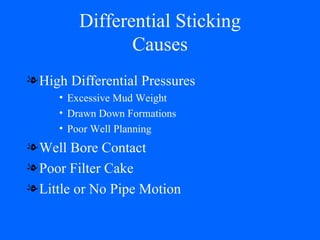

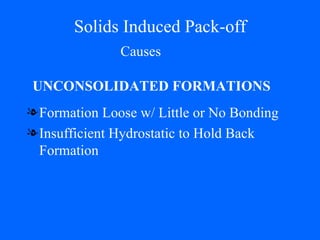

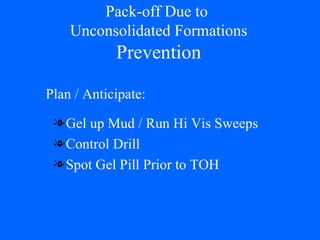

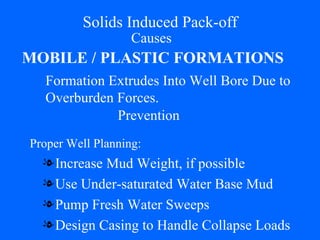

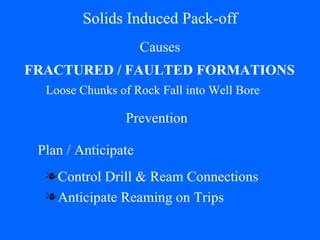

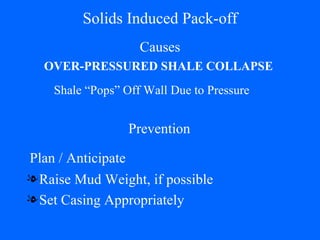

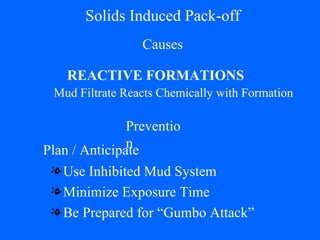

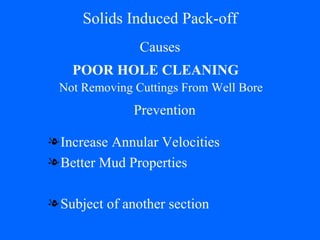

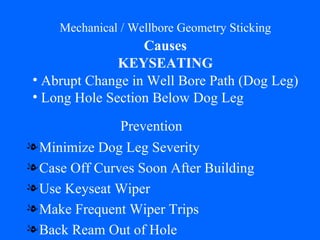

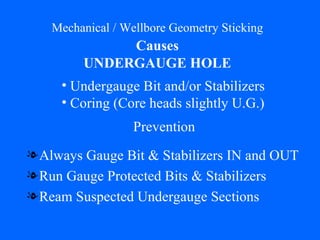

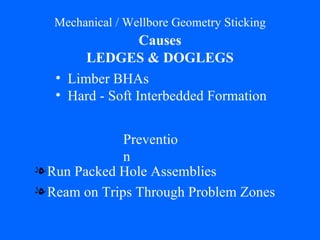

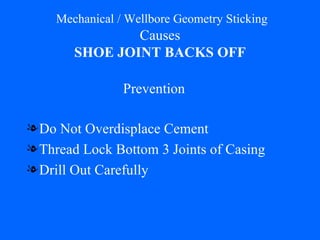

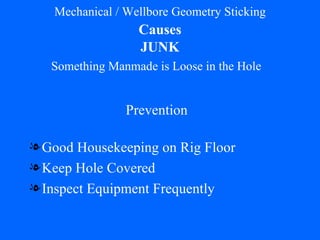

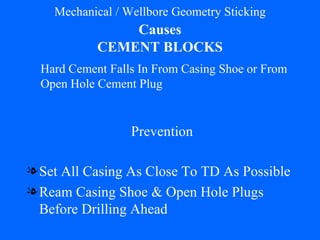

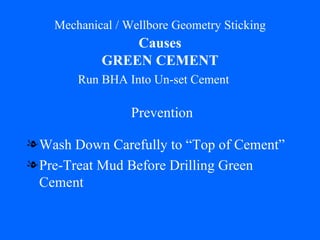

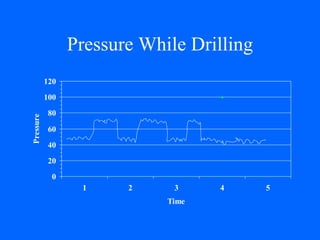

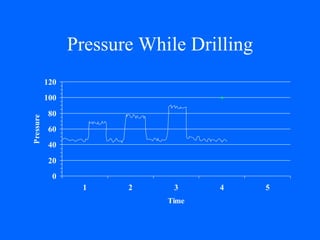

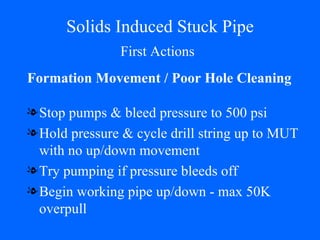

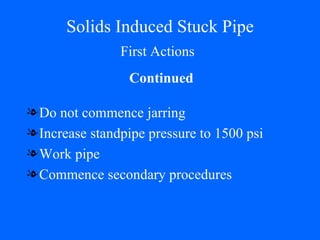

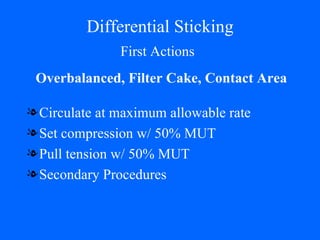

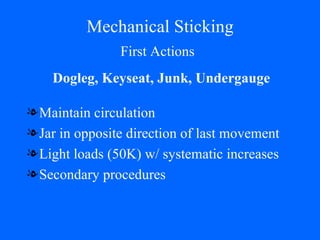

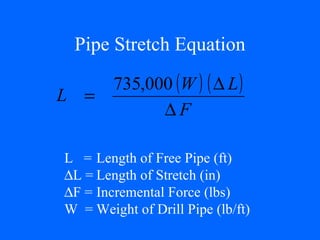

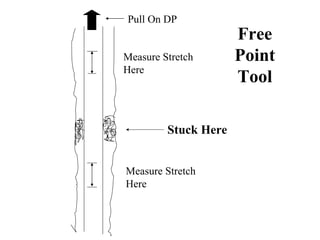

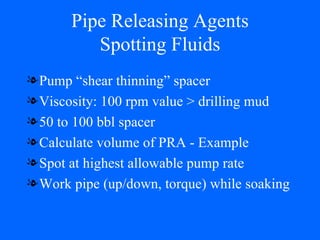

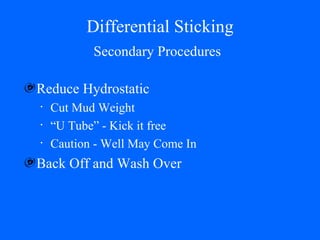

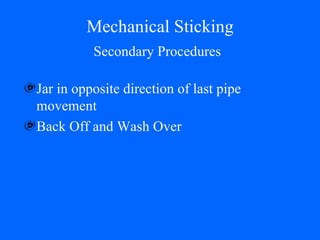

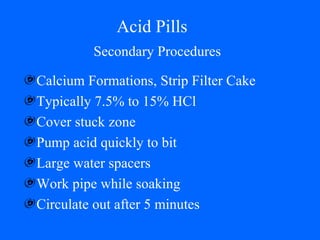

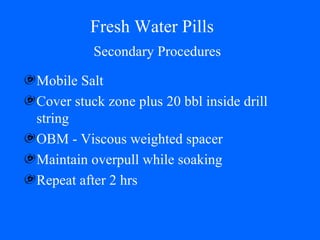

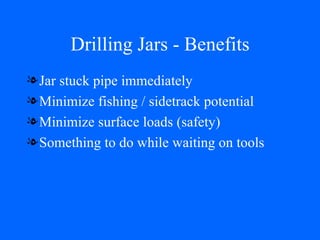

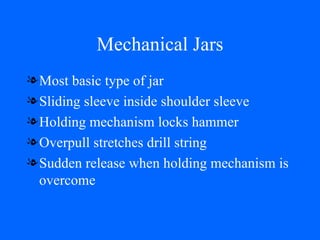

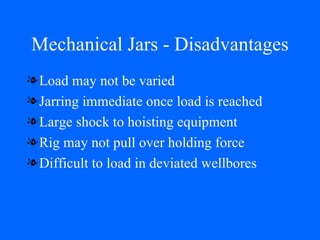

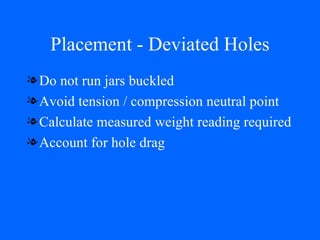

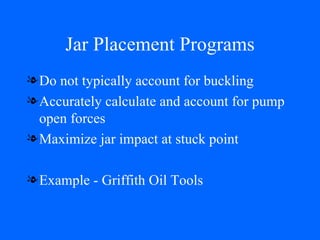

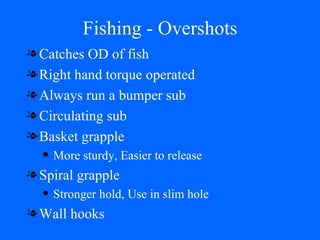

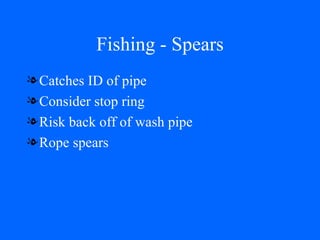

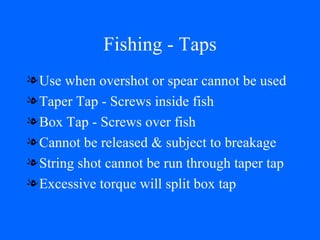

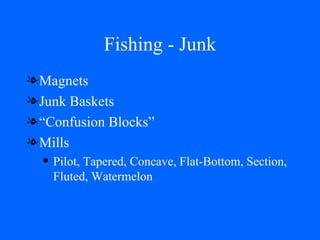

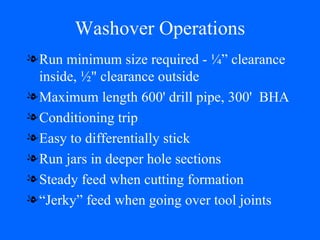

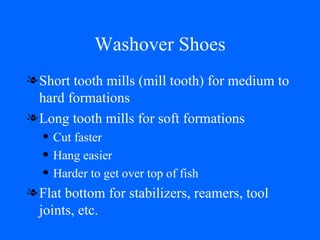

The document discusses various causes and prevention methods for different types of stuck pipe situations, including solids induced pack-off, differential sticking, mechanical/wellbore geometry issues, and reactive formations. It then outlines recommended first and secondary procedures for addressing different sticking scenarios, such as jarring, spotting fluids, reducing mud weight, milling, fishing tools, and washover operations.