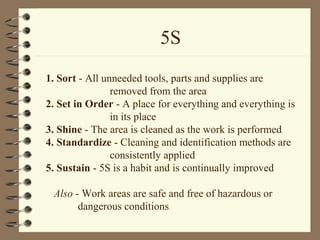

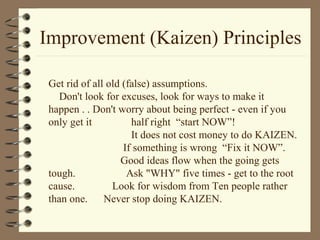

This document provides an overview of 5S, which refers to five disciplines for maintaining a visual workplace: Sort, Set in Order, Shine, Standardize, and Sustain. It describes each of the 5S disciplines and provides examples of work areas before and after implementing 5S. The document also introduces related concepts like kaizen (continuous improvement), lean manufacturing (reducing waste), and defines terms in Japanese. It emphasizes that 5S is foundational for improvement efforts and ensuring business survival by creating a cleaner, safer, and more organized work environment with less waste.