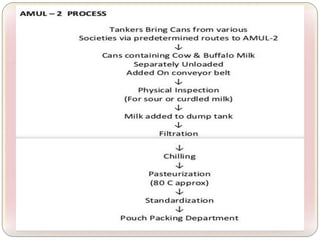

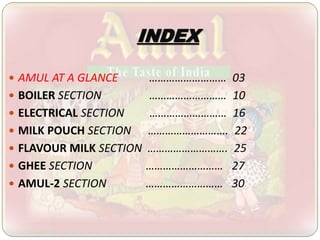

The document presents a comprehensive overview of the Amul dairy operations, detailing its history, organizational structure, and various production sections including milk pouch, flavored milk, ghee, and electrical systems. Established in 1946, Amul has grown to become a significant player in the dairy industry, with extensive facilities and a focus on quality and efficiency. Key information includes the operational capacity, branding, and specifics of various plants and processes involved in milk and product production.

![ Total Co-Operation Societies : 8000 (Around)

Size Of Unit : Having Capacity of process 18 lakhs liters of milk producing 10

different products

Revenue : 3.1 billion $ US [2013-2014]

Auditors : Internal Auditors and Government Auditors

Website : www.amul.com

E-Mail : amuldairy@kairaunion.coop](https://image.slidesharecdn.com/rinav-150328105550-conversion-gate01/85/Amul-Training-part-1-jan-2015-march-2015-5-320.jpg)

![ The main plant of AMUL DAIRY is located in ANAND and further AMUL has

more 3 Plants which is used to produce different items….

[1] KHATREJ PLANT : This Plant was established in 1960 and it was inaugurated by

Shri Morarji Desai , the Finance Minister. In this plant the production of CHEESE

is taking place.

[2] KANJARI PLANT : In this plant CATTLE FEED(Amul Dan) is being produced .It is

Donated by OXFAM and was formally commissioned on 31st October 1964 by

Shri Lal Bahadur Shastri.

[3] MOGAR PLANT : In this plant , production of HIGH PROTEIN FOOD, BREAD

SPREAD , CHOCOLATE , & MALTED FOOD (Amul Chocolate & Amul Ganthiya)

is carried out. This plant was established in 1974.Amul Bakery Plant is also

located here.

Recently , the Amul is Planed to open 2 new plants in 2016 at different

locations of Gujarat .](https://image.slidesharecdn.com/rinav-150328105550-conversion-gate01/85/Amul-Training-part-1-jan-2015-march-2015-10-320.jpg)

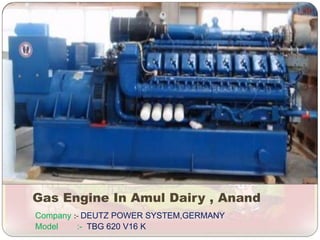

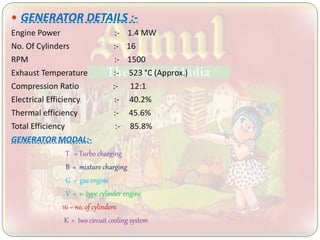

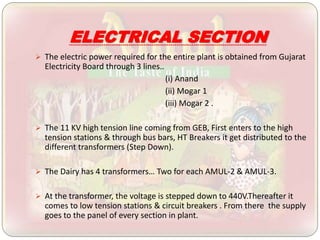

![ It is an automatically controlled system with a TEM[ Total Electric

Management ] touch screen panel.

The power generated by the generator is 440 V and it passes through

LT Breakers to different sections.

Each section panel is provided with charge over switches to utilize GEB

line or Generator.

The alternator is of Gas Engine , which use Natural Gas at 2 kg/cm2 as

a fuel.

The flue gas from the generator is utilized in VAM , thereby co-

generation of refrigeration along with savings in economy takes place.](https://image.slidesharecdn.com/rinav-150328105550-conversion-gate01/85/Amul-Training-part-1-jan-2015-march-2015-19-320.jpg)