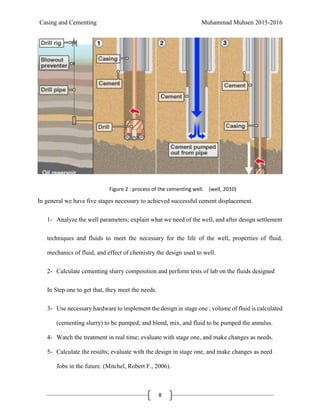

This document discusses casing and cementing in oil and gas wells. It describes the five types of casing used: surface, conductor, intermediate, and production casing. It also discusses cement composition, slurry design, when cementing is required, and well cementing techniques. The primary functions of casing and cementing are to prevent fluid migration and provide zonal isolation between geological formations in the wellbore. Cementing the casing strings helps achieve these functions and is an important part of well construction.

![Casing and Cementing Muhammad Muhsen 2015-2016

10

References

Anon., 2012. casing. [Online]

Available at: http://www.rigzone.com/training/insight.asp?insight_id=333&c_id=24

[Accessed 03 12 2015].

Erik. B. Nelson, 2012. Well cementing fundamentals, s.l.: schlumberger.

Gatlin, C., 1960. Petroleum Engineering : Drilling and Well Completion. Englewood Cliffs: Prentice-Hall

Inc..

I.N. KNAPP, A. P., 1914. Cementing oil and gas wells. In: s.l.:(New York, pp. 651-653.

Lyons, W. C., 1996. In: STANDARD HANDBOOK OF PETROLEUM & NATURAL GAS Engineering. Socorro

New Mexico: Houston, Texas , pp. 1127- 1129 .

Mitchel, Robert F., 2006. cementing. In: Petrolrum Engineering handbook volume ll:drilling engineering.

U. of Texas at Austin: socioty of petrolum engineers, pp. 376- 380.

well, c., 2010. casing and cementing. [Online]

Available at: http://ichef-

1.bbci.co.uk/news/624/media/images/48386000/jpg/_48386320_oil_drilling_466in.jpg

[Accessed 3 12 2015].](https://image.slidesharecdn.com/cementingwell-191127065744/85/Cementing-well-11-320.jpg)