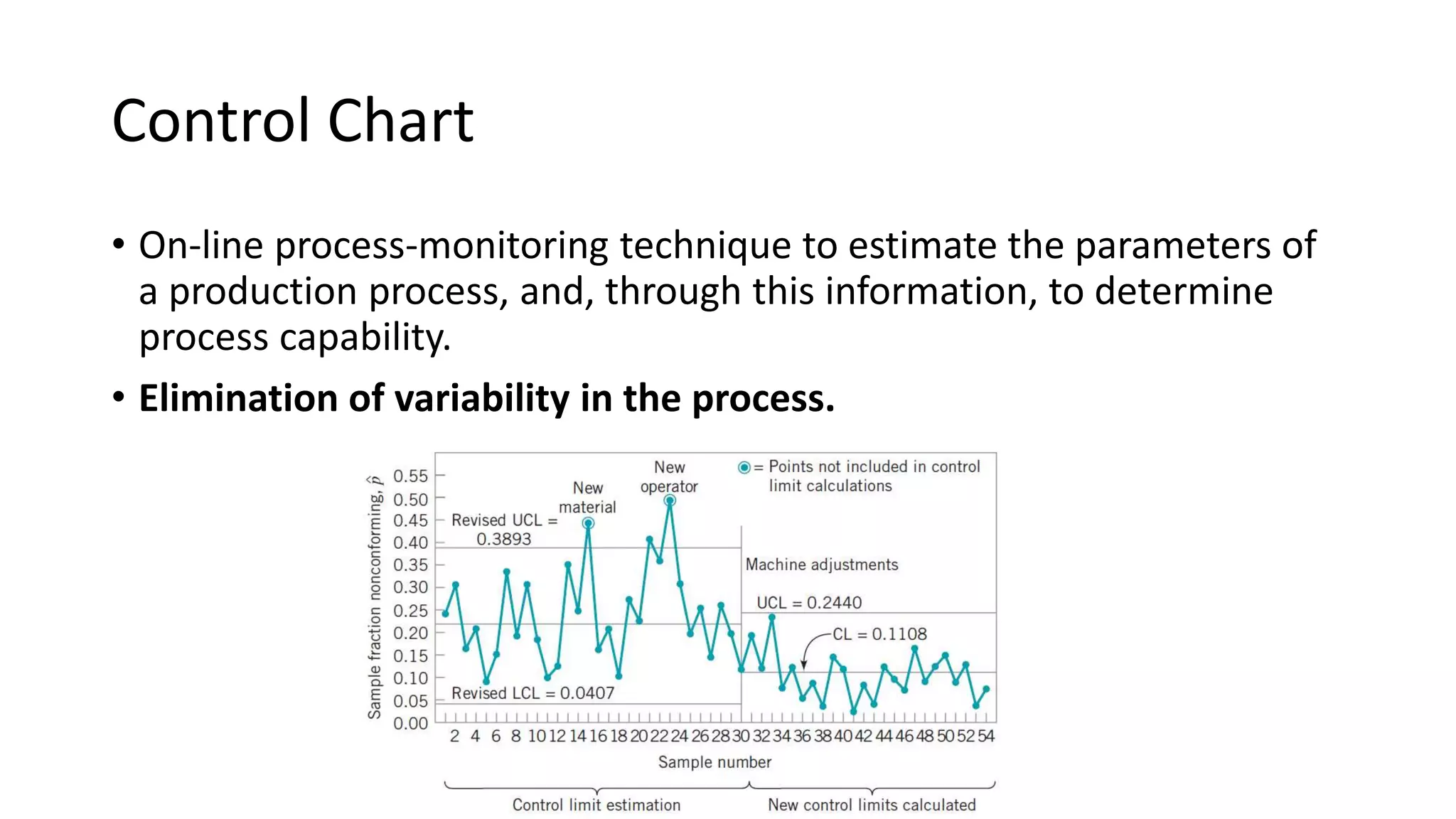

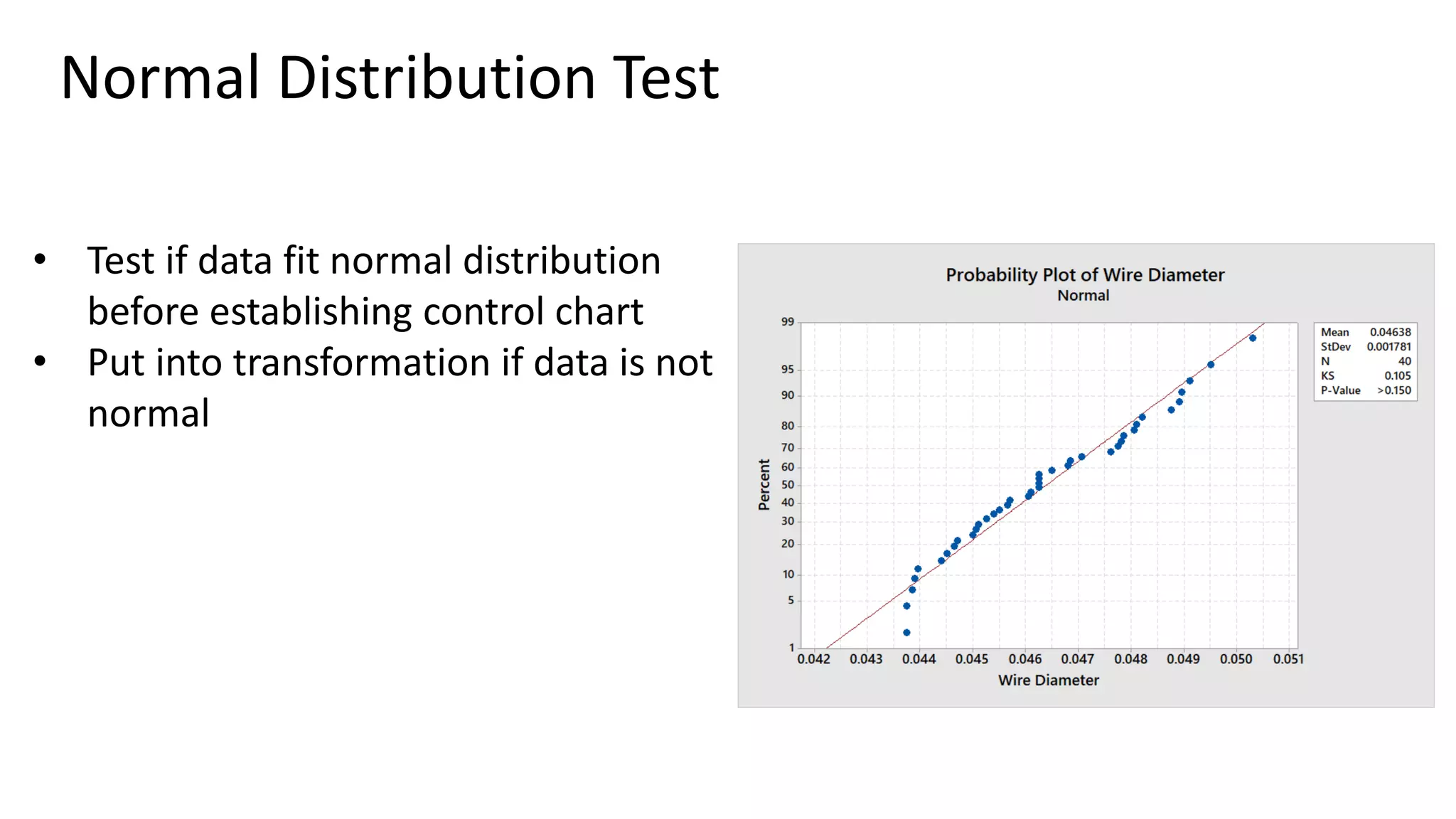

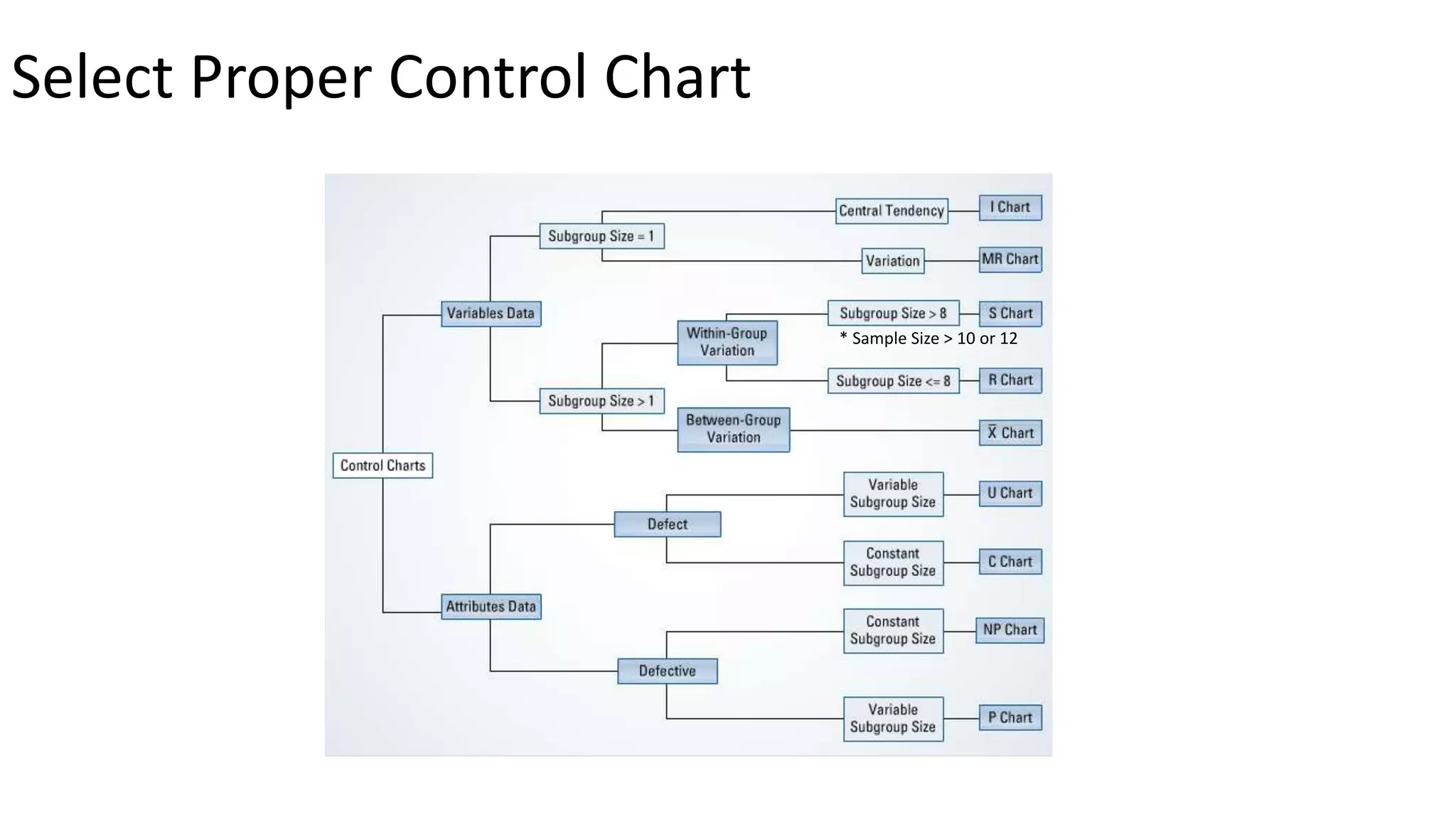

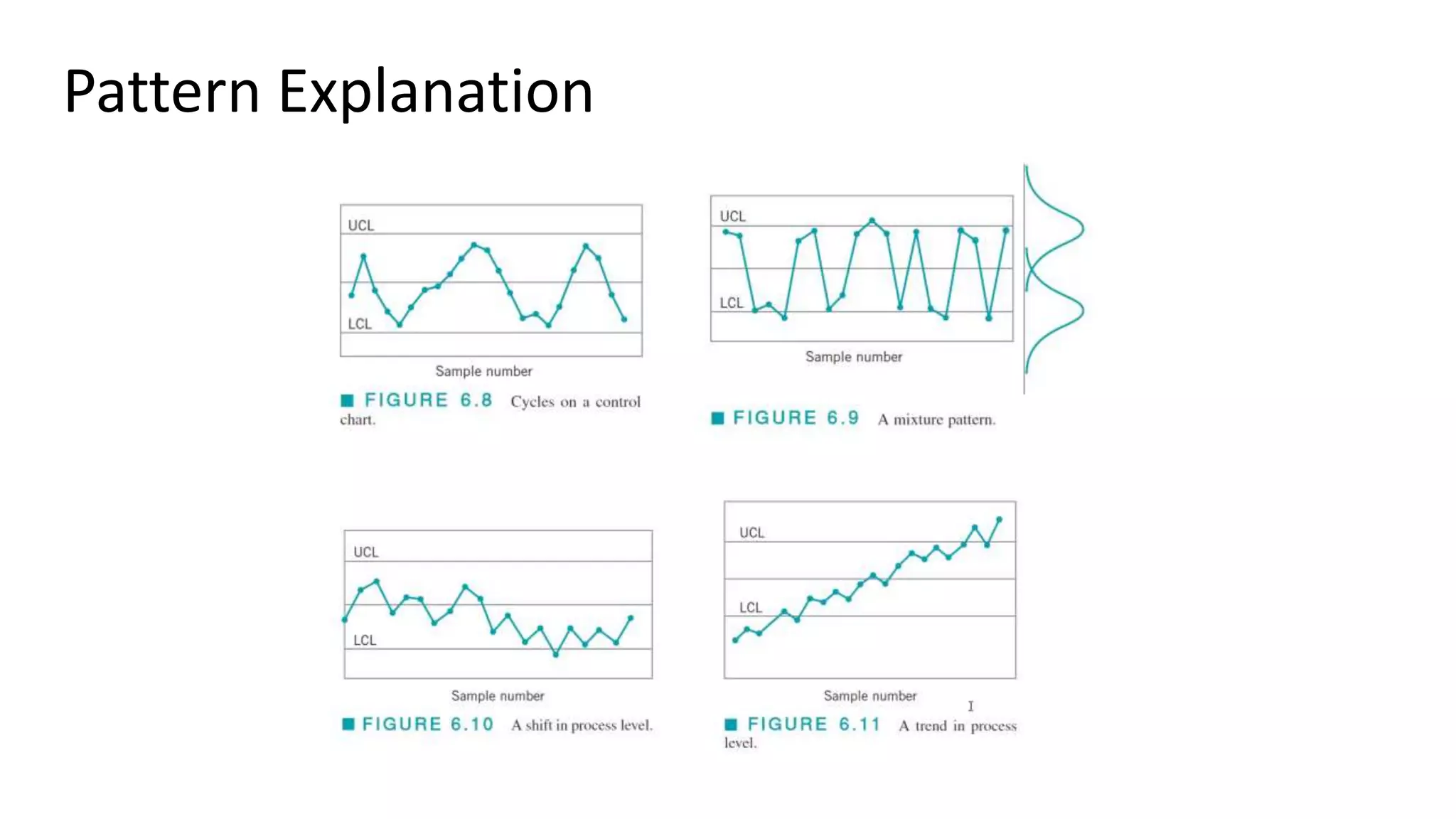

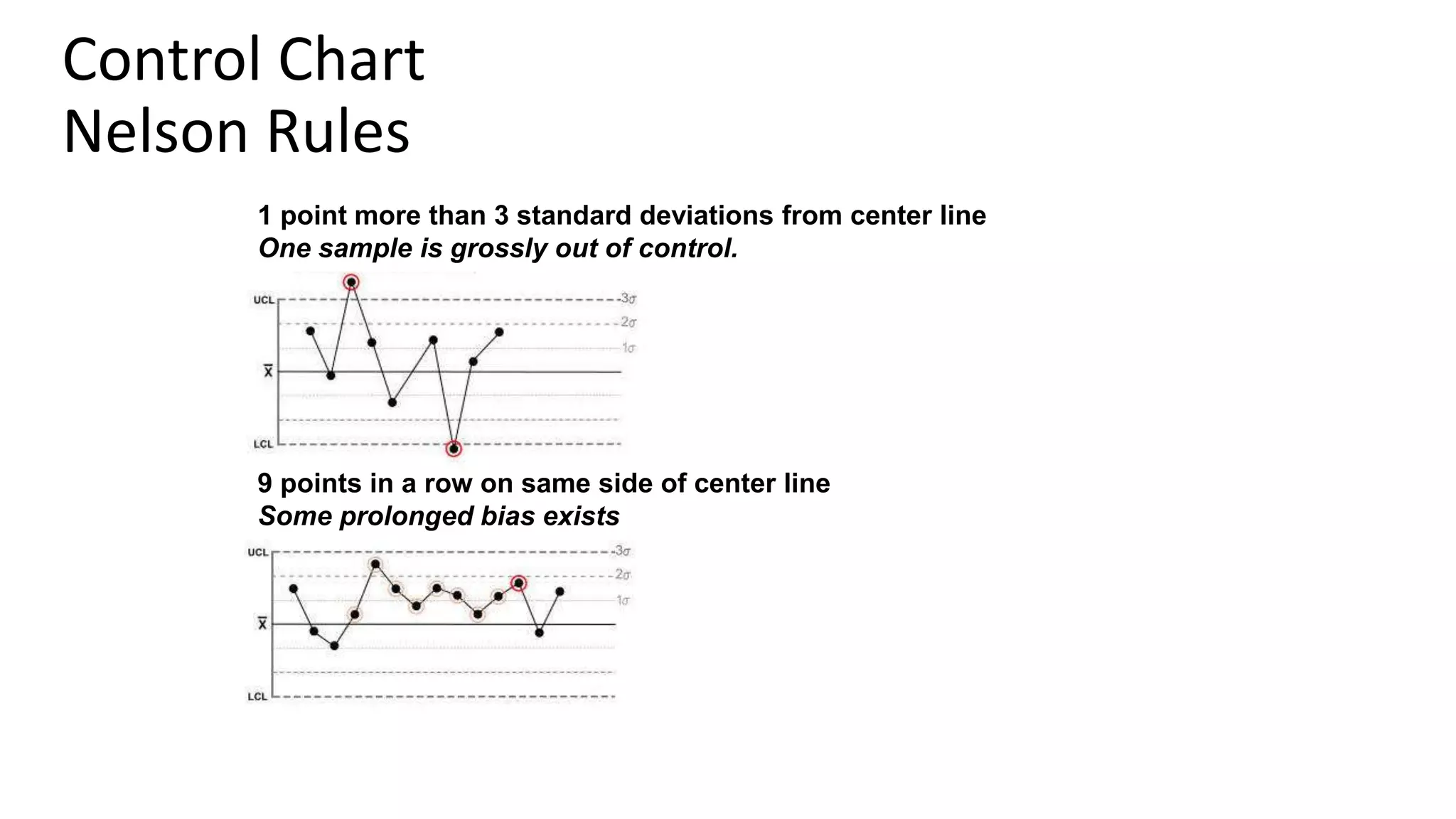

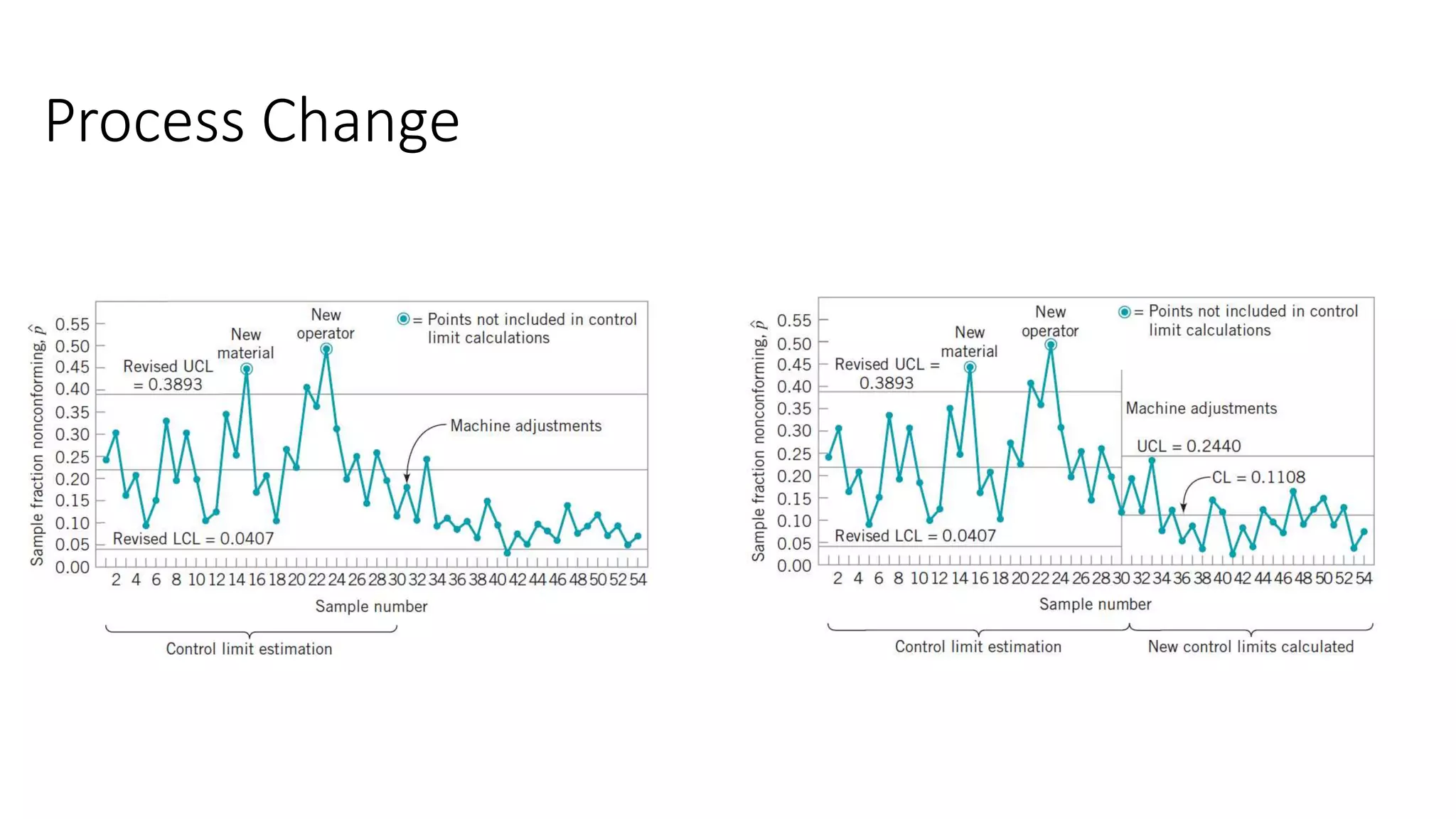

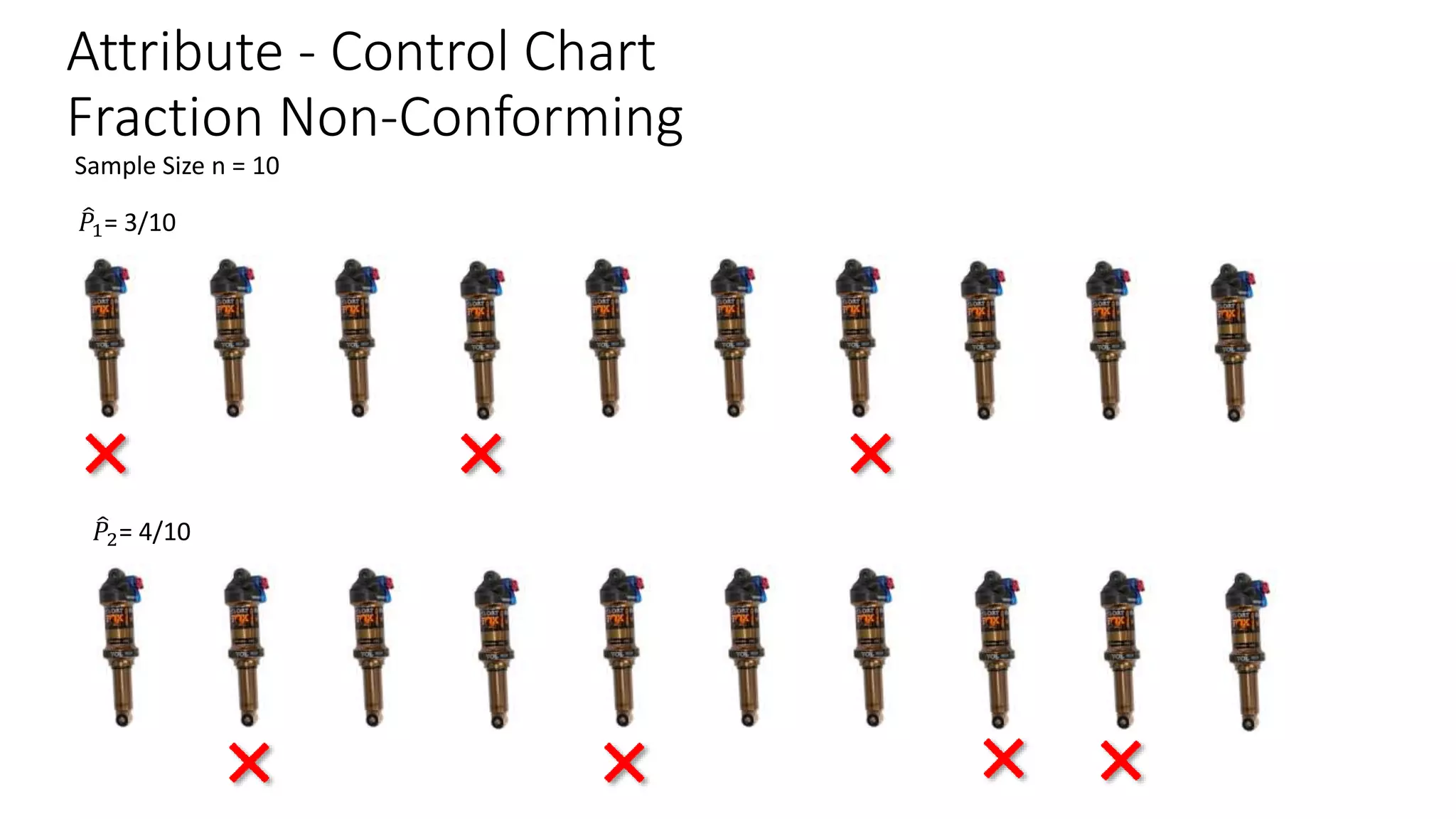

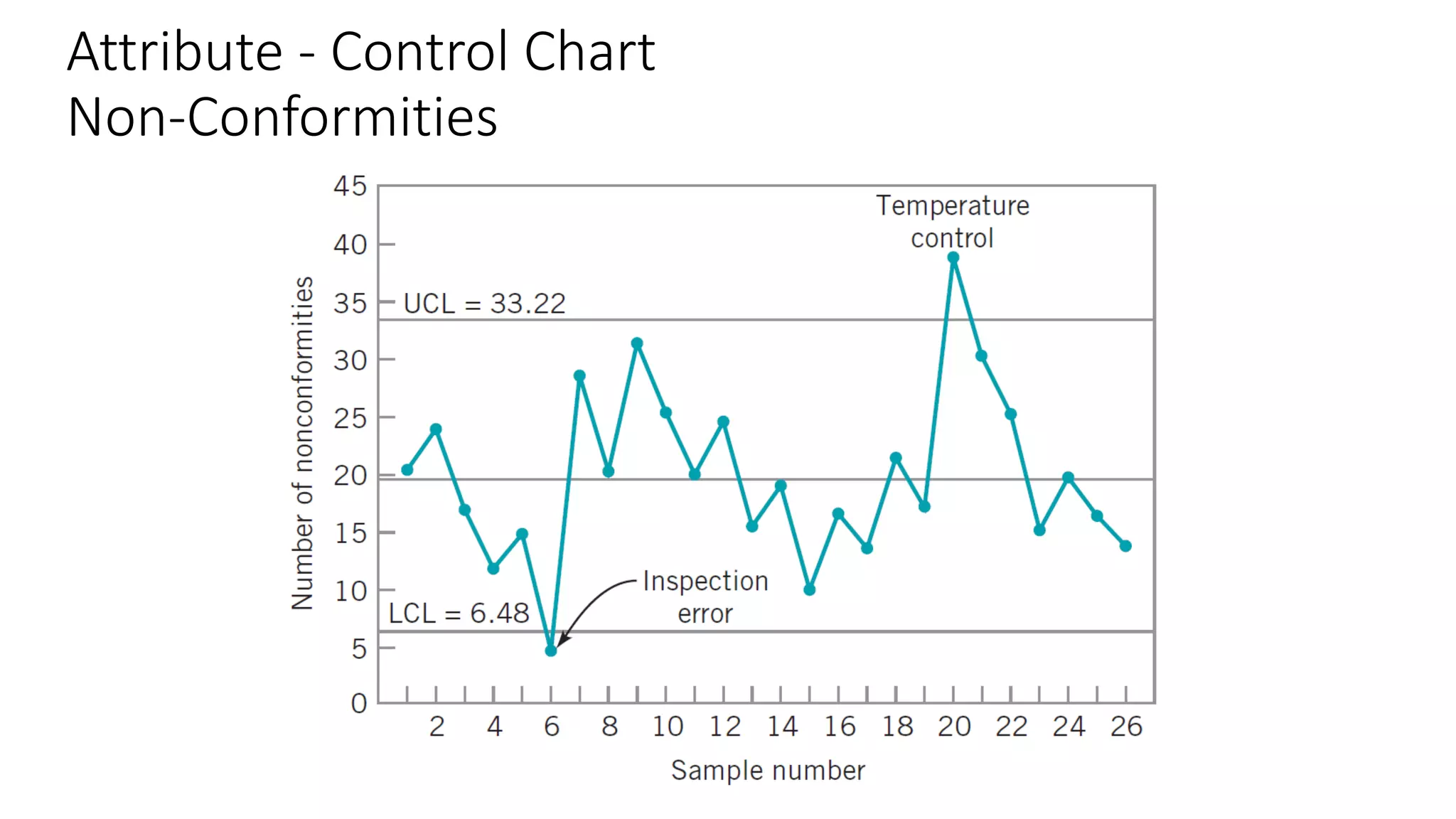

Control charts are used to monitor processes and determine if they are in a state of statistical control. There are two phases to constructing control charts: Phase I establishes initial control limits using large sample sizes, while Phase II involves ongoing monitoring using smaller sample sizes. Different types of control charts (x-bar, R, p, np) can be used depending on whether the data is variable or attribute. Nelson's rules provide guidelines for interpreting patterns in control charts that may indicate a process is out of control.