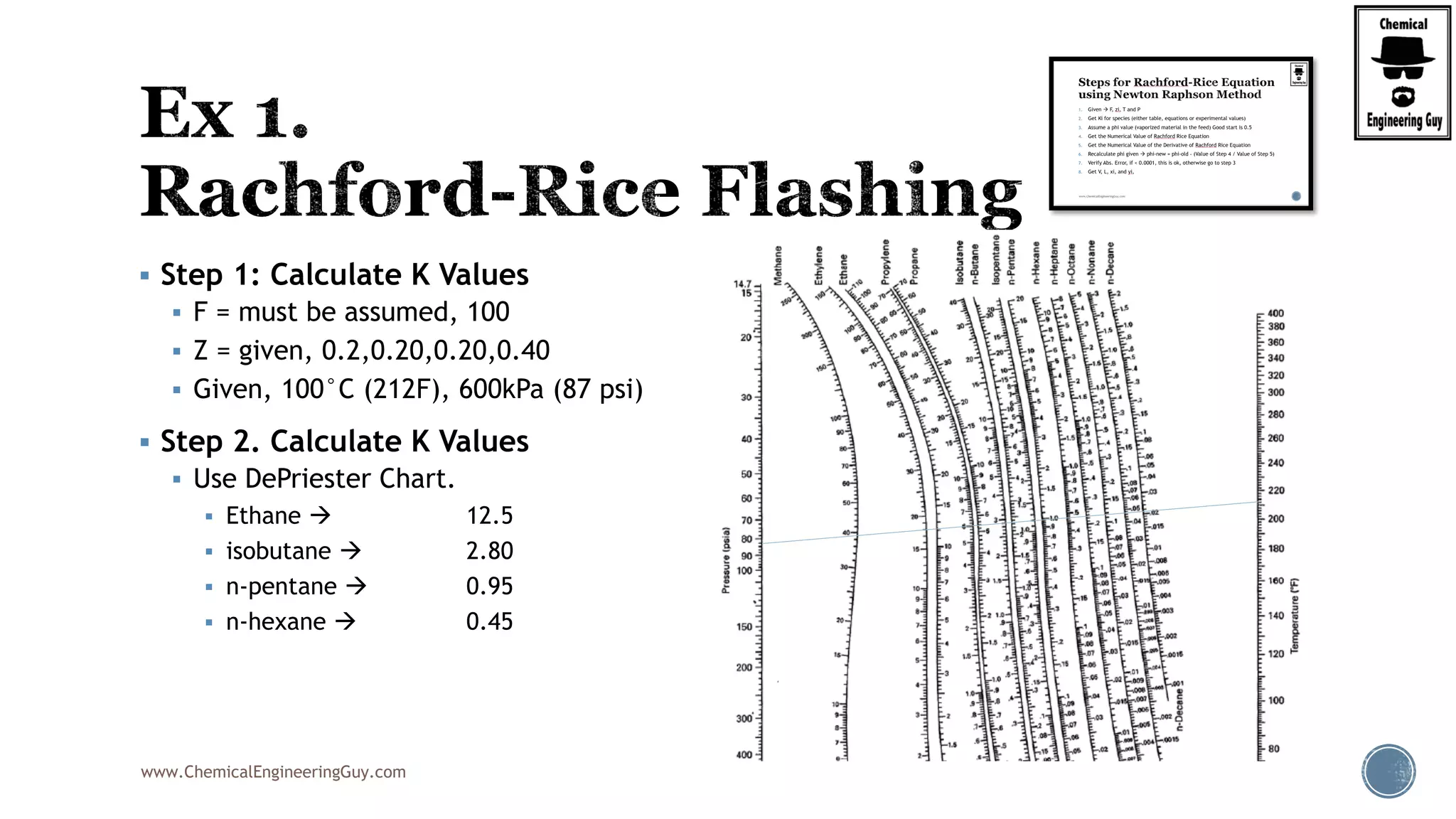

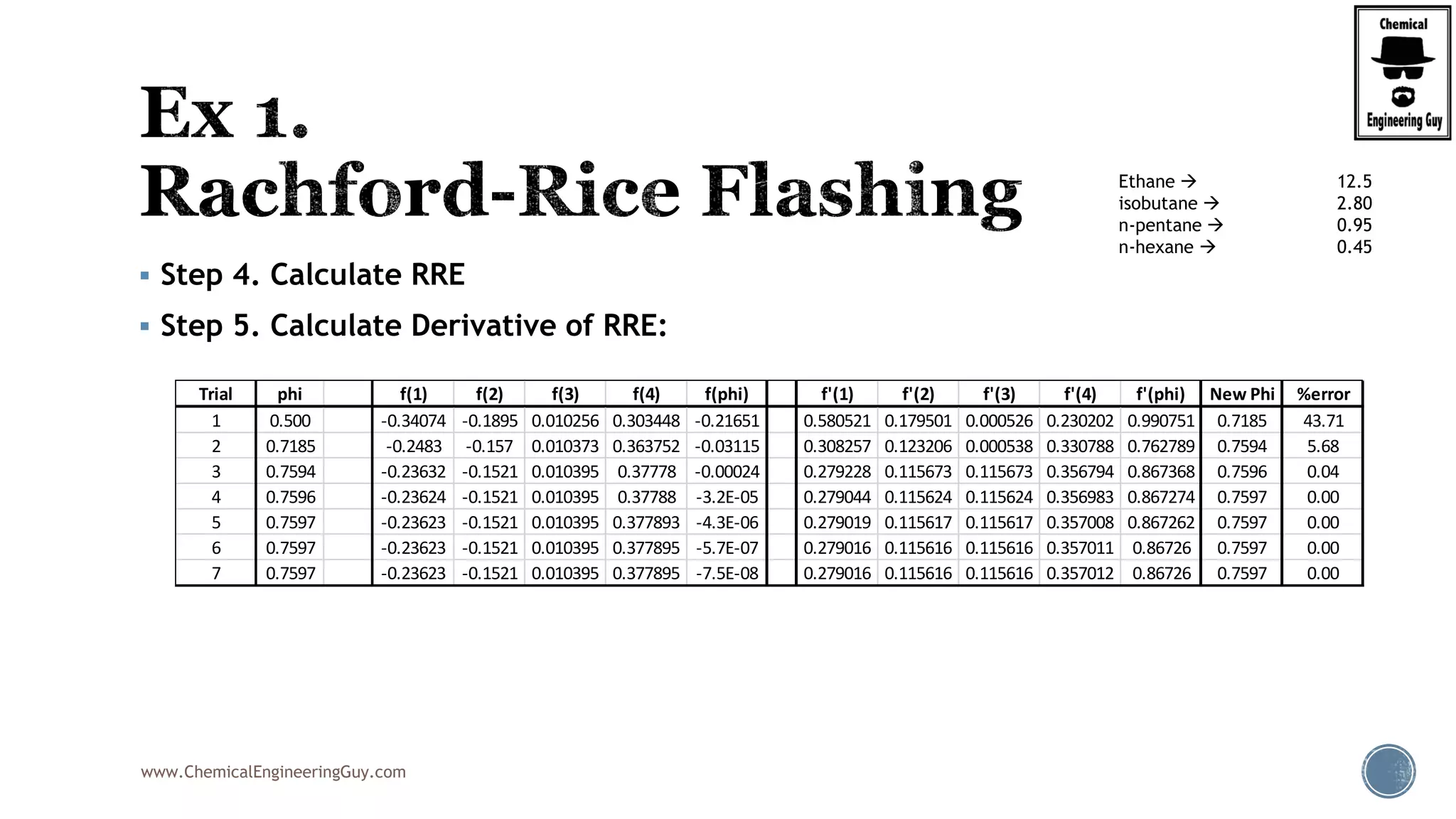

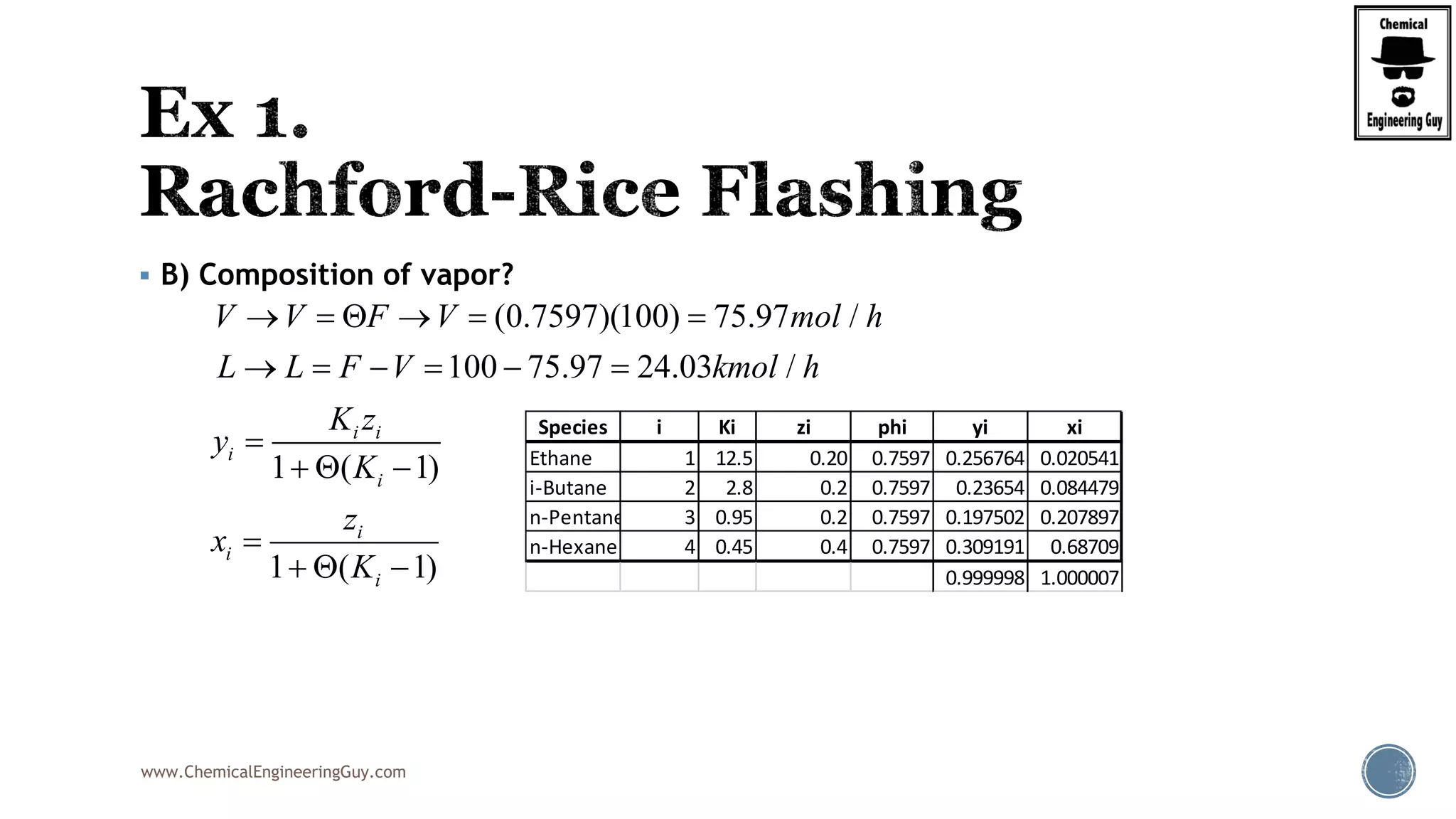

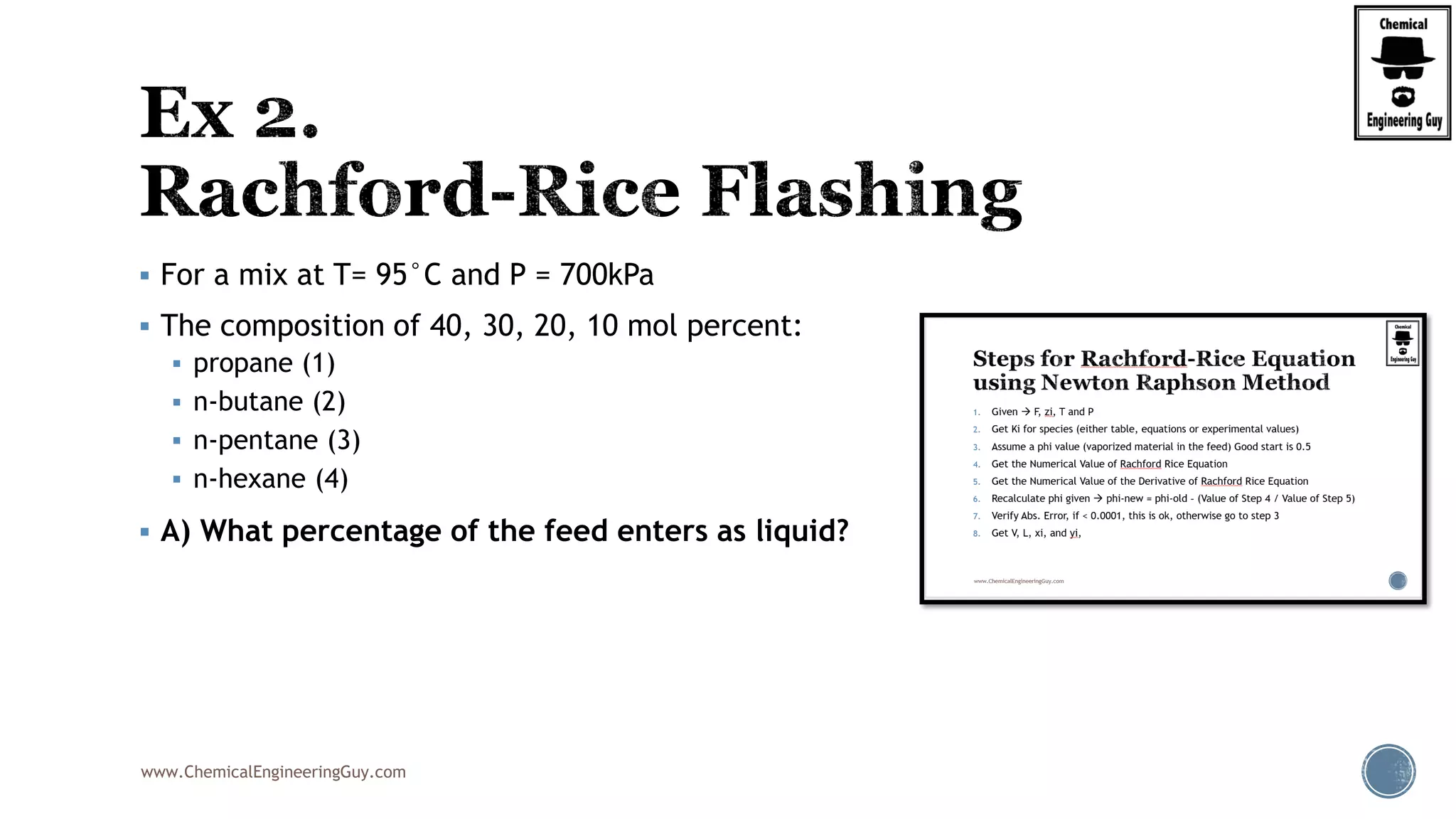

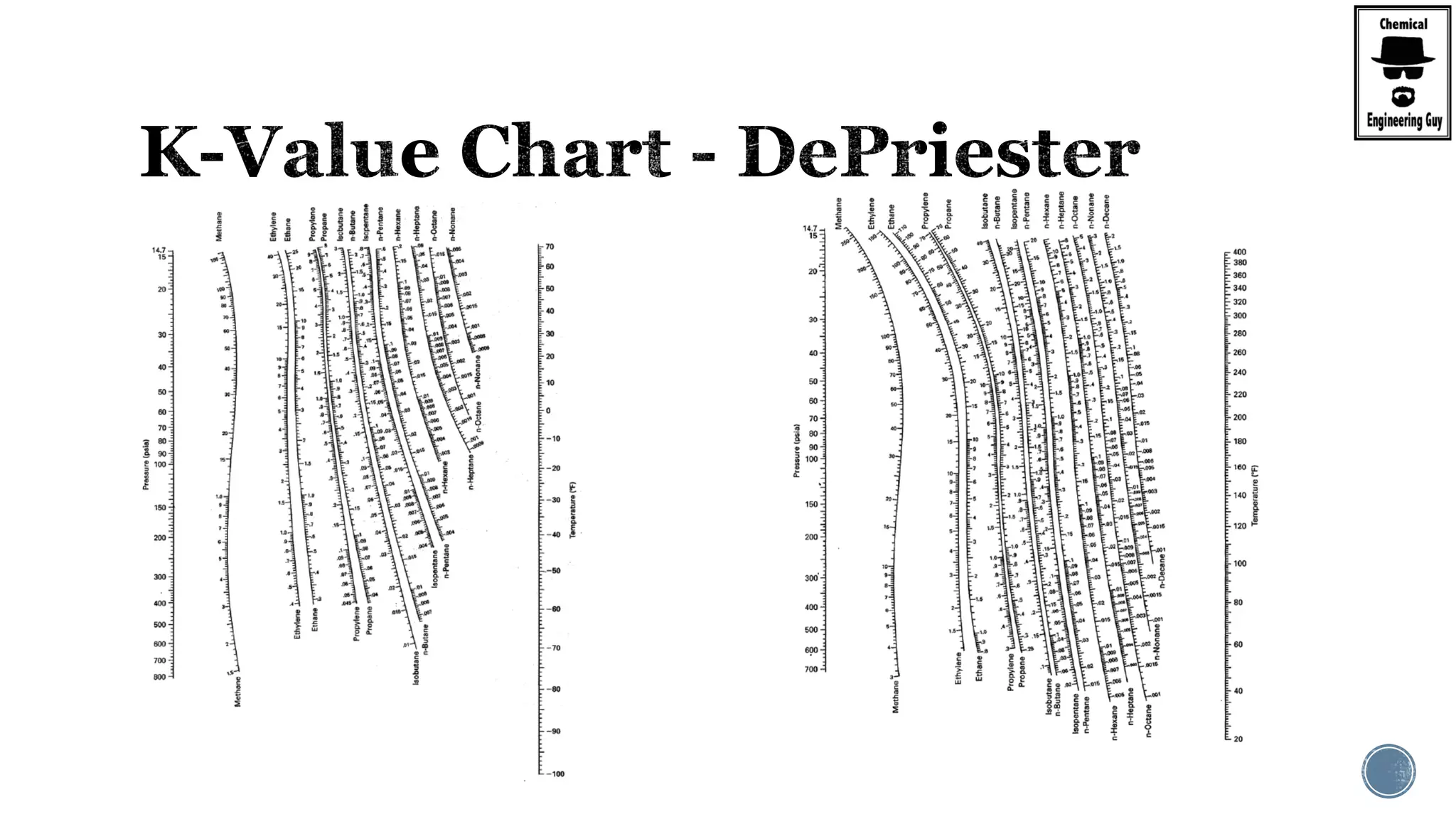

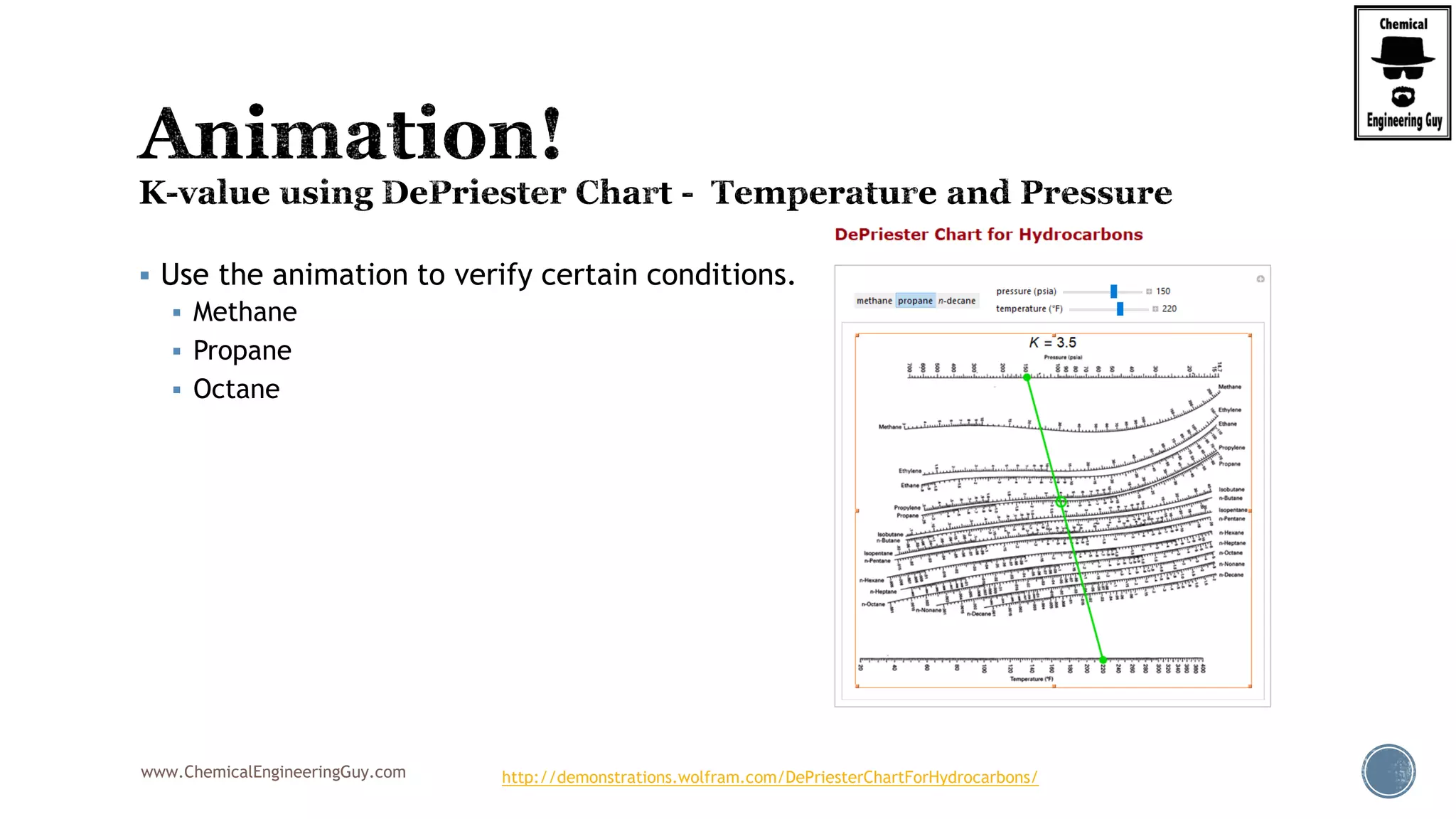

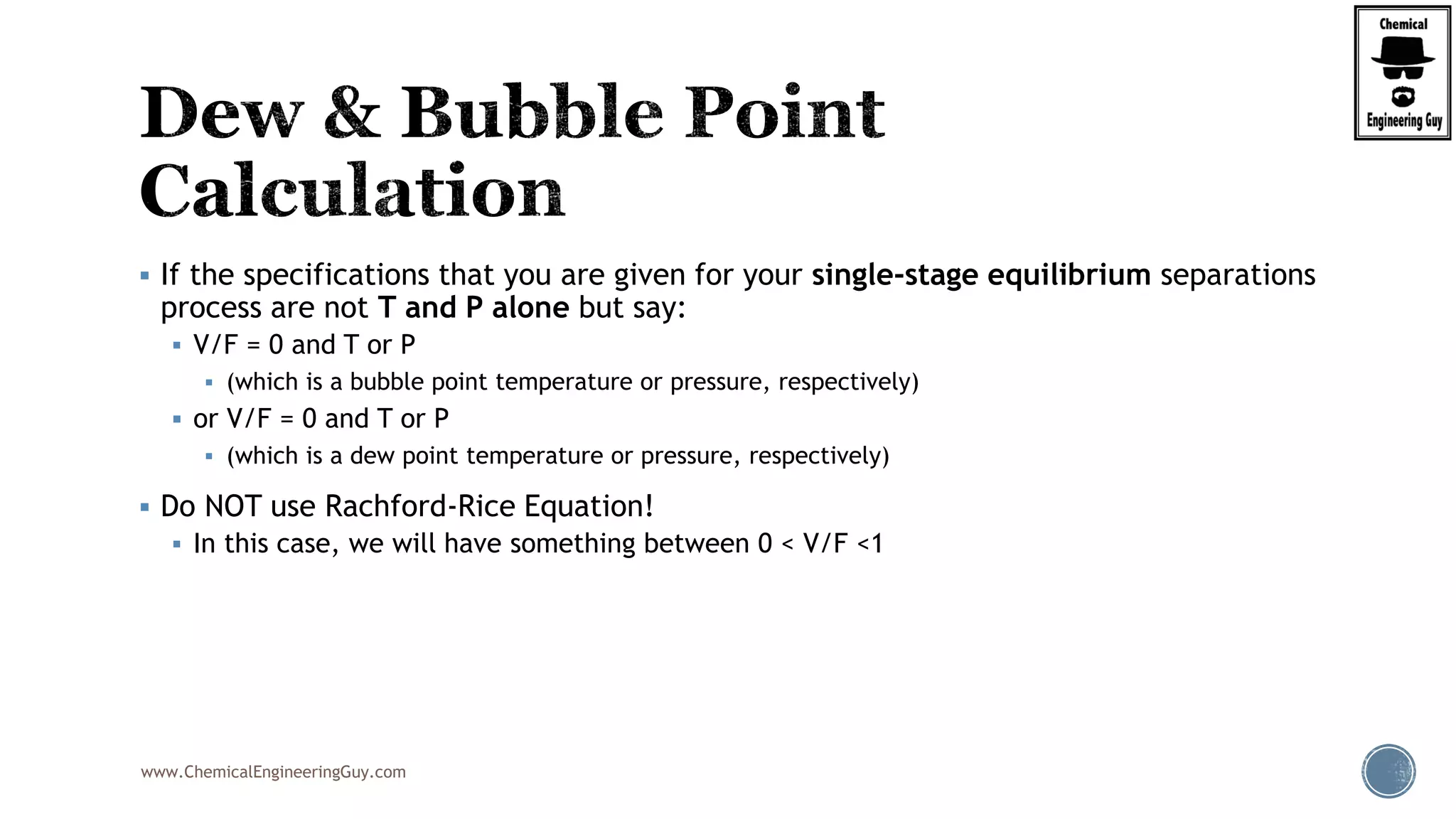

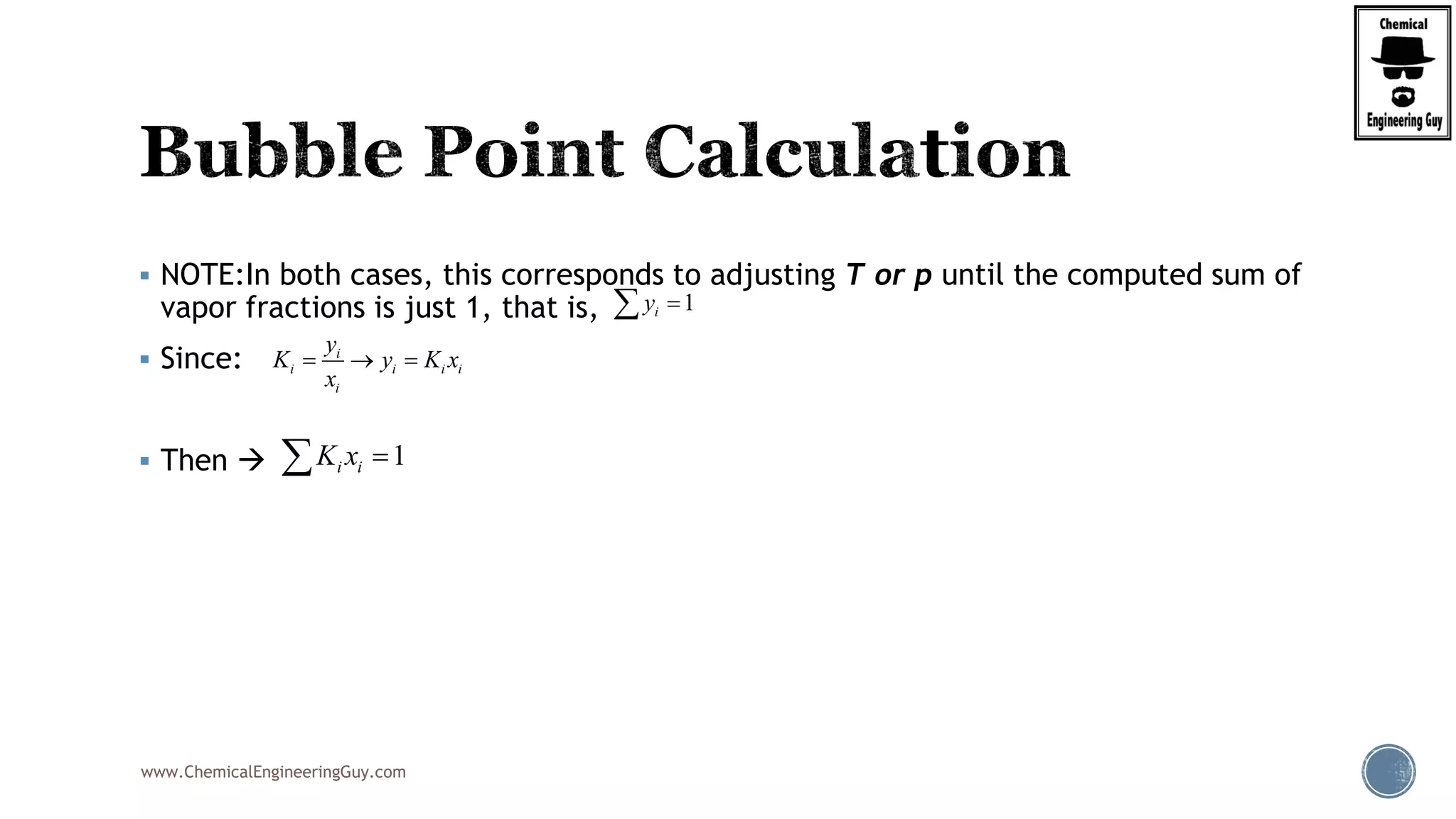

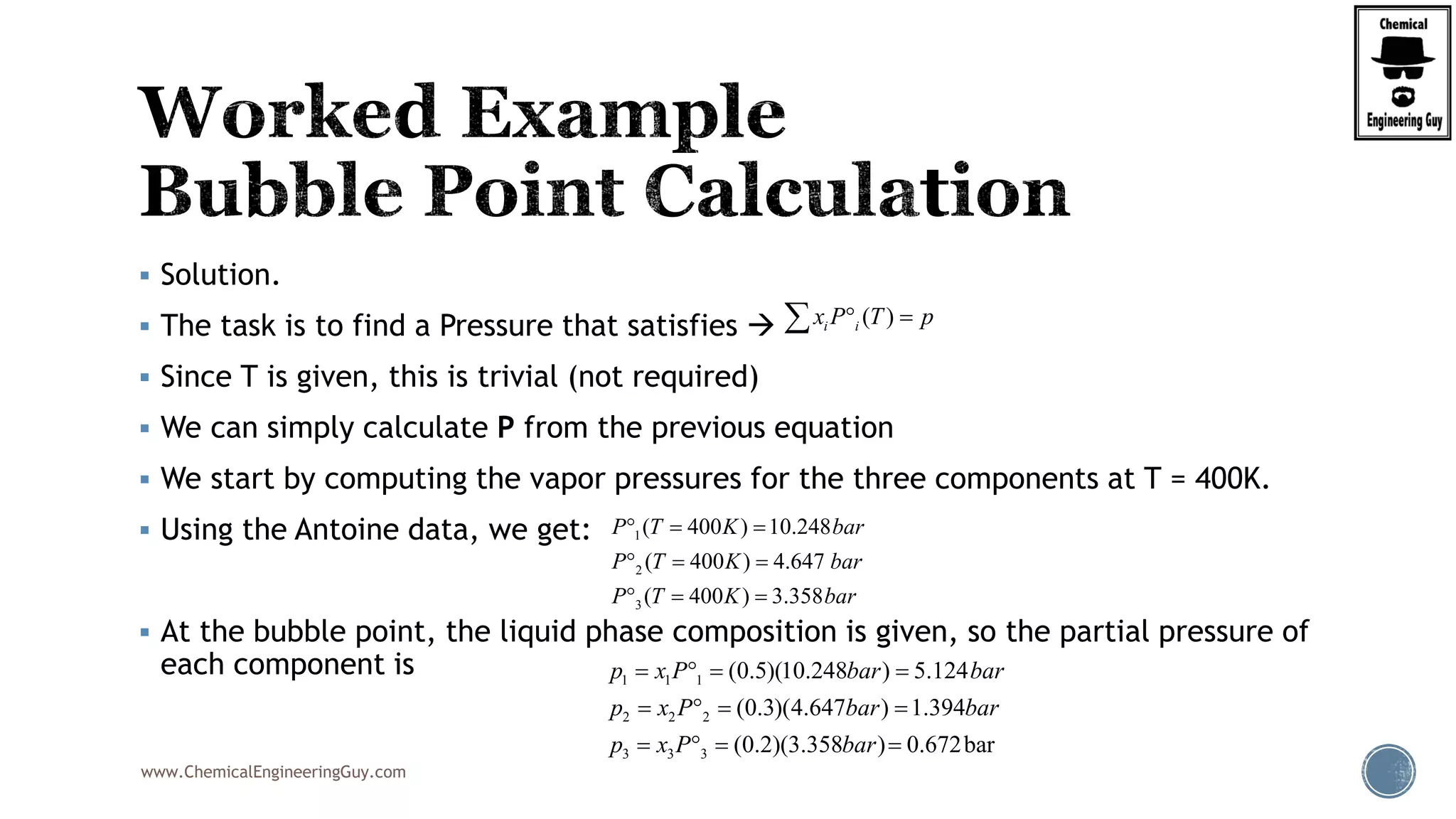

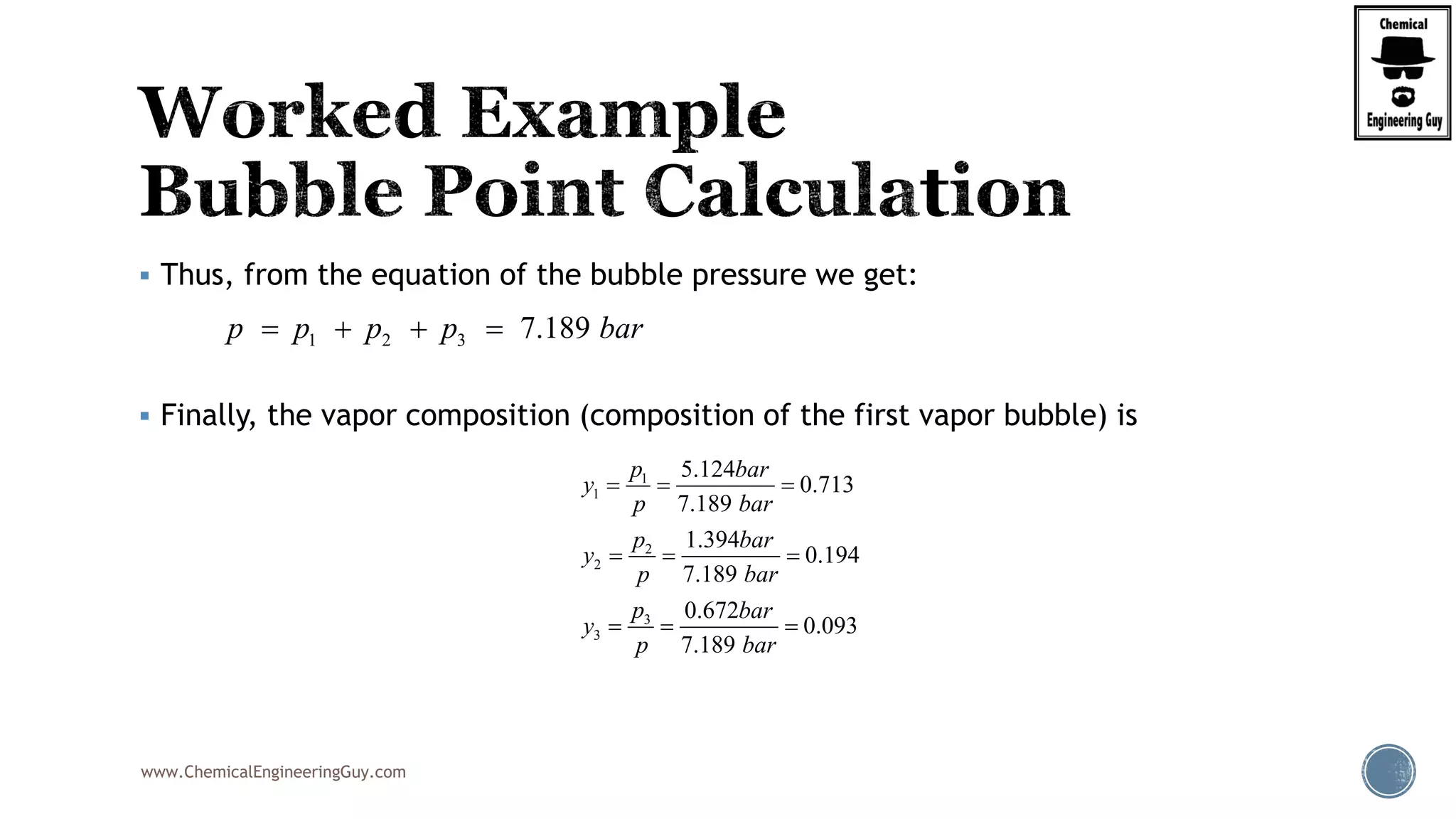

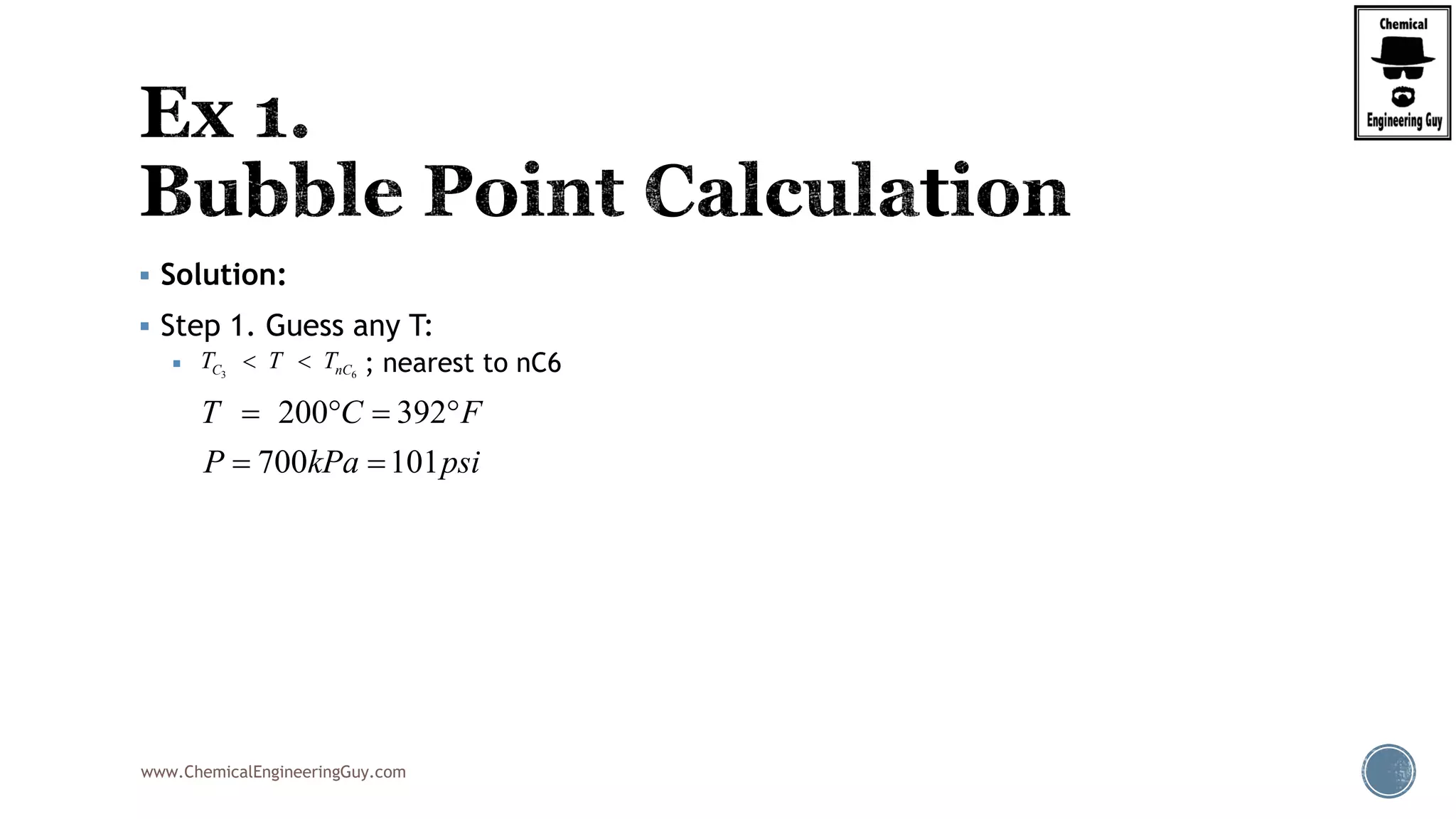

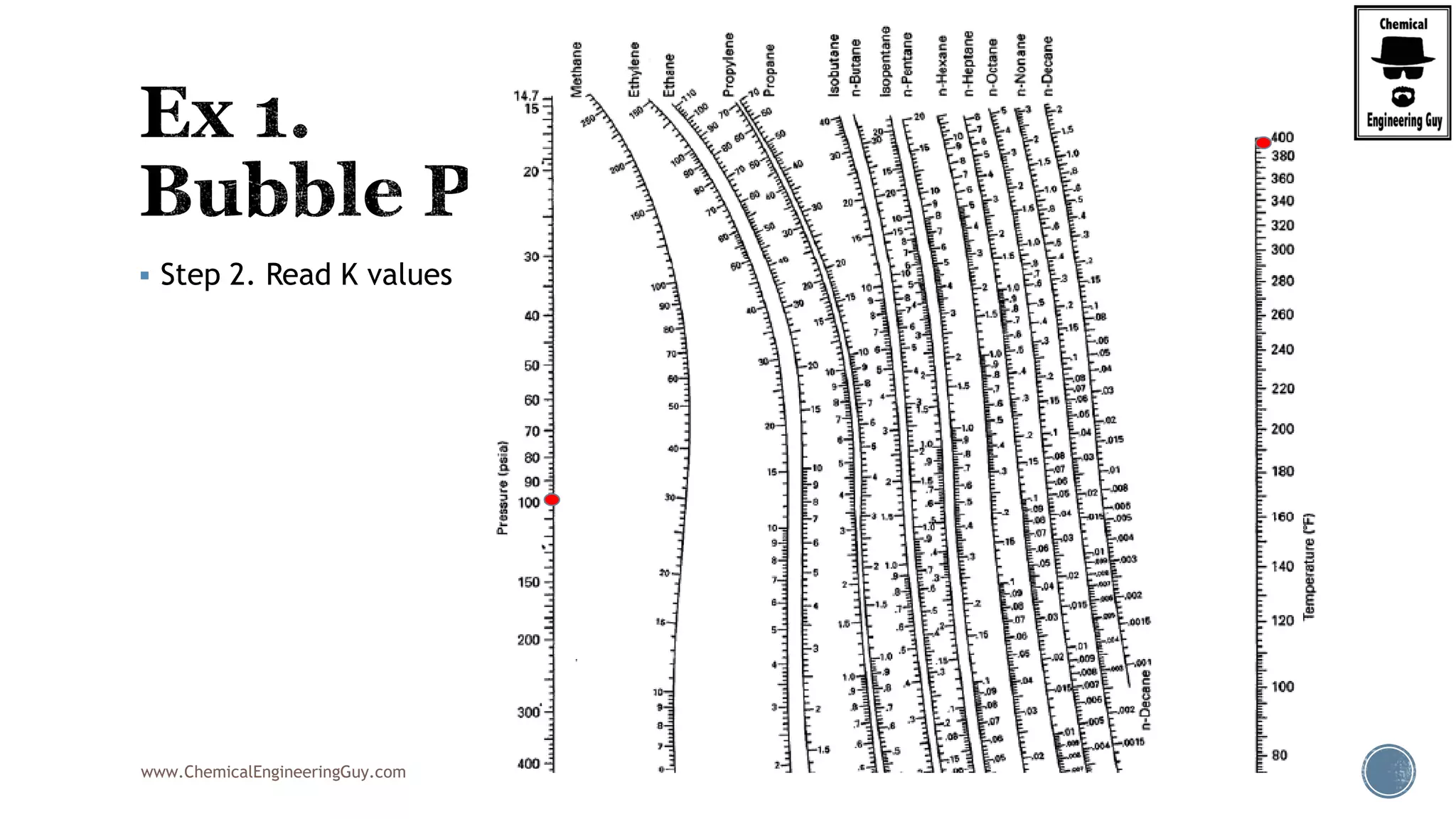

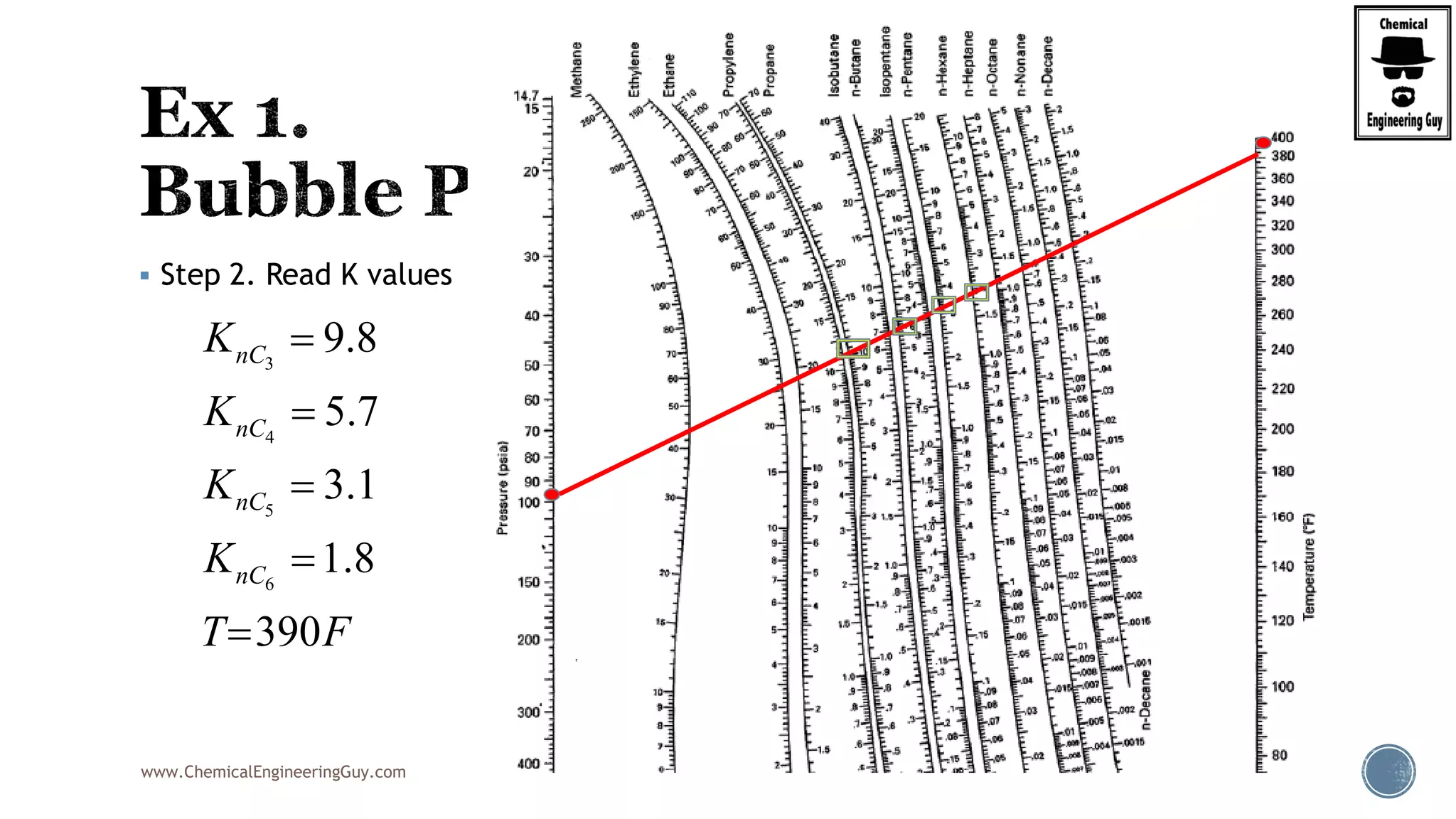

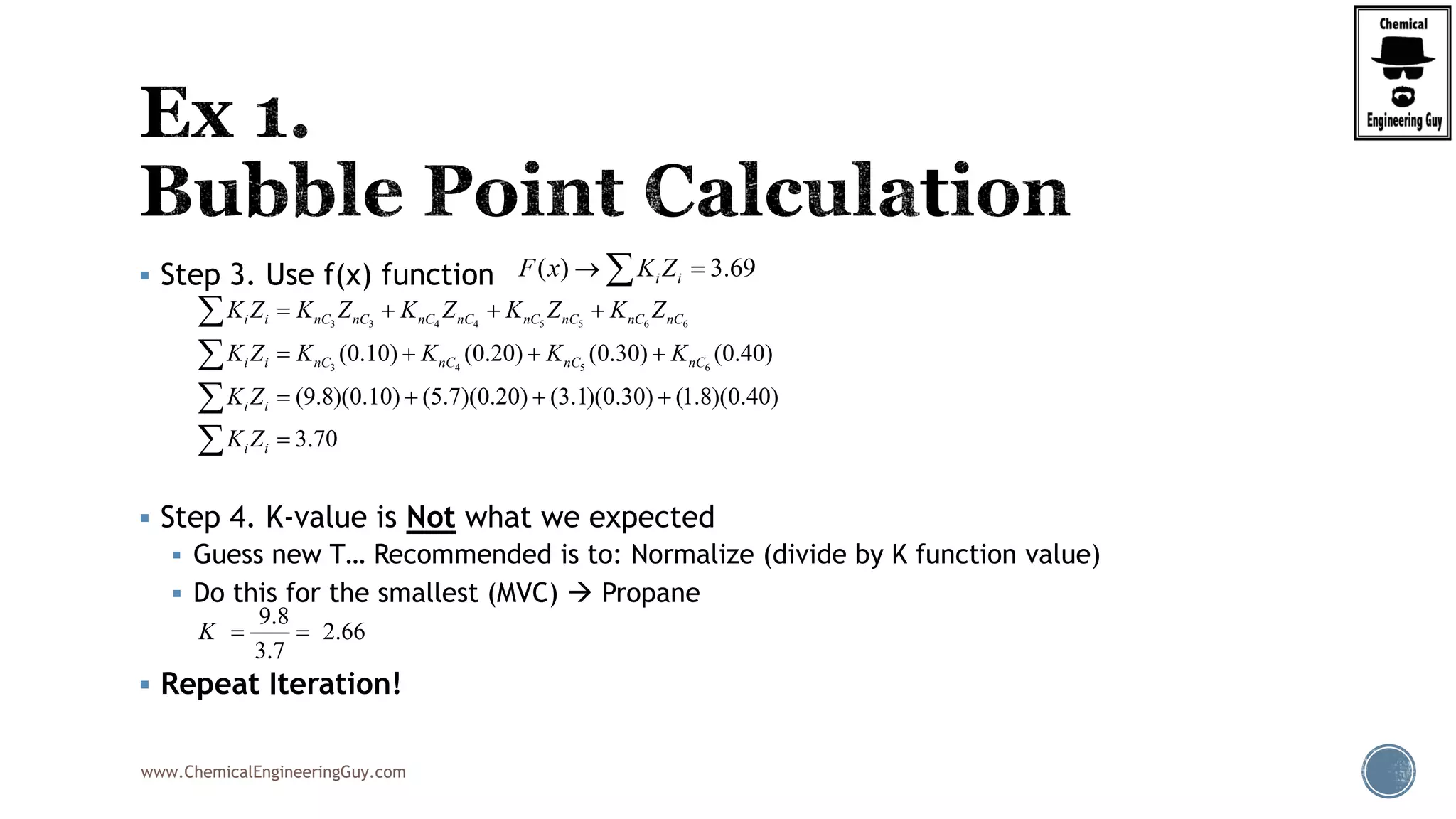

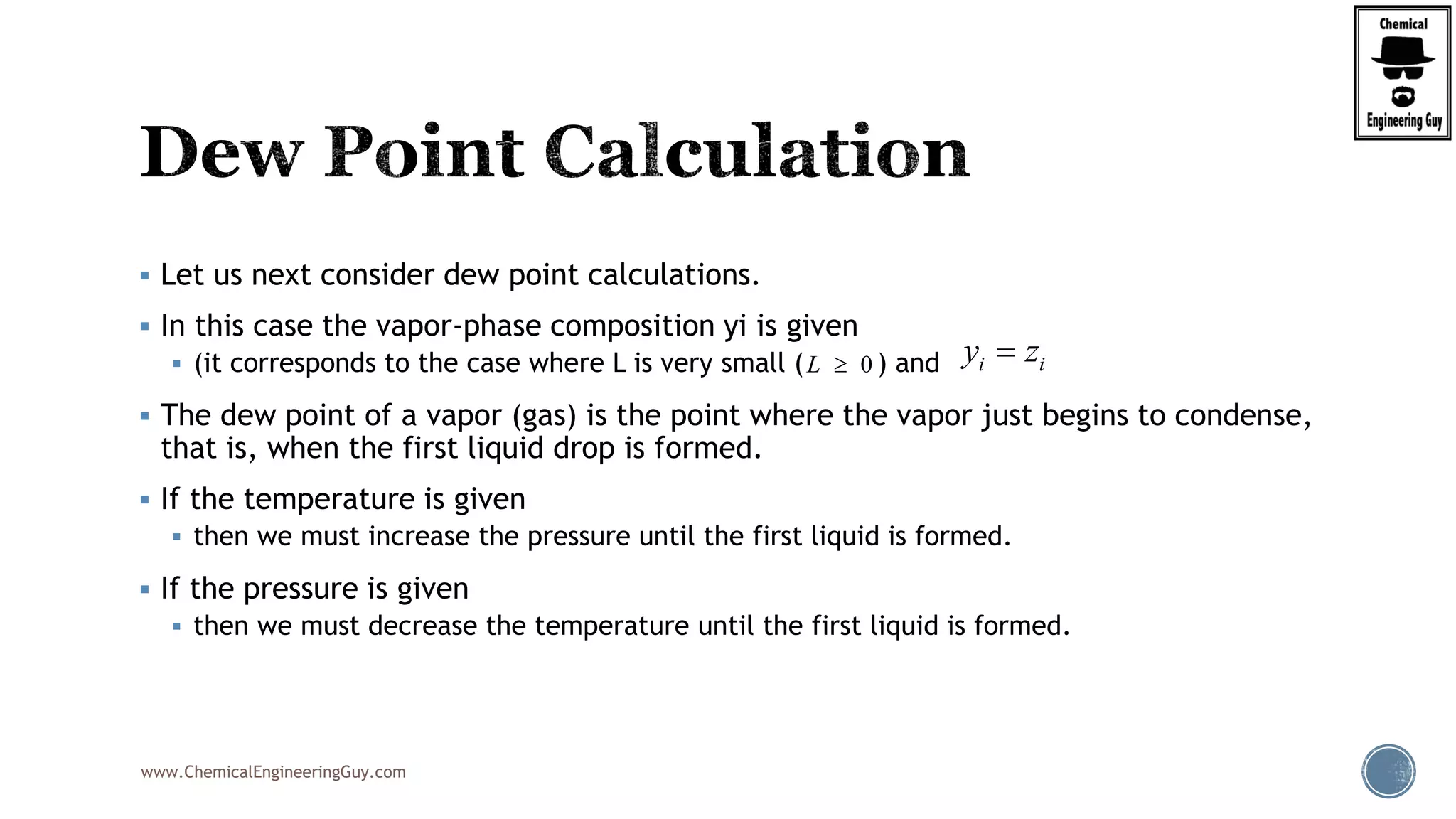

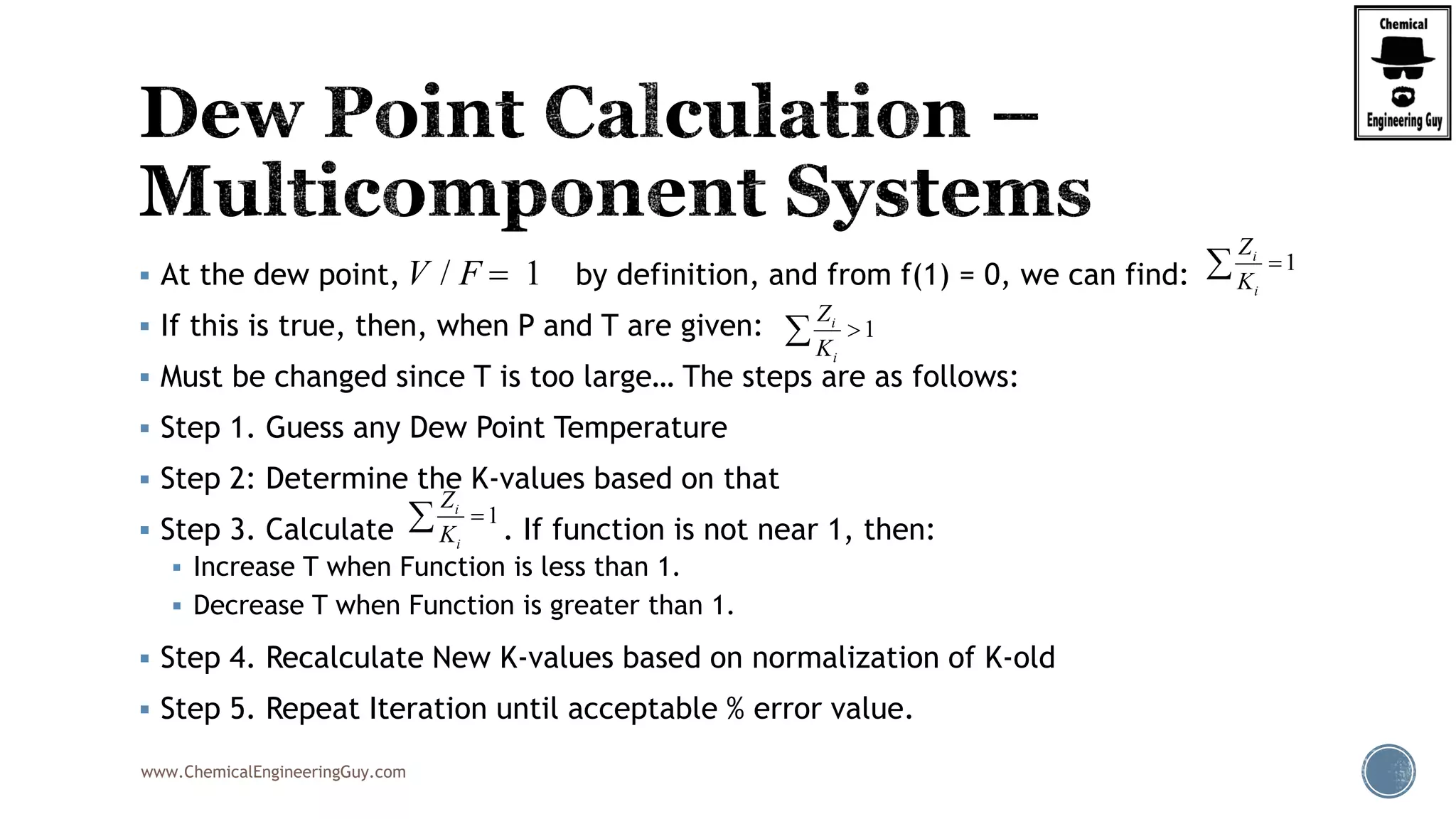

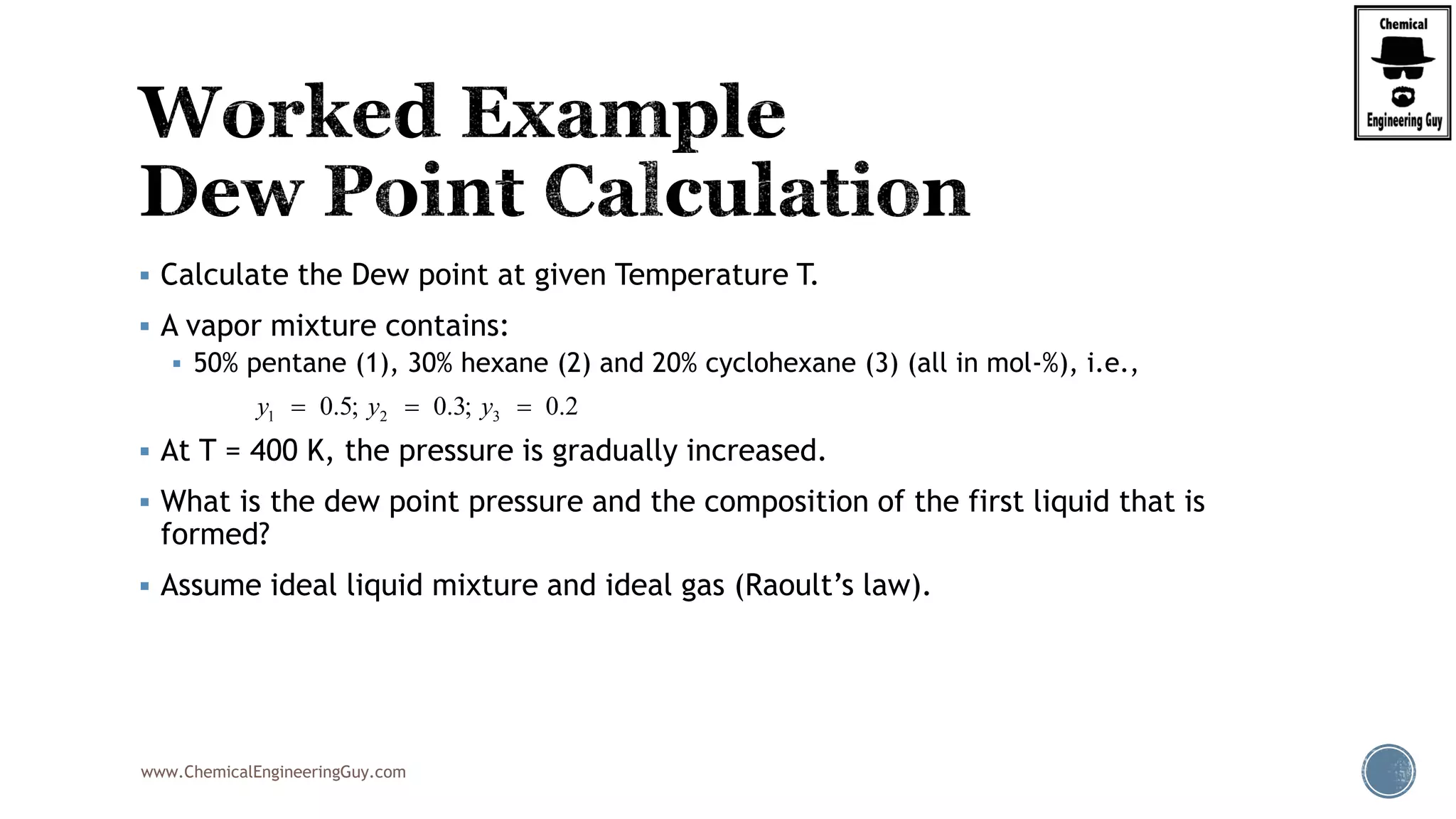

The document discusses the theory and calculations for multicomponent vapor-liquid equilibrium (VLE) and flash distillation, focusing on bubble and dew points and k-values for hydrocarbon systems. It explains the relationship between different phases and the phase rule while emphasizing methods for calculating bubble point and dew point conditions. Additionally, it provides practical examples and methodologies for evaluating hydrocarbon mixtures at specified temperatures and pressures.

![www.ChemicalEngineeringGuy.com

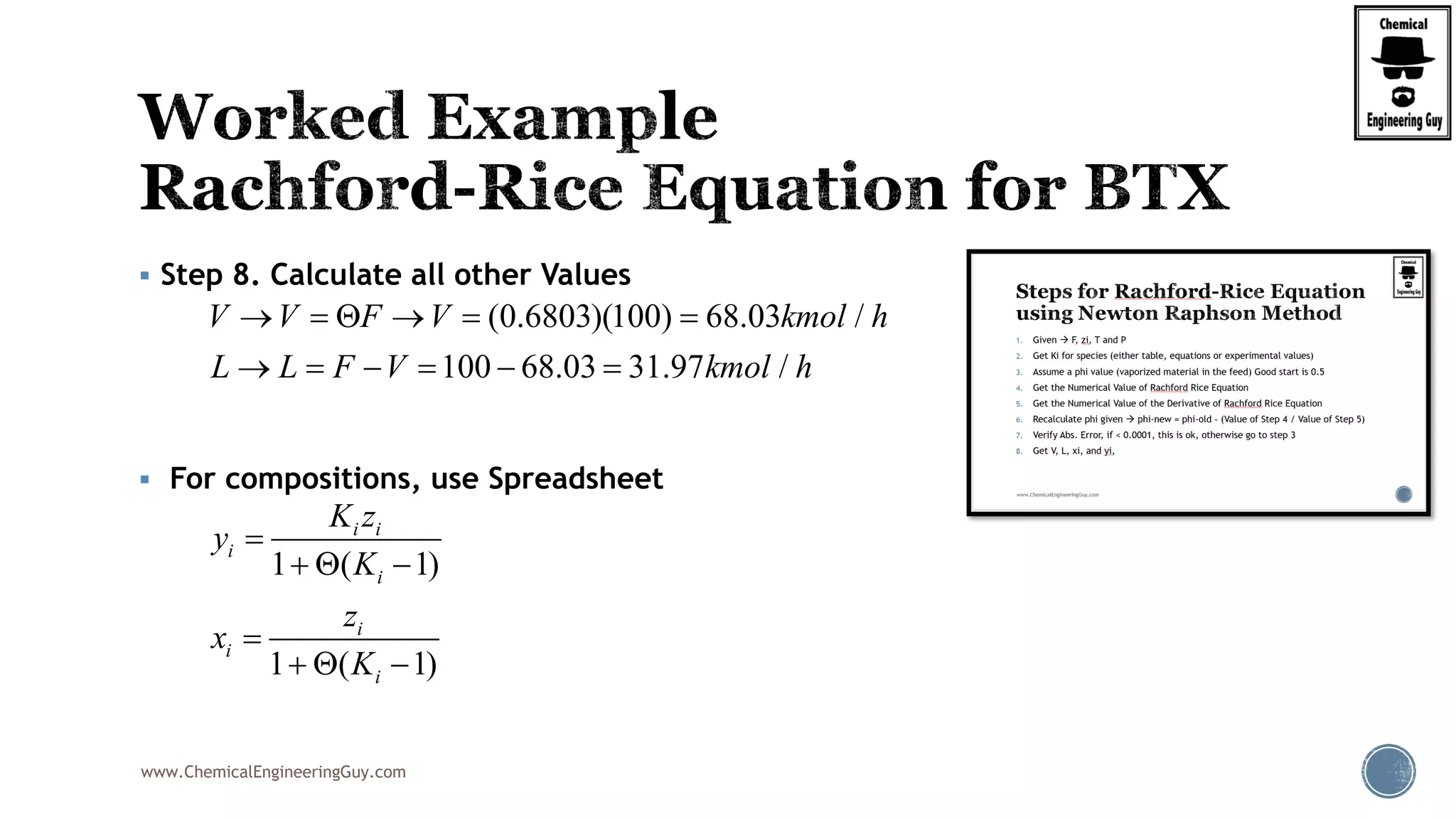

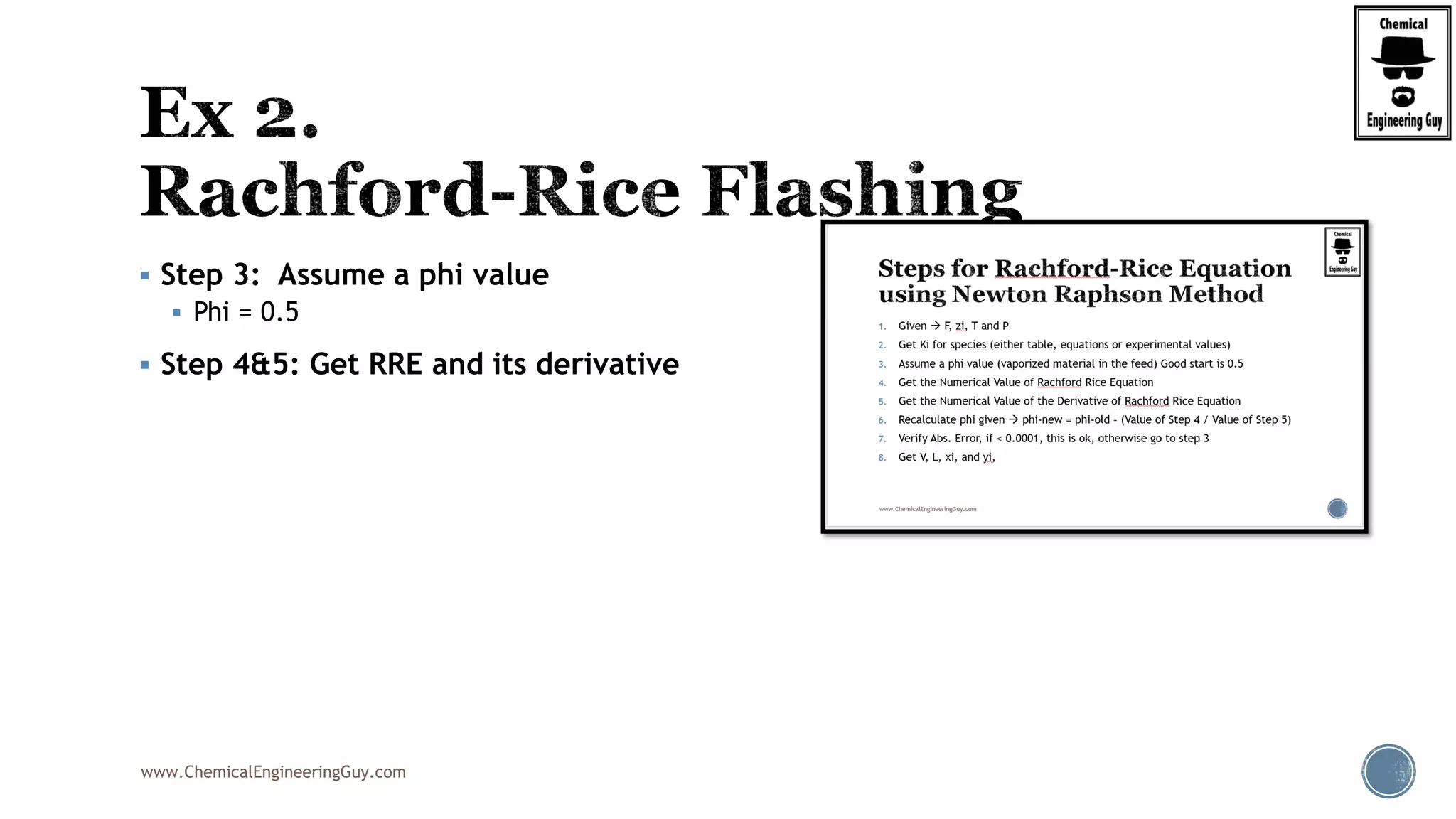

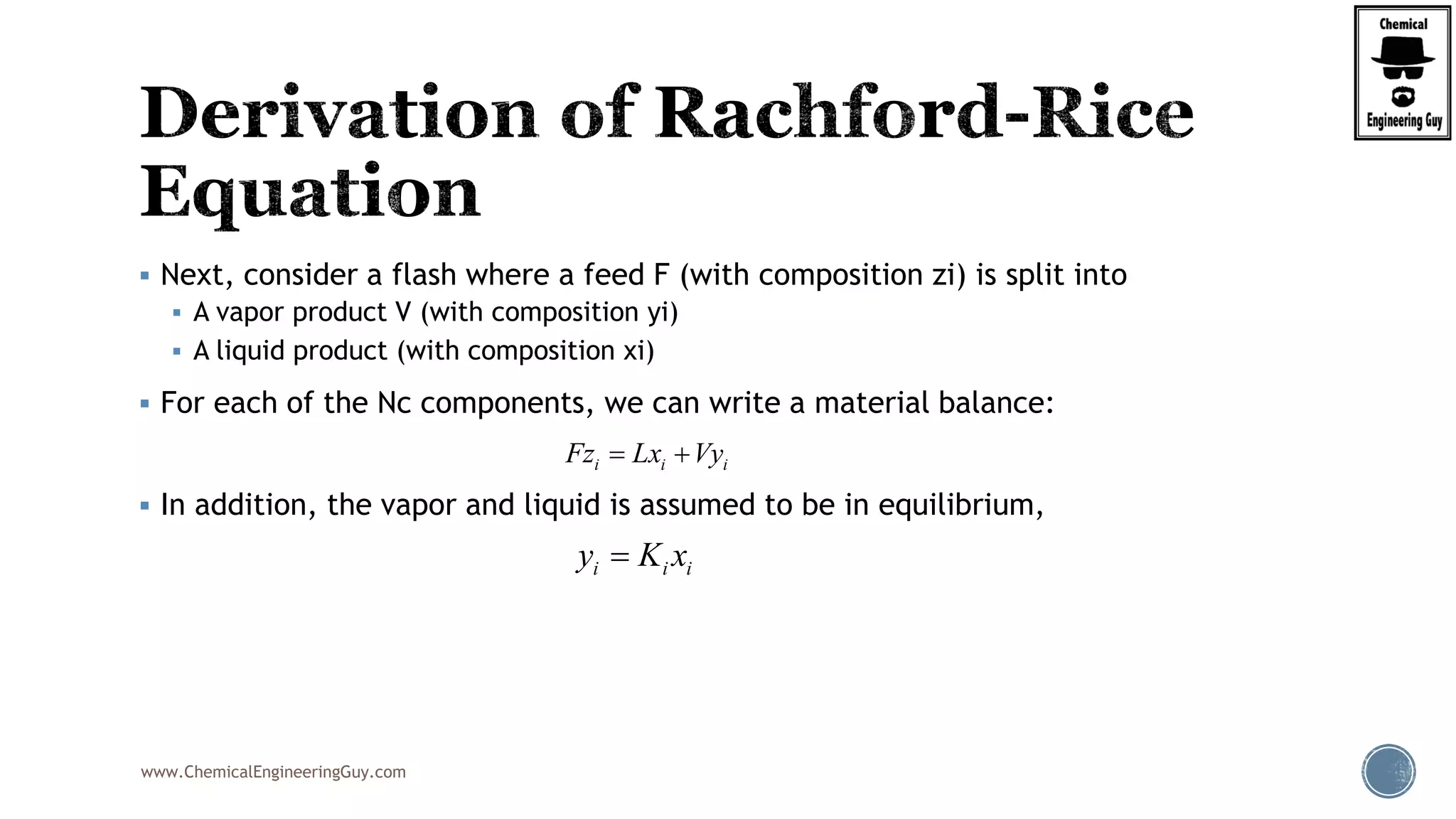

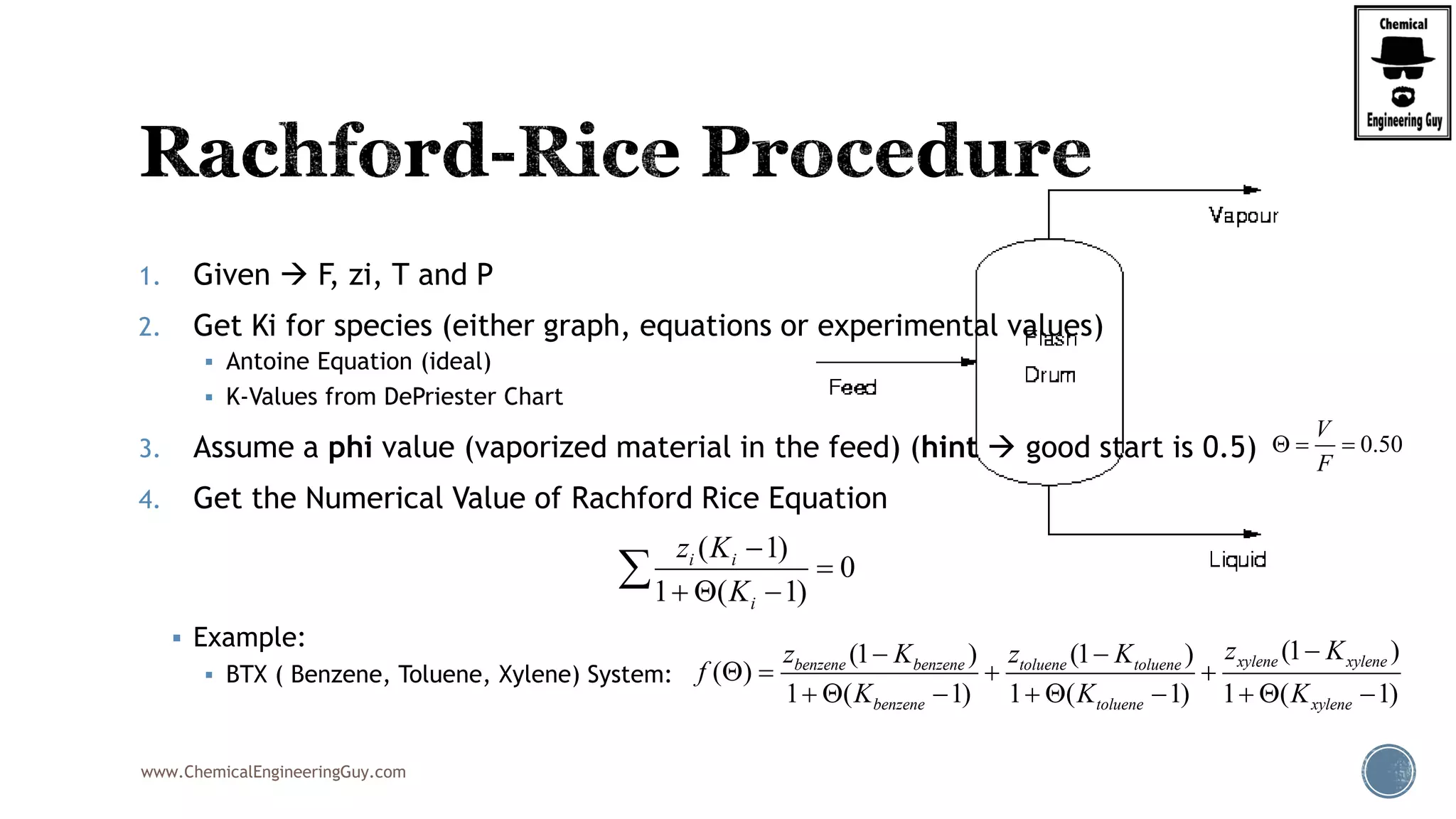

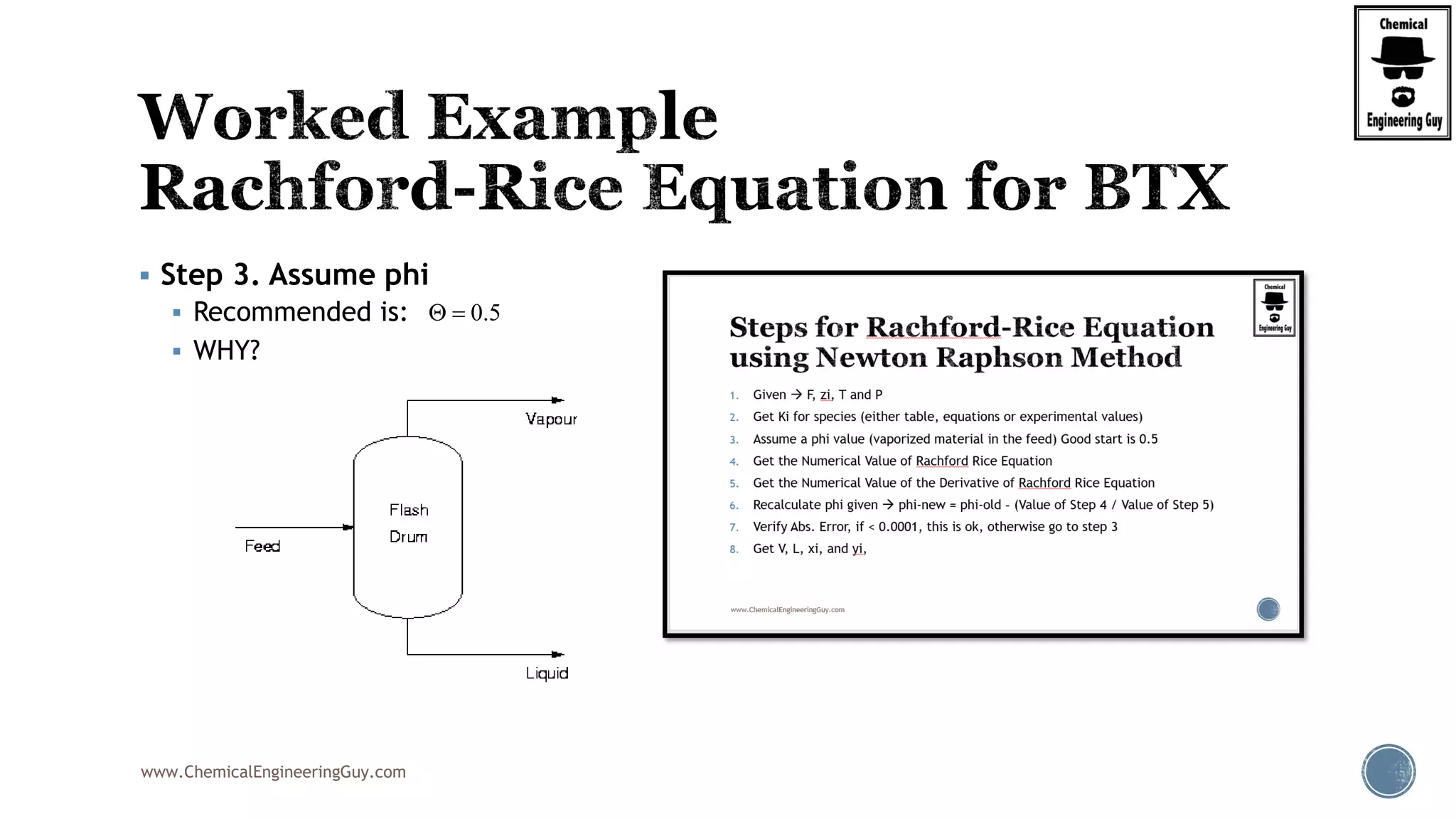

This will be the typical procedure for the RRE

Note that this is based on a numerical method

Newton-Raphson Method

Uses the original function, f(phi)

It also requires the derivative of the function, f’(phi)

( 1)

( )

1 ( 1)

i i

i

z K

f

K

0.50

V

F

2

2

(1 )

'( )

[1 ( 1)]

i i

i

z K

f

K

( , , , ... )i j k zF z z z z

(V,y ,y ,y ...y )i j k z

(L,x ,x ,x ...x )i j k z

( , )T P

( , , ... )i j k zK K K K

Do you need the Full Version?

Contact me if needed!

Contact@ChemicalEngineeringGuy.com

https://courses.chemicalengineeringguy.com/courses

You can also check out more content here:

My Youtube Channel

My Fan Page

The LinkedIn

My website:](https://image.slidesharecdn.com/flashdistillationslideshare3of3-191031011848/75/Flash-Distillation-in-Chemical-and-Process-Engineering-Part-3-of-3-49-2048.jpg)

![www.ChemicalEngineeringGuy.com

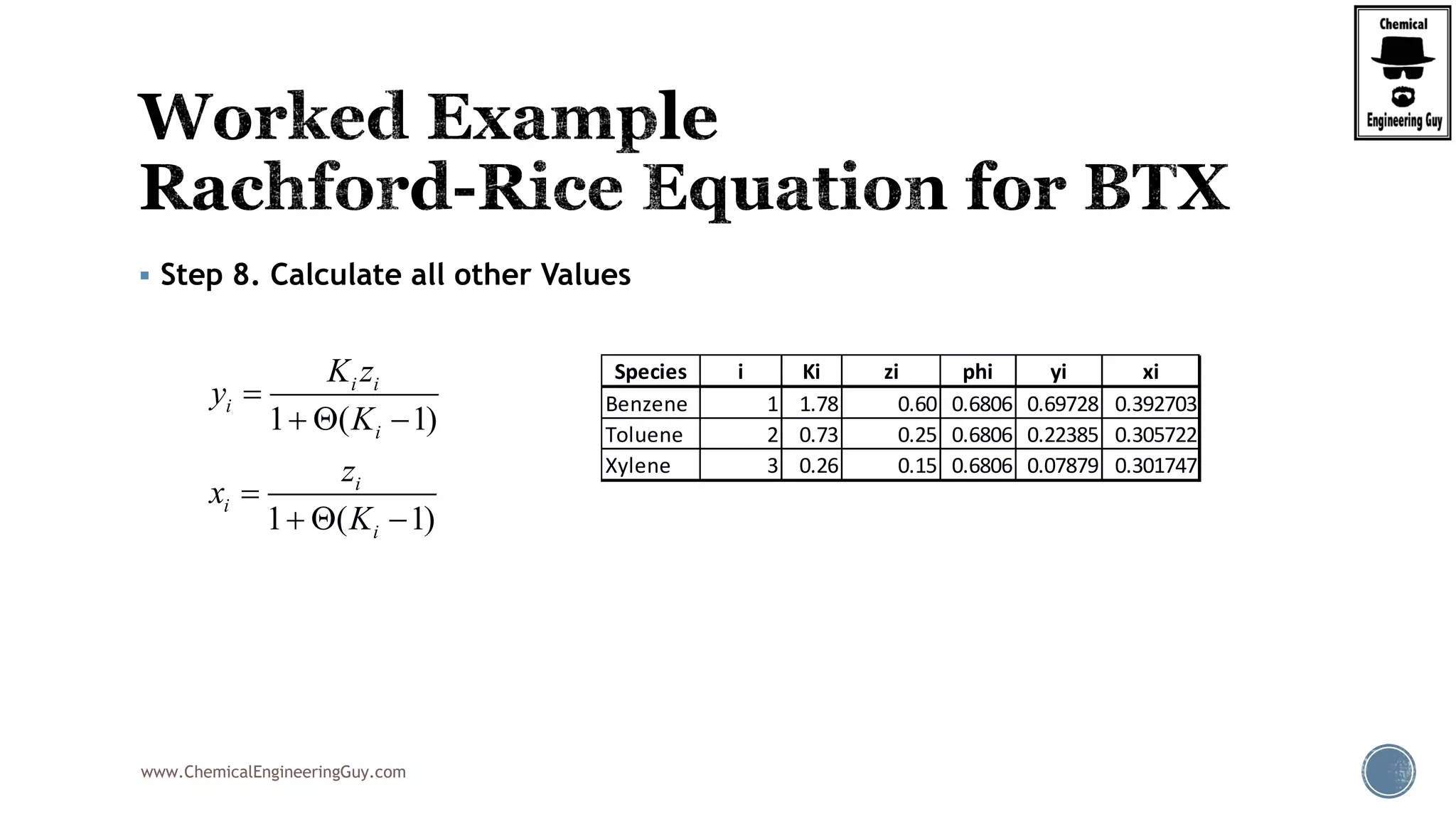

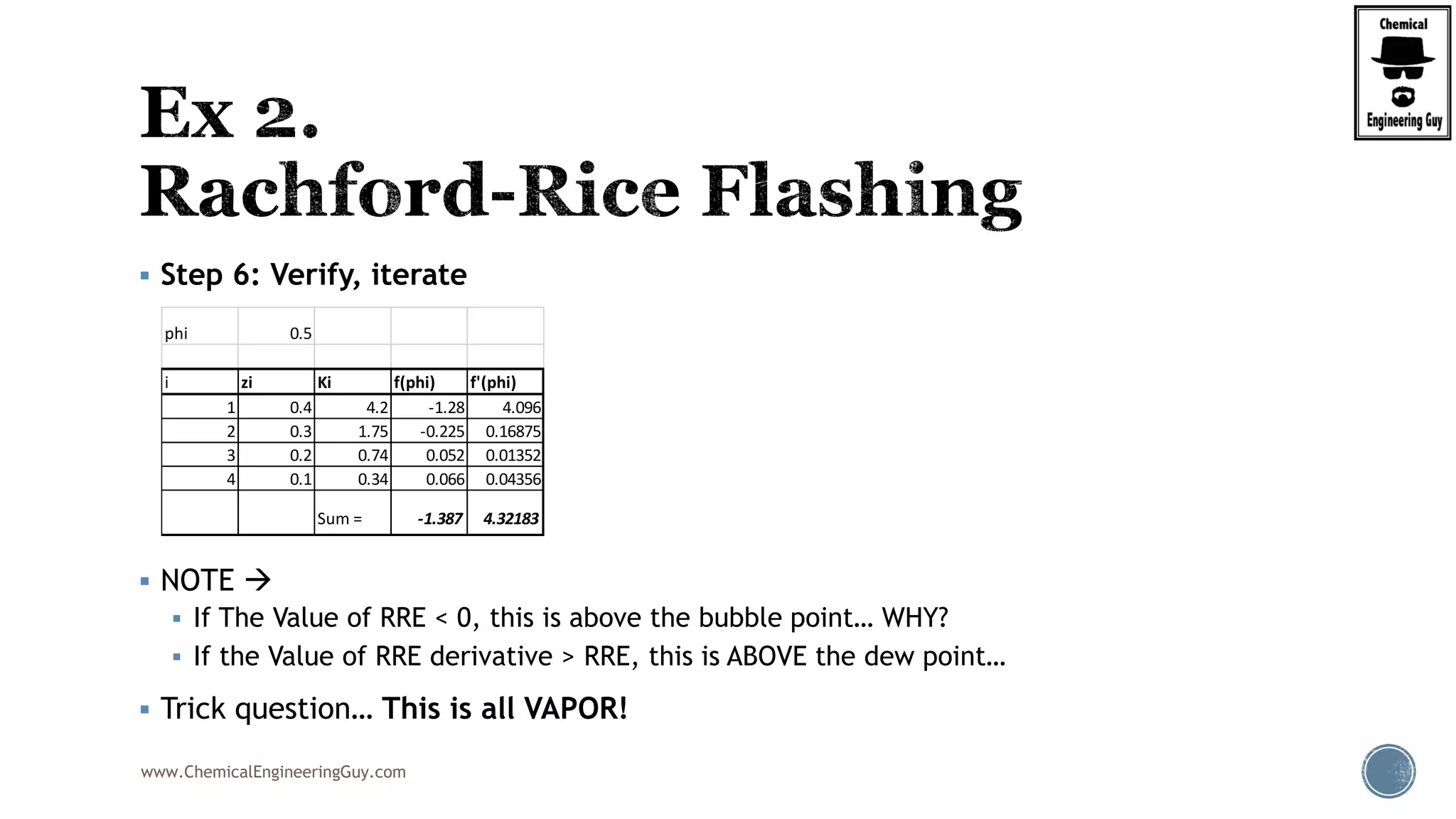

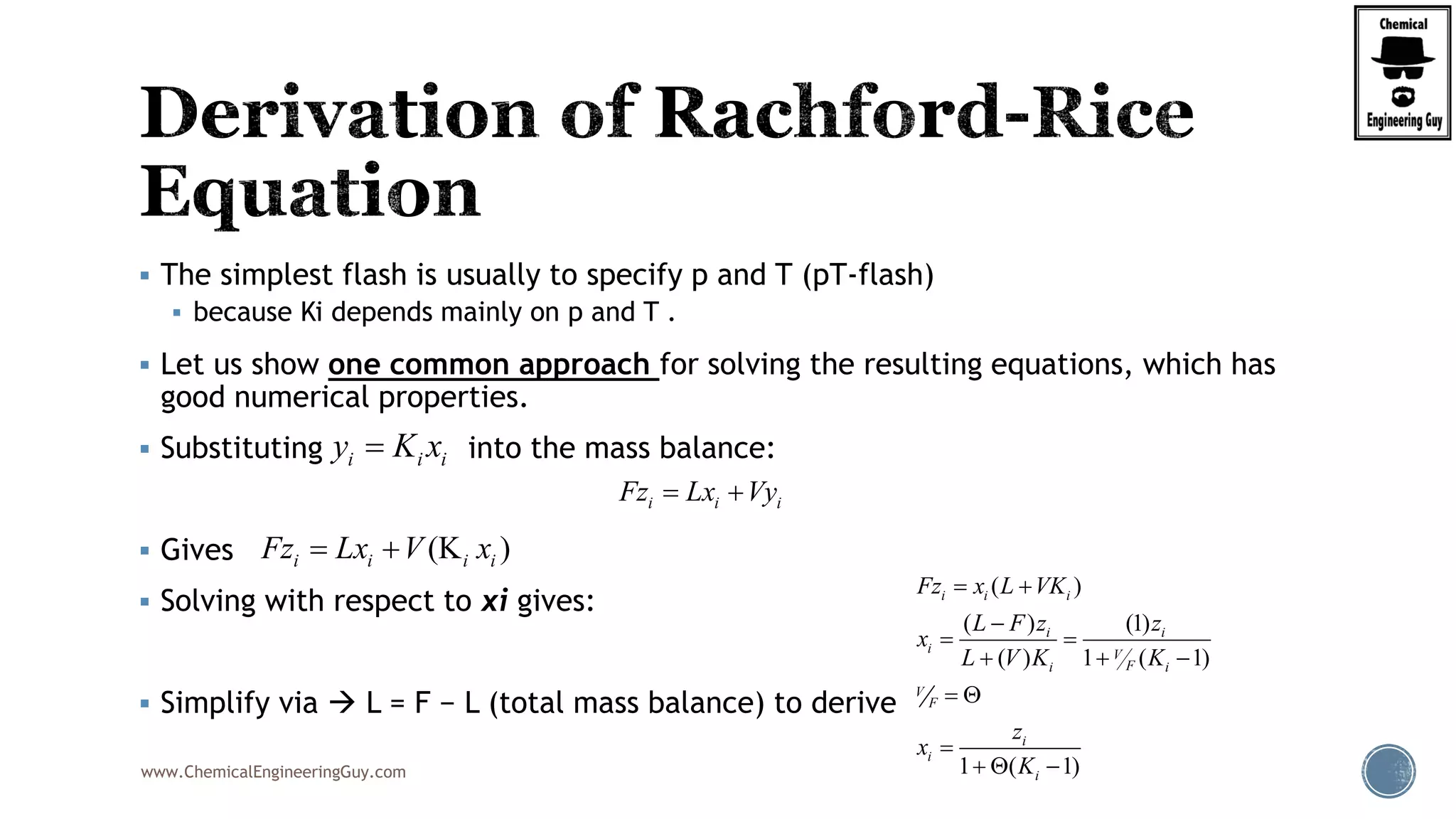

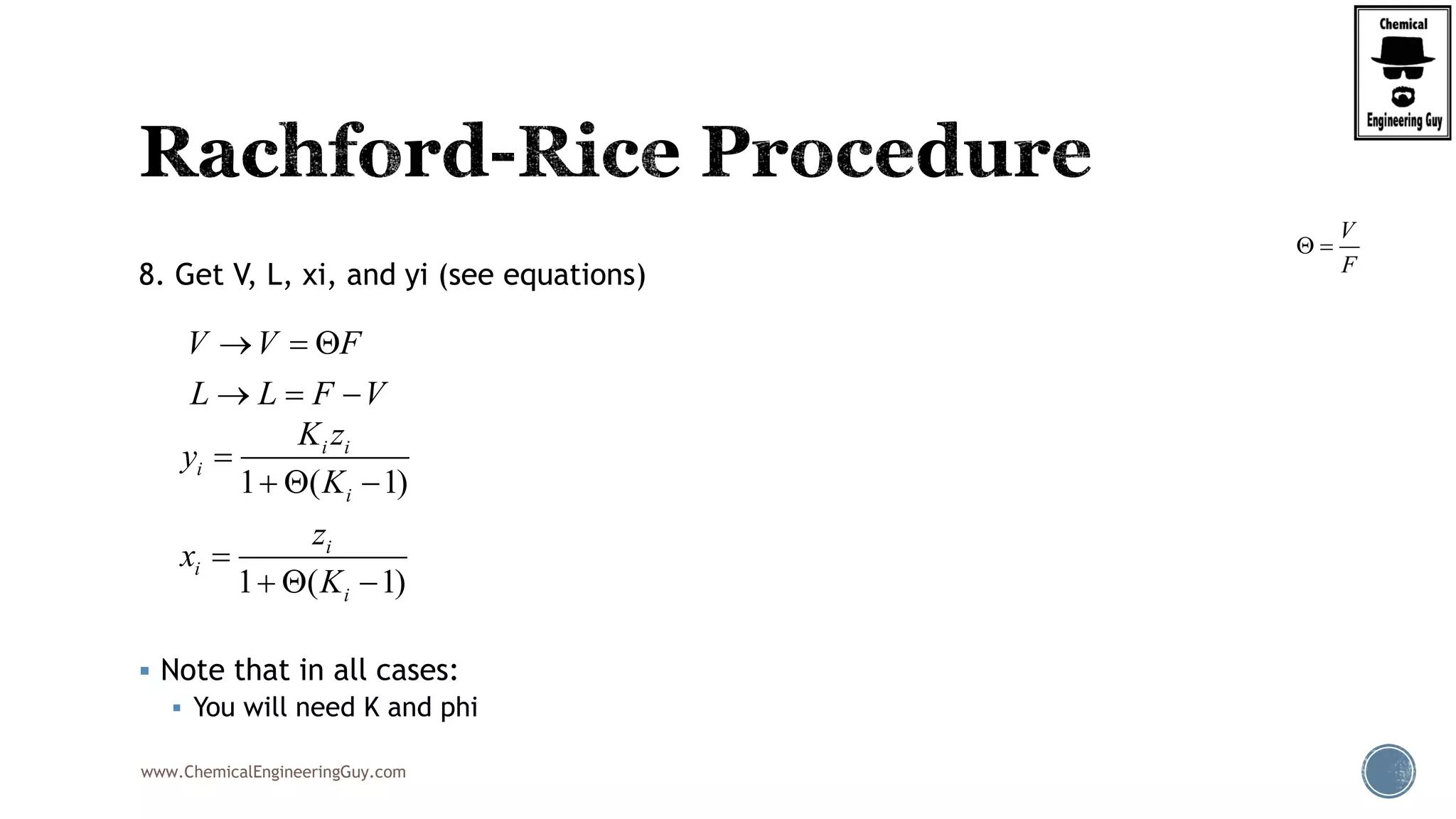

5. Get the Numerical Value of the Derivative of Rachford Rice Equation

Example:

BTX ( Benzene, Toluene, Xylene) System:

V

F

22 2

2 2 2

(1 )(1 ) (1 )

'( )

[1 ( 1)] [1 ( 1)] [1 ( 1)]

xylene xylenebenzene benzene toluene toluene

benzene toluene xylenei

z Kz K z K

f

K K K

2

2

(1 )

'( )

[1 ( 1)]

i i

i

z K

f

K

](https://image.slidesharecdn.com/flashdistillationslideshare3of3-191031011848/75/Flash-Distillation-in-Chemical-and-Process-Engineering-Part-3-of-3-51-2048.jpg)

![www.ChemicalEngineeringGuy.com

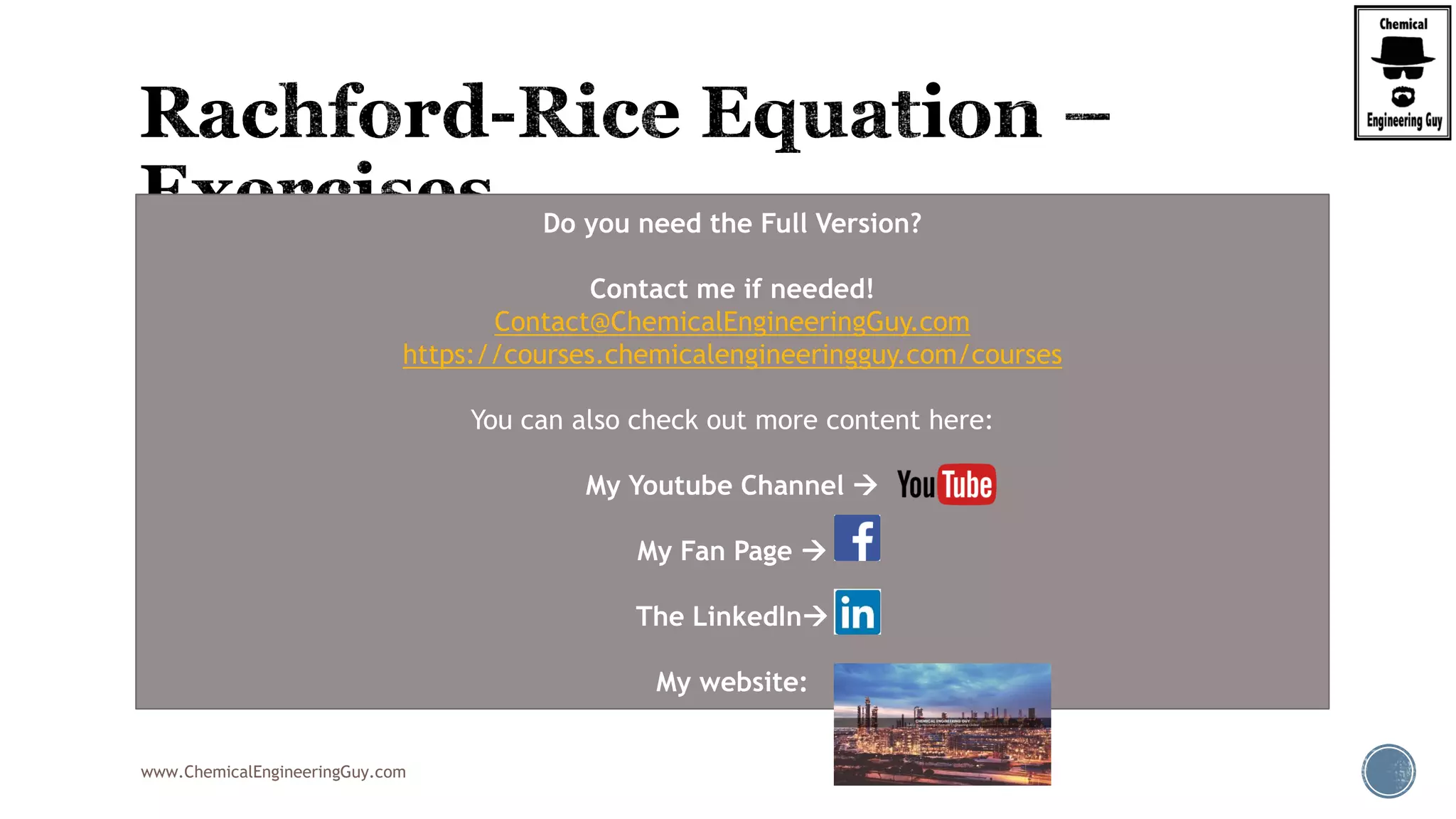

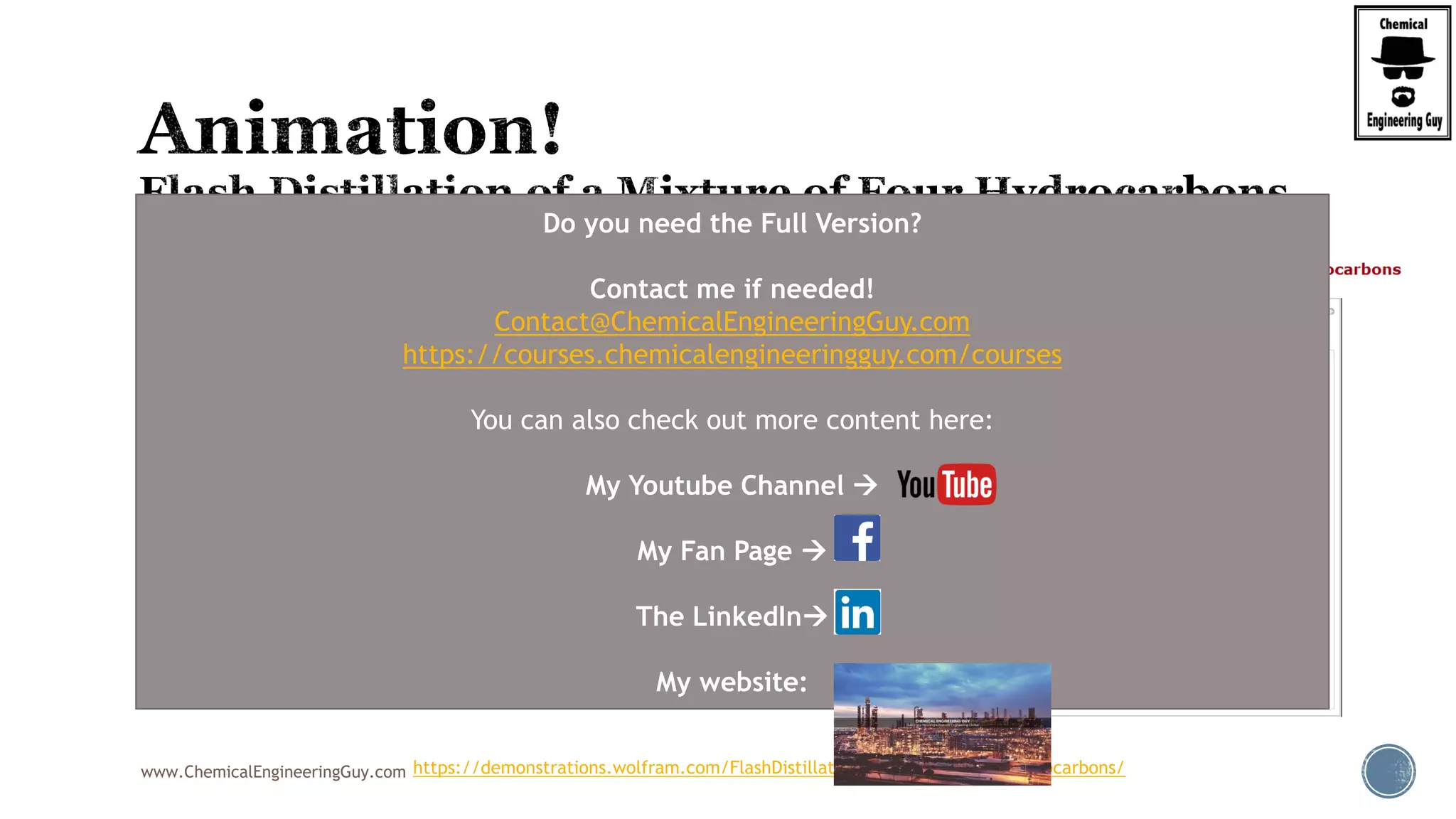

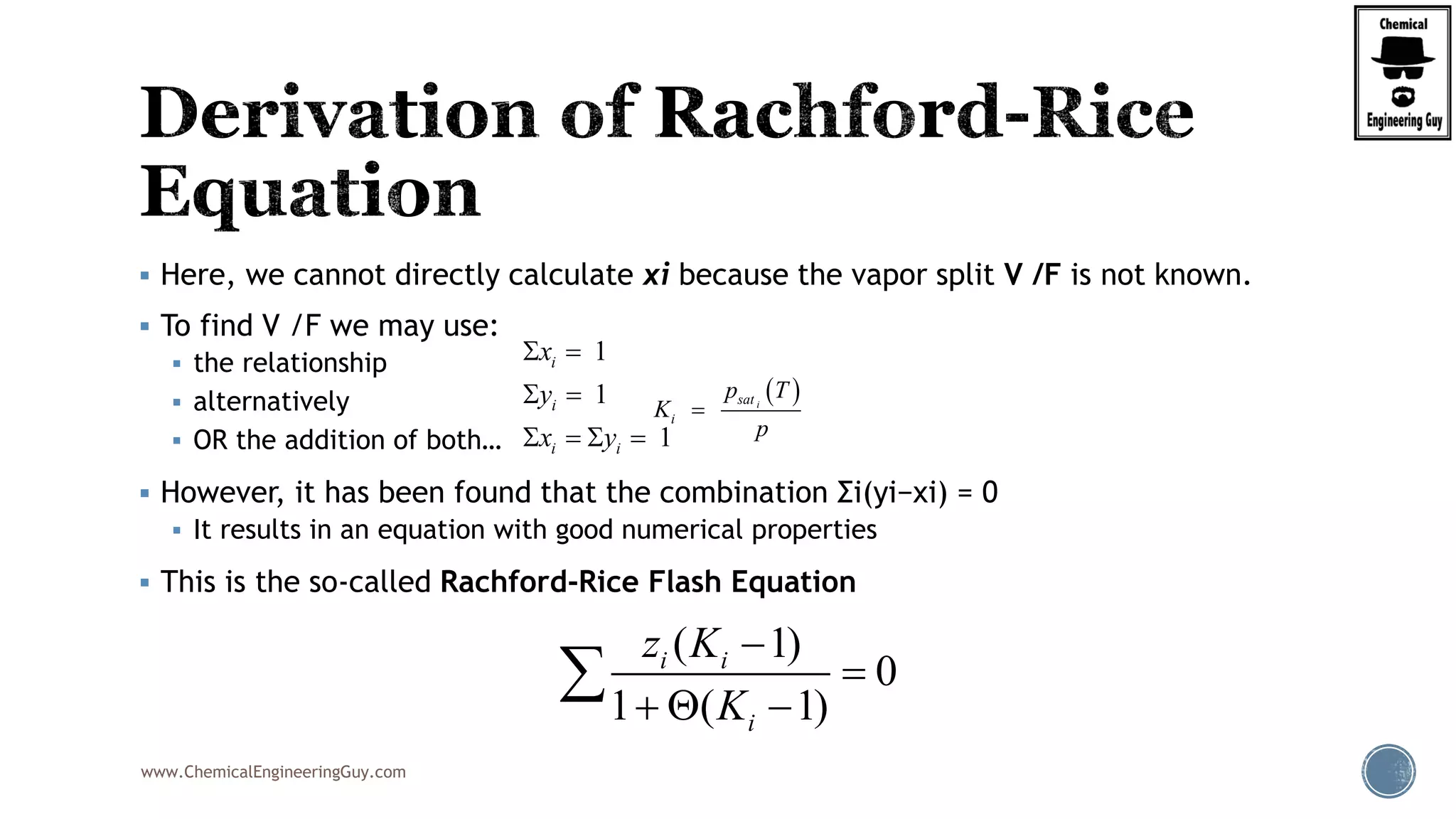

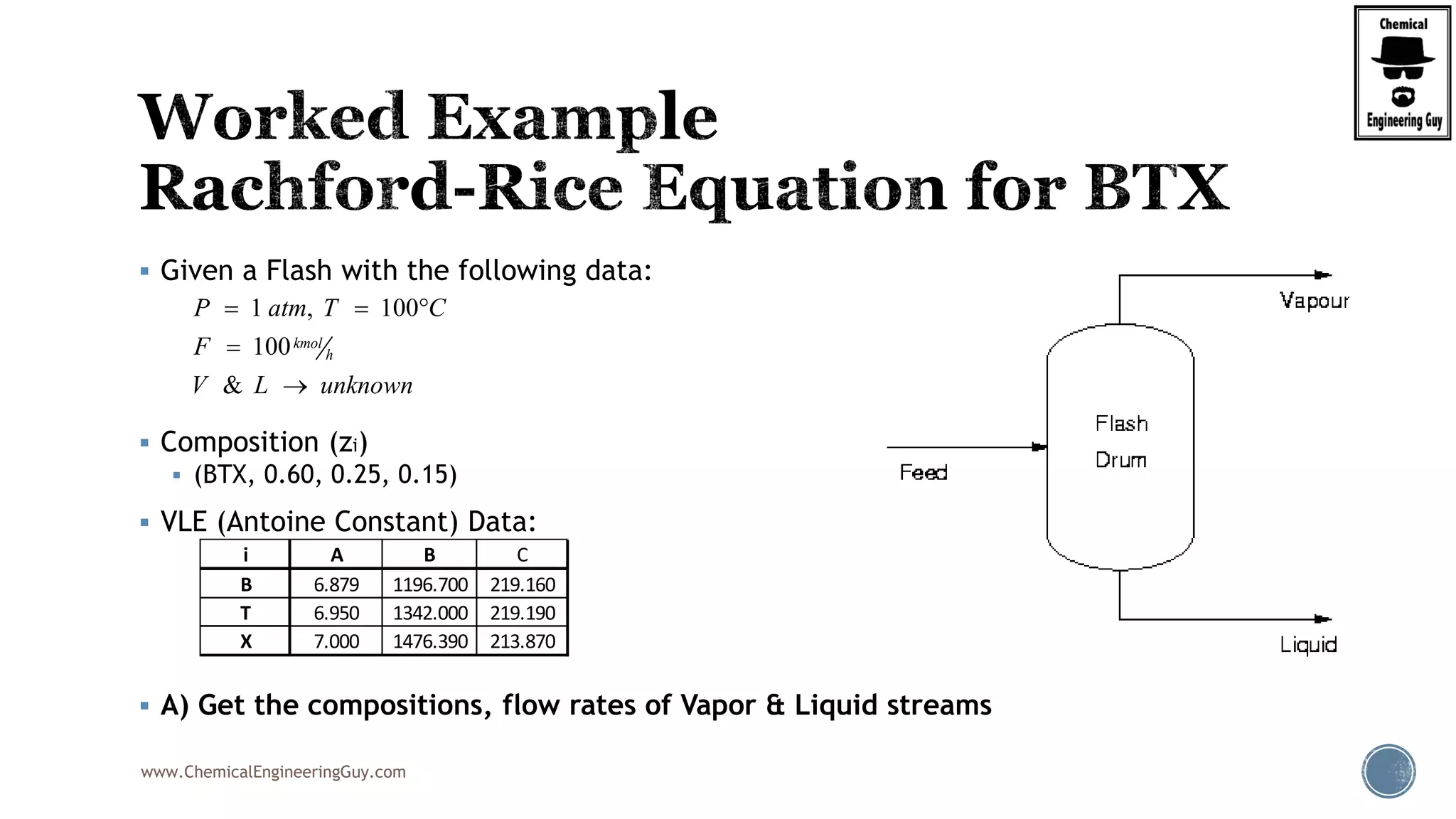

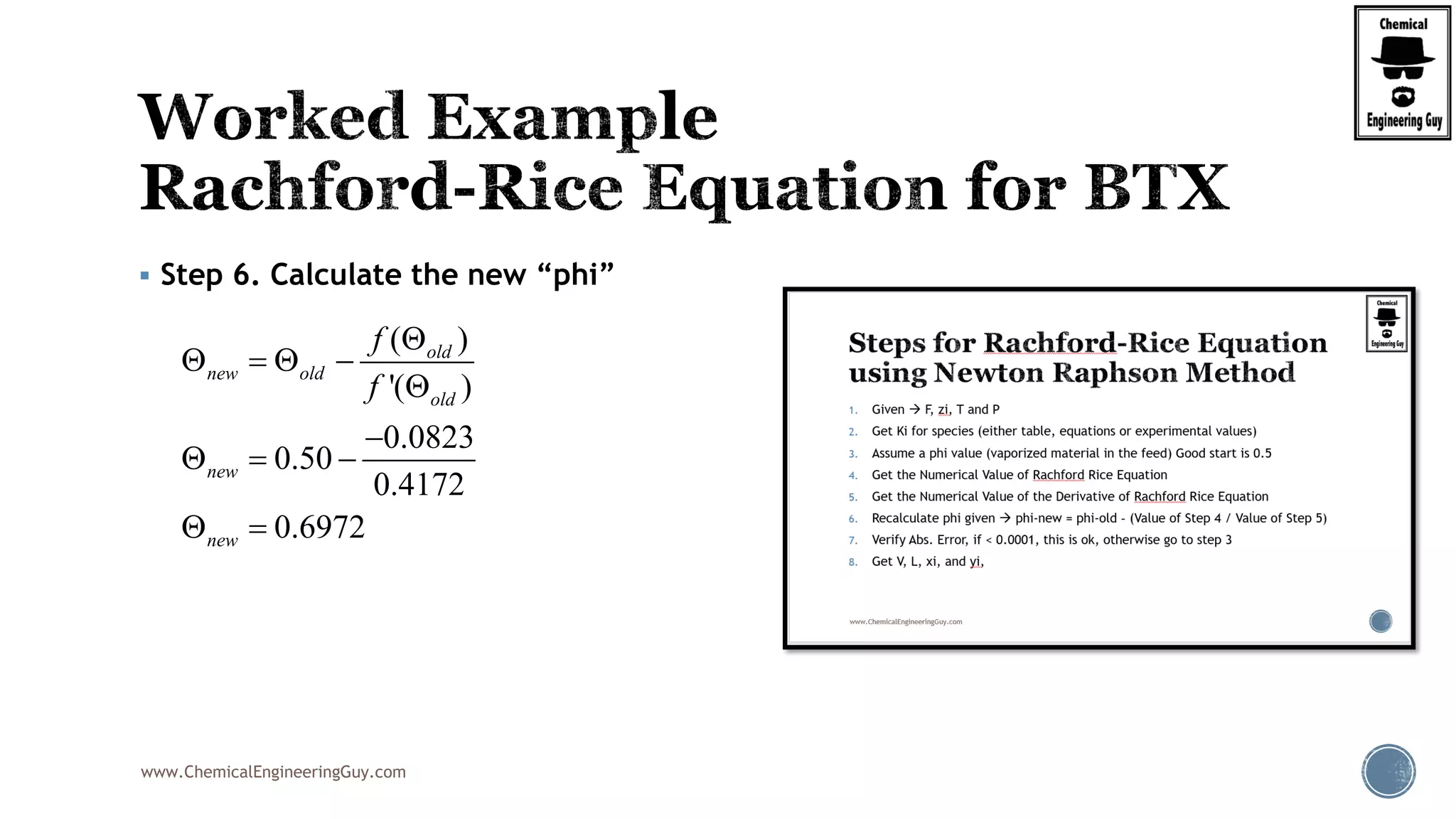

Step 5. Calculate The Value of the derivative of RRE

2

2

22 2

2 2 2

2

2

0.5

(1 )

'( )

[1 ( 1)]

(1 )(1 ) (1 )

'( )

[1 ( 1)] [1 ( 1)] [1 ( 1)]

0.60(1 1.7756) 0.25

'( )

1 0.50(1.7756 1)]

i i

i

xylene xylenebenzene benzene toluene toluene

benzene toluene xylenei

z K

f

K

z Kz K z K

f

K K K

f

2 2

2 2

(1 0.7322) 0.15(1 0.2611)

1 0.50(0.7322 1)] 1 0.50(0.2611 1)]

'( ) 0.4172f

Do you need the Full Version?

Contact me if needed!

Contact@ChemicalEngineeringGuy.com

https://courses.chemicalengineeringguy.com/courses

You can also check out more content here:

My Youtube Channel

My Fan Page

The LinkedIn

My website:](https://image.slidesharecdn.com/flashdistillationslideshare3of3-191031011848/75/Flash-Distillation-in-Chemical-and-Process-Engineering-Part-3-of-3-59-2048.jpg)

![www.ChemicalEngineeringGuy.com

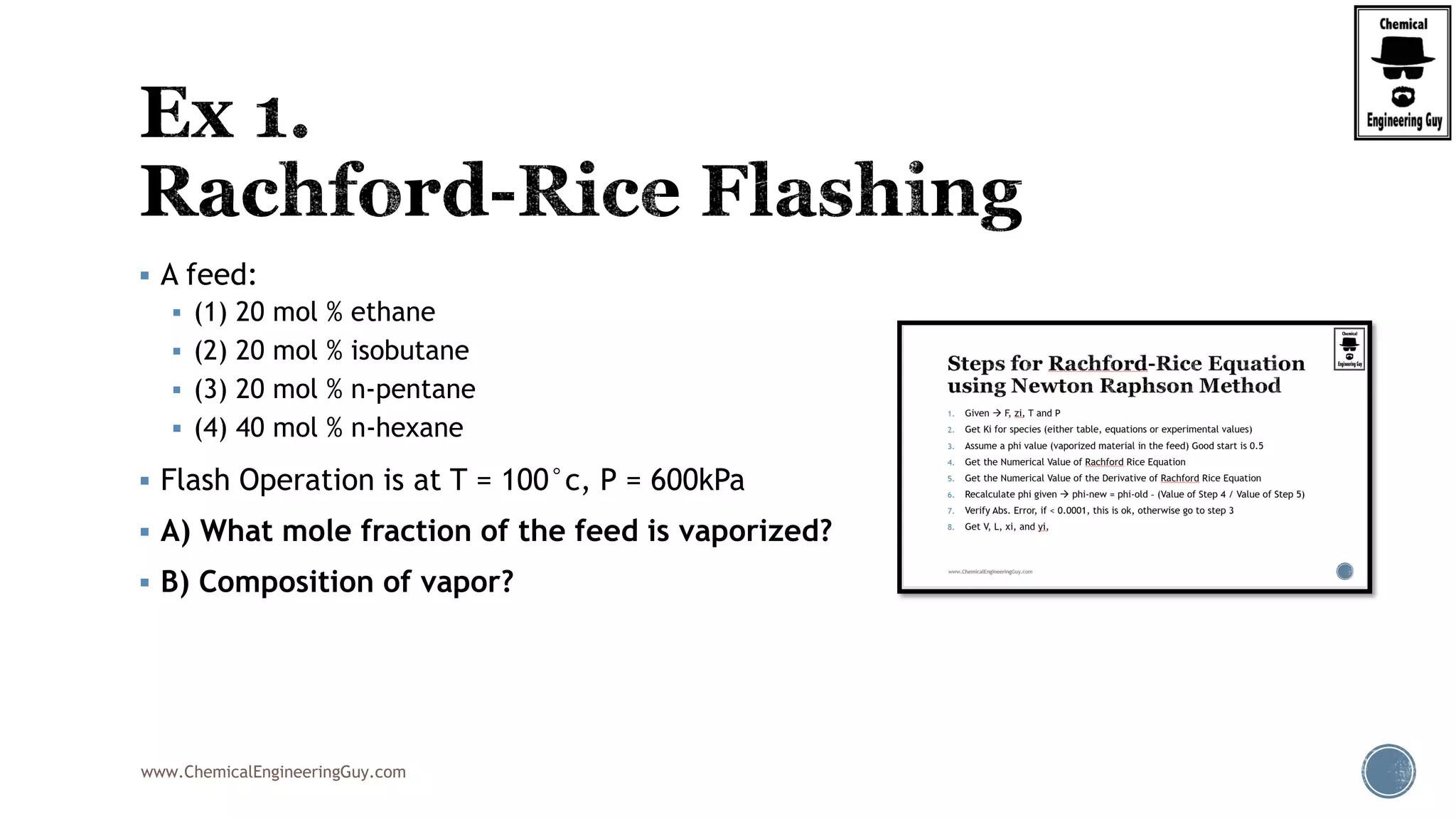

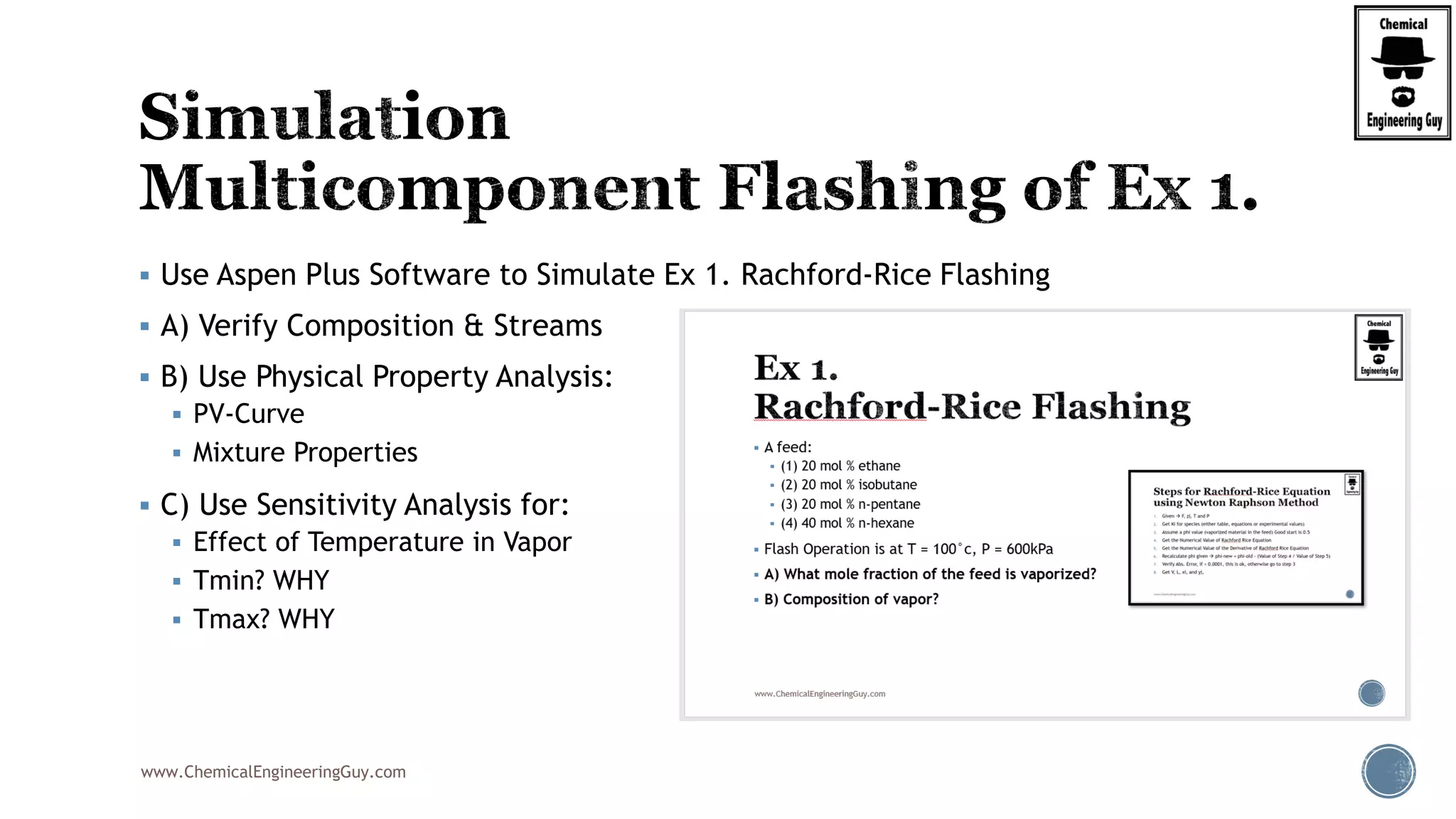

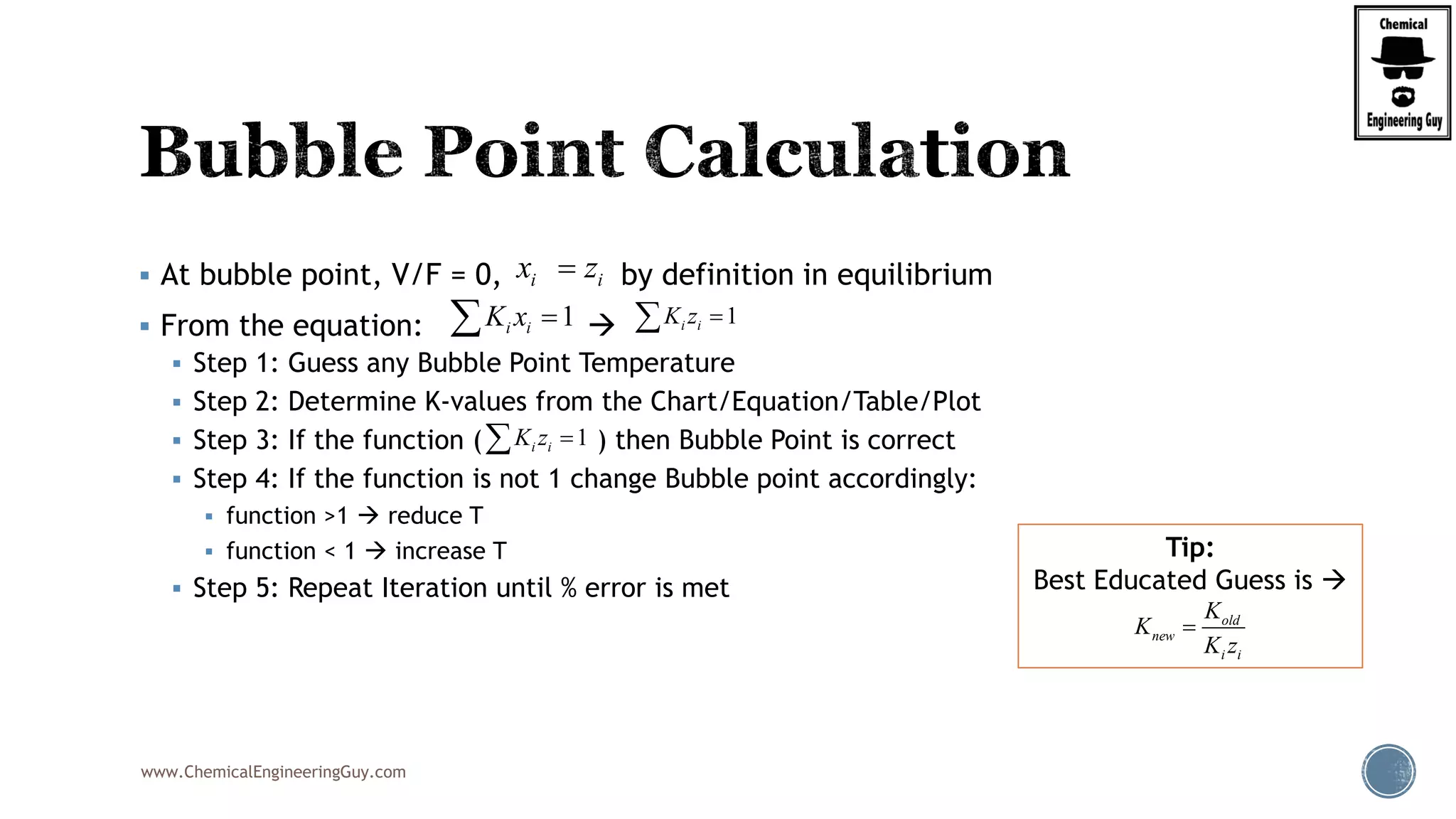

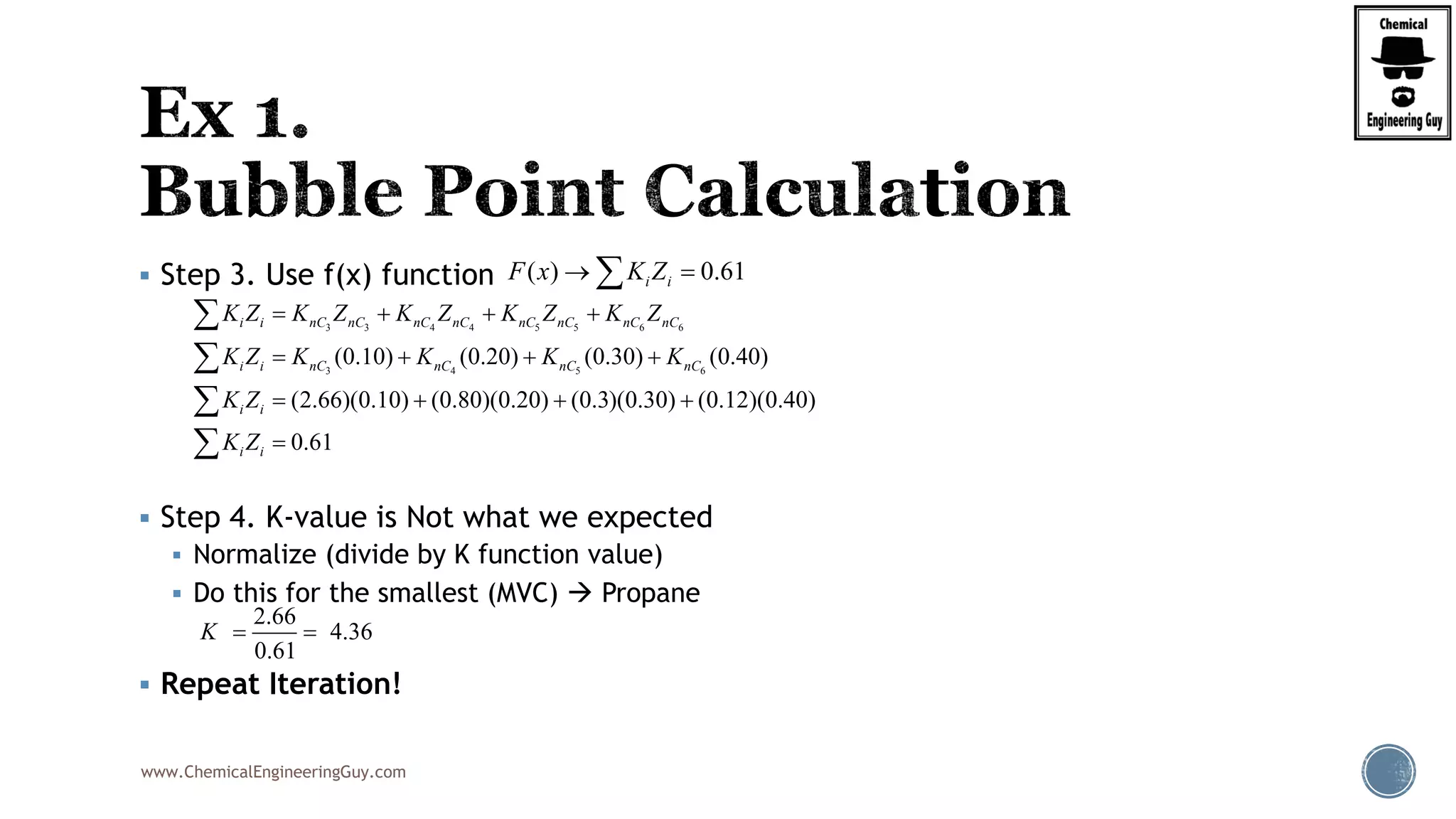

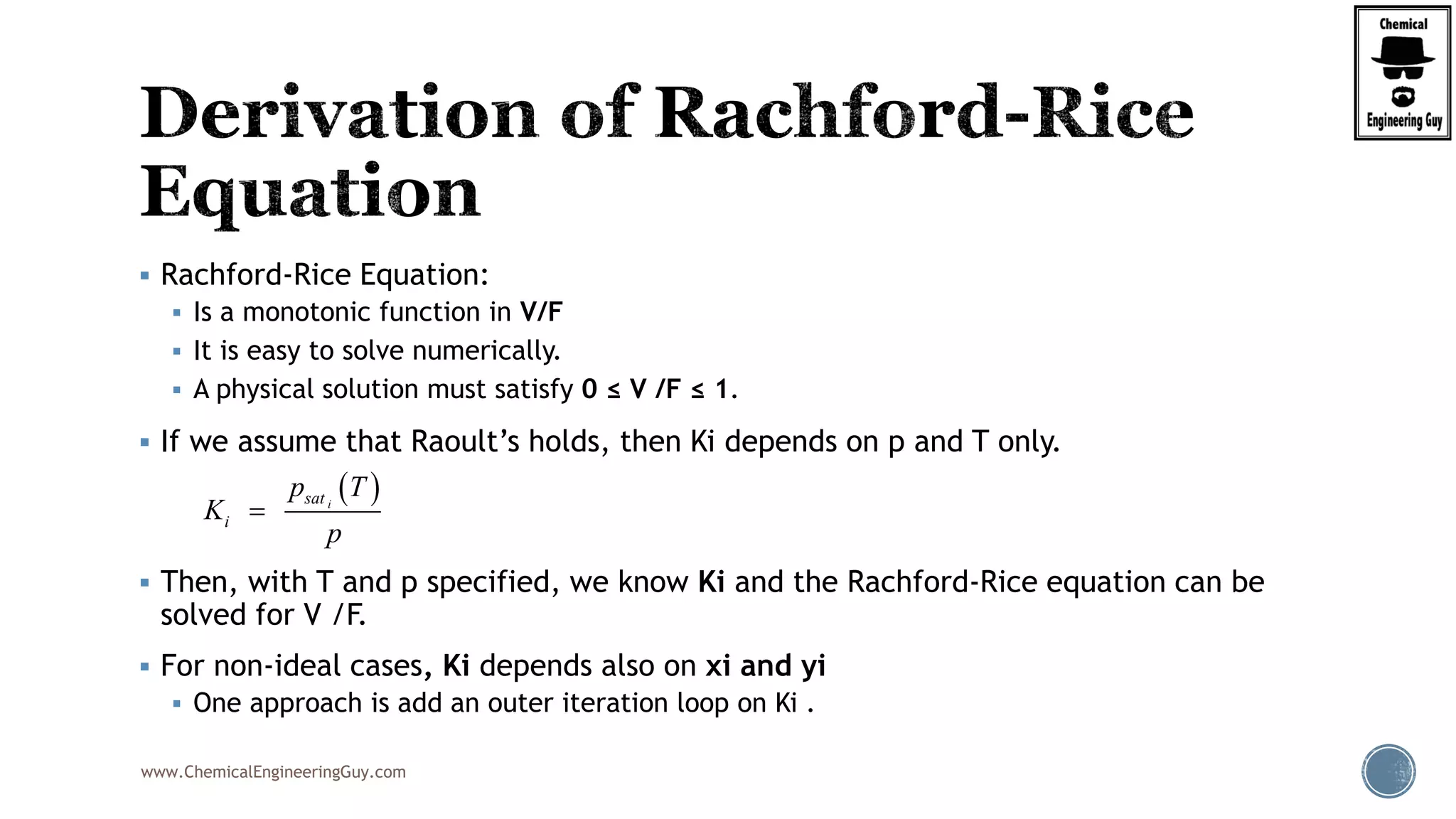

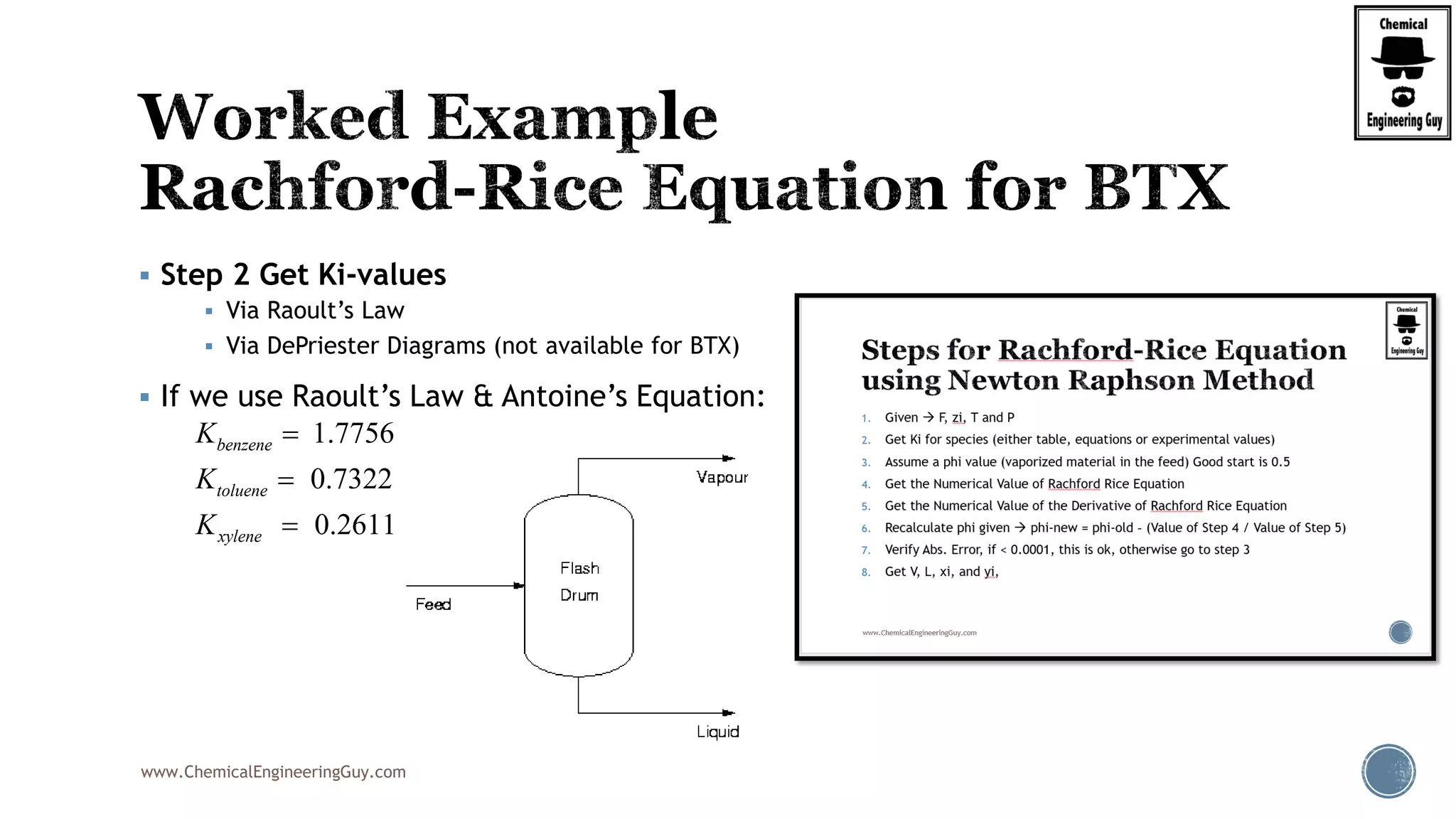

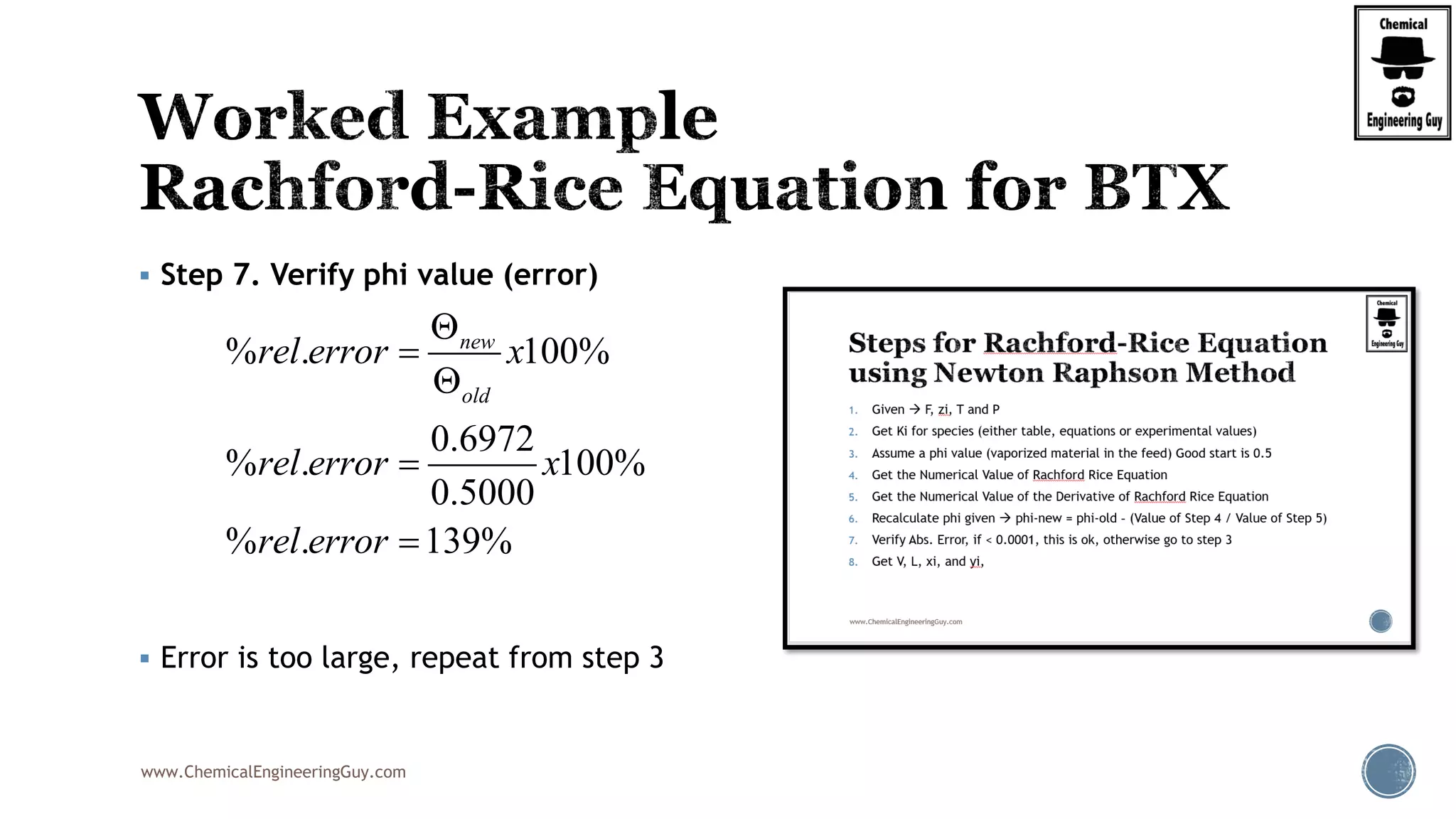

The most convenient way to do this is via a Spreadsheet… as we will need to iterate

Step 7. Verify phi value (error)

Best Case phi = 0.6806; error is acceptable

Trial phi f(1) f(2) f(3) f(phi) f'(1) f'(2) f'(3) f'(phi) New Phi %error

1 0.5 -0.33532 0.0773 0.175775 -0.08225 0.187402 0.023901 0.205979 0.417282 0.6971 39.42

2 0.6971 -0.30205 0.08232 0.228567 0.008834 0.152057 0.027105 0.348286 0.527447 0.6804 2.40

3 0.6804 -0.30462 0.08187 0.222879 0.000126 0.154654 0.026808 0.026808 0.20827 0.6797 0.09

4 0.6797 -0.30471 0.08185 0.222679 -0.00018 0.154749 0.026797 0.026797 0.208344 0.6806 0.13

5 0.6806 -0.30458 0.08187 0.222971 0.000269 0.154611 0.026813 0.026813 0.208236 0.6793 0.19

6 0.6793 -0.30478 0.08184 0.222544 -0.00039 0.154813 0.02679 0.02679 0.208394 0.6812 0.28

7 0.6812 -0.30448 0.08189 0.223167 0.000572 0.154518 0.026823 0.026823 0.208164 0.6785 0.40

2

2

22 2

2 2 2

2

2

0.5

(1 )

'( )

[1 ( 1)]

(1 )(1 ) (1 )

'( )

[1 ( 1)] [1 ( 1)] [1 ( 1)]

0.60(1 1.7756) 0.25

'( )

1 0.50(1.7756 1)]

i i

i

xylene xylenebenzene benzene toluene toluene

benzene toluene xylenei

z K

f

K

z Kz K z K

f

K K K

f

2 2

2 2

(1 0.7322) 0.15(1 0.2611)

1 0.50(0.7322 1)] 1 0.50(0.2611 1)]

'( ) 0.4172f

f’(1) f’(2) f’(3)

0.5

(1 )

( )

1 ( 1)

(1 )(1 ) (1 )

( )

1 ( 1) 1 ( 1) 1 ( 1)

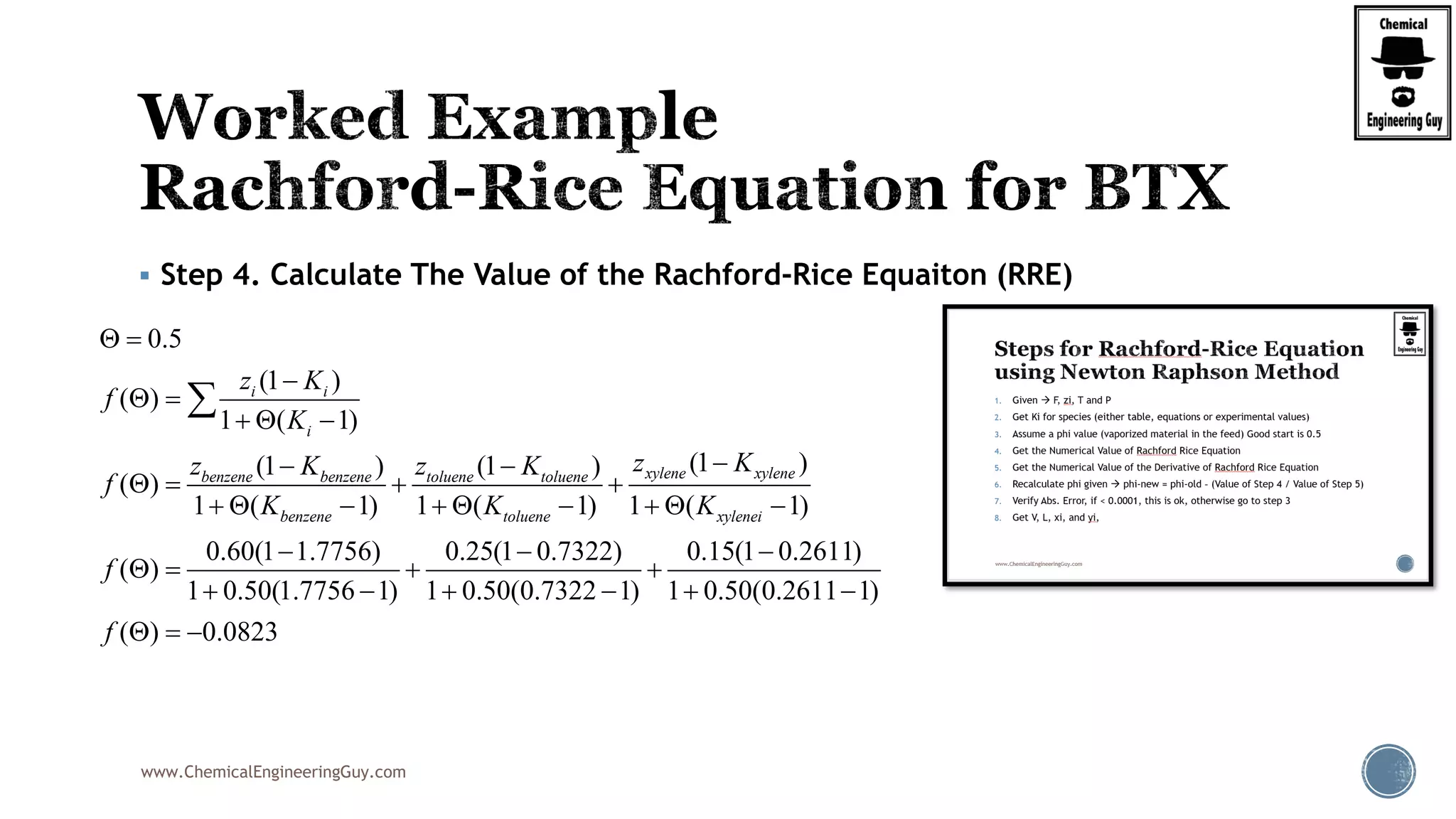

0.60(1 1.7756) 0.25(1 0.7322)

( )

1 0.50(1.7756 1) 1 0.50(0.732

i i

i

xylene xylenebenzene benzene toluene toluene

benzene toluene xylenei

z K

f

K

z Kz K z K

f

K K K

f

0.15(1 0.2611)

2 1) 1 0.50(0.2611 1)

( ) 0.0823f

f(1) f(2) f(3)

Do you need the Full Version?

Contact me if needed!

Contact@ChemicalEngineeringGuy.com

https://courses.chemicalengineeringguy.com/courses

You can also check out more content here:

My Youtube Channel

My Fan Page

The LinkedIn

My website:](https://image.slidesharecdn.com/flashdistillationslideshare3of3-191031011848/75/Flash-Distillation-in-Chemical-and-Process-Engineering-Part-3-of-3-62-2048.jpg)