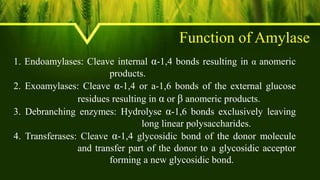

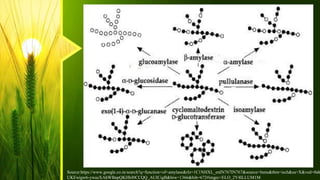

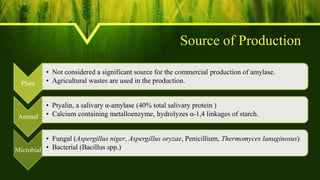

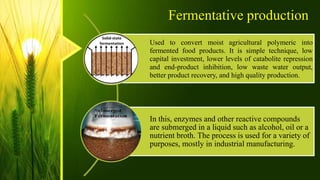

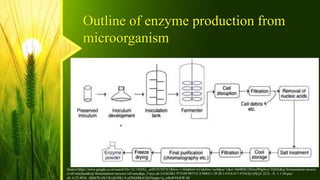

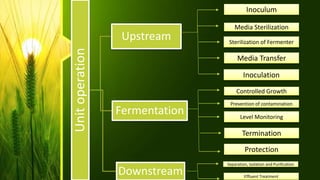

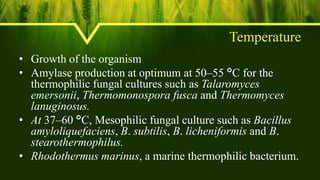

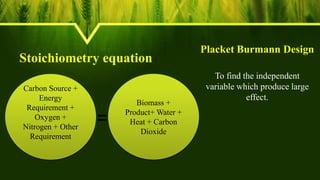

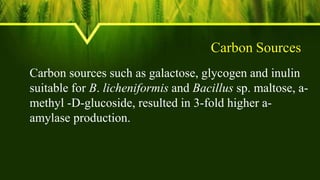

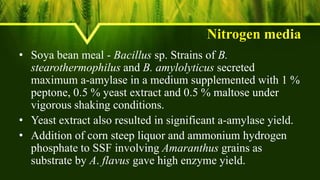

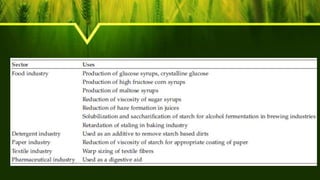

The document discusses amylases, which are starch-degrading enzymes that hydrolyze glycosidic bonds in polysaccharides, covering their classification, production sources, and applications. It emphasizes microbial fermentation as an efficient method for amylase production, highlighting optimal conditions such as temperature, moisture, and pH for different microbial strains. Additionally, it outlines downstream processing techniques crucial for purifying enzymes, which significantly impact production costs.