Embed presentation

Download to read offline

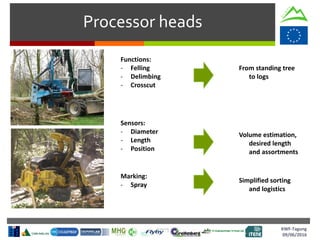

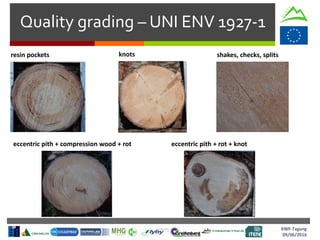

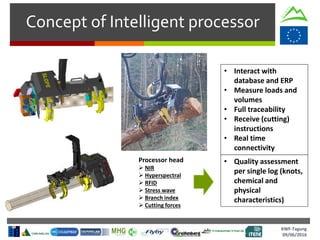

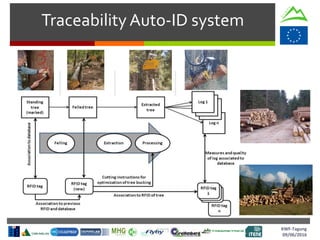

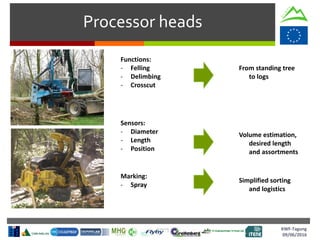

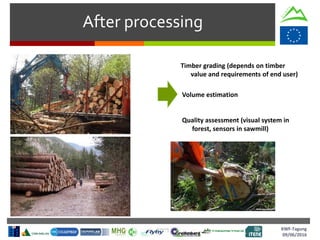

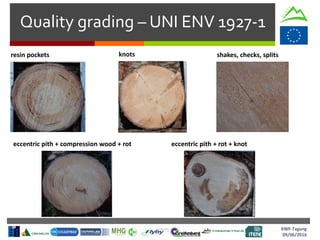

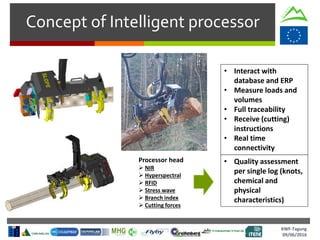

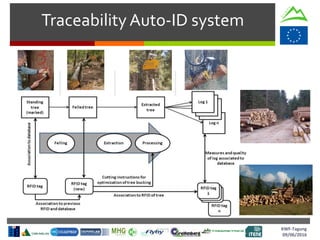

The document discusses processor heads for logging machines and quality assessment of logs. Processor heads are used for felling, delimbing, and crosscutting trees. Sensors can measure diameter, length, and position. Marking and sorting by volume, length, and assortment allows for simplified logistics. Quality is assessed visually in the forest and with sensors in sawmills. A concept for an intelligent processor head includes sensors like NIR, hyperspectral imaging, RFID, and stress waves to interact with databases, measure loads and volumes, and provide full traceability and quality assessment of individual logs. RFID marking associates quality indexes to logs for full traceability of timber products.