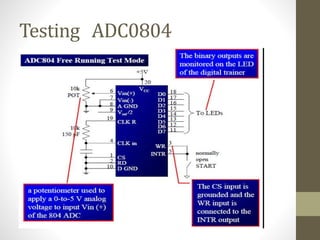

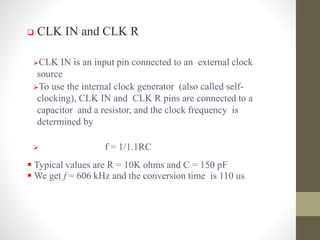

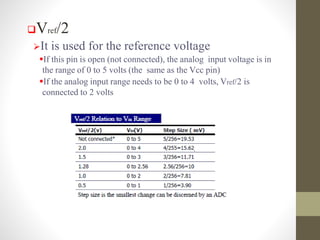

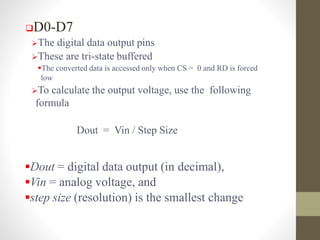

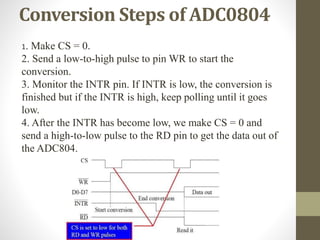

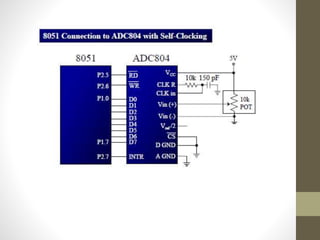

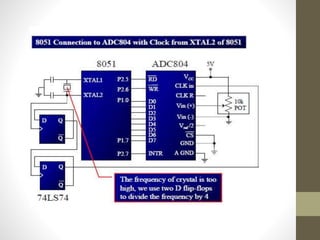

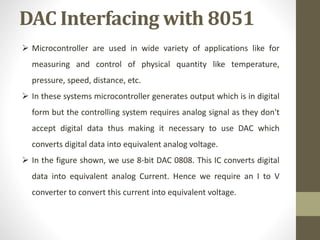

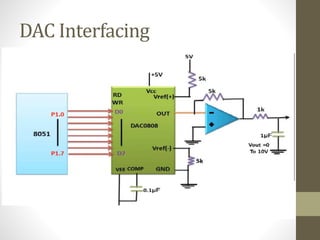

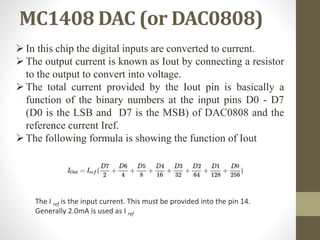

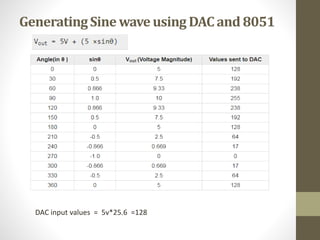

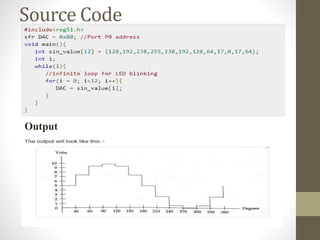

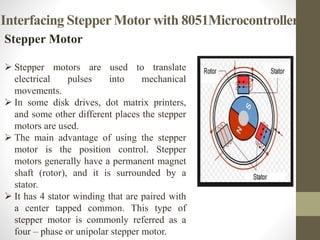

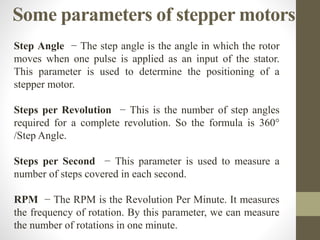

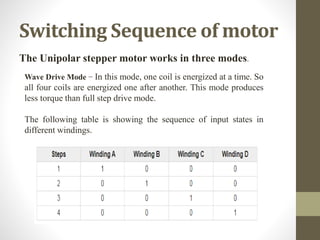

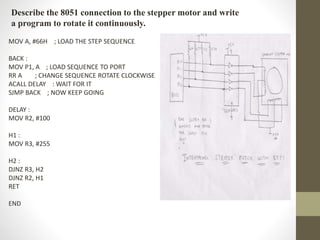

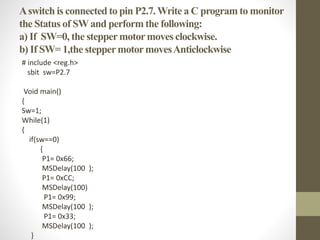

This document discusses interfacing an analog-to-digital converter (ADC) and digital-to-analog converter (DAC) with an 8051 microcontroller. It describes the ADC0804 and DAC0808 integrated circuits. The ADC0804 is an 8-bit ADC that converts analog voltages to 8-bit digital values. It has a resolution of 8-bits and a maximum conversion time of 110us. The DAC0808 is an 8-bit DAC that converts digital values to an analog current. Software is provided to generate a sine wave using the DAC and control a stepper motor by interfacing it with the microcontroller ports. Programs in C are given to read the switch status and rotate