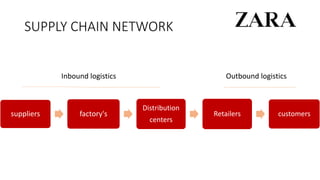

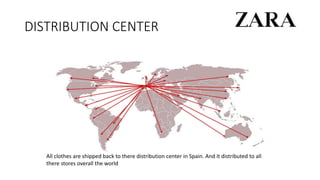

Zara is a fashion retailer owned by Inditex, one of the largest fashion groups in the world. Zara opened its first store in 1975 in Spain and has since expanded to over 2,000 stores globally. Inditex controls most of Zara's supply chain, with around 50% of products manufactured in Spain and Europe and the rest in Asia and Africa. Products are shipped to logistics centers in Spain and then distributed to stores within 24 hours in Europe and 40 hours elsewhere. Zara's unique approach is to produce trendy designs in small batches within a few weeks and refresh store inventory monthly, creating urgency for customers to purchase before items sell out.