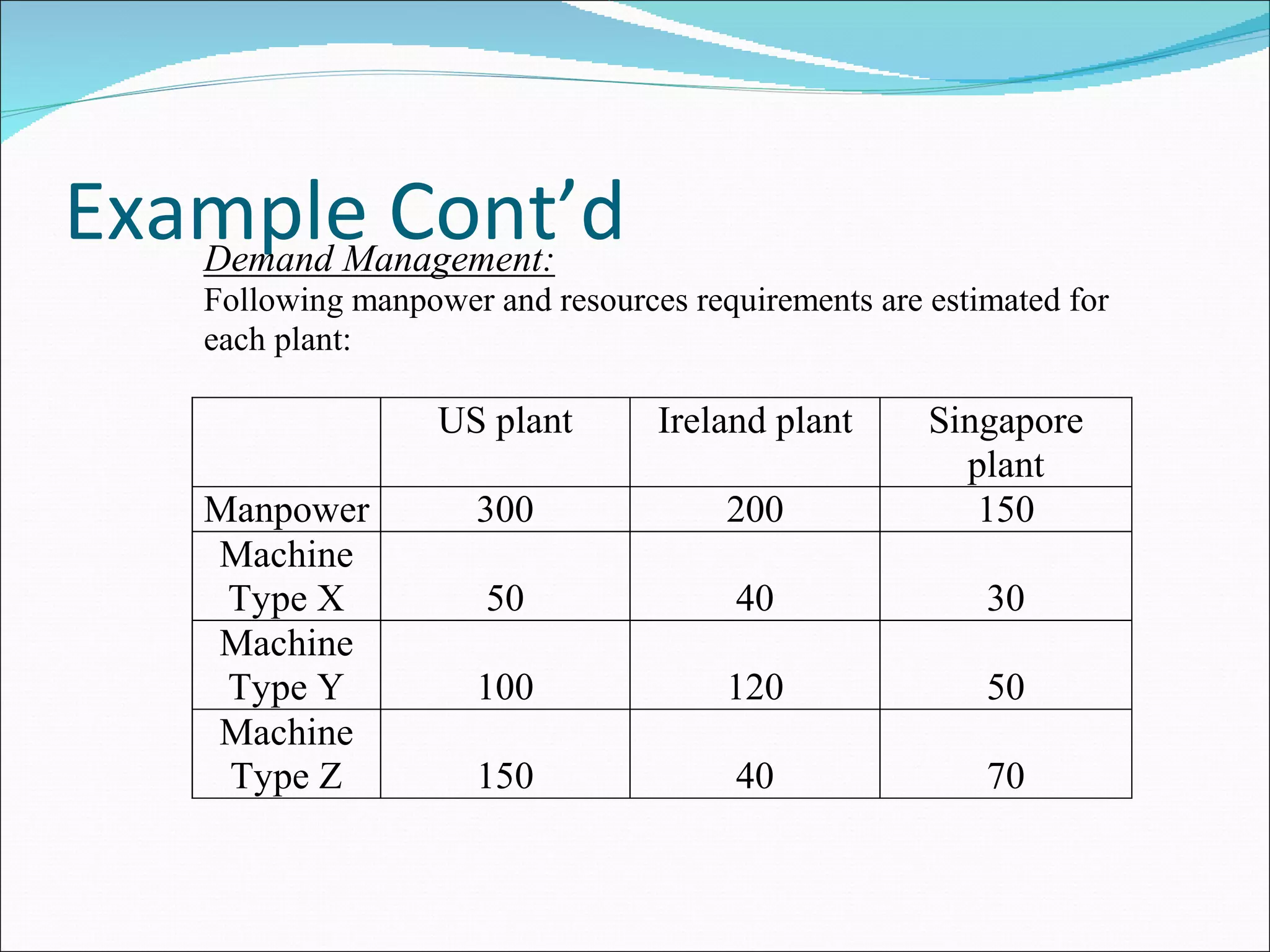

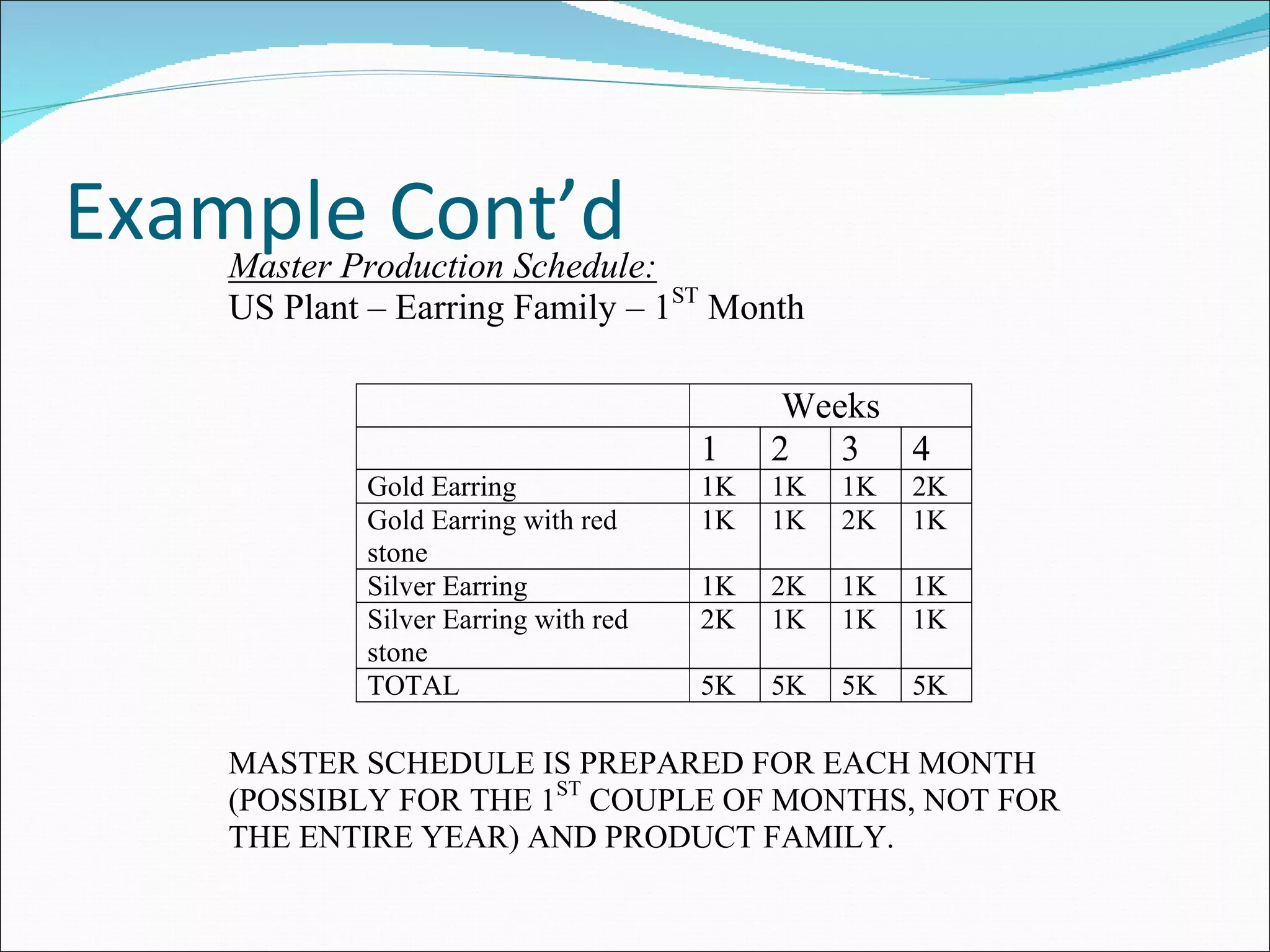

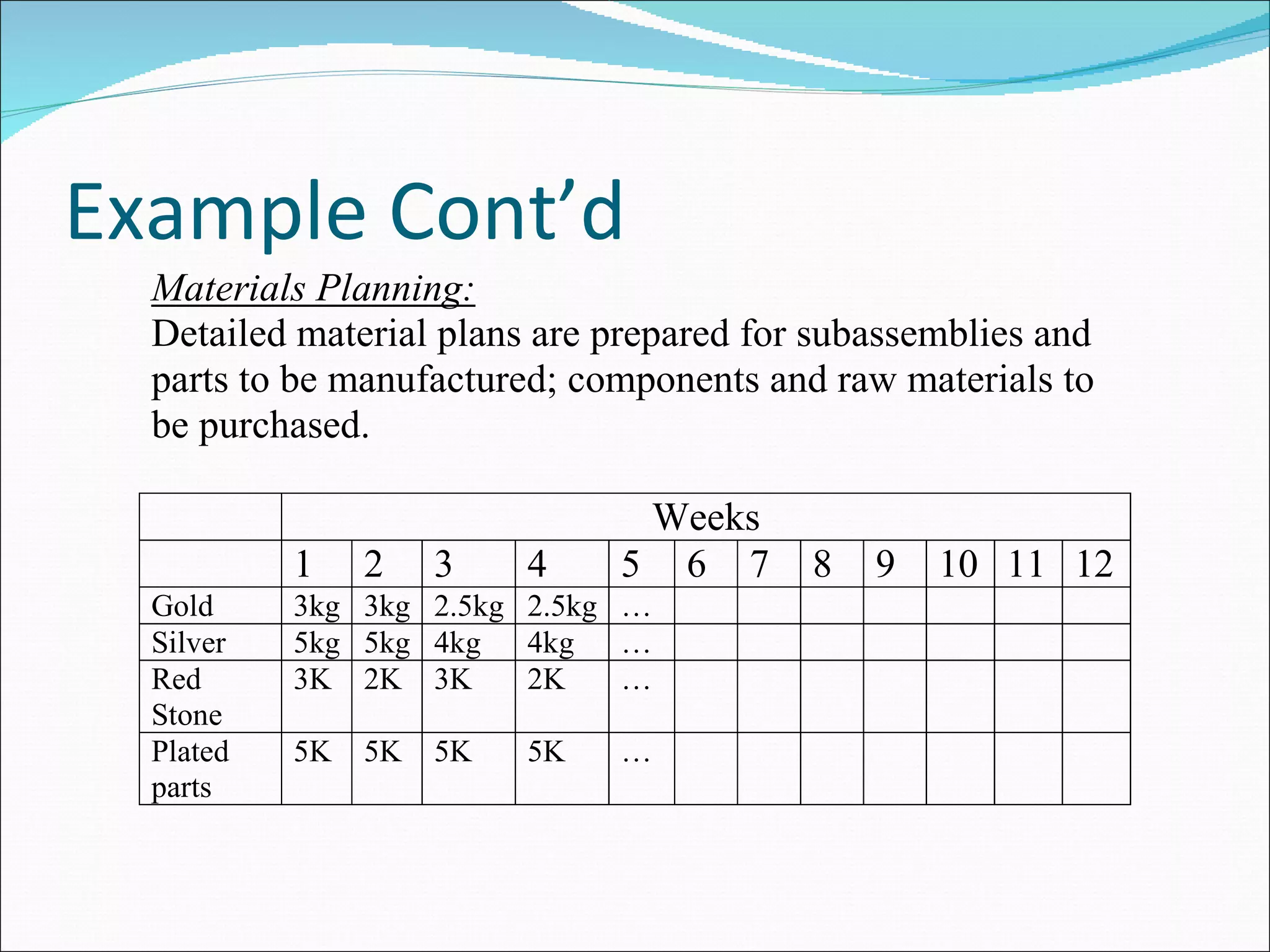

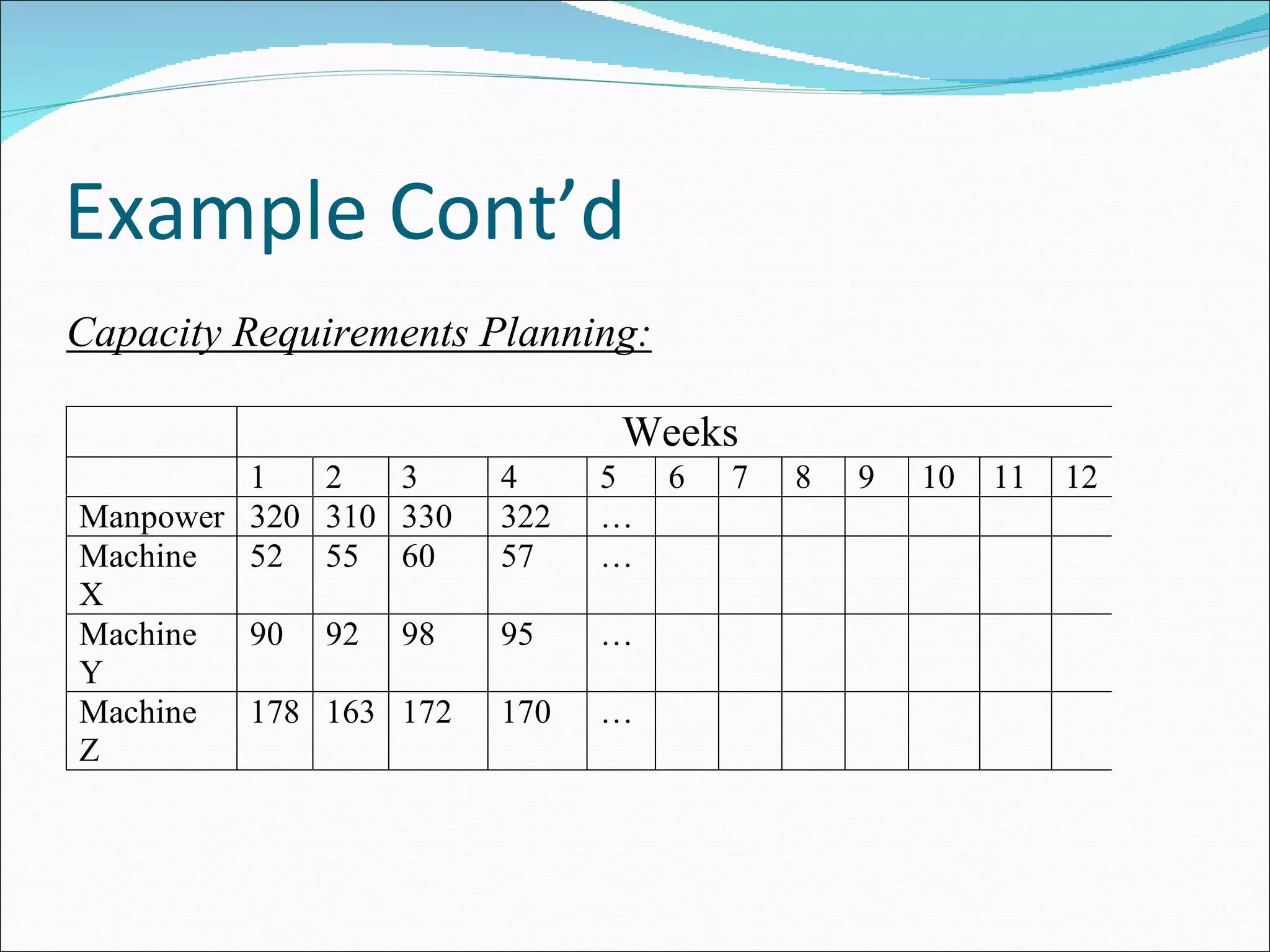

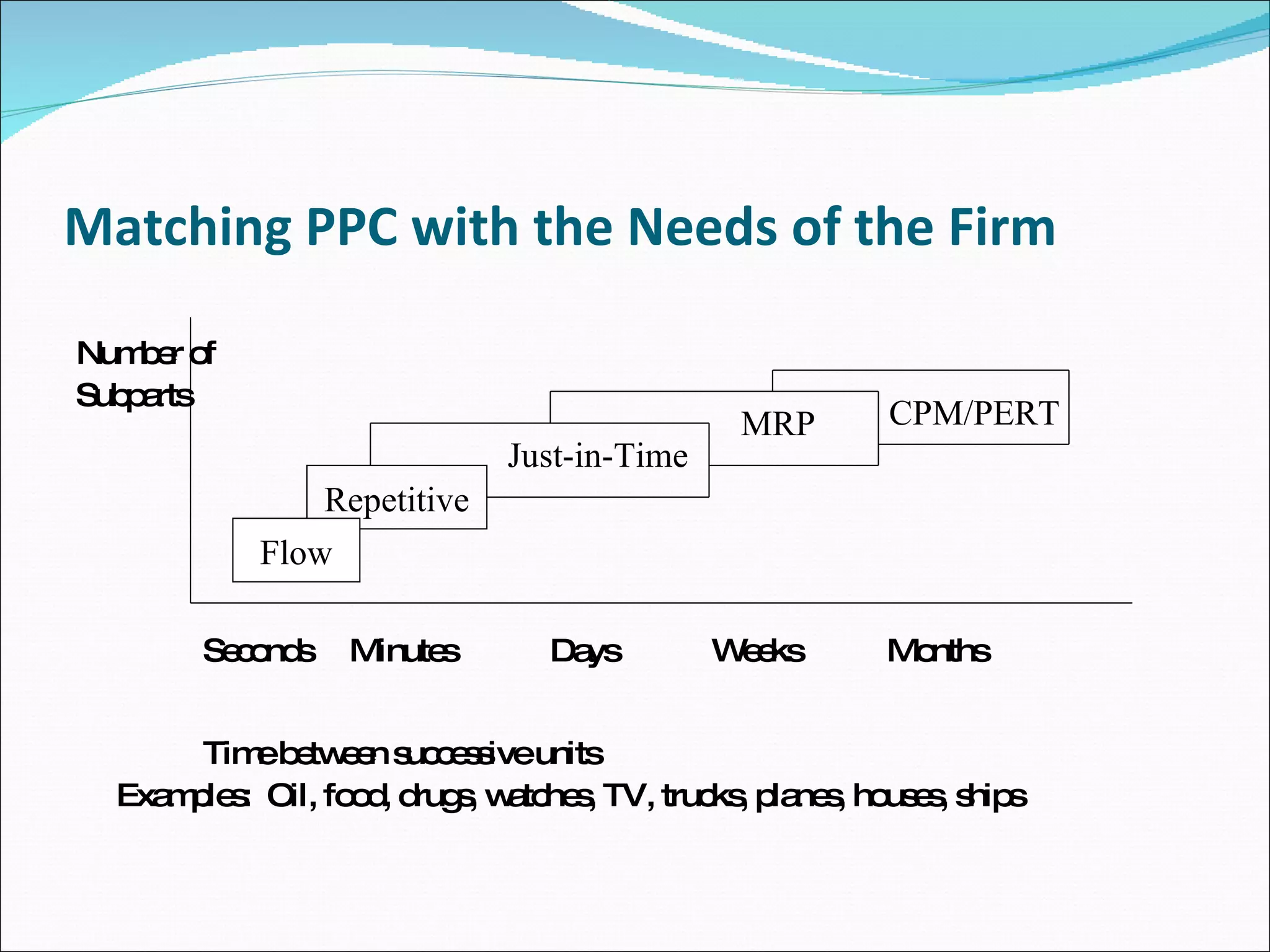

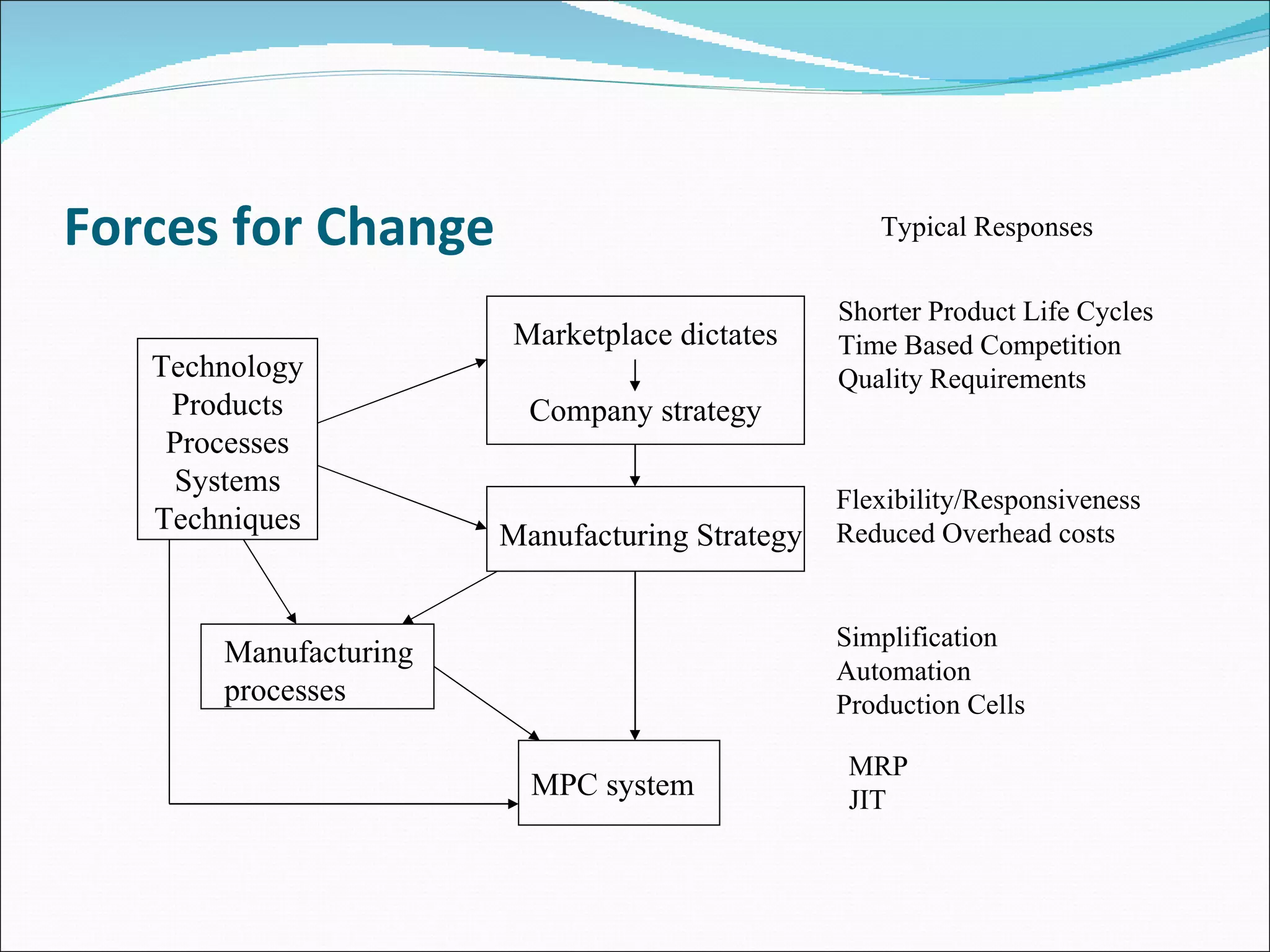

The document discusses production planning and control (PPC) systems. It describes that PPC systems provide decision support to managers rather than making decisions themselves. It outlines several techniques that PPC systems use for activities like materials planning, scheduling, and inventory control. Finally, it discusses how different types of PPC systems like MRP and JIT are suited for different manufacturing environments based on factors like production volume and product variety.