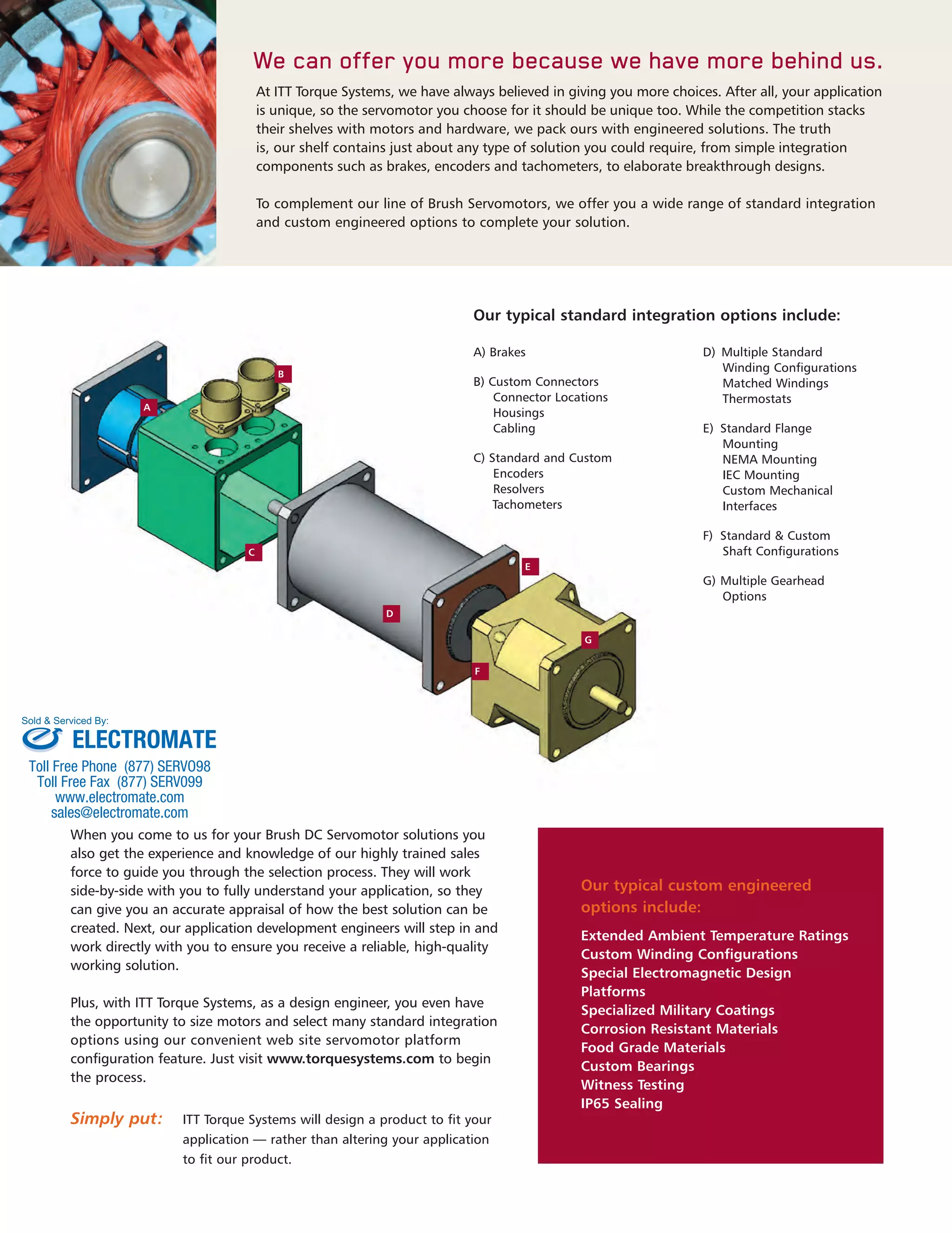

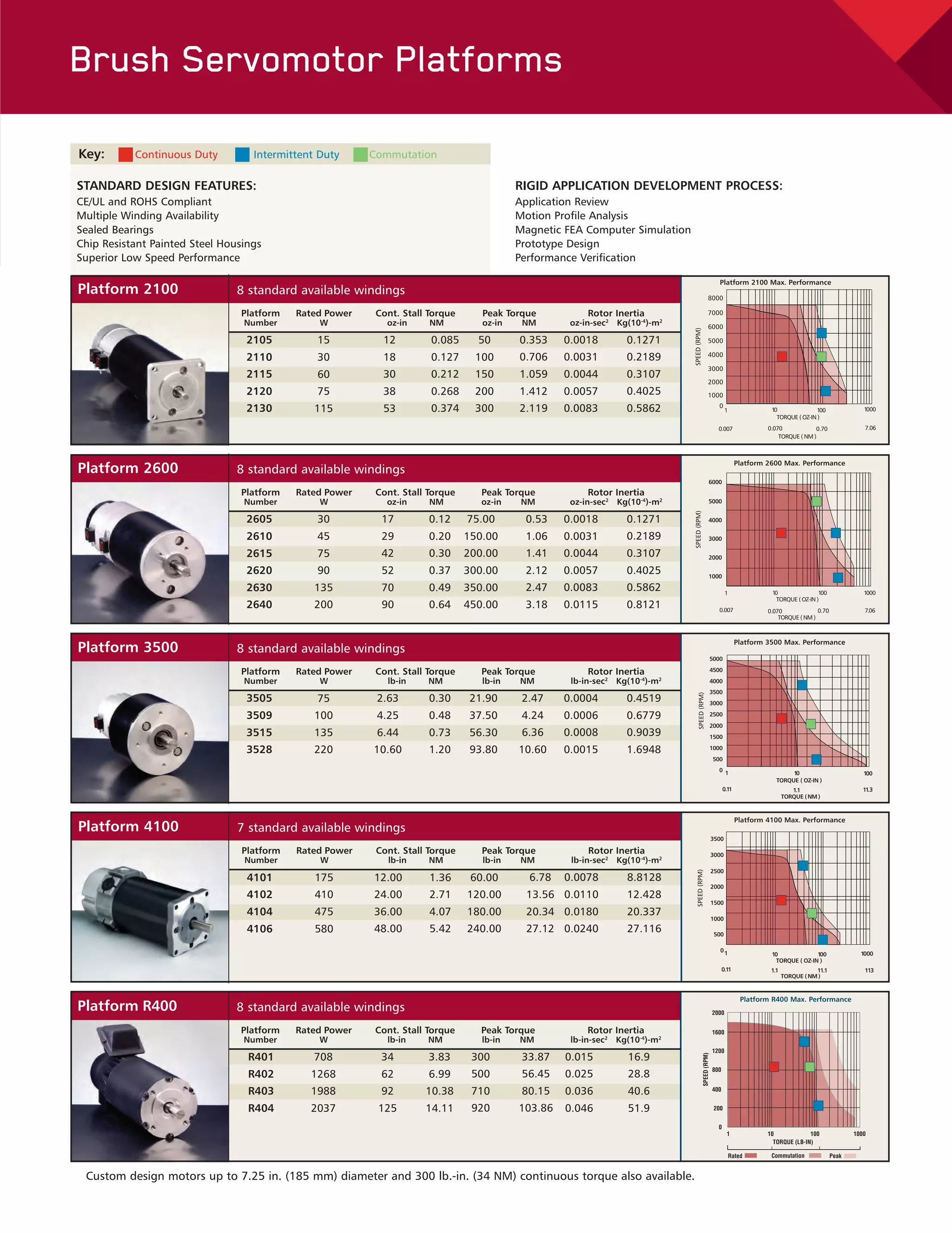

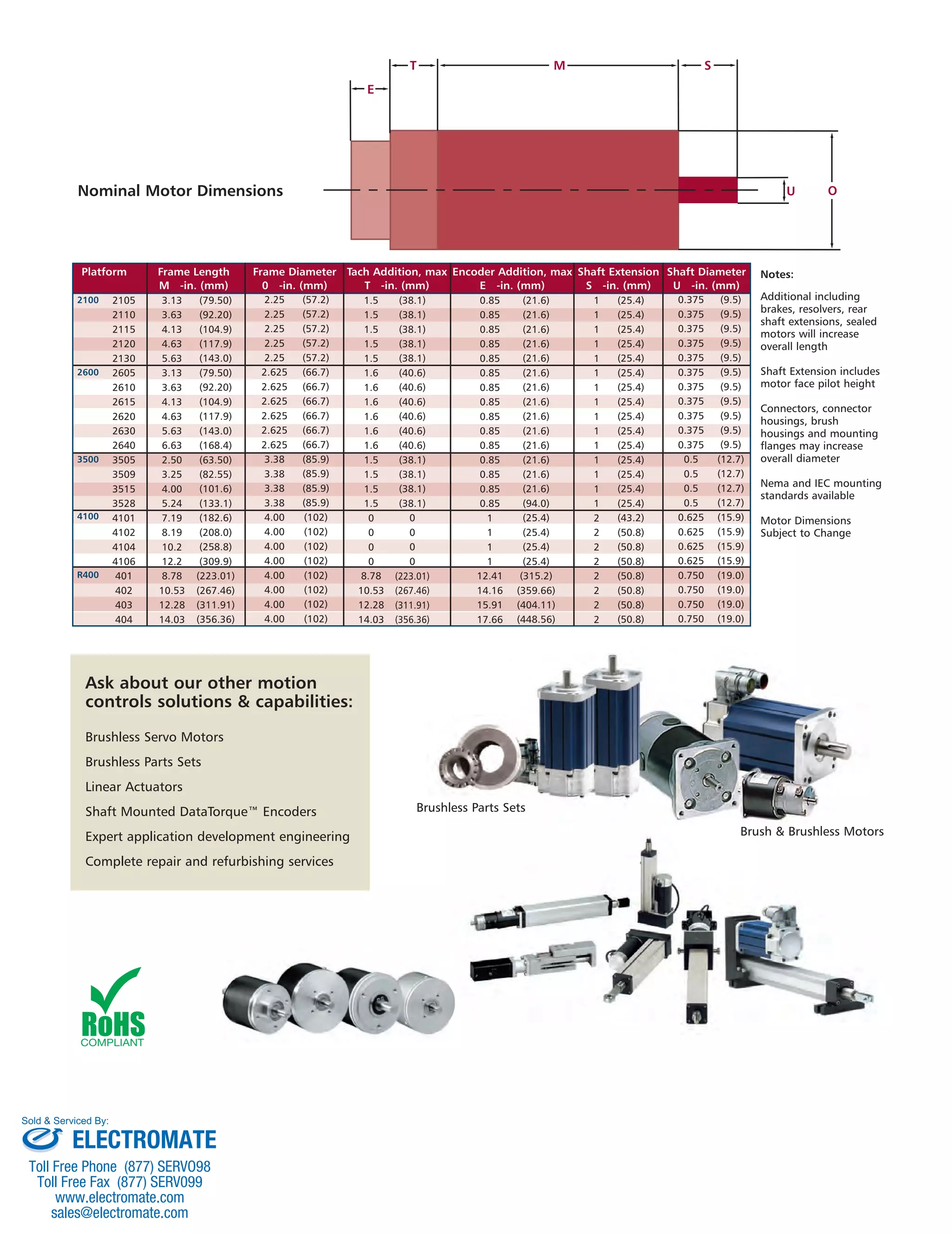

This document provides information on torque systems and brush DC servomotors from ITT Torque Systems. It discusses the company's ability to customize solutions and lists standard integration options including brakes, encoders, windings, and gearheads. Tables show specifications for multiple motor platforms including torque, power, and inertia. The document also includes dimensional information and diagrams for motor sizing.