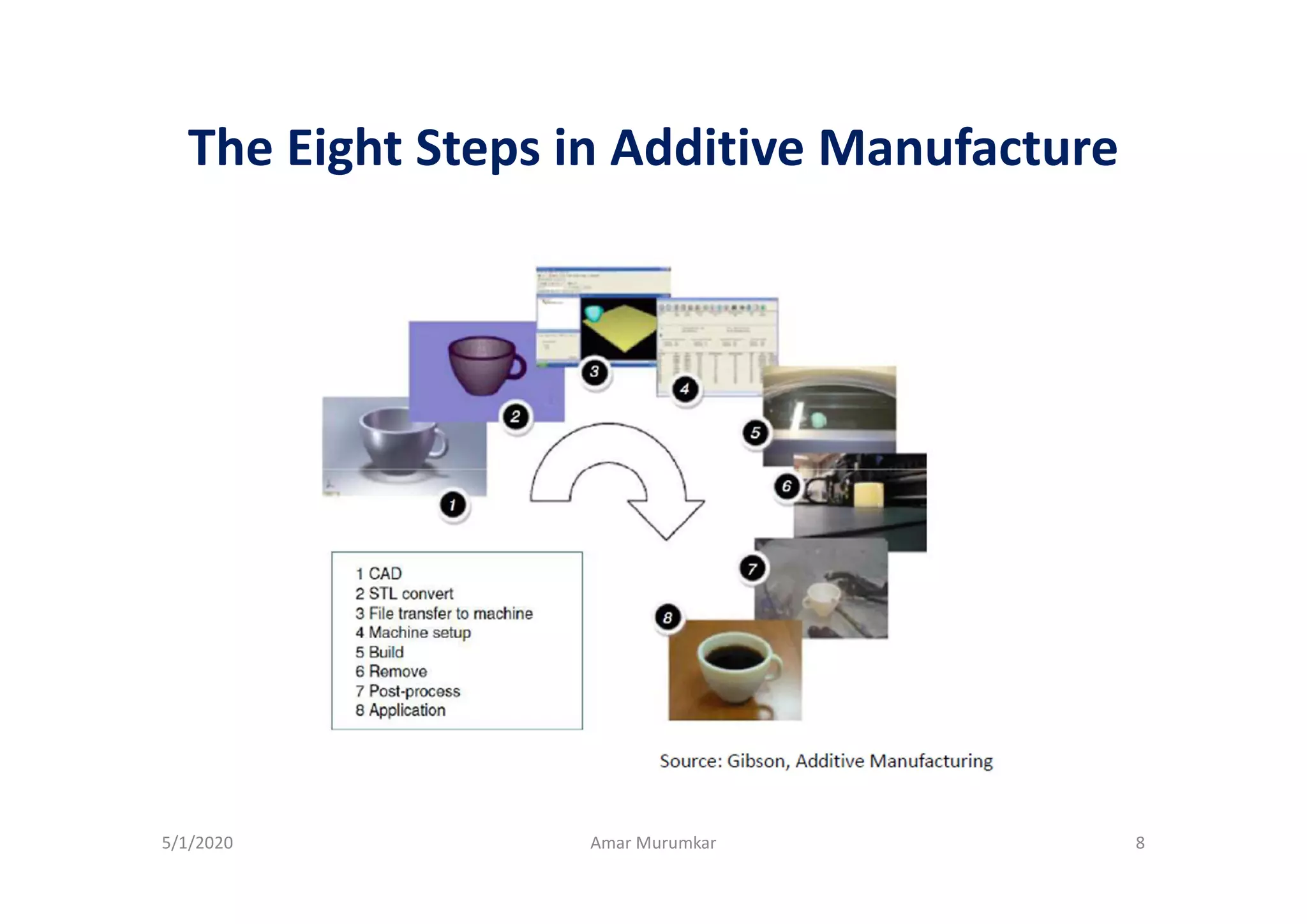

The document discusses additive manufacturing (AM) and rapid prototyping (RP) processes. It describes the historical development of AM and defines it as a process that builds up a 3D component in layers by depositing material based on a digital 3D design. Stereolithography (SLA) is discussed as one of the earliest AM techniques, using a laser to cure liquid resin into layers to build a part. The Solid Object Ultraviolet-Laser Printer (SOUP) system is also described, which uses a laser to scan and solidify resin according to cross-sectional data. Finally, the document outlines the eight generic steps in the AM process.