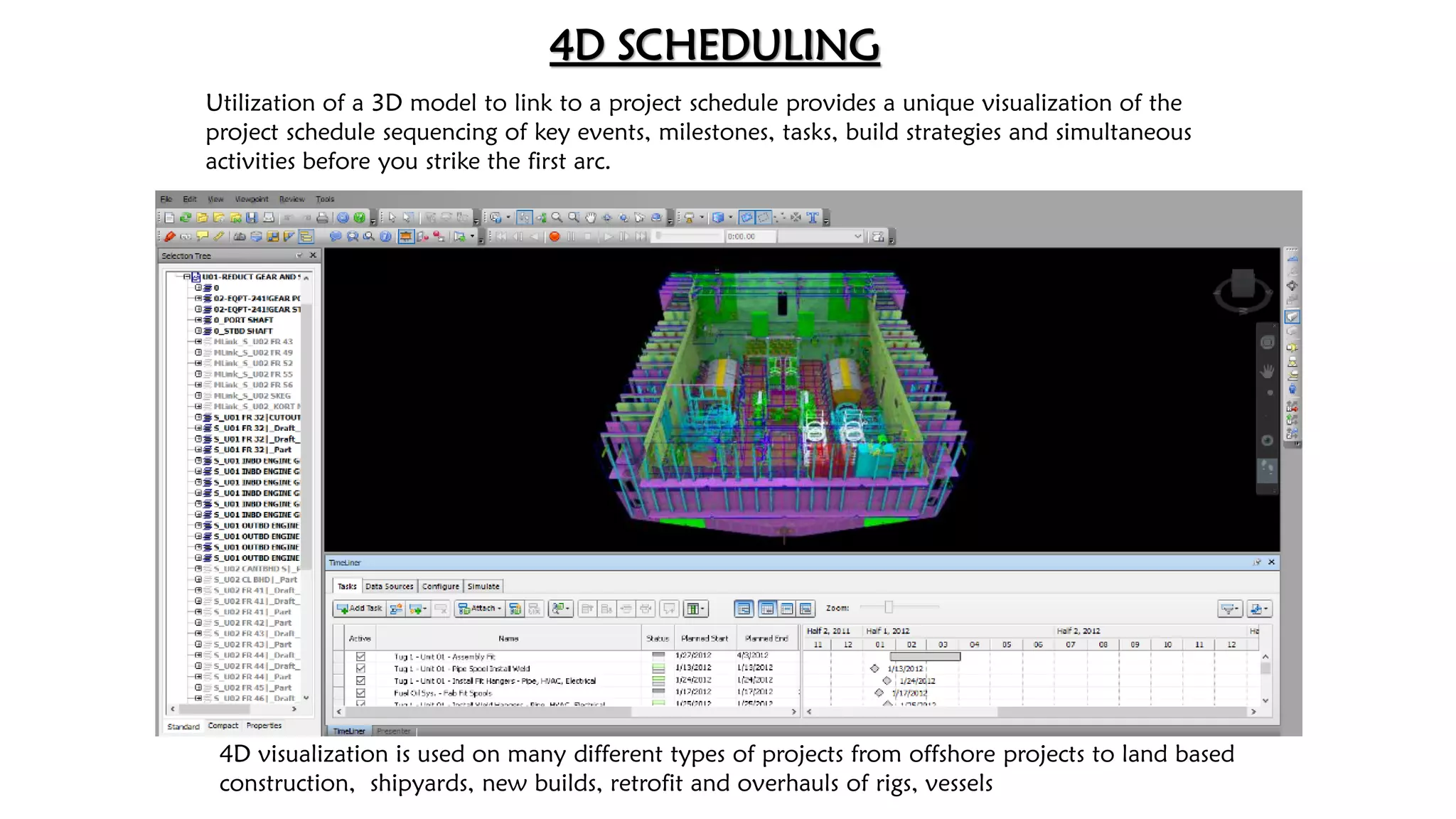

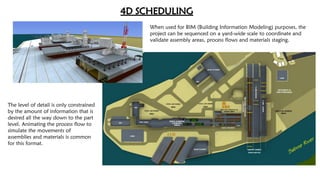

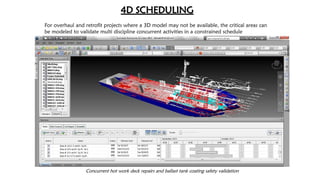

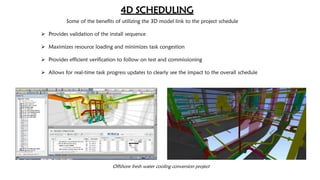

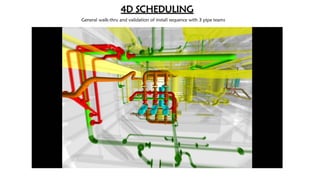

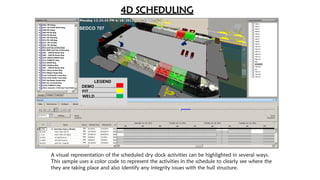

4D visualization links a 3D model to a project schedule, allowing visualization of sequencing, milestones, tasks, and simultaneous activities. The level of detail can go down to individual parts. Animating process flows simulates assembly and material movement. When used for BIM, the entire project yard can be sequenced to coordinate areas, flows, and staging. For projects without 3D models, critical areas can still be modeled to validate concurrent multi-discipline activities in constrained schedules. Benefits include validating sequences, optimizing resources, verifying tests, and allowing progress updates.