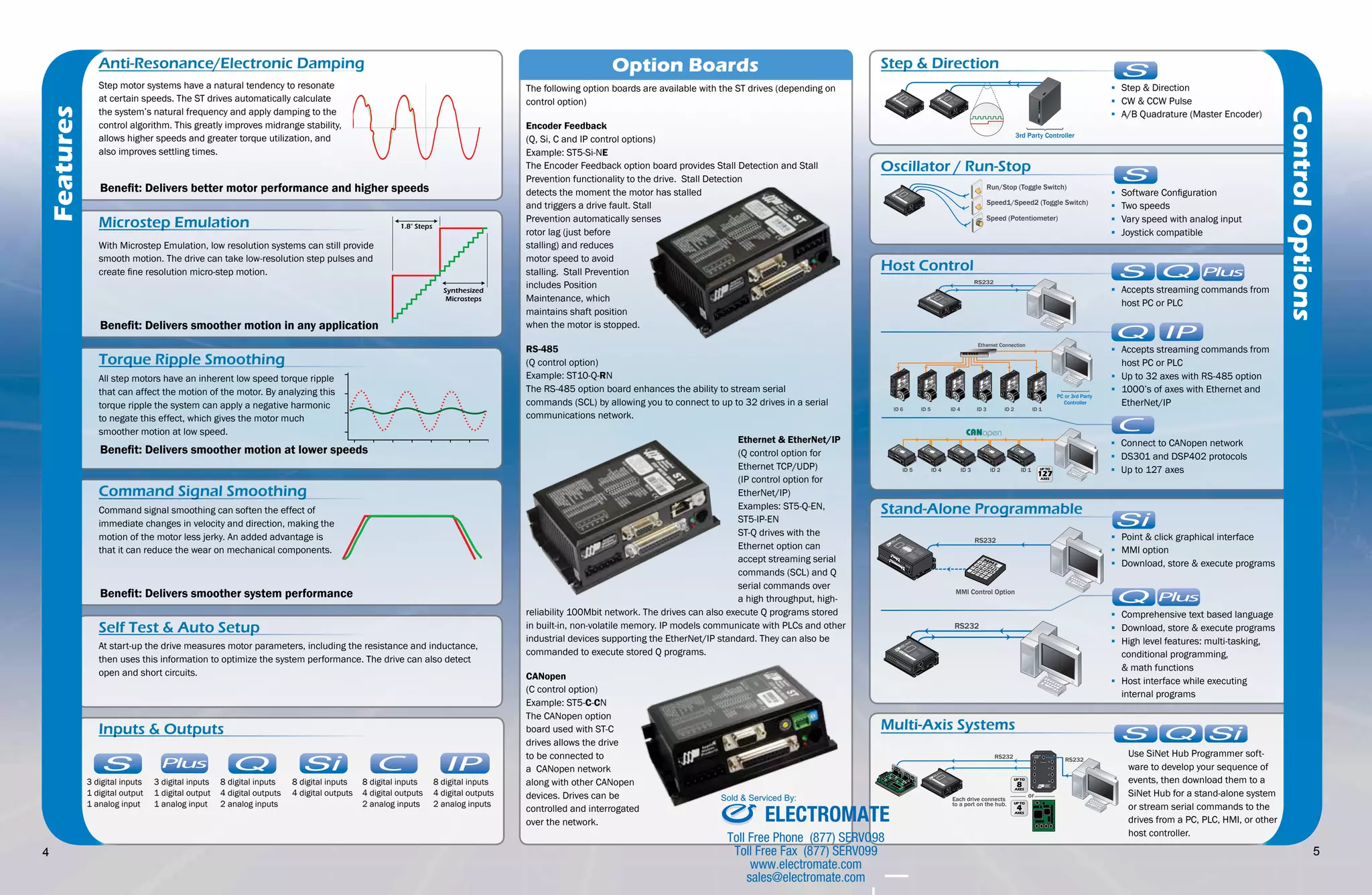

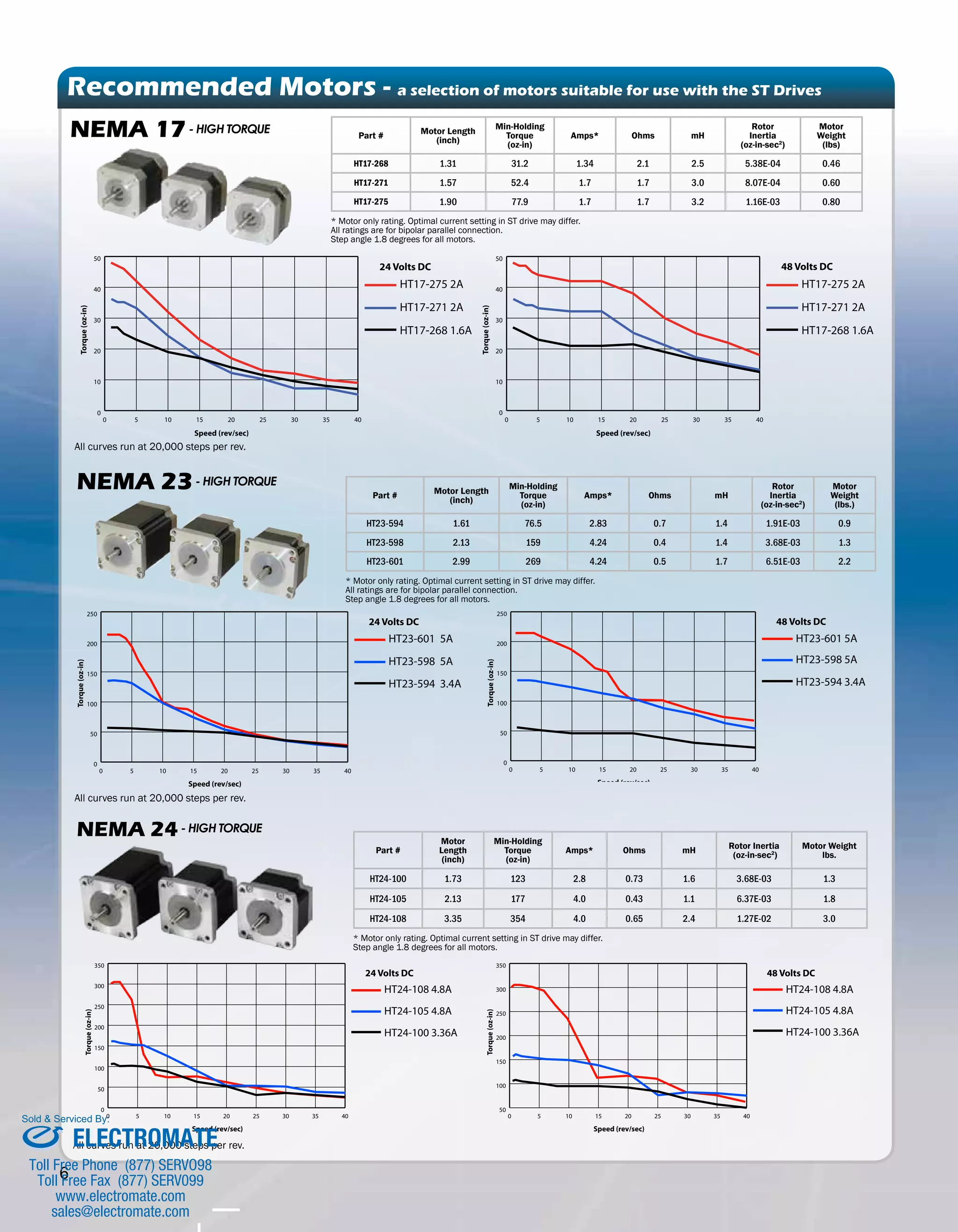

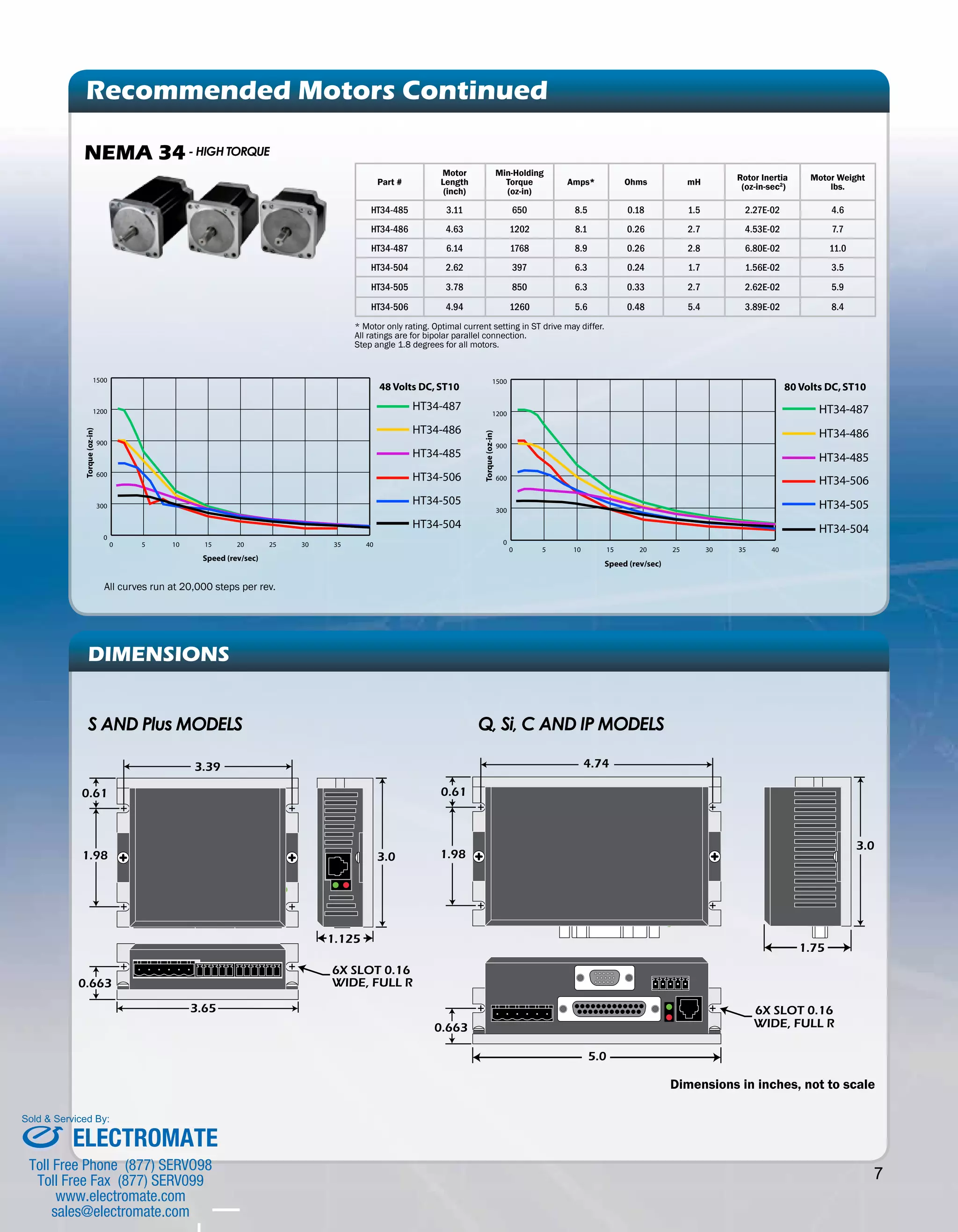

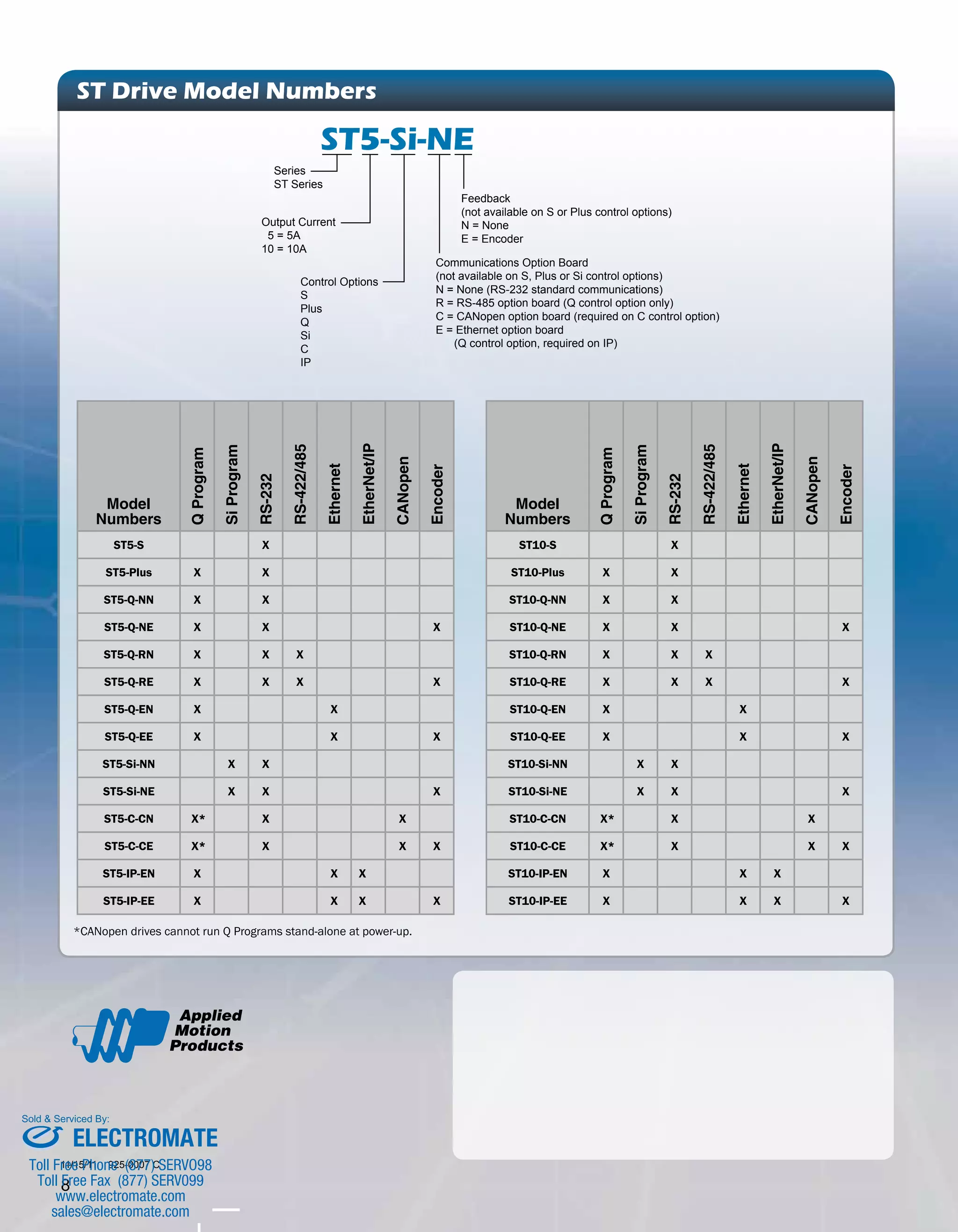

This document describes several step motor drive models with various control options. The ST drives can be controlled via pulse and direction, velocity mode, or host commands. Higher-level models also allow for programming, networking, and advanced motion control. The drives provide features like anti-resonance control, torque ripple smoothing, and stall prevention. Accessories include power supplies, regeneration clamps, and programming software.