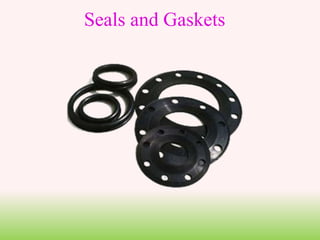

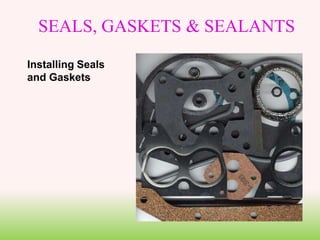

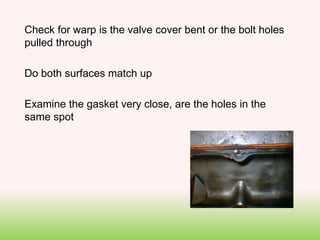

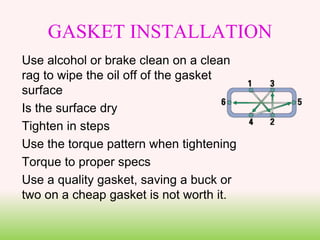

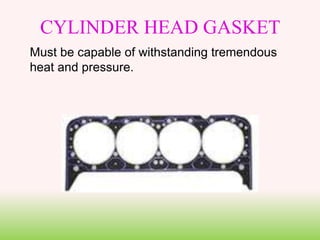

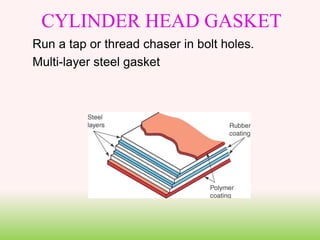

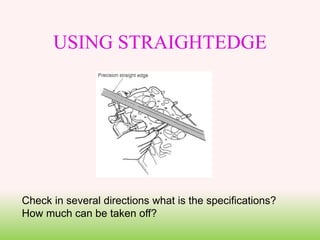

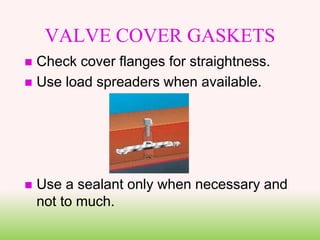

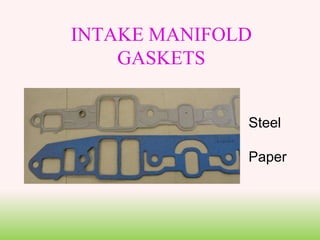

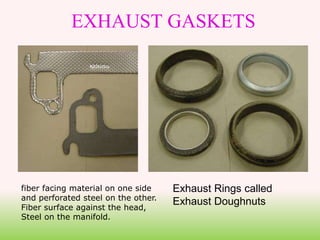

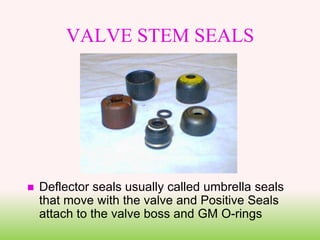

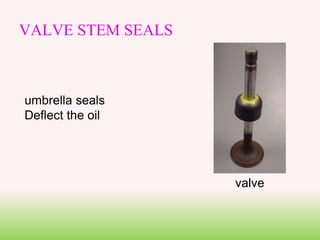

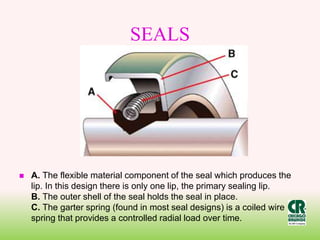

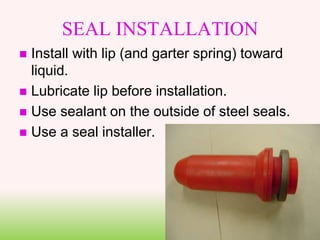

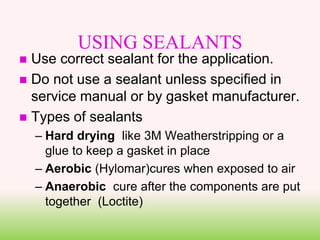

Seals and gaskets are used to prevent leaks and confine fluids like oil, water, gas and exhaust. Common gasket materials include cork-rubber, synthetic rubber and embossed steel. Leaks can occur if gaskets or seals are worn, parts are bent, fasteners are too loose or tight, or gaskets are installed improperly. Proper installation of gaskets and seals requires cleaning surfaces, checking for fit, and tightening correctly in steps according to specifications to prevent future leaks.