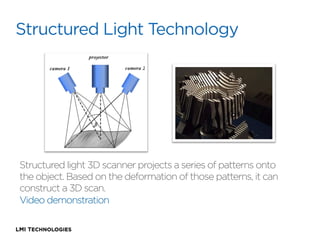

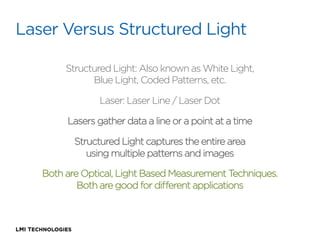

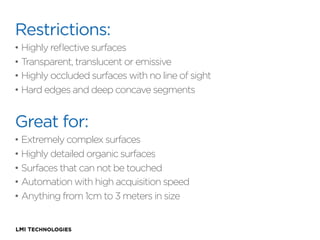

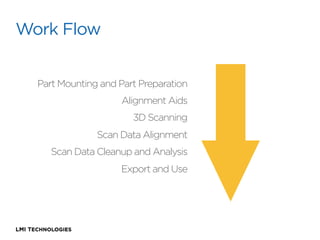

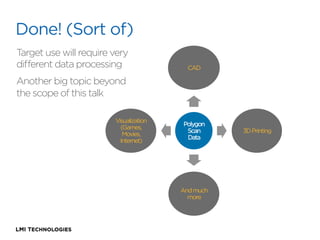

The document provides an overview of structured light 3D scanning technology developed by LMI Technologies, highlighting its applications, workflow, and challenges. It explains the scanning process, including the importance of proper preparation and alignment to achieve accurate results, as well as the differences between structured light and laser scanning. Additionally, it addresses potential restrictions while emphasizing the technology's suitability for complex surfaces and high-speed automation.