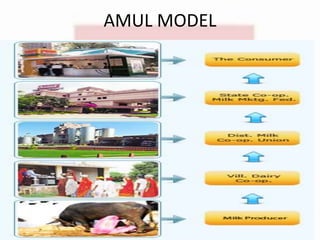

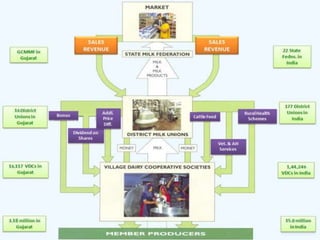

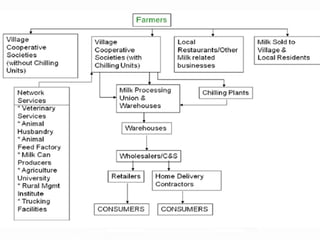

Amul began in 1946 with two village cooperatives collecting 250 liters of milk per day. It was founded to stop exploitation of milk producers by middlemen. Today, Amul collects over a million liters of milk daily from over 1000 village cooperatives owned by 500,000 farmers. Amul inspired India's white revolution and made the country the world's largest milk producer. It uses a three-tiered cooperative model with village, district, and state levels to efficiently procure, process and market milk and dairy products while empowering milk producers.