1) The document proposes an integration framework to tackle information system integration problems in manufacturing environments.

2) It uses a "decomposing-and-mapping" method from axiomatic design theory to design an integrated manufacturing information system.

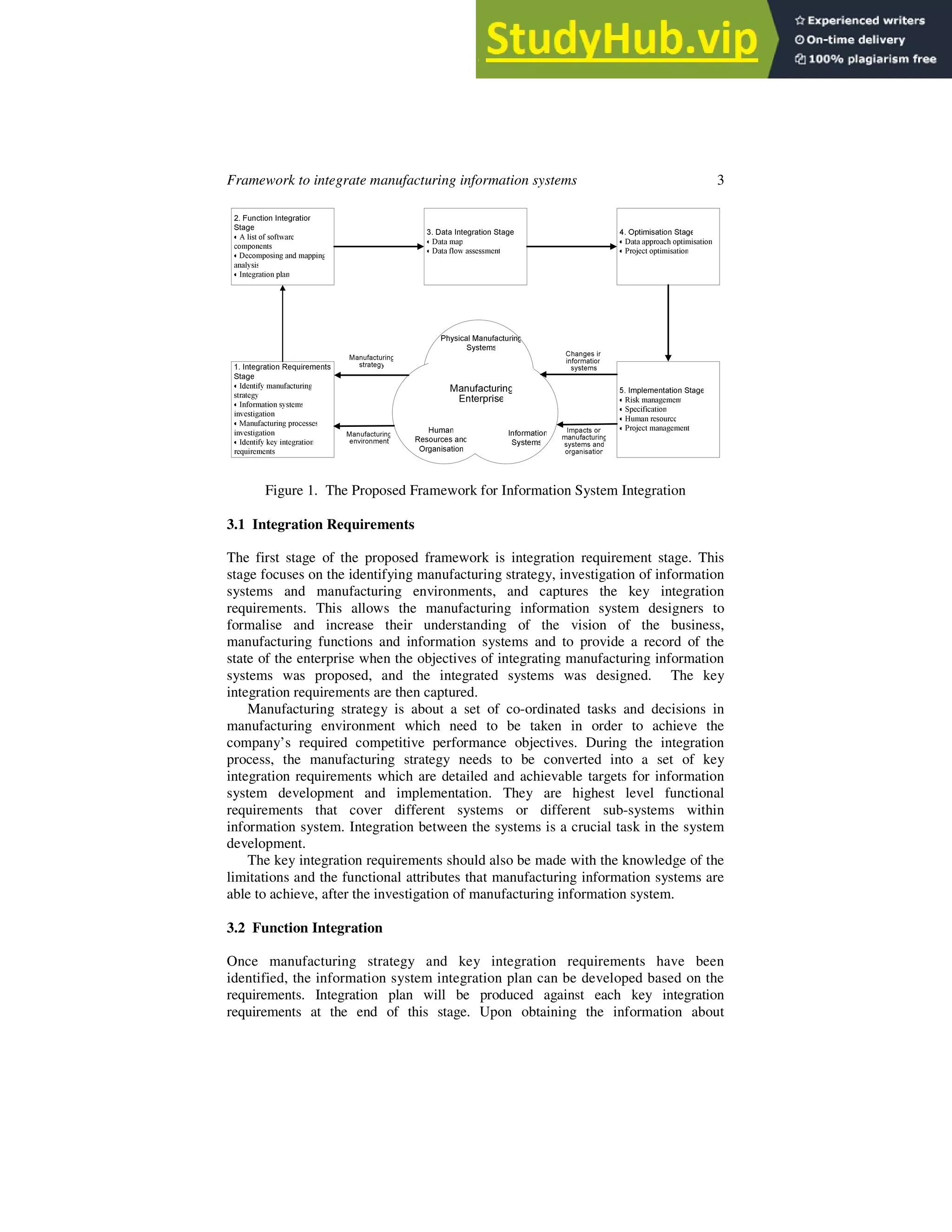

3) The framework consists of 5 stages with 15 steps to provide a structured methodology for analyzing integration requirements and implementing an integrated system.