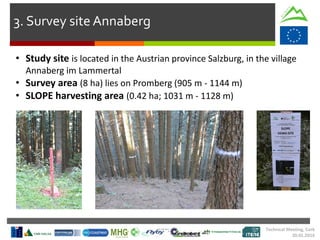

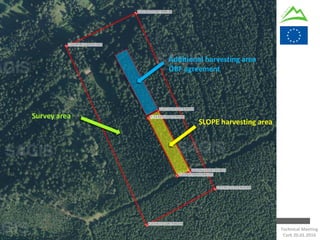

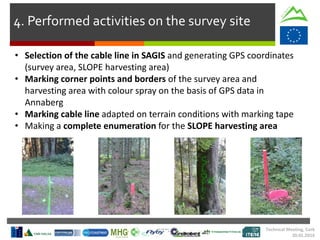

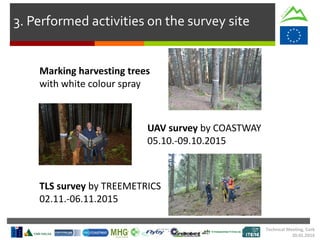

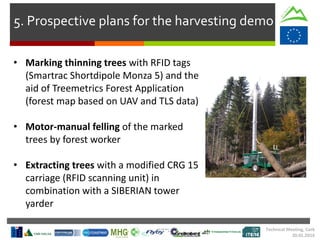

The document provides an overview of activities for piloting the SLOPE demonstrator. It summarizes preparations for demonstrators in Sover, Italy in spring 2016 and Annaberg, Austria in autumn 2016. It describes the survey site in Annaberg including the characteristics of the forest stand and outlines activities already performed at the site. It then presents prospective plans for the harvesting demo in Annaberg, including marking trees with RFIDs, felling, extracting and processing trees. An agreement with Austrian Federal Forests to support the demo is also summarized.

![References & Picture sources

Last downloaded on 21.12.2015:

• http://www.holz-broeker.de/images/ansicht-luftbild-saegewerk-schnittholz.jpg

• http://www.riebli-forst.ch/bilder/maschinen/holz-lkw04_b.jpg

• http://www.rfidjournal.com/lib/x/a/assets/2009/11/5350-3.jpg

• http://www.dronelife.com/cms/sites/default/files/product/eBee_0.jpg

• http://www.woodbusiness.ca/images/heads-arbro.jpg

• http://www.sparpointgroup.com/images/uploadedImages/Images/02.10.11.FARO-in-the-woods.png

• http://www.blaueberge.at/region-sommer.html#!lightbox[annaberg]/1/

• http://www.greifenberg.it/carrellipescanti/crg15s/gallery_2.jpg

• http://www.greifenberg.it/teleferiche/siberian/gallery_6.jpg

Picchi G. technical meeting Annaberg-UAV survey

Technical Meeting, Cork

20.01.2016](https://image.slidesharecdn.com/4thtechnicalmeeting-wp7-161025094540/85/3rd-Technical-Meeting-WP7-25-320.jpg)