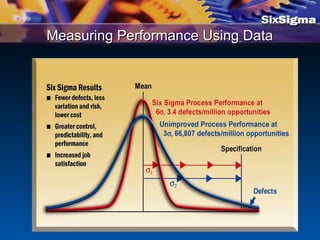

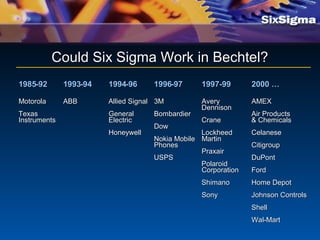

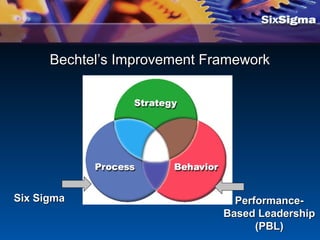

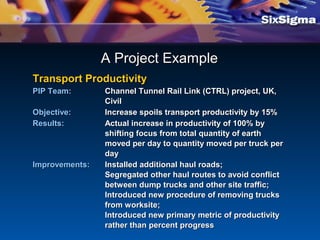

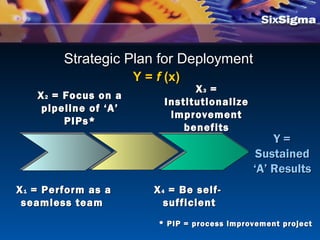

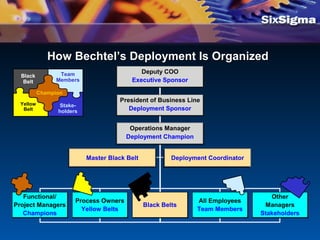

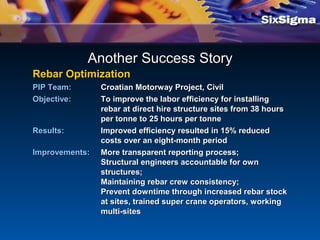

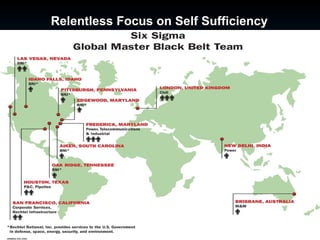

This document discusses the deployment of Six Sigma at Bechtel, an engineering, procurement, and construction company. It describes how Six Sigma uses rigorous tools and methodologies to improve work quality, profitability, and customer satisfaction. Bechtel implemented Six Sigma to address issues like ineffective lessons learned and talent shortages. The presentation outlines Bechtel's improvement framework, provides examples of Six Sigma projects that increased productivity, and describes how Six Sigma was organized within Bechtel with champions, belts, and executive support. It emphasizes becoming self-sufficient in improvement efforts and establishing a culture focused on process data.