Presentation.ppt

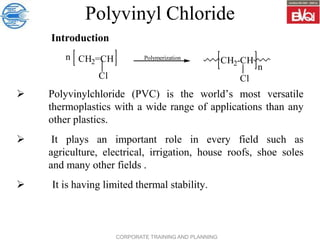

- 1. CORPORATE TRAINING AND PLANNING Polyvinyl Chloride Polyvinylchloride (PVC) is the world’s most versatile thermoplastics with a wide range of applications than any other plastics. It plays an important role in every field such as agriculture, electrical, irrigation, house roofs, shoe soles and many other fields . It is having limited thermal stability. Introduction Polymerization CH2=CH CH2-CH Cl Cl n n

- 2. CORPORATE TRAINING AND PLANNING Polyvinyl Chloride Introduction Vinyl Chloride was first synthesized and reported by Reghawlt in 1835 . The first report of polyvinyl bromide was published by Hoffmann in 1860. The full scale commercial production of PVC resin began in 1931 in Germany. In India the manufacturing of PVC began in 1961 when Calico started its plant in Mumbai.

- 3. CORPORATE TRAINING AND PLANNING Preparation of Monomer Commercial Method - Vinyl chloride monomer is prepared by cracking 1,2-dichloro ethane. - Vinyl Chloride may be produced by the addition of HCl to acetylene. CH2-CH2 CH2=CH Cl Cl Cl + HCl HC CH + HCl CH2=CH Cl + 95.5 KJ/mol

- 4. CORPORATE TRAINING AND PLANNING Polymerization Suspension Polymerization Emulsion Polymerization

- 5. CORPORATE TRAINING AND PLANNING About 85% of the world’s PVC production are by suspension polymerization. Dr. Berg at Wacker-Chemie Polymerization developed this technique in 1935. Vinyl chloride is dispersed in water with stirring. Monomer soluble organic peroxides are used as initiators. Protective collides such as Cellulose ethers are added to prevent the monomer droplets from coalescing. After the polymerization reaction, unreacted vinyl chloride is removed and is passed to monomer recovery plant. The polymer is then centrifuged to remove free water and resulting wet polymer is dried by hot air. The particle size of PVC resin is about 100-150µm. Suspension Polymerization

- 6. CORPORATE TRAINING AND PLANNING Suspension Polymerization Vinyl chloride monomer Water Suspending agent Polymerization Vessel Stripping Centrifuging Water Drying Water PVC

- 7. CORPORATE TRAINING AND PLANNING Emulsion Polymerization The system consists of the monomer- water containing emulsifier and water soluble initiator. In presence of the emulsifier, agitation of the charge in the autoclave disperse the monomer into very fine droplets. Initiator starts polymerization. Monomer-Water containing Emulsifier Conc(2-3%) Water soluble initiator Autoclave Drying Grinding Final Size Classification Packing

- 8. CORPORATE TRAINING AND PLANNING Structure Property Relationship - PVC is polar in nature due to presence of C-Cl dipole. - Resistant to non- polar solvents. - Flame retardant and self extinguishing. - Presence of chlorine atom causes an increase in inter chain attraction and increase hardness and stiffness of polymer. CH2-CH Cl n

- 9. CORPORATE TRAINING AND PLANNING Properties of Poly Vinyl Chloride Name Value Unit Specific gravity 1.18-1.70 -- Tensile Strength 5.5-26.2 MPa Tensile modulus 4.8-12.4 MPa Flexural modulus 30 MPa Elongation at break 150-450 % Hardness A85 --- Glass transition temperature 80-85 °C Dielectric Strength 9.9-15.8 KV/mm

- 10. CORPORATE TRAINING AND PLANNING Dilute Solution Viscosity (K Value Of PVC) PVC is heat sensitive material and therefore instead of melt flow index, K-value is calculated. The K-values of PVC for processing lie between 55 and 60. Higher K-values lead to better mechanical and electrical properties of the moulded material at the cost of decreasing processibility. Optimum results can be achieved in each type of processing using products of suitable K-value.

- 11. CORPORATE TRAINING AND PLANNING The value of ‘k’ is calculated by the relationship Log10 ηrel = 75 k2 x 10-6 + (k x 10-3) C 1+ 1.5 kc x 10 -3 ηrel = relative viscosity = η/ ηo k = k-value C= concentration in gm/ml. From K-value one will know the grade of PVC material K-Value 60-65 Injection Moulding 65-67 Extrusion Process 67-70 Calendaring Process Dilute Solution Viscosity (K Value Of PVC)

- 12. CORPORATE TRAINING AND PLANNING Additives and Compounding A PVC compound may contain the following ingredients. - Polymer - Stabilizers - Plasticizers - Polymeric Processing Aids - Impact Modifiers - Fillers - Pigments Some other miscellaneous materials include flame (fire) retardants, optical bleaches and blowing agents.

- 13. CORPORATE TRAINING AND PLANNING Stabilizers - Heating of PVC at temperature above 70°C has a number of adverse effects on the properties of the polymers. Sufficient degradation may take place during standard processing operations (150-200°C) making the product useless.Therefore to avoid degradation ‘stabilizers’ are found useful. - The compounds of Cd, Ba, Ca and Zn are prominent as PVC stabilizers.

- 14. CORPORATE TRAINING AND PLANNING Plasticizers Plasticizers are used - For reducing processing temperature of polymer below the decomposition temperature. - To modify the properties of finished products such as flexibility. - To modify processability. All PVC plasticizers have a solubility parameter to that of PVC. Di-iso-octyl phthalate (DIOP) and di – ethyl hexylphthalate (DEHP) are most important plasticizers used in PVC.

- 15. CORPORATE TRAINING AND PLANNING Extenders - Sometimes plasticizers are not found useful in PVC because of their limited compatibility with the polymer. - When mixed with ‘true plasticizer’ (commercially called extenders), a reasonable compatibility is acquired. - Extenders are cheaper than ‘plasticizers’. - Plasticizers can often be used along with ‘Extenders’ without any adverse effects on the properties of compound. Commonly used extenders in PVC are - Chlorinated paraffin waxes - Chlorinated liquid paraffin fraction - Oil extracts

- 16. CORPORATE TRAINING AND PLANNING Lubricants - Two types of lubricants are generally used in PVC - internal lubricants and external lubricants. - External lubricants prevent sticking of the compound to the processing equipments by forming a film between the bulk of the compound and the metal surface of the processing equipment. - Internal lubricants improves flow behaviour of the materials. - Calcium Stearate, normal Lead Stearate, Dibasic Lead Stearate, Graphite are employed to improve flow properties.

- 17. CORPORATE TRAINING AND PLANNING Fillers Fillers are commonly employed in order to reduce cost. They may also be incorporated for technical reasons such as; To increase the hardness of a flooring compound, To reduce tackiness of highly plasticized compounds, To improve electrical insulation properties To improve the hot deformation resistance of cables. For electrical insulation, china clay is commonly employed while various carbonates are used for general purpose work.

- 18. CORPORATE TRAINING AND PLANNING Pigments To add a pigment, firstly the following facts are to be considered - Will it decompose, fade or plate out? - Will the pigment adversely affect the functioning of stabilizer and lubricant. - Will it fade, bleach out or will it bleed. - Will the pigment adversely affect properties that are relevant to the end usage (because many pigments will reduce the volume resistivity of a compound).

- 19. CORPORATE TRAINING AND PLANNING Polymeric Impact Modifiers & Processing Aids - Unplasticized PVC has a high melt viscosity leading to some difficulties in processing. The finished product is also too brittle for some applications. In order to overcome these problems ‘impact modifiers’ are generally added. - Impact modifier are semi-compatible and often somewhat rubbery in nature. - Examples for Impact modifier are ABS graft copolymers, Methacrylate – butadiene - styrene (MBS) terpolymers, Chlorinated Polyethylene, EVA-PVC graft polymers. - Chlorinated Polyethylene is being widely used as an ‘impact modifier’ particularly where good aging properties are required.

- 20. CORPORATE TRAINING AND PLANNING Formulations The formulation given below is intended as a general guide but not for a specific application (Flexible Pipe). Suspension polymer ( K- 65) 100 DIOP 40 Trixylyl Phosphate 20 China clay 20 Tribasic lead sulphate 7.0 Stearic Acid 0.5 Pigment 2.0

- 21. CORPORATE TRAINING AND PLANNING Compounding of PVC This is the most important operation in the PVC processing where the PVC resin is formulated into a compound with the desired properties with respect to processing and end product by addition of selected additives. Adding and mixing additives into plastics is an integral part of a much broader operation called compounding in which ingredients including the colorants are intimately mixed together into a nearly homogenous mass. Compounding operation can be classified into following two Categories; Melt blending , where the mix is fluxed or fused. Dry blending, where the resultant compound is a dry relatively free flowing powder containing the liquid ingredients absorbed on the polymer particles.

- 22. CORPORATE TRAINING AND PLANNING Melt compounding In this process a premix is prepared which is then fluxed. The fluxed mixture is made into pallets and fed to process equipment. Simple mixers like ribbon or tumble blenders are used for the preparation of premix of the ingredients.

- 23. CORPORATE TRAINING AND PLANNING Dry Blending The dry blending process constitutes the following steps Addition of polymer to blender and heating it at a temperature of 80-105°C. The premixed and heated plasticizers are added to blender through a spray spread over a period of 10-20 minutes. The stabilizer, pigments are added. Other compounding additives are added and the mixture is allowed to dry up. The lubricants dissolved in the plasticizers are added and the mixer is agitated thoroughly. The mixture is then cooled to below 60°C, screened and transported to storage.

- 24. CORPORATE TRAINING AND PLANNING Processing Considerations Polymer lacks thermal stability and degradation is rapid during processing evolving hydrochloric acid. All the metal surfaces that come in contact with the melt should be resistant to this acid. Good ventilation of the working area is also essential. Polymer doesn’t absorb water but some plasticizers may do so. uPVC melts are viscous and typical flow path ratio is in the order of 60 : 1 viscosity of plasticized PVC depends on plasticizer level. Polymer is amorphous in nature so that shrinkage is low.

- 25. CORPORATE TRAINING AND PLANNING Processing Techniques Injection Moulding Typical Injection Moulding Conditions Recommended melt temperatures are 180-200 °C for uPVC and 150-190 °C for PPVC. Mould temperature is 20-60 °C. Injection pressures are in the range of 100-175 Mpa for uPVC and 80 – 120 Mpa for PPVC.

- 26. CORPORATE TRAINING AND PLANNING Extrusion Typical Extrusion conditions are Temperature profile is 150-180°C for uPVC and 140- 175°C for PPVC. Recommended screw L/D ratio 14:1 to 17:1 for uPVC and 17:1 to 20:1 for PPVC. Recommended compression ratio is 2:1

- 27. CORPORATE TRAINING AND PLANNING Blow molding - UPVC has a much lower average specific heat between the processing temperature and room temperature than polyethylene. - Because of this much less heat is removed on cooling of mouldings and hence very short cycle times are possible. - Blow molding is confined to UPVC using general conditions given under extrusion.

- 28. CORPORATE TRAINING AND PLANNING Calendaring Calendaring is an important process for making UPVC film or sheet. High molecular weight PVC is compounded and partly agglomerated in an extruder mixer. The heated mix is then fed to an L- type calendar mixer. The hot calendar rolls simply partly consolidate the granules so that the resulting film or sheet is strong enough to be drawn over a train of heated drums which are well above the fluxing temperature of the compound. The PVC is therefore subjected to only a very short but intense heating process. The resulting films with the high mechanical properties are used for packaging applications.

- 29. CORPORATE TRAINING AND PLANNING PVC Plastisol and Organosol Plastisol and organosol are pastes types obtained when the voids between particles are completely filled with a plasticiser so that the polymer particles are suspended in it. A typical plastisol includes paste making polymer, plasticizer, small mount of stabilizer and filler. Organosols are distinguished by the presence of volatile diluent used for reducing the paste viscosity. Most PVC pastes are used in the manufacture of leathercloth. Coating of objects are also done by pastes. Rotational casting , paste injection moulding processes have been developed for making flexible products.

- 30. CORPORATE TRAINING AND PLANNING Trade names IPCL, India - Indovin Reliance, India - Relcair Mitsubishi gas Ind, Japan - Vinylfoil Mitsui toatsu chemical, Japan - Vinychol B.F. Goodrich, US - Vynaloy Goodyear, US - Vycell ICI - Vynide Solvay - Benvic

- 31. CORPORATE TRAINING AND PLANNING Applications of PVC Automotive PVC is widely used in air filters, boat bumpers, mats, seat belts, head and arm rests, spark plug covers, seat covers, transmission covers. Agriculture PVC is used in manufacturing of irrigation pipes and profiles, pipe fittings, drip irrigation systems, reservoir liners, horticultural and green house irrigation system, sprinkler system fittings. Building Floor tiles & covering, fencing, wall coverings, furniture covers, sofa seats, house sidings, windows, doors, cabinets, swimming pool liners, carpet backing, heat seal adhesives, foil coatings.

- 32. CORPORATE TRAINING AND PLANNING Electrical/ Electronics Pipe and profiles, wire extrusions, cable insulation, TV back, cable fittings, wire sacks, electrical parts, plating racks, tool handles. Industrial PVC is used in manufacturing of film, fittings, printing plates, screens, steel strip coatings, profiles, printing inks, conveyor belting, battery separators, storage tanks, gloves. Medical PVC is used in medical sector to manufacture of blood bag, glucose bag, urine bag, syringes, infusion set, tubing, catheter tubes.

- 33. CORPORATE TRAINING AND PLANNING Applications of PVC Vinyl records PVC flexible blood bag PVC Automobile interiors PVC wire and cable

- 34. CORPORATE TRAINING AND PLANNING Applications of PVDC - Copolymers may be used in the manufacturing of extruded pipe and moulded fittings and in chemical plants. - Copolymers are used in the manufacture of filament which may be extruded from steam heated extruders with L/D ratio 10:1 and compression ratio 5:1 into a quench bath. These filaments are used for deck chair fabrics, car upholstery, decorative radio grills, dolls hair, filter brushes. - Biaxially oriented film is used in packaging for exceptional clarity, brilliance, toughness, and water and gas impermeability.