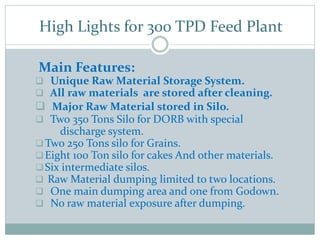

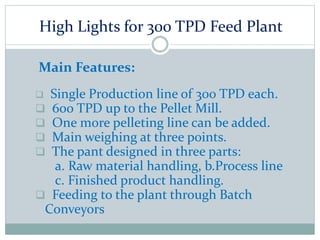

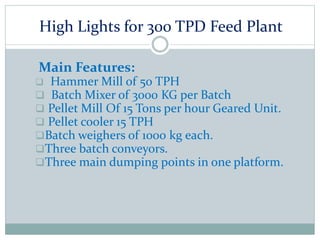

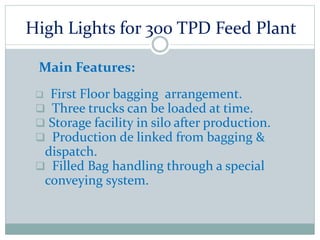

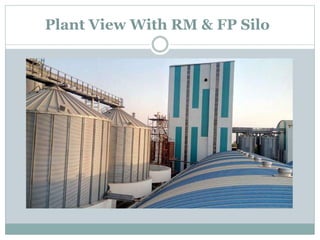

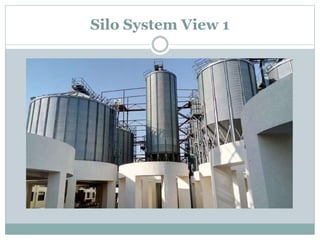

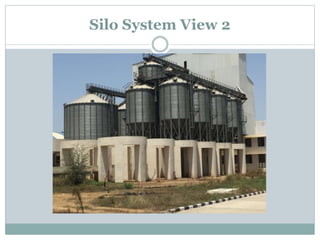

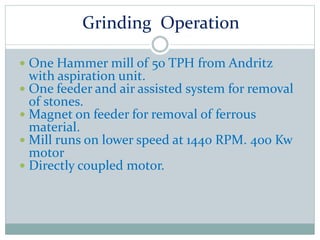

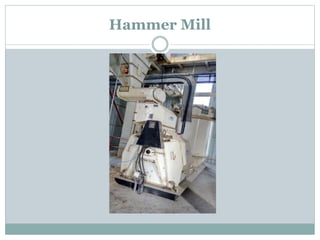

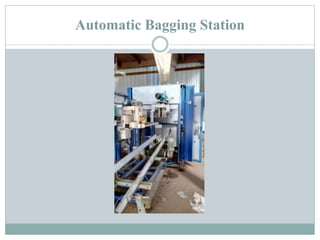

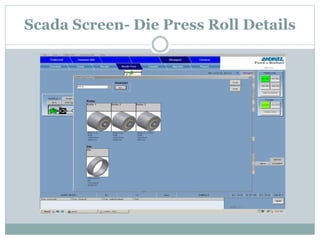

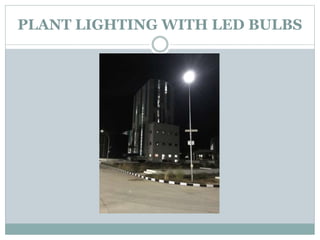

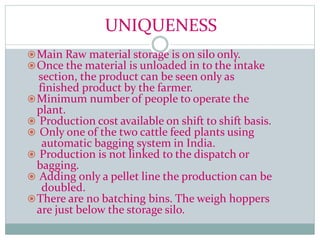

The document describes a 300 tons per day (tpd) feed plant designed by Conceptual Equipments and Services Pvt. Ltd. in India, which features a unique raw material storage system and a single production line capable of scaling up to 600 tpd. Key components include various silos for raw material storage, a hammer mill, a batch mixer, and an automatic bagging system, making it one of the few cattle feed plants in India with such automation. The plant emphasizes efficiency with energy-saving measures and a centralized control system to monitor operations.