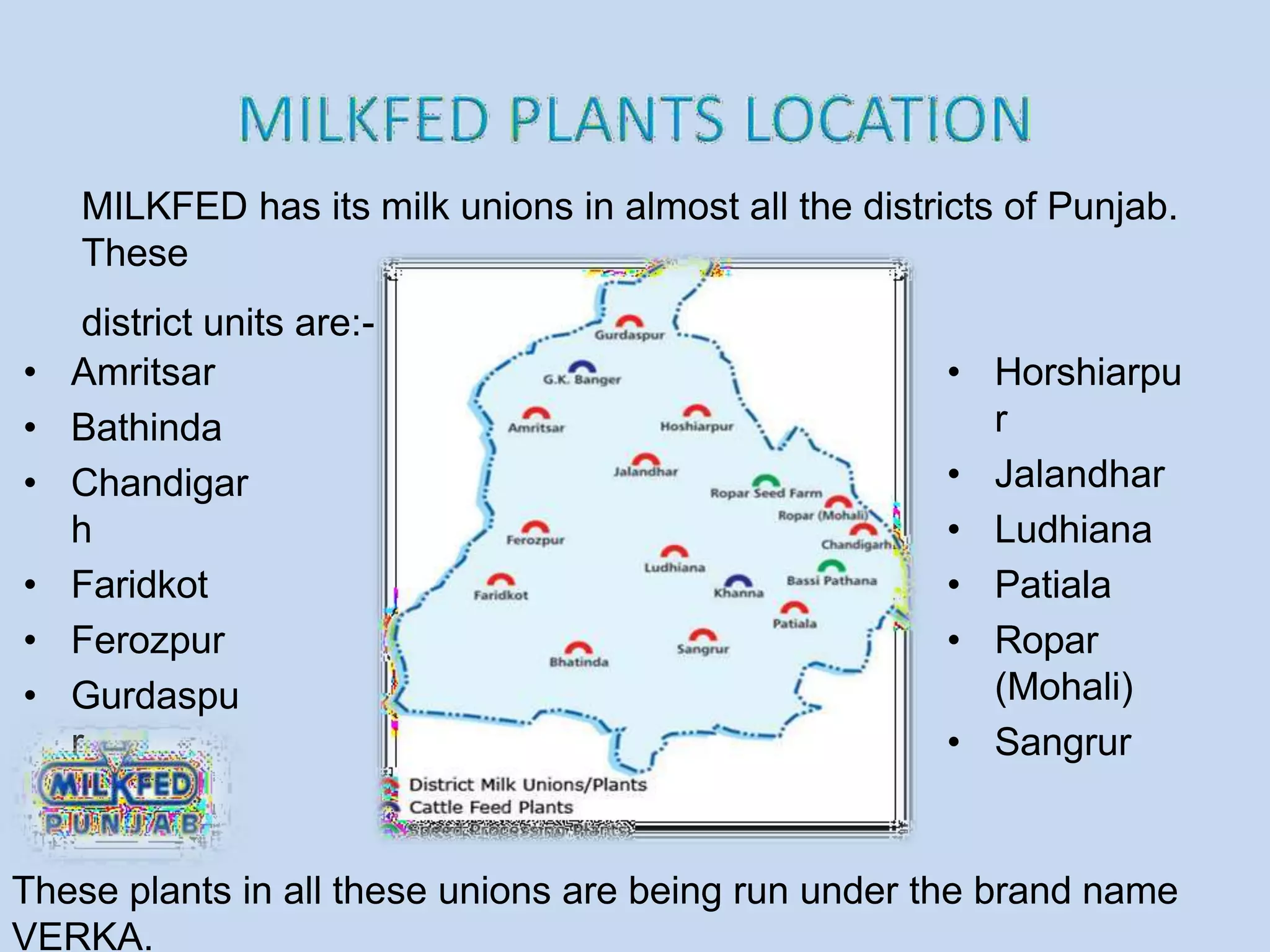

The Ludhiana District Co-operative Milk Producers' Union Ltd. was established in 1970 with a milk handling capacity of 1 lakh litres per day. It has since expanded to handle 6 lakh litres daily. The plant manufactures milk, butter, ghee, paneer, lassi, kheer and other products under the VERKA brand. Strict quality standards are followed in processing and the plant has received international quality certifications. It aims to improve the economic conditions of milk producers and provide quality dairy products to consumers.