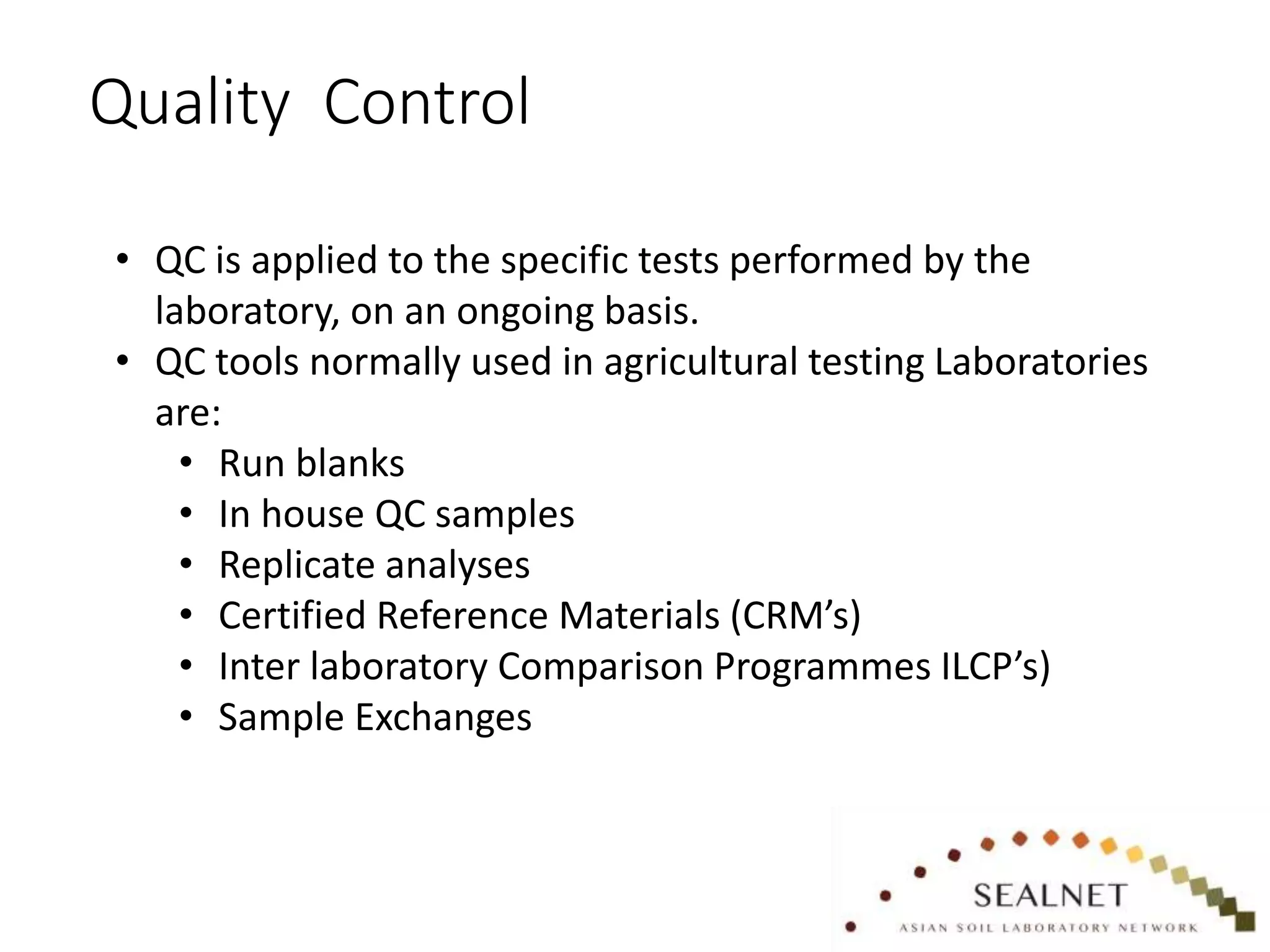

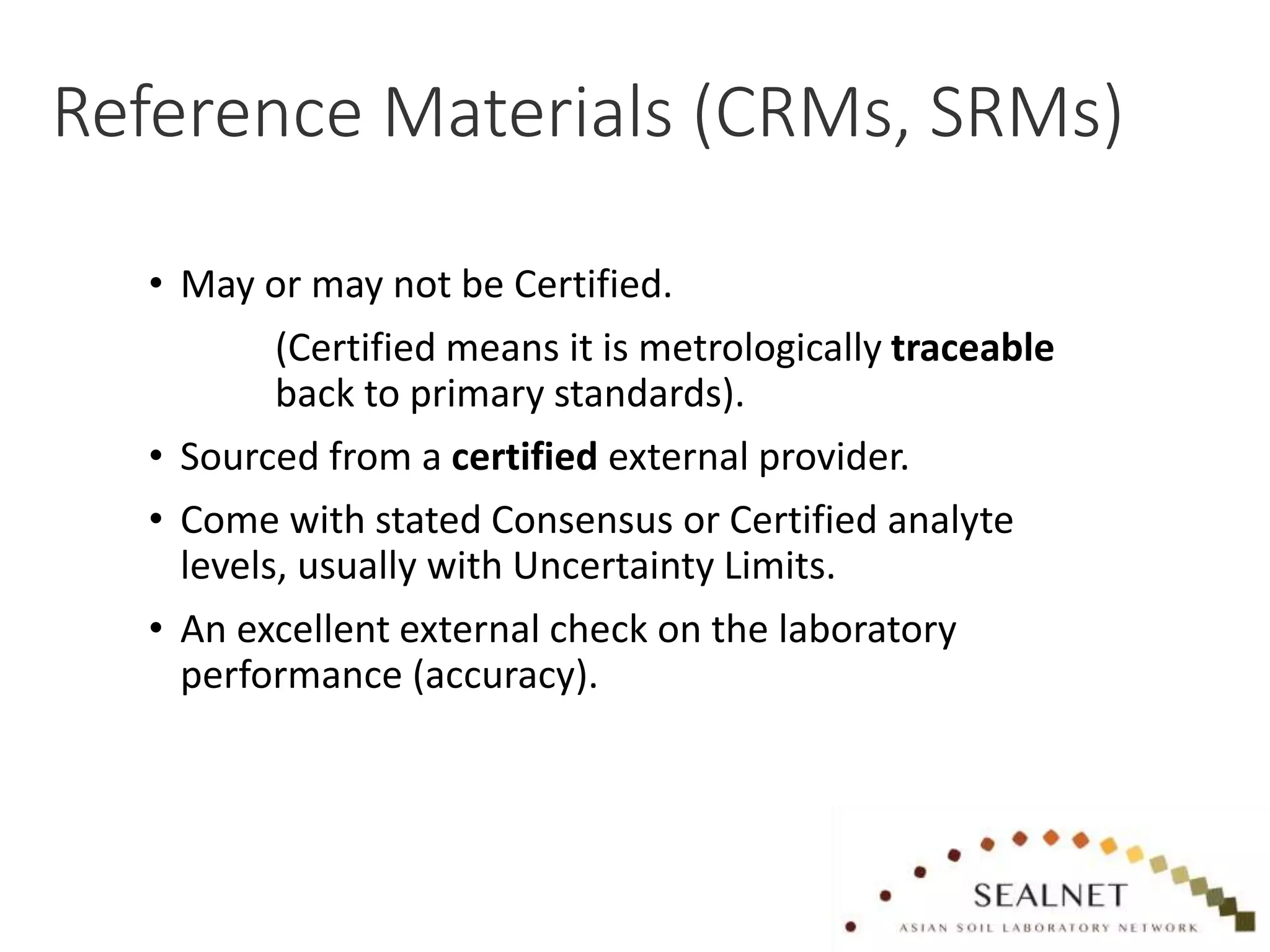

The document outlines the Quality Management System (QMS) and Quality Assurance/Quality Control (QA/QC) procedures in laboratories, specifically focusing on agricultural testing. It details various QC tools and methodologies, including the use of standards, duplicates, and recovery spikes to ensure the accuracy and reliability of test results. Additionally, it emphasizes the importance of ongoing calibration, reference materials, and adherence to acceptance criteria for effective laboratory performance.

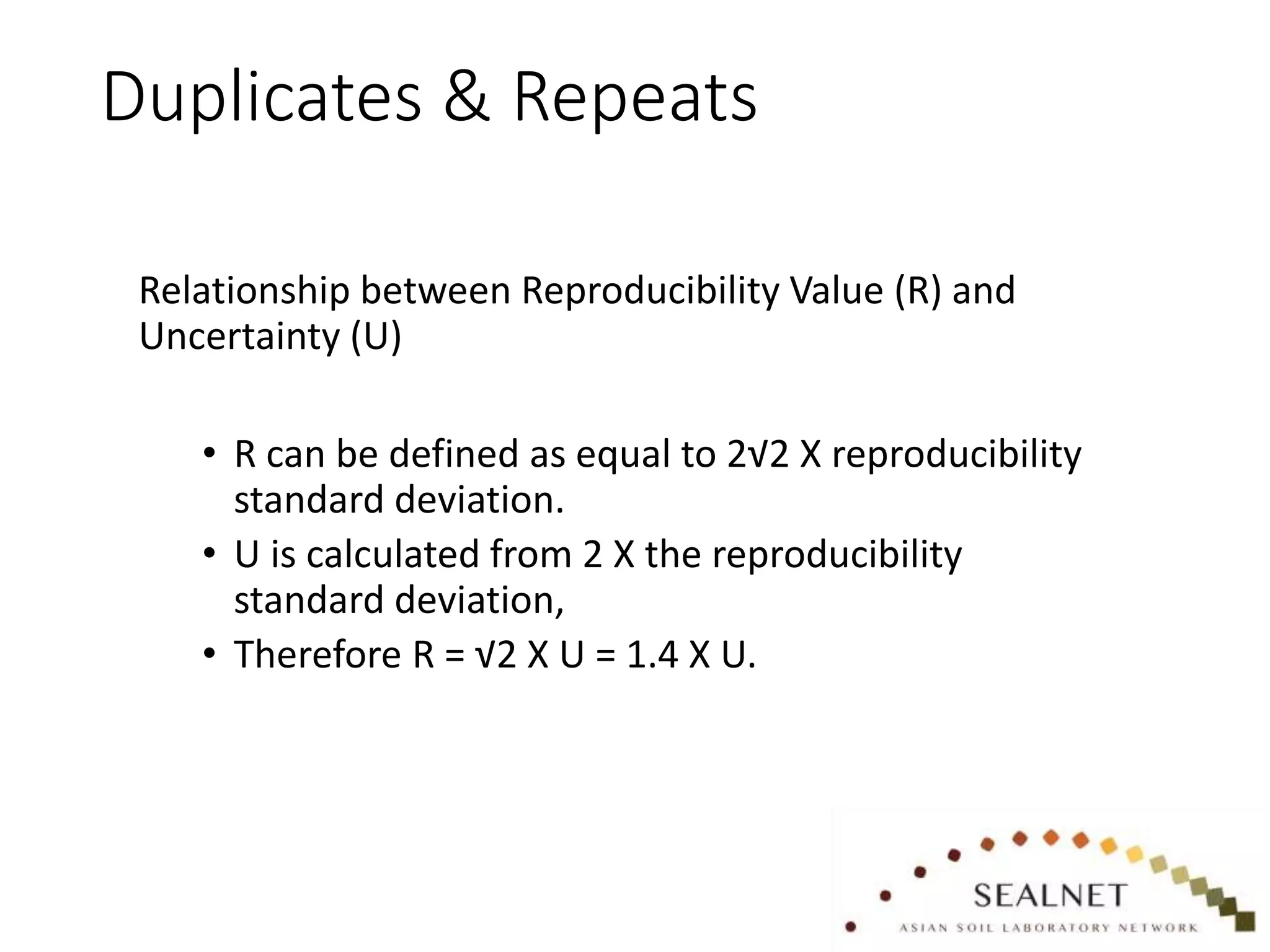

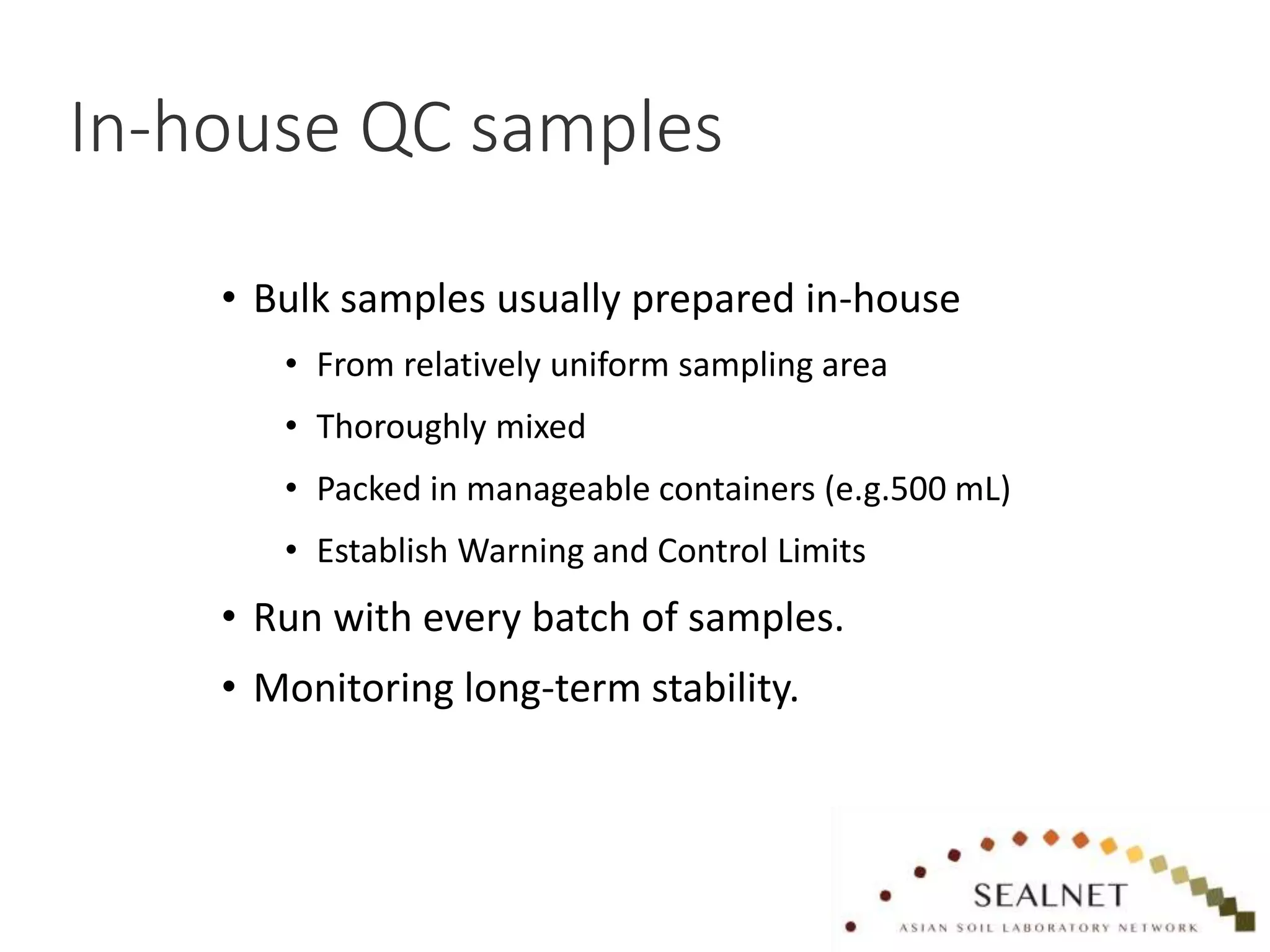

![Some acceptance criteria for verification checks

Chemistry Centre, Qld, Australia

Check Acceptance Criteria

Instrument QC ICPOES

- two monthly repeatability check

- two monthly limit of quantitation

check

- fortnightly check of sensitivity

- %RSD < 5%

- <50% change from month to

month

- if >30% change in sensitivity

of any one analyte

investigate causes.

Ion chromatograph

- repeatability check

- monitoring of system pressure, total

conductivity & retention time

- %RSD < 5%

- Retention Time ± 1 min

Calibration of

Instrument

Most instruments R2 > 0.99

Old vs new

standards

Normal concentration

Ultra-trace concentrations

< 3% at mid-range (25%-70% of

calibration range)

< 10% at mid-range (25%-70% of

calibration range)

Blanks < 2 times PQL

Duplicates (of

full method)

Minimum frequency = 1 in 20 - Difference < uncertainty (same run)

- Difference < 1.4 times x uncertainty

(different runs)

Recovery Spikes %Recovery at ultra-trace concentrations

= [Spiked Conc–Sample Conc] x 100

Spiked Conc

100% ± 20%](https://image.slidesharecdn.com/laboratoryqaqcday2presentation1-200703114327/75/4th-SEALNET-meeting-item-8-Training-on-internal-quality-control-Overview-of-internal-quality-control-measures-18-2048.jpg)