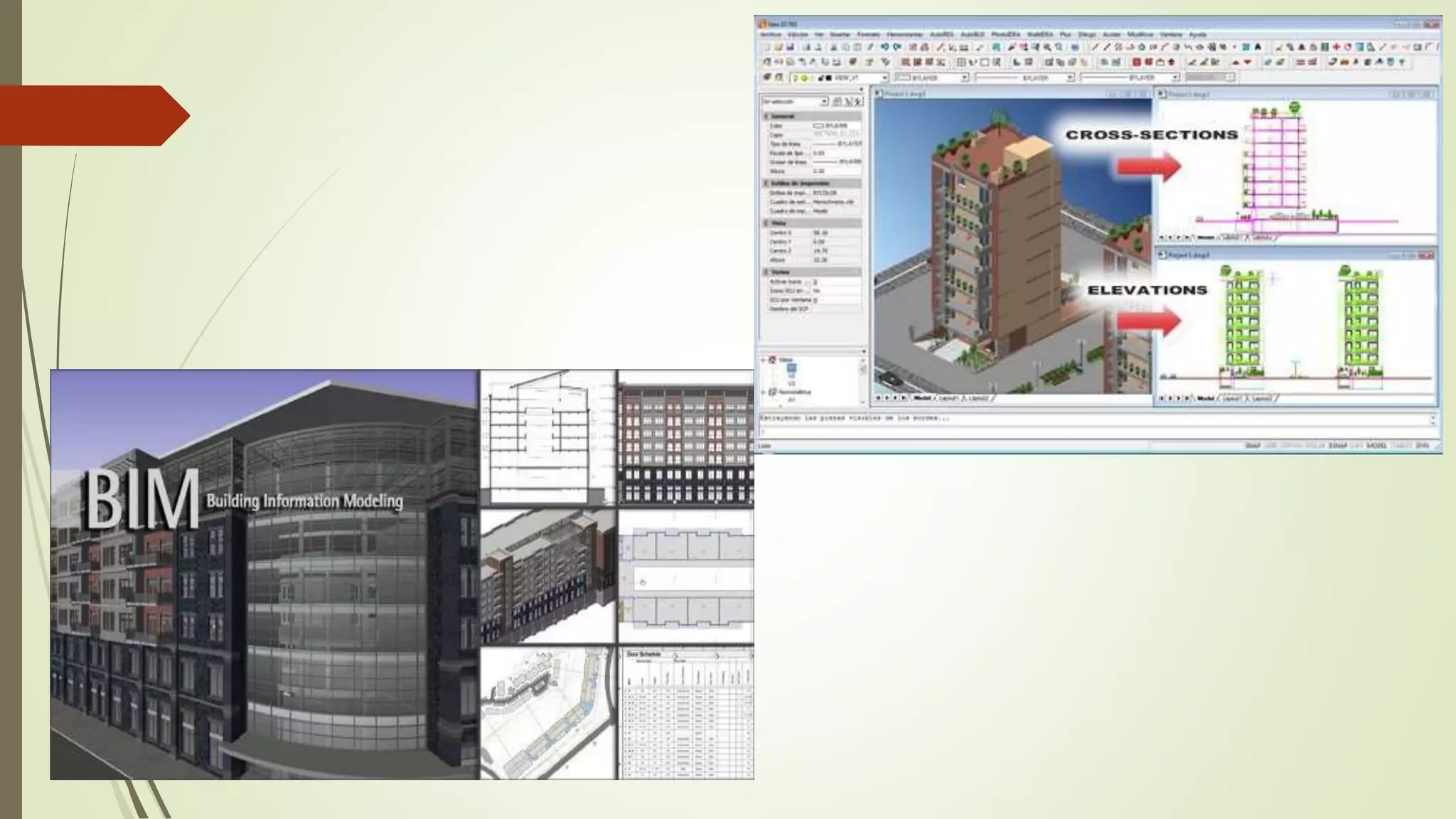

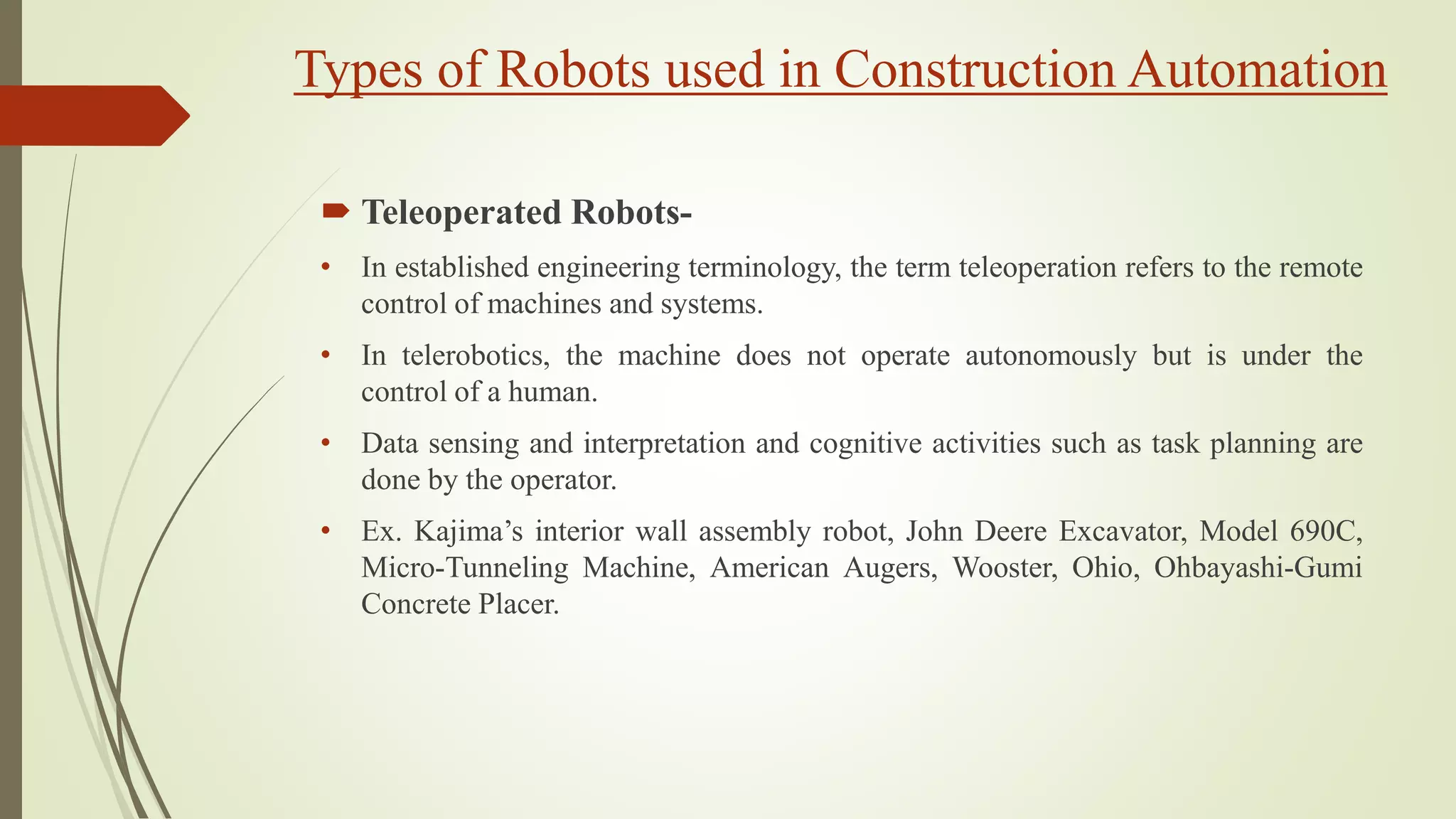

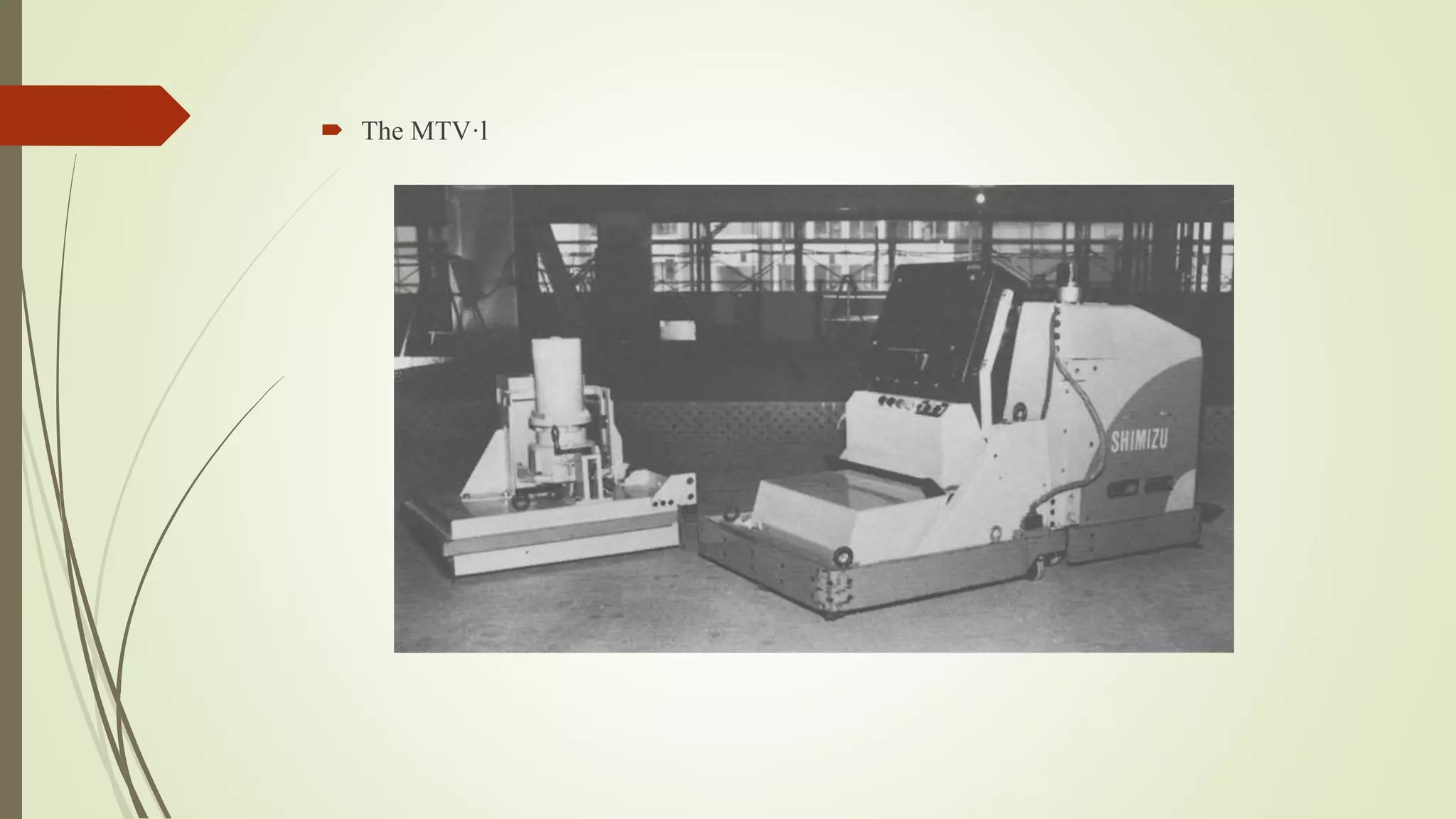

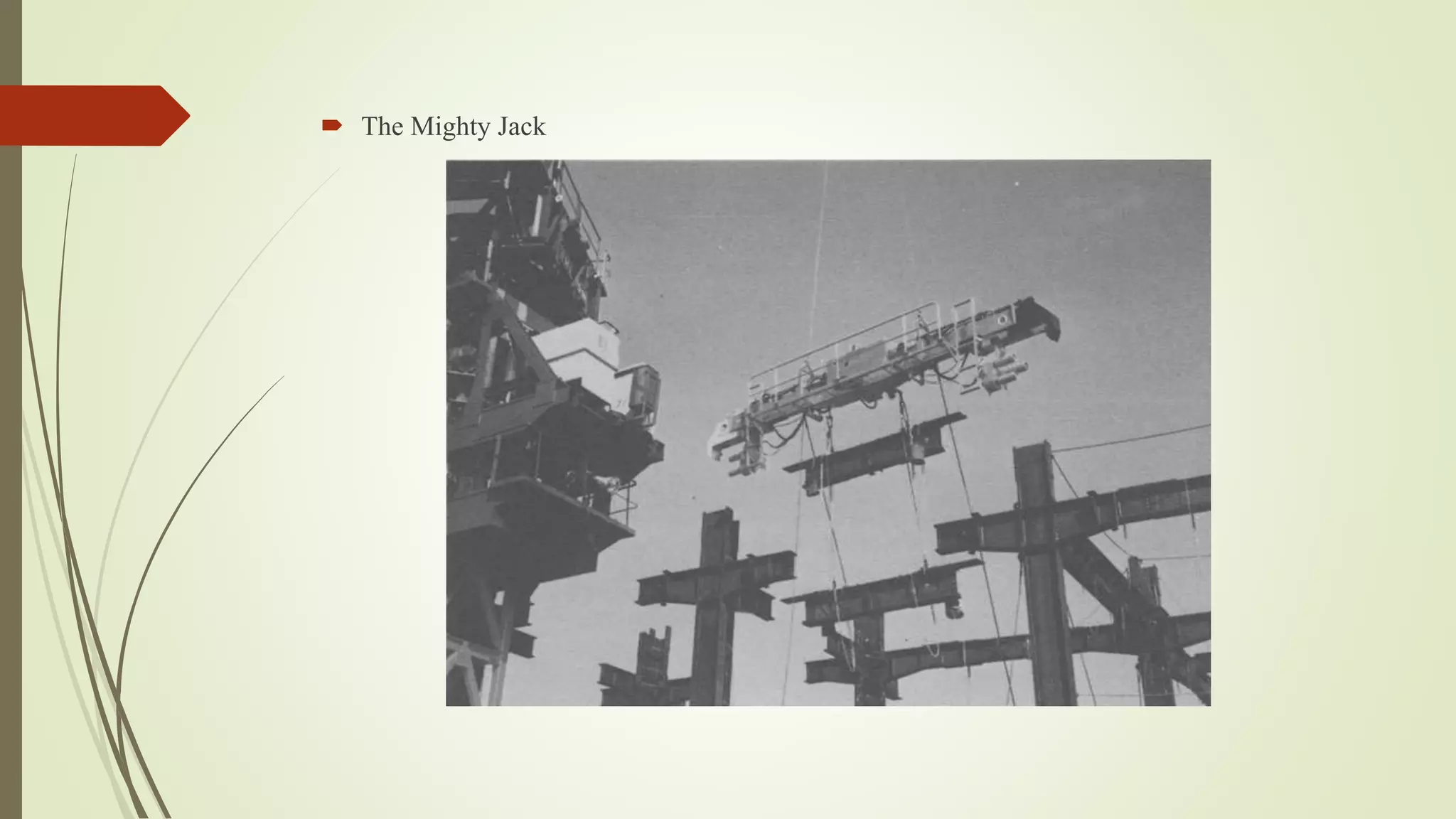

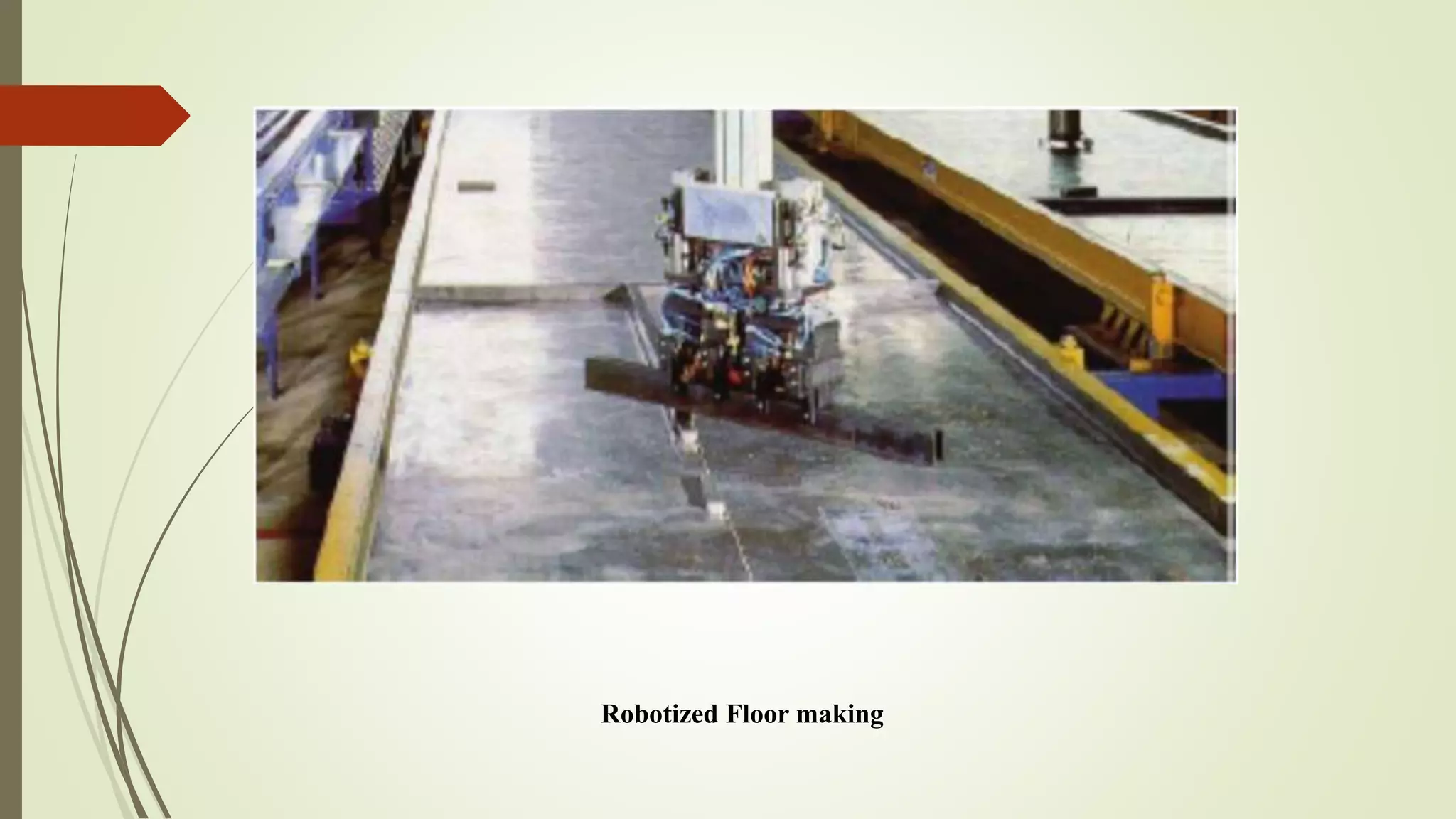

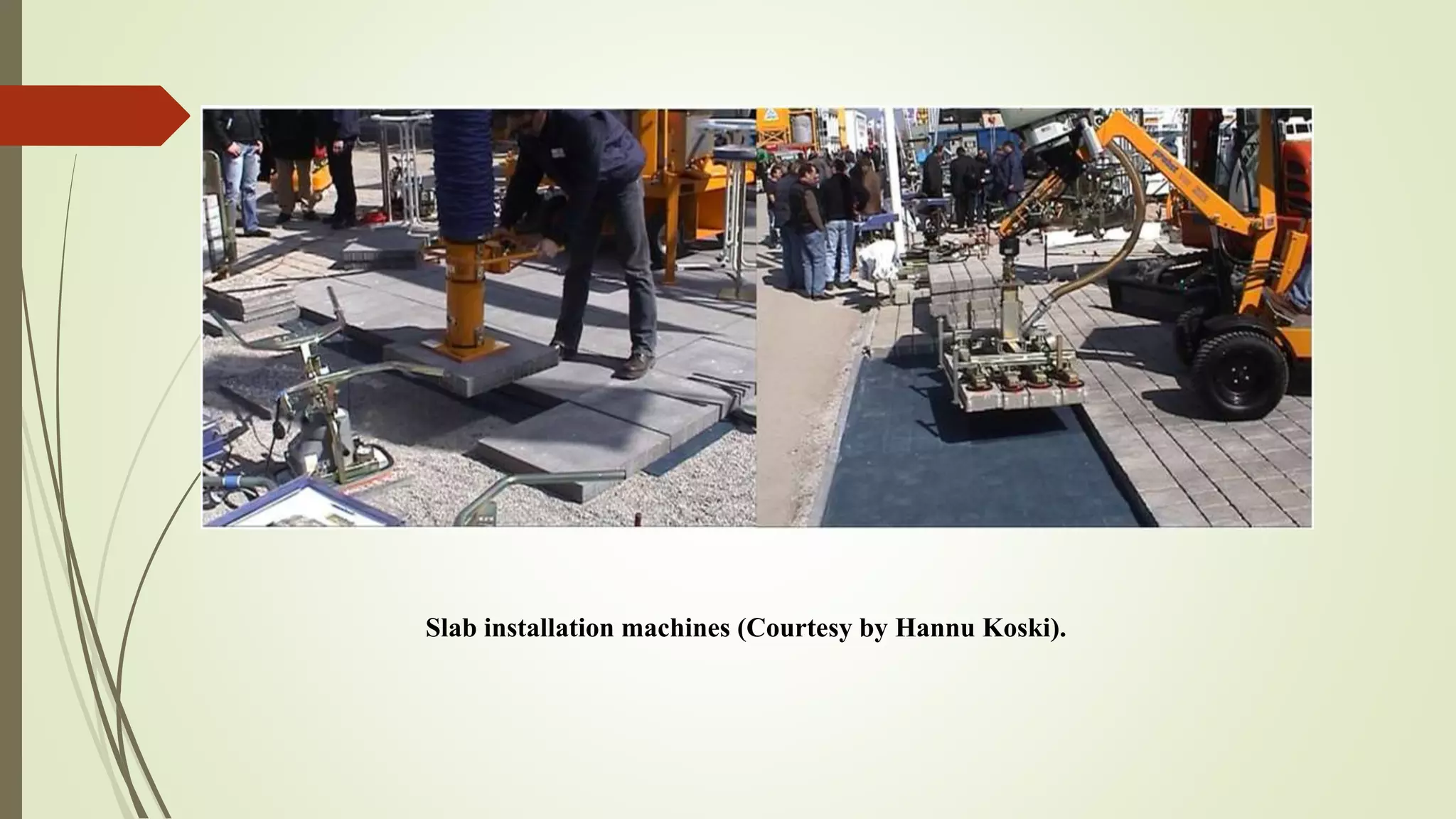

This document discusses automation in the construction industry. It begins by defining automation and describing some automated systems used. It then discusses the history and objectives of automation in construction, including the use of building information modeling (BIM) to plan robotic motions at construction sites. Various types of construction robots are also described, such as teleoperated, programmed, and cognitive robots. Examples are provided of specific robots used for tasks like spraying, welding, and grinding. The document concludes that integrating automation and robotics can improve productivity, quality, and safety in construction.