CMMS - From Theory to Execution

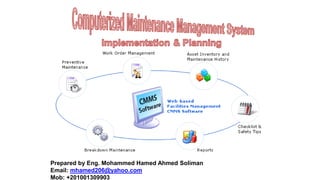

- 1. Prepared by Eng. Mohammed Hamed Ahmed Soliman Email: mhamed206@yahoo.com Mob: +201001309903

- 3. Benefits (Savings) derived from a CMMS: 1. Reduction of overtime. الفاقد الوقت تقليل 2. Reduction of outside contract work. الصيانه عقود تقليل 3.Reduced maintenance backlog. الصيانه عمليات تنفيذ فى التأخر تقليل 4. Reduced cost per repair. التكلفه تقليل 5. Improved morale of employees by diffusing employee frustration; a happy worker is a productive worker. االحباط وتقليل العاملين معنويات رفع 6. Better service to other departments. واألقسام االدارات لجميع الخدمات توفير 7. A significant reduction in paperwork to make the most productive use of employee time. الورق مأل فى الفاقد الوقت تقليل 8. Effective utilization of maintenance and supervisory personnel’s time. تقليل االشراف وقت 9. Reduced follow-up role required of the supervisor.المتابعه فى الفاقد الوقت تقليل 10. A useful step to the ISO certificate. العالميه الجوده شهاده على الحصول تسهيل

- 4. CMMS Modules Basic CMMS includes: A. Equipment data management* B. Preventive maintenance* C. Labor* D. Work order system E. Scheduling/planning F. Vendor G. Inventory control* H. Purchasing I. Budgeting

- 5. Wait a moment!, what is CMMS? CMMS isn’t a SAP or Maximo or Oracle or others, it’s any kind of program used to save date on a data base system and initiate reports for different purposes. It can be a simple program like Visual Basic or complicated one like SAP or Oracle or Maximo, but all should be connected to a data base program such as Oracle, SQL, or Access….most of big programs like SAP or Maximo use the Oracle Data Base.

- 7. Important of codes: Shortcut for many activities Unify all things so it doesn’t matter what the technician is writing. A failure code can let you know the history of how many times this failure has occurred for several years ago if used with the CMMS or maintenance software effectively. Facilitate dealing with the data inside the maintenance software or CMMS. Reduce searching time inside the maintenance software. Codes for: Equipments, Work classes, WO, Priorities, Locations, cost centers, failures, PM.

- 8. Equipments Coding Methodology (Functional & Geo Functional Codes) XXX-XXXX Sequential Equipment no( الرقم للمعده )التسلسلى Equipment Location or Type or Both. If you choose to use the equipment’s location, then plant areas or the plant’s cost centers should be designated the first three digits. EX. Coding a Compressor in Factory 2. CMP-02-001 Air Compressor#1-160KW or CMP-001 ملحوظه:مكان على اعتمادا التكويد أبدا يتم فال مستمر يشكل يتم المعدات أماكن تغيير معدل كان اذا المعده.الصناعيه الخدمات كمعدات ثابته المعدات كانت اذا التكويد فى المكان يستخدم. AAA-NNN-NNN AA-NN-NN AANNNN

- 9. PM Coding Methodology X-XXXXXXX-XX PM Eq code PM level EX. First Weekly maintenance for a compressor in factory 2 Code=P-CMP001-W1 Weekly=W, Monthly=M, Quarterly=Q, Semi Annually=S, Annually=A 5A=Scheduled every 5 yrs.

- 10. Failure Coding Methodology العطل كود أهميه: ال حجم مدى لمغرفه يستخدم شىء أبسطfailureال أم العطل حجم مع متناسب الصيانه فيه تمت الذى الوقت وهل بالمعده حدث الذى ال أم بزمن عطل هو وهل ايقافها بدون عمله يمكن كان أم المعده اليقاف ضرورى كان العطل هذا وهلال ويسهلdowntime reportingتكرارا األكثر األعطال حاله فى.. No CODE DESCRIPTION 1 ARLK Air Leak 2 ALRM Alarm or Problem Indicator 3 BRNG Bearing Problem 4 CALB Calibration Problem 5 DIRT Dirt or Foreign Matter Problem 6 ADJS Equipment Adjustment Required 7 CUTO Equipment Cutting Out 8 JAMD Equipment Jammed 10 XLUB Excessive Lubrication 12 VIBR Excessive Vibration 13 LLUB Lack of Lubrication 14 WIRE Loose or Broken Connection or Wire 15 ALIN Misalignment 16 NAIR No Air 17 NPWR No Power 18 OLLK Oil Leak 19 OPER Operator Error 20 XHOT Overheating or Smoking 22 SHRT Short Circuit

- 11. Tips of Failures Coding: •Limit the code number or character to 4 or 5 digits. •Make codes related to failures. •You can create list of problems (symptom) & list of failures (causes). •List of problems will be more general & failures will be more deep. •You can add 1,2,3 to specify the failure criticality. •You can add A, B, C to specify the shift which the failure occurred to. EX. Excessive Vibration take code VIBR But VIBR1, VIBR2, VIBR3 will indicate the grade of vibration and the priority of failure. And VIBR-A mean in the first shift, VIBR-B mean in second shift. And VIBR1-A mean excessive vibration with priority 1 & occurred in the first shift. Or Another way failure codes can be divided by groups. For Ex. لألسانسير بالنسبه,بالرمز لها ويرمز الفرامل مجموعه أعطالBRKEمن مجموعه عمل يتم الجروب هذا داخل برمز عطل لكل ونرمز األعطال: •الفرامل تيل تاكل عطلبالرمز له ونرمزPDWR •الرمز له ونرمز الفرامل دسك تاكل عطلDCWR األلى للجلى بالنسبه,بالرمز لها يرمز البستم مجموعه أعطالCYLRبالرمز عطل لكل نرمز: •العامود تلف عطلSTWR •هواء تسريب عطلARLK ISO:14224

- 12. You can add cause code: sources of problems, this will be used for root cause analysis & continuous improvement. Adding action code is also useful: nature of the work that remedied the problems. Benefits: Perform failure analysis to disclose formerly unknown weaknesses in business processes, system design, operational utilization.

- 13. Work Requests/Work Orders Coding. Use numeric numbers 1,2,3,4..and put notes under each work order number to specify whether it was urgent or emergency or planned corrective or preventive work order. EX.PM01 PM101(breakdown stopped the line). PM102(breakdown didn’t stop the line). PM02 CBM201(Predictive) CBM202(Improvement) PM03 PM301(Planned Preventive Maintenance). PM302(Preventive Maintenance Inspection). PM303(Preventive Maintenance Calibration). PM304 (Preventive Maintenance Lubrication). PM305(Preventive Maintenance Overhaul). PM04 PM401Projects PM402Commisioning PM Stands for Plant Maintenance Note: this coding system is a real one taken from SAP CMMS. PM Stands for Plant Maintenance Note: this coding system is a real one taken from SAP ERP.} Can be changed to normal corrective to match current Asfour system till we apply CBM CP: work done to correct an equip defect as a result of PM/PdM action. بالغ ان حاله فى االنتاج من العطل PM02 PM201 (Corrective Maintenance) PM202 (CP Maintenance)

- 14. Coding should depend on the initiation type & the originator. Notification from Production in case of emergency or line stop=N1 Notification from maintenance inspection team for corrective maintenance that didn’t cause line stop=N2. Work Request/ Notification Coding

- 15. A- Equipment Data Required •Equipment ID المعده تعريف كود •Serial no المتسلسل الرقم •Model no الموديل رقم •Purchase data المعده شراء تاريخ •Installation data التركيب تاريخ •Warranty ومدته الضمان •Eq criticality or priority المعده تصنيف •Spare parts list •Spare parts price •Safety considerations (OSHA) األمان اعتبارات •Condition monitoring parameters •Attachments } CMMS program use this data to determine the cost of the WO, perform MRA (material replacement analysis, and perform salvage analysis Vibration limits, temp limits…etc. Drawings & others.

- 16. Equipment Module Inputs Equipment Code (ID) Eq Serial No Eq model Eq Purchase Date* Eq Installation Date* Eq Criticality Eq Warranty* Eq Spare Parts List Eq Spare Parts Price Safety tips* Condition Monitoring Parameters* Drawings* Eq Hierarchy

- 17. List of Eq ID Serial Model Spare parts list Purchase Data Spare parts Price Eq Installation Date Eq Criticality Eq Warranty Safety Tips CM Parameters CMMS Equipment Data Preparation Sheet

- 18. Sample for equipment model

- 19. Spare parts code Spare part description Availability in warehouses

- 20. Determination of the maintenance cost effective based on the maintenance cost data & equipment price, depreciation data. المعده استهالك معدل قيمه فى التناقص اجمالى المعده االستهالك بعد المعده قيمه اصالحها أو المعده اعمار عمليه جدوى مدى بحساب البرنامج يقوم السابقه البيانات على بناء....تكل كانت فاذافه ذلك باظهار البرنامج يقوم المعد تكلفه من أعلى االصالح.

- 21. Equipment Module Outputs Equipment Mean Time Between Failures Equipments Reliability Equipments Availability Equipments no of Failures Eq Depreciation Equipment List of Failures Equipment T.Cost Equipment Meter reading & life time estimation Equipments Mean Time to Repair Equipment CM/PM Ratio CM WO/PM WO

- 22. Cost (equipment number, date installed, original cost, LTD cost) Equipment failure (equipment number, description, failure codes: with report queries you can get details of failures). Equipment hierarchy (equipment number, location, description. Top level equipment and its children are listed). Failure count (displays number of failures for each piece of equipment in a given time period) Equipment warranty (equipment number, description, warranty expiration date). Equipment availability (equipment number, description, times available during a specified period). Special tools (equipment number, description, special tools required). Meter reading (equipment number, description, date, current meter reading, previous date, and meter reading). Location (equipment number, description, location, department). Summary (equipment number, description). Master (all fields). Equipments Reports

- 23. B-Preventive Maintenance Data •Procedure •Priority •Frequency PM will be performed by meter or time based •Tools or parts •Labor •Contractor •Route. PM Enter routine maintenance steps that are being done daily by the maintenance team or the operators. Enter PM steps CMMS use this to define job or WO priority Tools needed for PM job Technicians assigned for each PM job If this type of PM is performed by an outsourcing contract. Labor & Tools data will be used by the CMMS program to determine the cost of the WO. Labor data will be used by the CMMS program to determine the loading rate.

- 24. PM Module Attachments PM Priority PM. Routine Maint PM Contractor PM Labor PM Tools & Parts PM Frequency PM Steps

- 25. Sample for the PM module

- 26. PM Module OutputsList of all PM actions in a specific time* PM Material Projection PM Labor Projection* Cost of PM (material, labor..etc)

- 27. PM reports ■ PM list (list of all PM jobs that are due in a specified period of time) ■ PM labor (details including money spent on PM labor) ■ PM material (details including money spent on PM material) ■ PM labor projection (forecast labor requirements for a specified period. This report can be further broken down by craft category or individuals) ■ PM material projection (forecast material requirements for a specified period.)

- 28. C-Labor Data

- 29. Labor Data: •Job title •Dept •Employee or not •Location •Address •City •Telephone •Email •Craft code •Hourly rate •Attached photo • Labor vacation •Sick time information ELEC Electrician MECH Mechanic CARP Carpenter This is employee hours wage, CMMS should accommodate overtime (OT), double time, call in, or other applicable rates.

- 30. Labor Module Inputs Labor Attached Photo Labor Hourly Rate Labor Craft Code Labor Telephone No Labor Address Labor Location Labor Employment Status Labor Email Labor City Labor DeptLabor Job Tile Sick time information Labor Vacation

- 31. Labor Module Outputs Labor summary by calendar* Labor productivity Labor Skills* Labor Overtime* Labor Vacation* Labor Summary by Employee ID Labor Summary by Eq Labor Summery by account no

- 32. Labor overtime (employee ID, name, OT taken, OT refused) Labor vacation (employee ID, name, hours earned, hours scheduled, hours used) Labor skill (employee ID, name, craft code, skill level) Labor summary by account number (employee ID, WO number, hours queried by account number) Labor summary by employee ID (employee ID, WO number, hours queried by employee) Labor summary by calendar (employee ID, WO number, hours queried by specific time period) Labor summary by equipment (employee ID, WO number, hours queried by specific equipment) Labor productivity (can be used to monitor performance based on estimated and actual hours) Labor master (all fields) Labor Reports

- 33. D-Work order system (WO): WO is heart of a CMMS. This module would allow you to generate, print, and complete WOs. It stores all preventive and corrective maintenance WOs while work is either going on, or planned for in the future. It can also serve as a powerful tool for cost estimating. Once you enter the labor, material, and outside cost information, the system will calculate the estimated cost of the project. You should be able to accommodate both unplanned work (emergency) and planned work (scheduled). All the work requests are generated through work request module or WO module. The information stays in there until the work is finished. Upon completion, the record is transferred into the work history file. “Mobile technology with CMMS” section of this book shows how a CMMS with mobile technology can minimize the steps in WO completion process. You can have a completely paperless WO system Electronic work requests Status update CMMS System View work orders Work performed Manager Update work order Paperless work order system. ال اصدار يتمWOاالصالح أو الطارئه والصيانه الوقائيه للصيانه,ع فى المستخدمه والمعدات االدوات تحميل ويتممليه االصالح+ف المعده لهذه االجماليه التكلفه معرفه وبالتالى الشغل ألوامر تكلفه حسابات فى جدا مفيد وهذا العمالهسنه خالل ى مثال.

- 35. Work Order Generated Planner Print Work Performed End of Shift Paper Work Data Entry Filling Paper Work Flow for Work Orders

- 36. WO module.

- 37. Priority. Priority code for this job. Assign the importance of the job (you may use a number from 1 to 10 or any other scheme your CMMS provides). Status. Indicates the status of this WO. For example, waiting for approval and waiting for material. This makes it easier for any one to access the system and view the status of a job. Category. Work category for this job, for example, PM, emergency, repair, and project. These should be user defined. Failure code. Failure code suitable for this job. Explains what is wrong with the equipment/asset. These should be user defined. Action code. Action code for this job, explains the action taken, that is, what was done to fix the problem. Over a period of time, you build useful history WO Associated Data الشغل بأوامر المرفقه البيانات ال أهميه درجهWOعلى وتتوقفcriticalityالصيانه ونوعيه المعده(اصالح,وقائيه)على تكون وقائيه كانت واذا ال حسبPM priorityال فى المعرفهPM module عمل يتمupdateللWOوحالته(عمله تم أو االنتظار واسباب انتظار.....الخ.) ال تصنيفWOوقائى أو اصالح كان اذا بالمعده الخاص العطل كود ووضع المشكله توضيح يتم عطل الصالح الشغل أمر كان اذا.

- 38. Labor. Allows you to enter the ID of the person, who is scheduled to perform this job, and the estimated hours required to complete the job. You can enter multiple crafts. For example, a machine installation job might require an electrician, a mechanic, and a carpenter. Once the job is completed, you can record actual labor time spent. Material. Allows you to enter material required for each WO. Upon completion or as material is withdrawn, you can record that in the system. فى المستغرقه العمل ساعات وعدد العماله تحميل ونسب التكلفه حسابات فى يفيد وهذا الشغل أمر مع العماله ارفاق يتم الصيانه. الصيانه فى المستخدمه واألدوات الغيار قطع وضع.

- 39. Material cost. Based on the material used for this WO and the unit cost information entered in the inventory file, the program computes the total cost of material. Labor cost. Based on the actual time spent by each technician and the corresponding hourly rate entered in the labor file, the program computes the total cost of labor. Outside cost. Any outside cost incurred for this job. This provides the ability to track maintenance costs performed by outside contractors. This cost is added to the material and labor cost when calculating the total cost.

- 40. Total estimated cost. This is sum of estimated material, labor, and outside costs. Total cost. This is the sum of actual material, labor, and outside costs. Total cost is computed after the job is completed. WO completion. You go through a process of initiating, approving, completing, and closing a WO. Typically, WOs can be closed individually or as a batch. Batch completion allows you to select a number of WOs and close them with one touch of key. Downtime. You should be able to track both planned and unplanned downtime. Planned downtime means equipment is scheduled to be available for maintenance work. Unplanned downtime means the equipment goes down unexpectedly. Reducing unplanned downtime saves you money. You can track downtime, analyze downtime trends, and take action to reduce unplanned downtime in the future. You can analyze the data to find the total downtime for a piece of equipment, cause of downtime, and the cost of downtime to your company. This kind of analysis will help you make decisions on rescheduling PMs and replacing existing equipment.

- 41. WO Module Inputs WO Type or Category WO Completion Status Update Material Cost Labor Cost Material Labor Outside Cost Failure Code DowntimeAction Code

- 42. WO Module OutputsEquipments Performance* WO Overdue* Equipments Downtime Summary Eq Depreciation * Equipment List of Failures Equipment T.Cost Equipment CM WO/ PM WO* WO Performance* Equipment History Equipment Meter reading & life time estimation*

- 43. WO reports الموديل هذا طريق عن عليها الحصول يمكن التى التقارير ■ WO parts shortage (WO number, part number quantity required, quantity on hand, quantity on order, quantity short). ■ Active WO (all WOs pending during a specified time period). ■ Overdue WO (all WOs that are overdue at a specified date). ■ WO material requirement (part number, WO numbers, quantity required, quantity on hand, quantity on order). ■ WO labor requirements (craft categories, WO #, required and available hours). ■ WO detail (WO number, date, work description). ■ Downtime summary (WO number, lost operation hours, cost). ■ Account history (account number, WO numbers, category, failure code, cost). ■ Activity (category, number of WOs, percentage of WOs by categories). ■ Performance [WO number, date required, date completed, difference (days), percent completed in time]. ■ Cost summary (WO number, labor cost, material cost, outside cost, total cost). ■ Labor summary (WO number, hours, labor cost) Material summary (WO number, part number, material cost). ■ Equipment history (equipment number, WO numbers, category, failure code, cost). ■ Cost variance (WO number, estimated cost, actual cost, percent variance)

- 44. F-Vendor Module: Stores information about suppliers & outside contractors. It contains all vendor information such as name, address, fax, telephone, email..etc. Vendor reports ■ Address labels (print address labels for all or selected vendors) ■ Contact reports (vendor ID, name, contact, address) ■ Cost variance (percentage of cost increases)

- 45. G-Inventory Managing inventory is an important part of maintaining any plant/facility. Inventory control keeps track of items in stock, indicates when stock falls to user-defined reorder points, creates POs to restock needed items. It keeps track of locations for each part. This module keeps track of quantities in stock. You can specify a reorder point (ROP) and an economic order quantity (EOQ) for each item. When the parts reach ROP, CMMS generates a requisition for those parts and a PO upon approval. Inventory module interacts with equipment, WO, planning/scheduling, and purchasing.

- 46. Inventory Module Function •Issues. Keep track as items are depleted from inventory. Items are typically withdrawn against WOs. •Receipts. Add items to inventory as parts are received. Items are typically received against purchase orders (POs). •Allocations (reserve). Items are reserved for WOs. Inventory Data Entry •Description. •Substitute. •Where Used الغيار قطعه وصف(سير,بليه,بلف.....الخ) الضروره حاله فى القطعه هذه محل تحل أن يمكن التى البدائل حاله فى مفيد ويكون الغيار من القطعه هذه تستخدم التى المعدات أرقام كل كتابه يتم أخرى معده من قطعه فنأخذ متوفره غير غيارها وقطع بالمعده عطل وجود

- 47. • Transfers • Vendor • Cross reference • Open WOs • Open POs • Physical counts المخزن والى من النقل وسيله تحديد غيار قطعه كل مورد اسم تحديد Between your code, catalogue code & manufacturer code. Show all open WOs Show all open WOs Use mobile technology or paper based work • Location • Unit of measure • Re Order level • Quantity عمل لكل المحدده الكميهjob شراء طلب عمل يتم الطلب حد عن الكميه تقل فعندما الطلب حد معدل تحديد Gallon, feet, rolls, m, cm مخزن كذا فى المخزون متابعه من نتمكن حتى القطعه مكان كتابه

- 48. Inventory Module Inputs Open WOs Spare parts Cross Reference The Vendor Name Quantity Spare parts Unit of Measure Spare parts Location Spare parts Place of Use Transfer Method Re Order Level Spare parts Substitutes Open POs

- 50. Inventory Module Outputs Parts usage history* Obsolescen ce Parts* Below ROP* Parts usage history by Eq Spare Parts Cost Spare Parts Location* Inventory on hand* Parts Allocation* Inventory Transactions*

- 51. Inventory reports ■ Below ROP (part number, description, quantity on hand, ROP, quantity on order) ■ Location (part number, description, location, shelf/bin) ■ Inventory on hand (part number, description, quantity, unit cost, extended cost) ■ Part cost (part number, description, vendor, cost) ■ Obsolescence (part number, description, date last used, date last received) ■ Summary (part number, description) ■ Parts usage history (part number, description, number of transactions, quantity used, quantity on hand, extended cost) ■ Parts usage history by equipment (same as the preceding point, queried by equipment number) ■ Inventory transactions (part number, addition, subtraction, quantity) ■ Parts allocation (part number, description, WO number, quantity available, quantity allocated) ■ Print labels (part number, description, location)

- 52. H- Purchasing There are two steps to purchasing with CMMS: ■ Requisition ■ Actual issuing of the POs First, a requisition is generated for all parts below ROP (When quantity on hand plus quantity on order is less than the reorder point, the system sends a flag requesting that the item be reordered.). This becomes a request for purchasing items. Someone must then approve this request. Once approved, the PO is issued. With one key command, a CMMS should be able to issue all POs that are due and approved. You should be able to revise a PO before the vendor processes it. Some CMMS have provision to receive price quotes. A request for quotes is sent out to vendors in the database. This is how a CMMS saves you money in purchasing parts. The vendors are aware of competition and you get the best prices. ROP detected Purchase Request Requisition ManagerApproval request PO Issued To the Vendor (request for quotation) Parts received and arrived to the store house

- 53. Purchasing Module benefits: •Dates. •PO status. •Receiving. •Blanket PO. •Currency. •Closing POs. Track data required, data promised, data received. Using codes defined by user (status codes). When parts received, cost is updated, quantity is updated so inventory activity is recorded as well Convert between different currencies. Like WOs, you go through a process of initiating, approving, receiving, and closing a PO. Complete report

- 54. Purchase Module PO Closed Currencies Parts Receiving PO Status Update Purchase Order Date Purchase Order Date Received

- 56. Purchase Module Outputs Vendor Performance* Cost Variance* Parts Received* This module interact with Inventory, Budget & WOs Open PO*

- 57. PO reports ■ Open PO (PO number, PO date, vendor, required date, promised date, cost) ■ Parts received (PO number, PO date, part number, quantity ordered, quantity received) ■ Cost variance (PO number, part number, price promised (or last price), price charged, percentage of variance) ■ Vendor performance (PO number, date promised, date delivered, late days, percentage variance)

- 58. Interaction Between Purchase, WO, & inventory Modules.

- 59. I- Budgeting This module allows you to set up various budget accounts and allocate funds to each account (e.g., repairs, PM, projects). Every time a transaction takes place (e.g., WO, parts issue), the cost is charged to the appropriate account number. CMMS keeps track of money spent toward each account . It serves two purposes: 1. To control the expenditure 2. To help set up budget for the following year 1. To control the expenditure االنفاق معدالت فى التحم 2. To help set up budget for the following year الماليه االحتياجات متوسط معرفه سنويا

- 60. Budget Module Outputs Budget Variance Budget Cost Material Variance Labor Variance

- 61. Integration of Modules: االموديالت بين الربط أهميته:الموديل بباقى ربطها عند الى عليها الحصول اليمكن موديل كل مخرجات من الكثير. Equipment PM Labor Planning Inventory Purchasing Vendor Budjet WORK ORDER For Ex. To get cost data you have to connect WO with Labor & Pm & Equipment. To get Maintainability KPIs you have to connect WO with Pm & Equipment.

- 62. Condition Monitoring in the System ال فى دمجها يتمtasksعمل يتم مشكله اكتشاف وعند معده لكل الوقائيه بالصيانه الخاصهWork orderلتنفيذ ال ضمن الحاله هذه فى ويندرج المناسب الوقائى االجراءPM WOفحص نتيجه عمله تم انه مالحظه ويضاف الوقائيه الصيانه باستخدام. By the Mean of CMMS: PdM Inspection Report CMMS (CBM Module) PM WO (Automatically Initiated) Condition monitoring parameters are known and recorded for each equipment.

- 63. Common CMMS Programs Available in the Market: ERP CMMS ERP CMMS

- 65. Maintenance Performance Evaluation Parameters “KPIs” Indicator Current Value Target Value Reliability/Maintainability Eq Availability % <98% Eq Reliability % <95% Mean Time Between Failures MTBF (Eq hrs) Increasing trend Mean Time Between Failures MTBF (Operating hrs) Increasing trend Mean Time To Repair MTTR (hrs) Decreasing trend Mean Time Between Repair MTBR Increasing trend Overall Equipment Effectiveness (OEE) Preventive Maintenance (include PdM) CM/PM (number) 3-10% CM/PM (duration) <10% CM/PM (Cost) <10% CM WO/PM WO (number) 3-10% CM WO/PM WO (Cost) <10% Backlog Ratio

- 66. Indicator (Continue) Current Target Work Order Overdue (number) PPM Labor Hrs/ Emergency Labor Hrs 9:1 PPM WOs / CM WOs from inspection 6:1 Planning & Scheduling Planned/schedule Compliance- All Labor Hrs Actually Completed to Schedule/ Total Maintenance Labor Hrs Available >90% Planned Work- Total Labor Hrs Planned/ Total Labor Hrs in Scheduled >95% Maintenance Supervision Maintenance Control-Planned Labor Hrs/ Unplanned Labor Hrs 1:9 Crew Efficiency- Actual Hrs Completed / Estimated Time Financial Maintenance Cost/ Net Asset Value Over Time Hrs as % of Total Labor Hrs <5% Process Availability %- Actual Production/ Total Planned Production Downtime Losses Trend Annual Maintenance Cost/ Total Operation Cost Trend Total Maintenance Labor Cost/ Total Maintenance Cost

- 67. Indicator (Continue) Current Target Performance Indicators % of Emergency WOs <10% % of Planned Work >80% % of Up Time >90% % of Predictive Planned Maintenance Work

- 68. KPI Source of Information Optimum Value Total No of Downtimes Covered by WOs / Total No of Downtimes. Work Order & Production Data 100% Percentage of Total Maintenance Hours Covered by WOs (Total Labor Hrs Covered by WO/ Total Labor hrs). Work Order 100% Ratio of fake or inaccurate WOs to Pertinent WOs. Work Order Percent of Work Orders Covered by planned job packages Work Order not less than 80% Percent of Total Paid Maintenance Hours Captured by Work Order Charges Work Order & Account Dept 100% Work Order System Evaluation Parameters “Used for The Operational Level”

- 69. Downtime Analysis by Work Classes PPM PdM Inspection Lubrication Cleaning Corrective Breakdown Calibration Overhaul Test Emergency Urgent Critical Environment Improvement Adjusts Minor repairs

- 70. Downtime Analysis by Equipment:

- 71. 0 5 10 15 20 25 30 35 40 Inspection Routine Planned PM Unplanned Training Maintenance Labor Hrs Analysis: Hours

- 73. Calculate total software costs: ■ System analysis and definition ■ Program installation and testing ■ Data entry (plant personnel or outside help) ■ Software acquisition cost ■ Installation cost ■ Cost of modification, if any ■ Training cost ■ Operating cost ■ Software maintenance cost ■ Calculate total hardware costs: ■ Hardware ■ Maintenance ■ Supplies Calculate total cost & include every possible cost factor. Determine net savings. Subtract total fixed cost from total savings to find net savings. Compute return on investment (ROI). A ROI calculation for justifying a CMMS project results in a value that represents the savings (benefits) received from a CMMS against the total cost of implementing it.

- 74. total savings total costs-total costs ROI% = -------------------------------------------------- x100 total costs

- 75. أمرى لى ويسر صدرى لى اشرح رب Eng. Mohammed Hamed Ahmed Soliman The American University in Cairo Email: mhamed206@yahoo.com m.h.ahmed@ess.aucegypt.edu https://eg.linkedin.com/in/mohammedhamed Tel: +201001309903