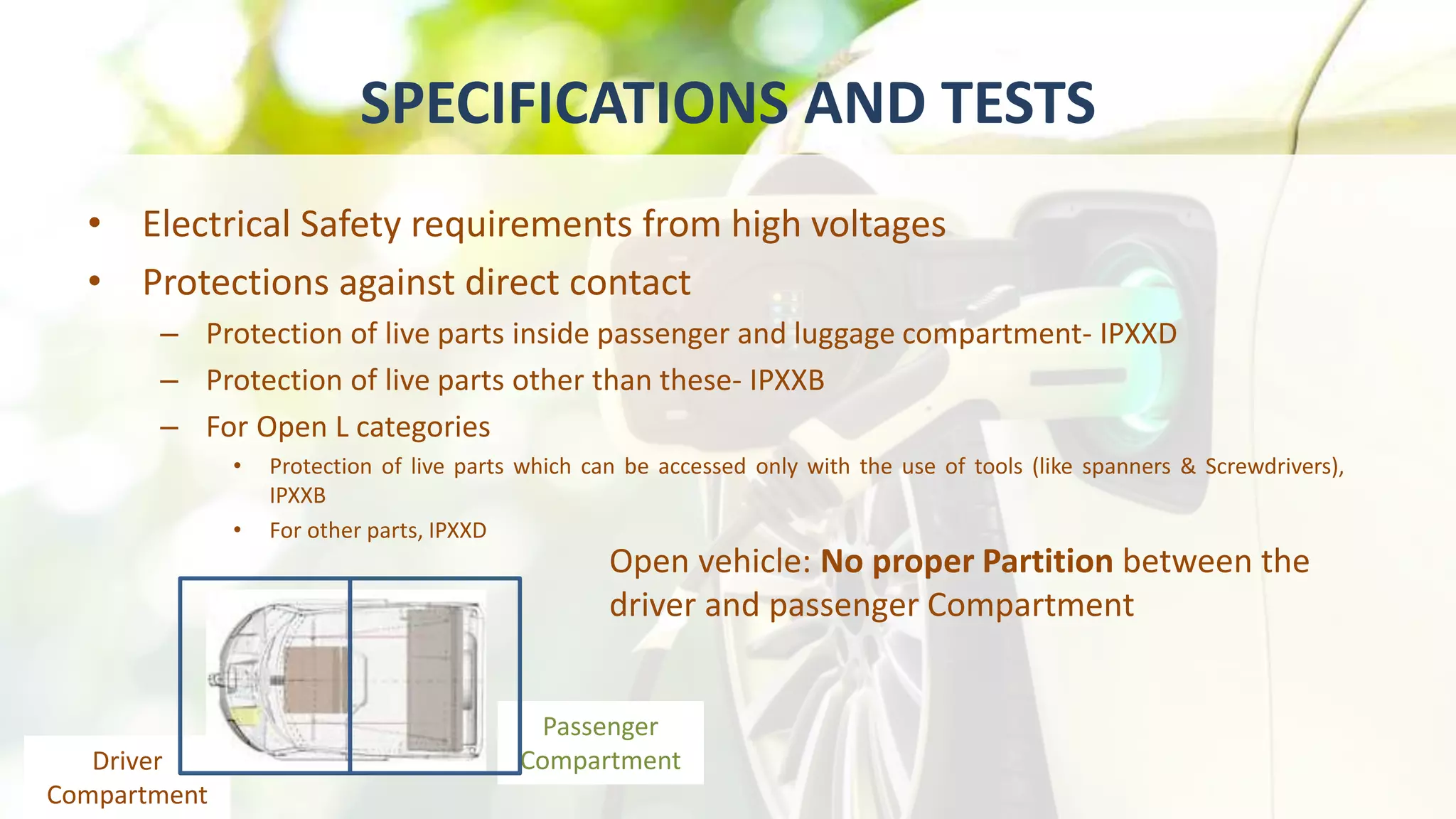

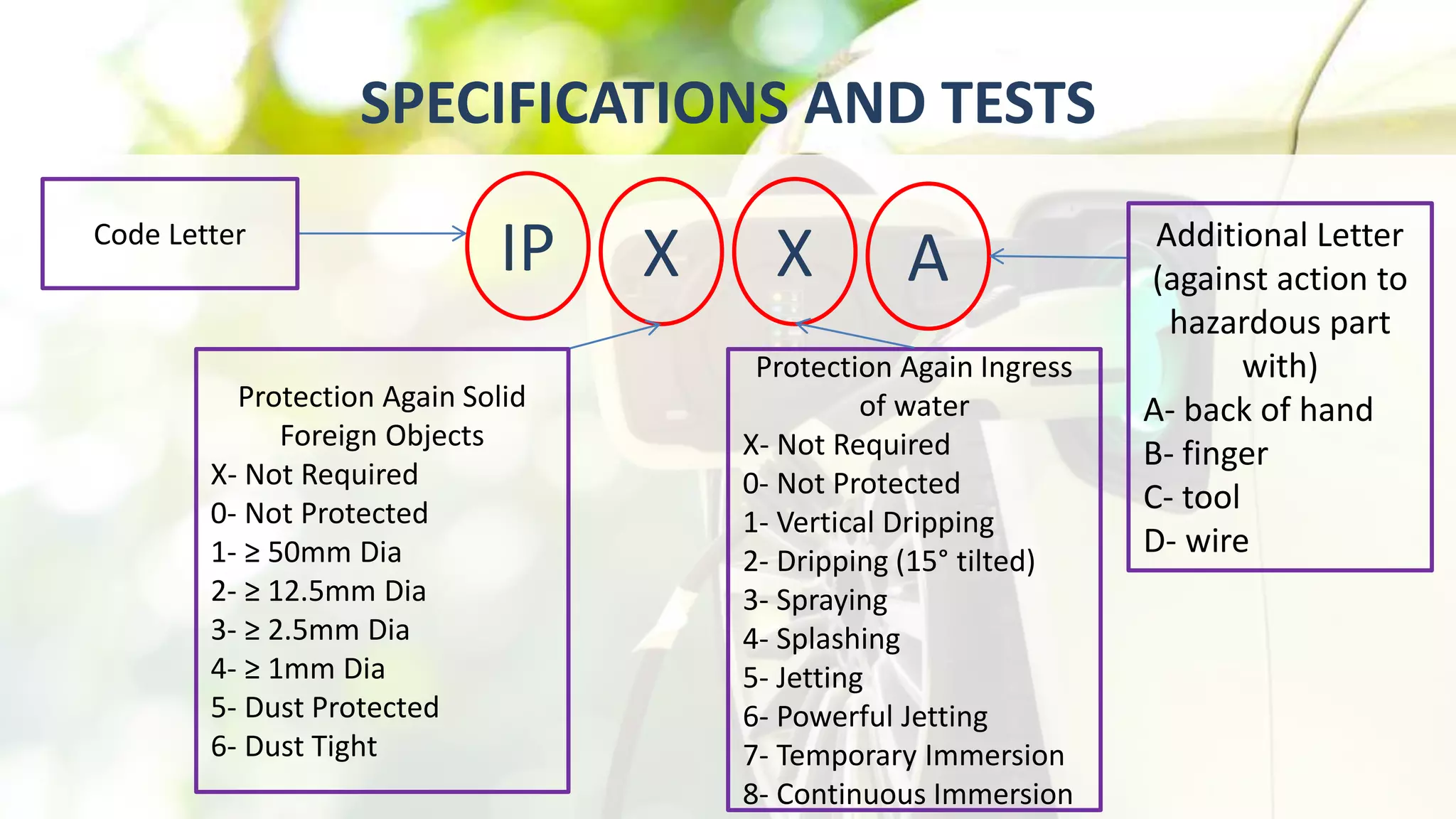

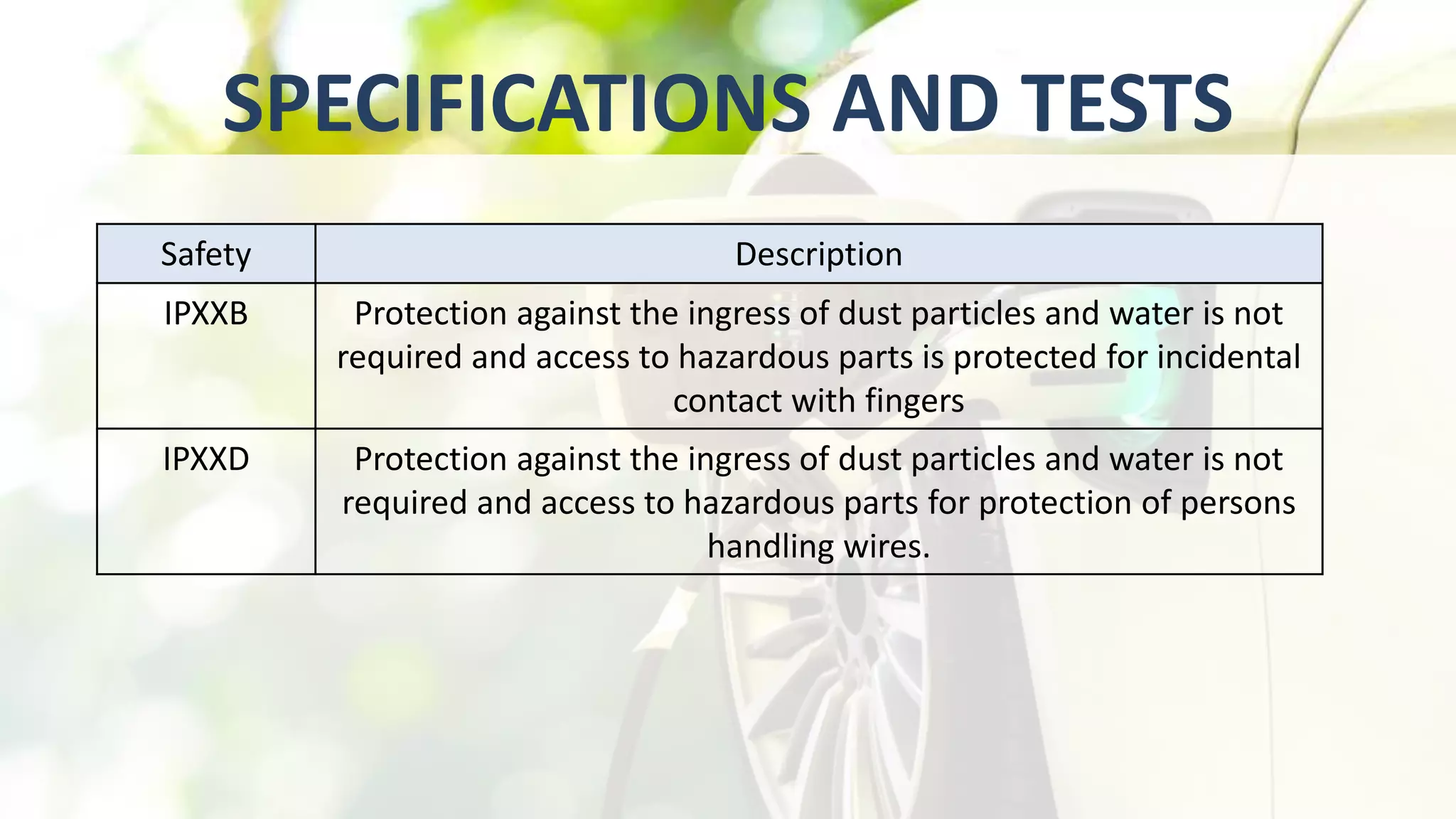

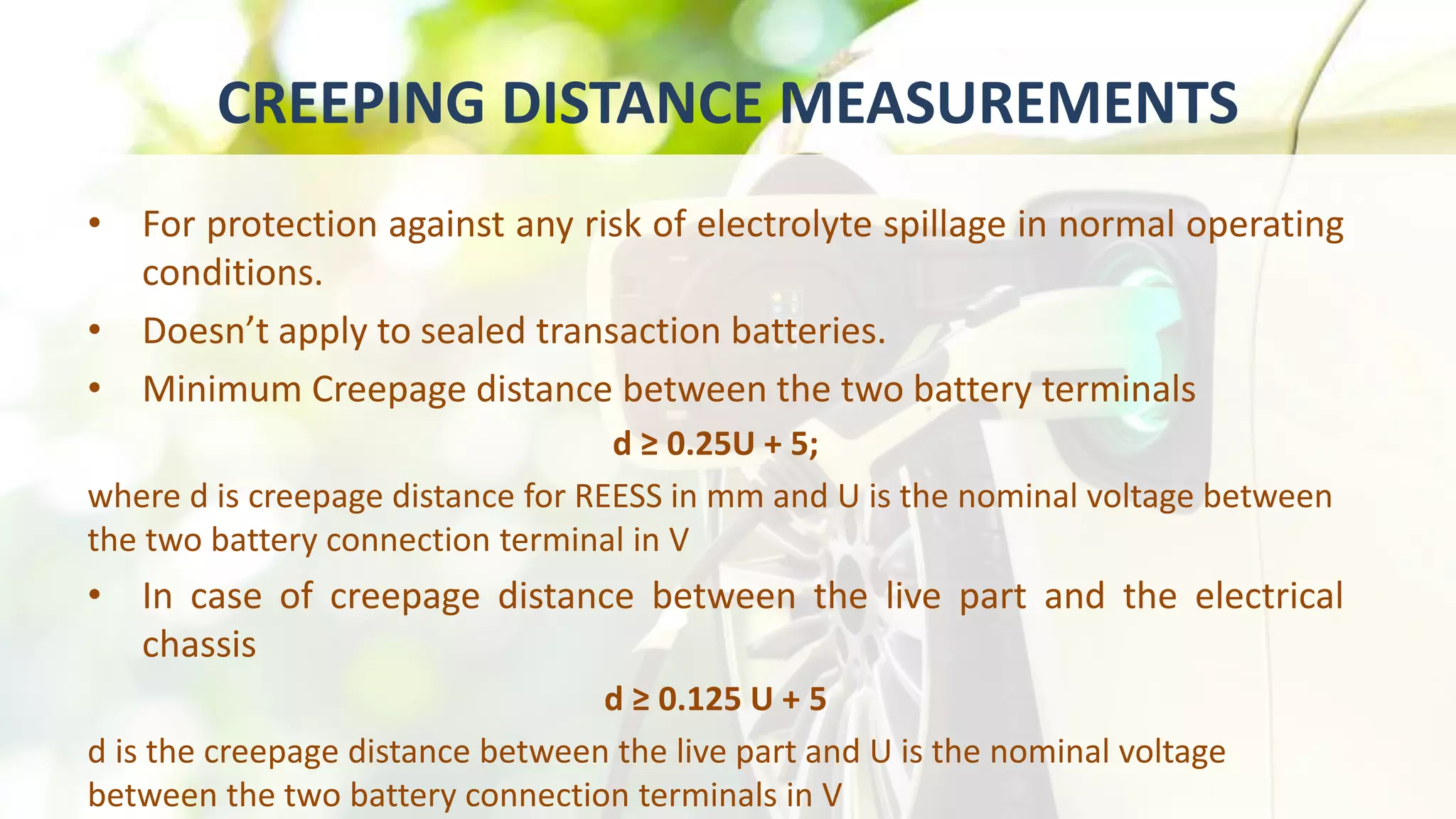

This document specifies construction and functional safety requirements for electric power train vehicles in India. It outlines electrical safety requirements to protect against direct and indirect contact with live parts. Vehicles must meet IPXX protection ratings to prevent ingress of dust and water into passenger compartments. The document also specifies isolation resistance values, protections for rechargeable energy storage systems against overheating, and minimum creepage distances between battery terminals and chassis. Vehicles must pass heavy rainstorm and washing tests to demonstrate protection against water effects.