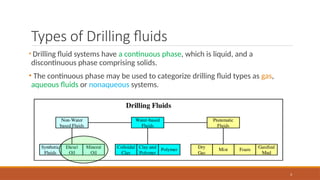

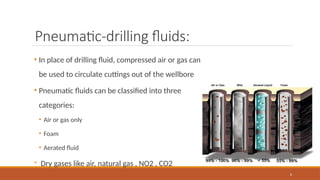

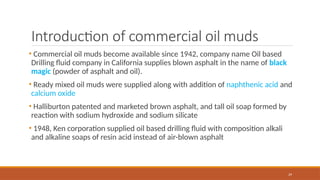

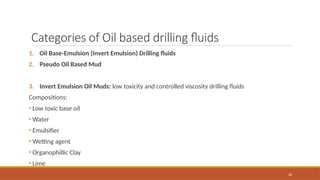

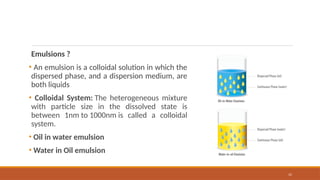

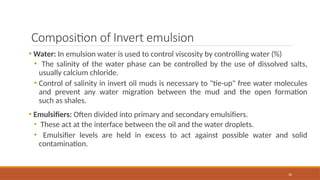

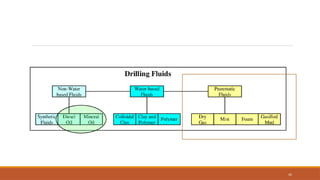

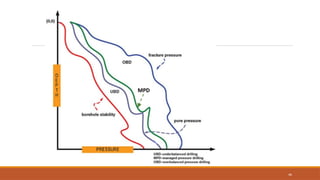

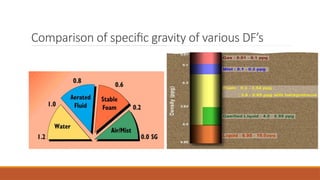

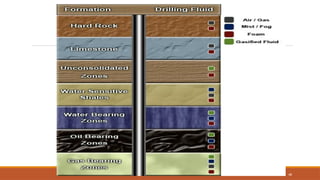

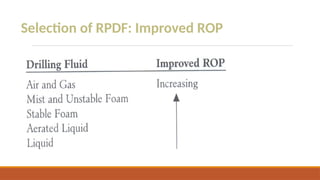

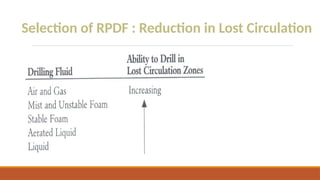

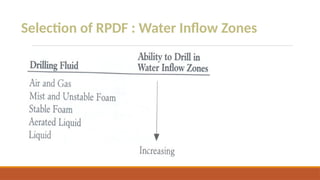

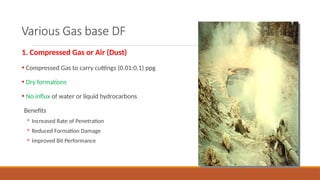

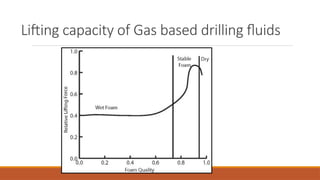

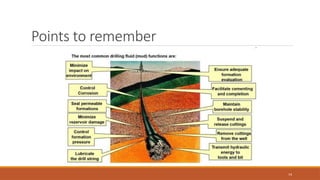

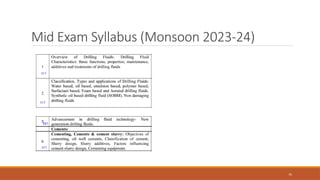

The document provides a comprehensive overview of various types of drilling fluids, including water-based, oil-based, and gas-based fluids, highlighting their properties, applications, and historical evolution. It discusses the advantages and challenges associated with each fluid type, such as cost, environmental impact, and performance in different drilling conditions. Additionally, it details advancements in fluid technology and the development of specialized muds to address specific drilling challenges.