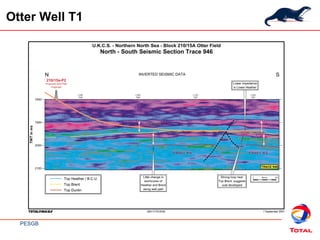

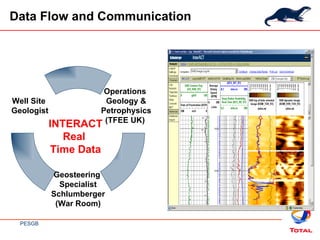

This document summarizes the geosteering objectives, issues, and results for Well T1 drilled in the Otter Field. The key objectives were to maintain standoff from the oil water contact, target the best quality "T10 sands", avoid poor quality sandstones and coals. Real-time resistivity imaging allowed adjustments to the well trajectory and confirmation of targets like coals. The well landed within tolerance and identified key geological features like faults. Real-time data helped optimize the well path for maximum reservoir contact.