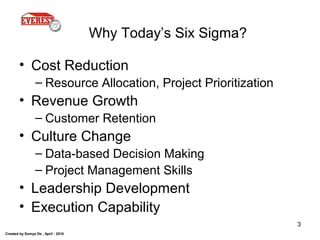

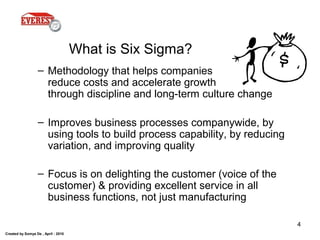

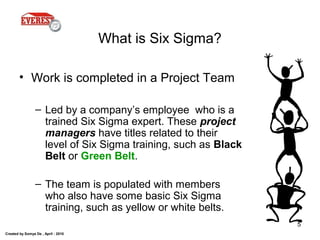

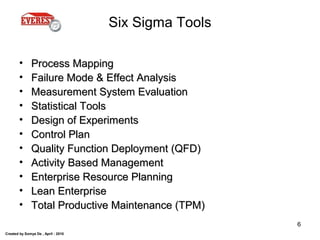

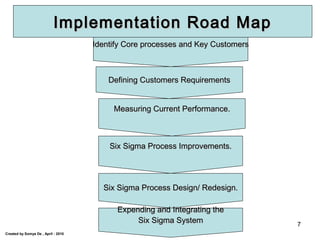

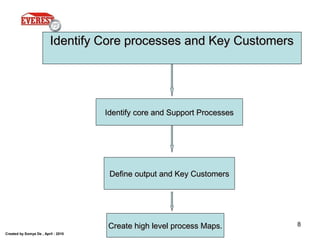

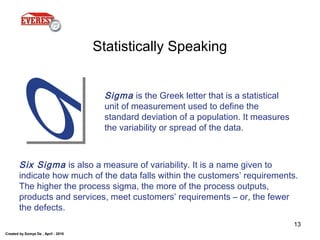

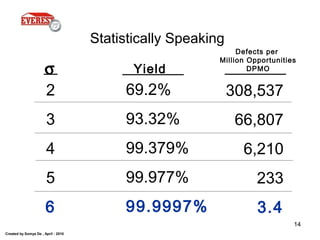

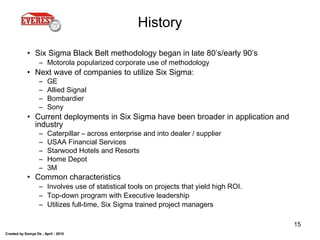

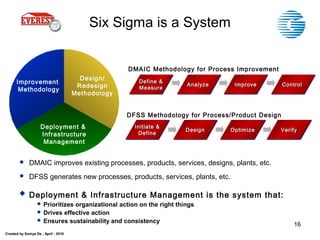

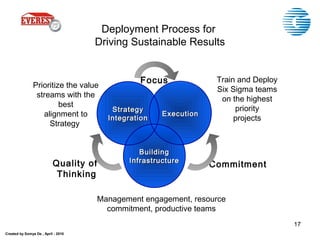

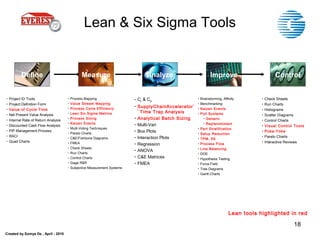

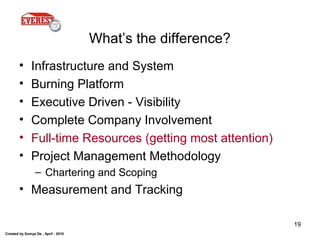

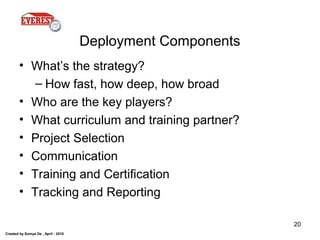

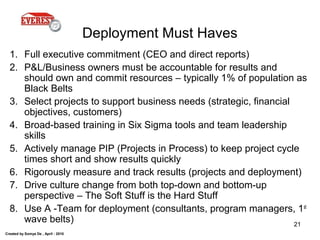

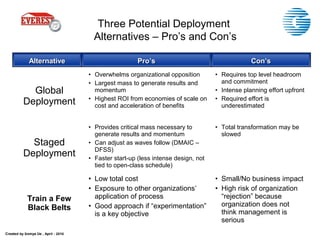

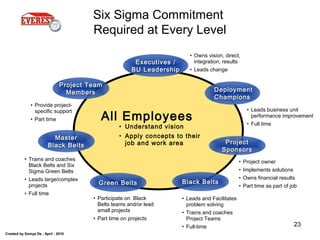

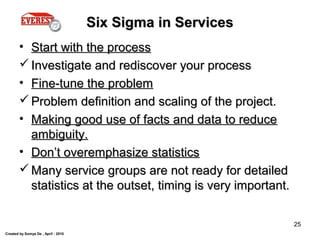

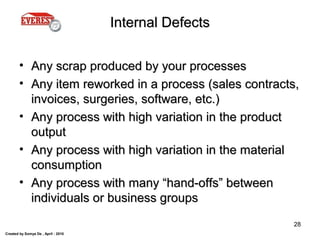

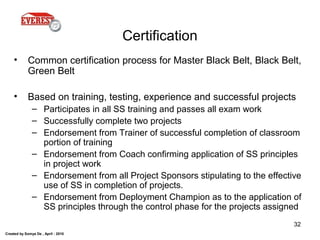

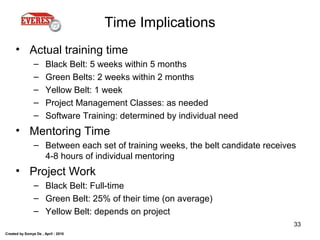

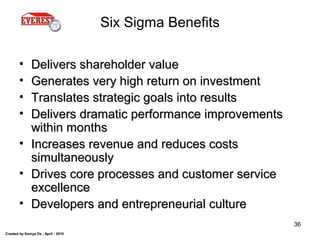

Six Sigma is a methodology that uses statistical tools and lean principles to reduce costs and improve processes. It aims to reduce defects and variation and improve quality through disciplined project management. Companies implement Six Sigma through deployments that involve training employees in Six Sigma roles and tools. Successful deployments require executive commitment, selecting strategic projects, and tracking results to drive culture change and sustain improvements.