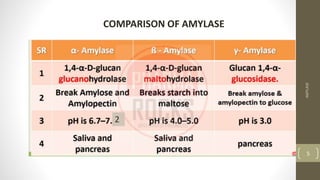

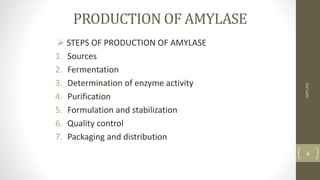

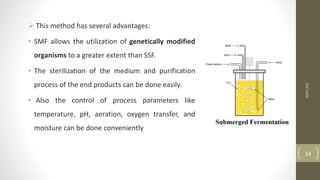

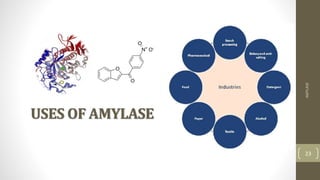

The document provides a detailed overview of amylase, an important enzyme that catalyzes the breakdown of starches and glycogen. It discusses its production from various sources, methods of fermentation, enzyme activity determination, purification, stabilization, quality control, and packaging. Additionally, it outlines its extensive applications across multiple industries, including food, textiles, biofuels, and pharmaceuticals.