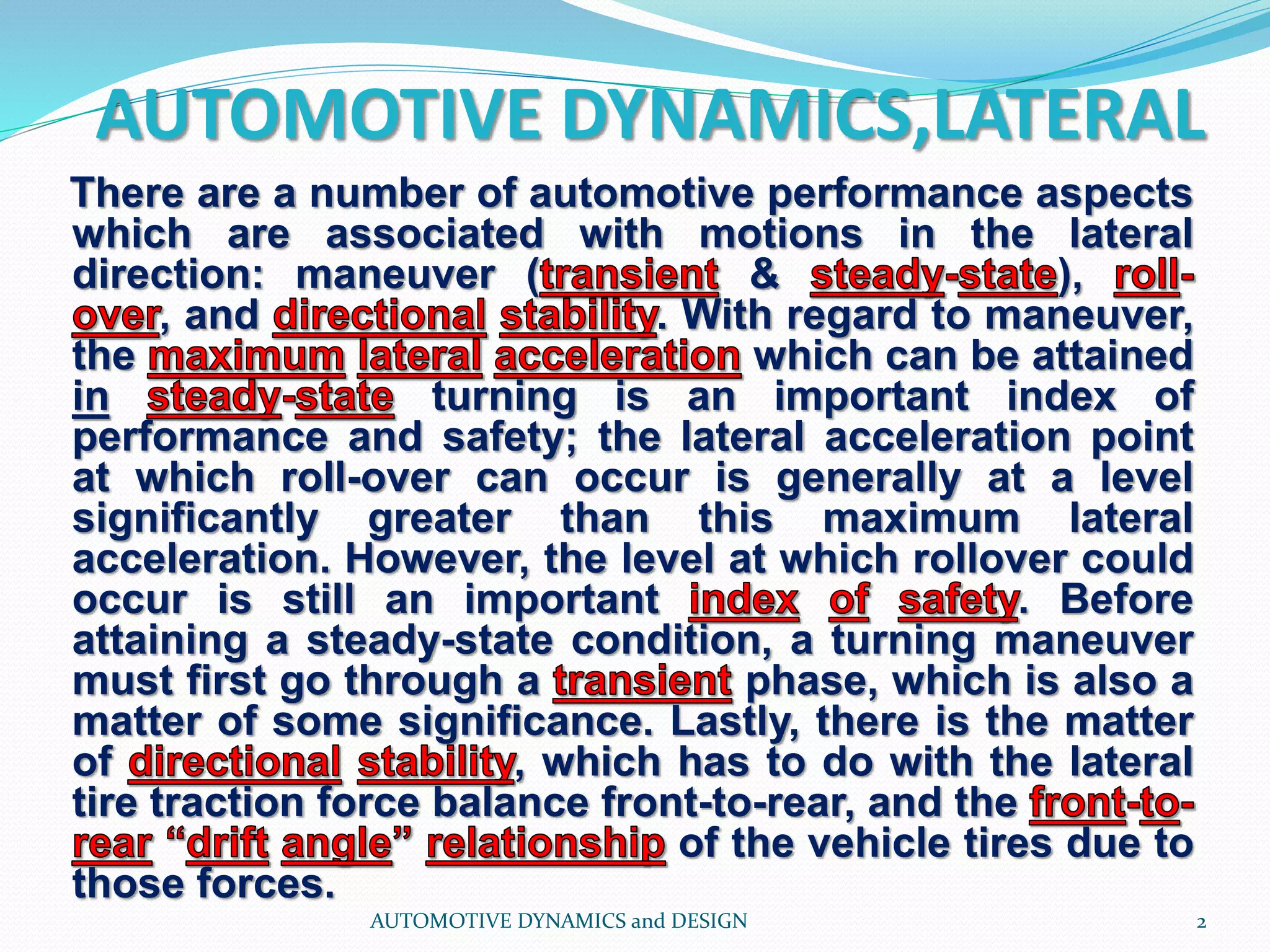

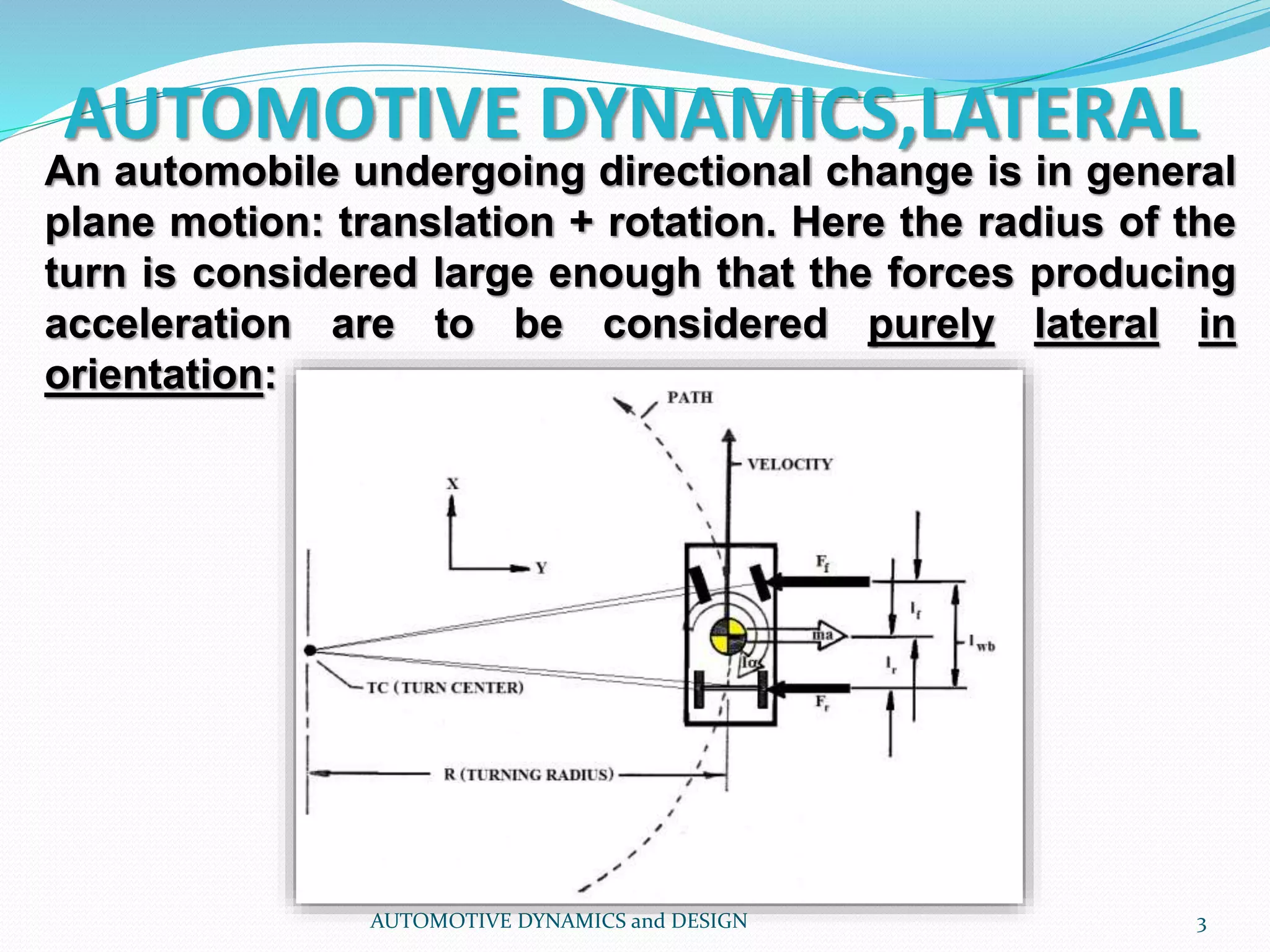

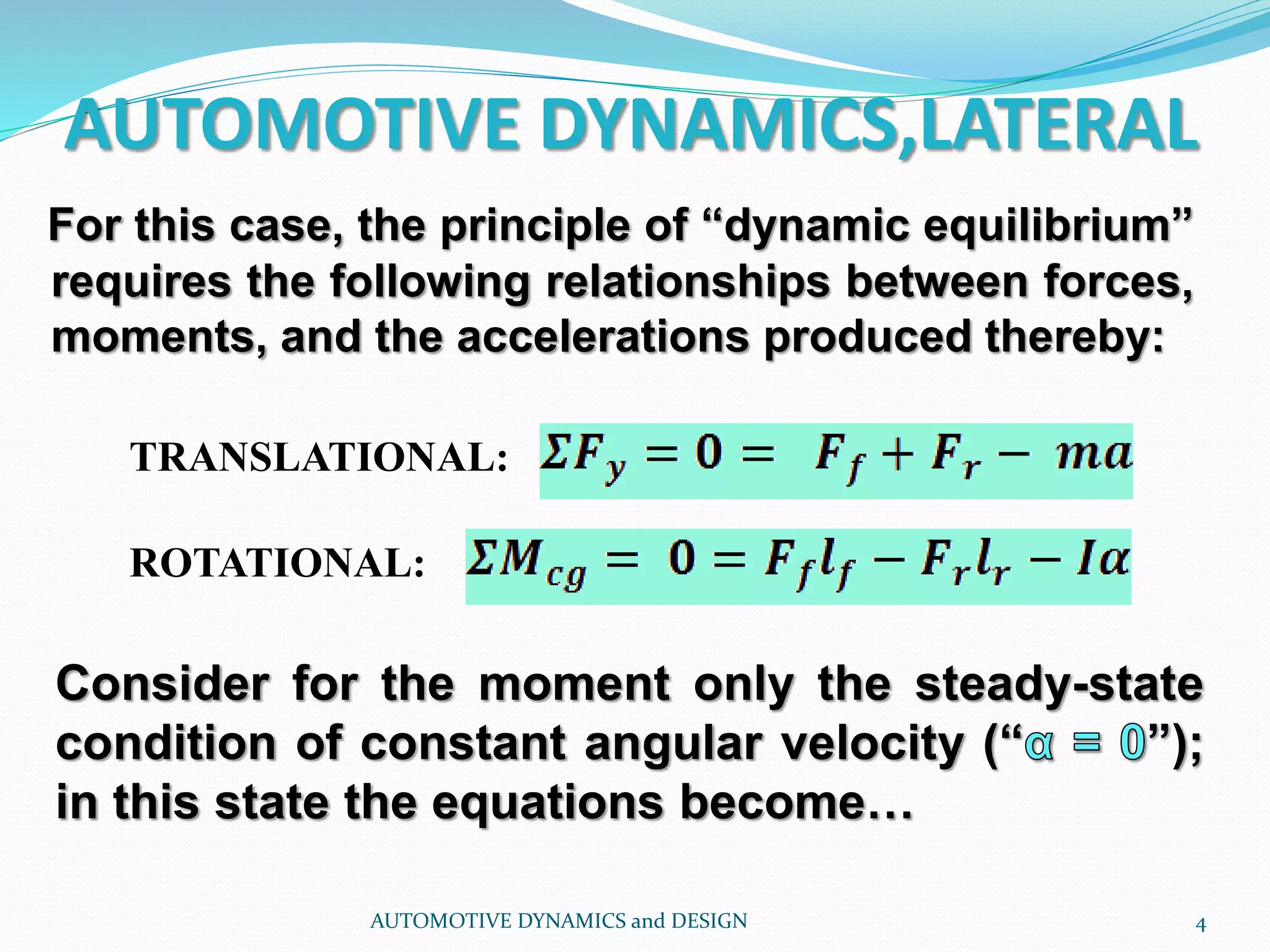

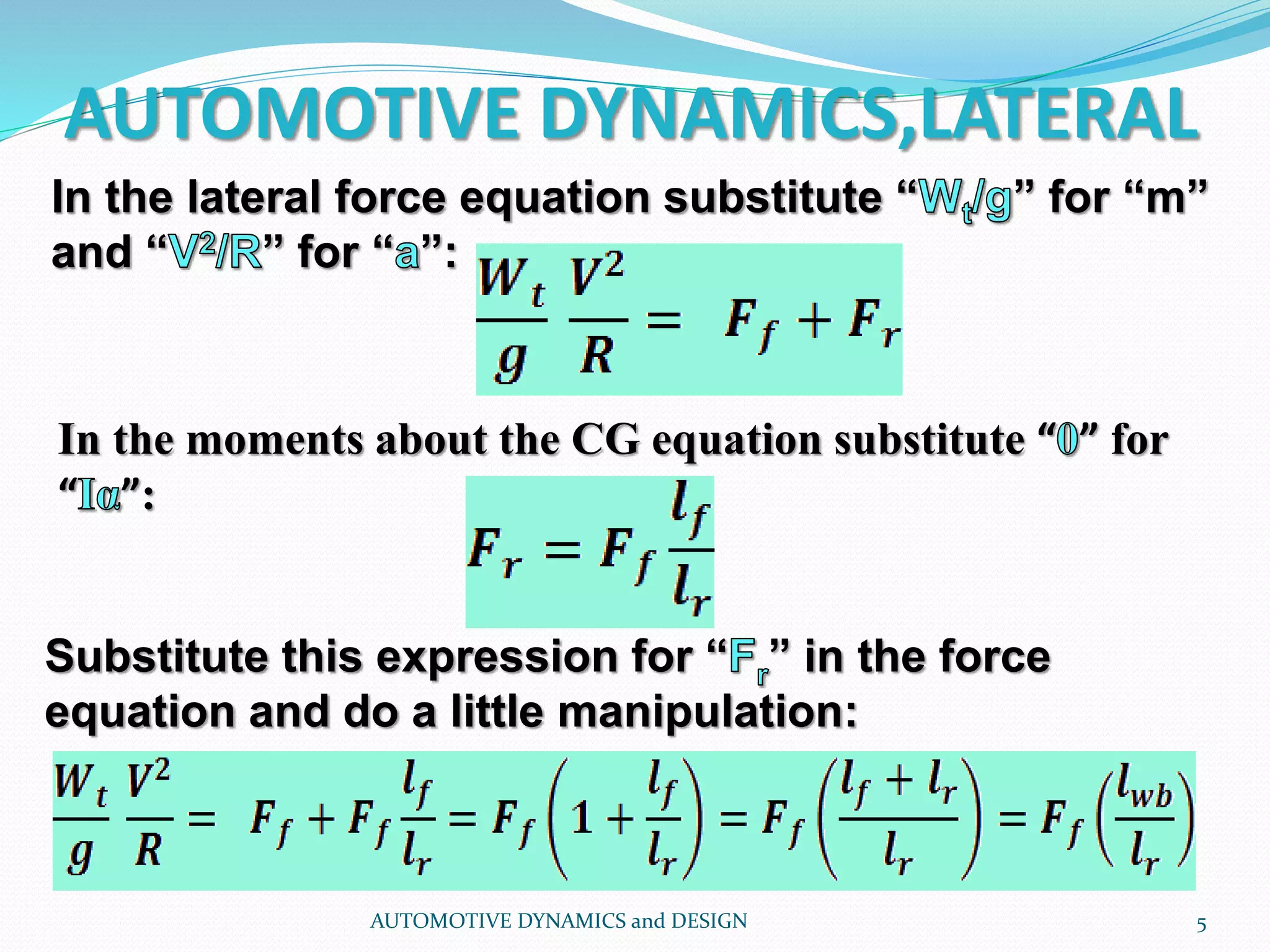

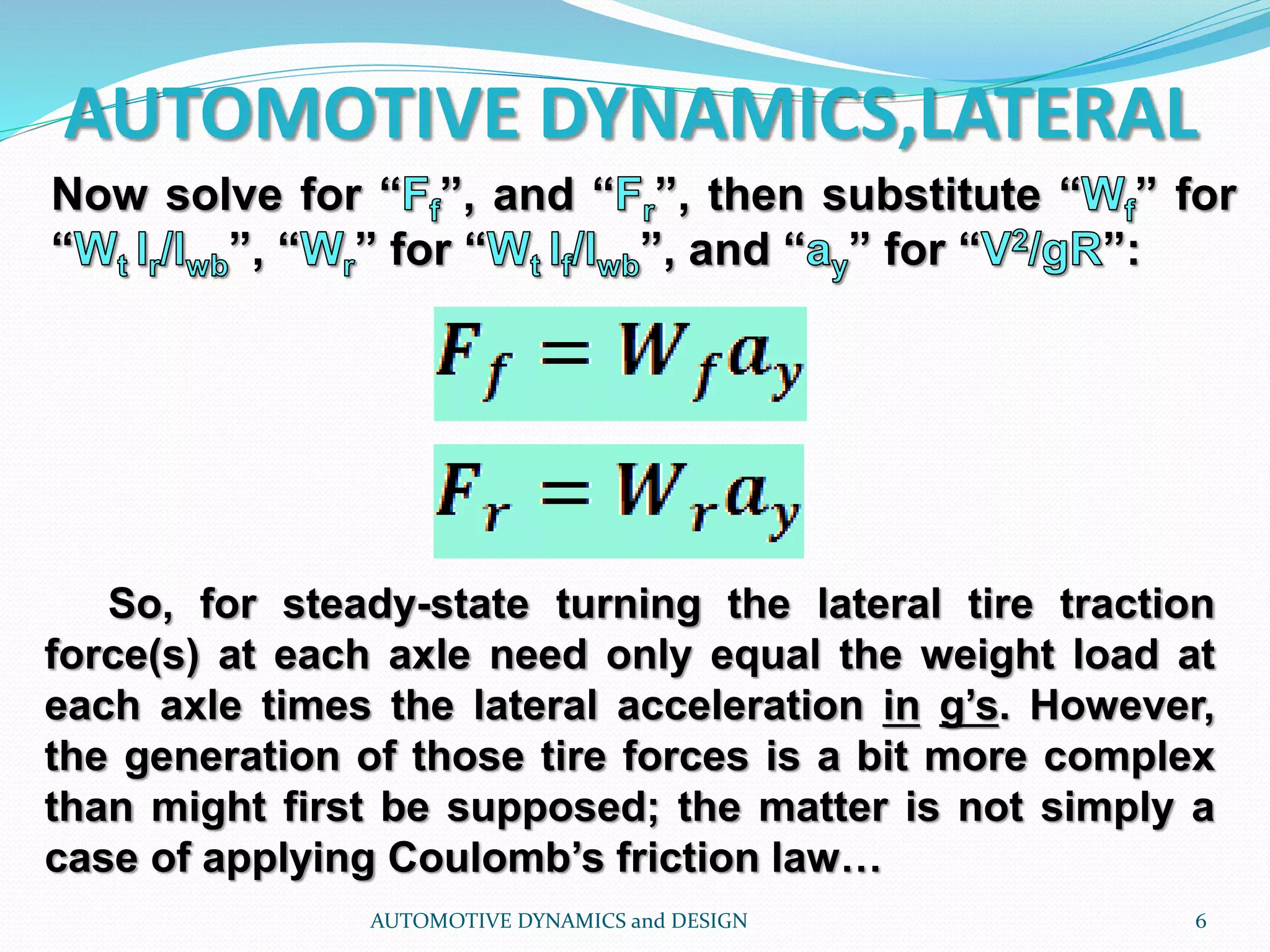

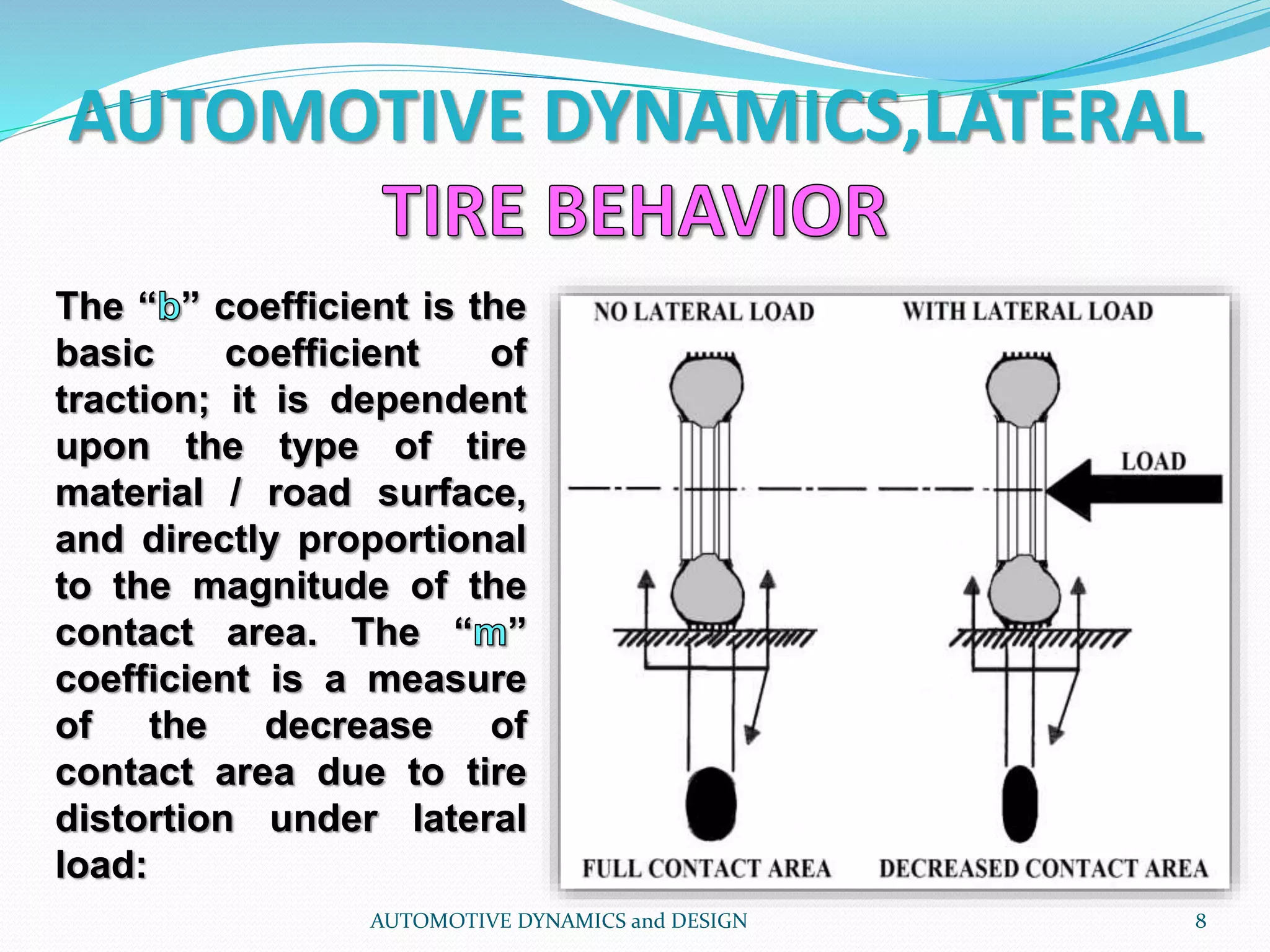

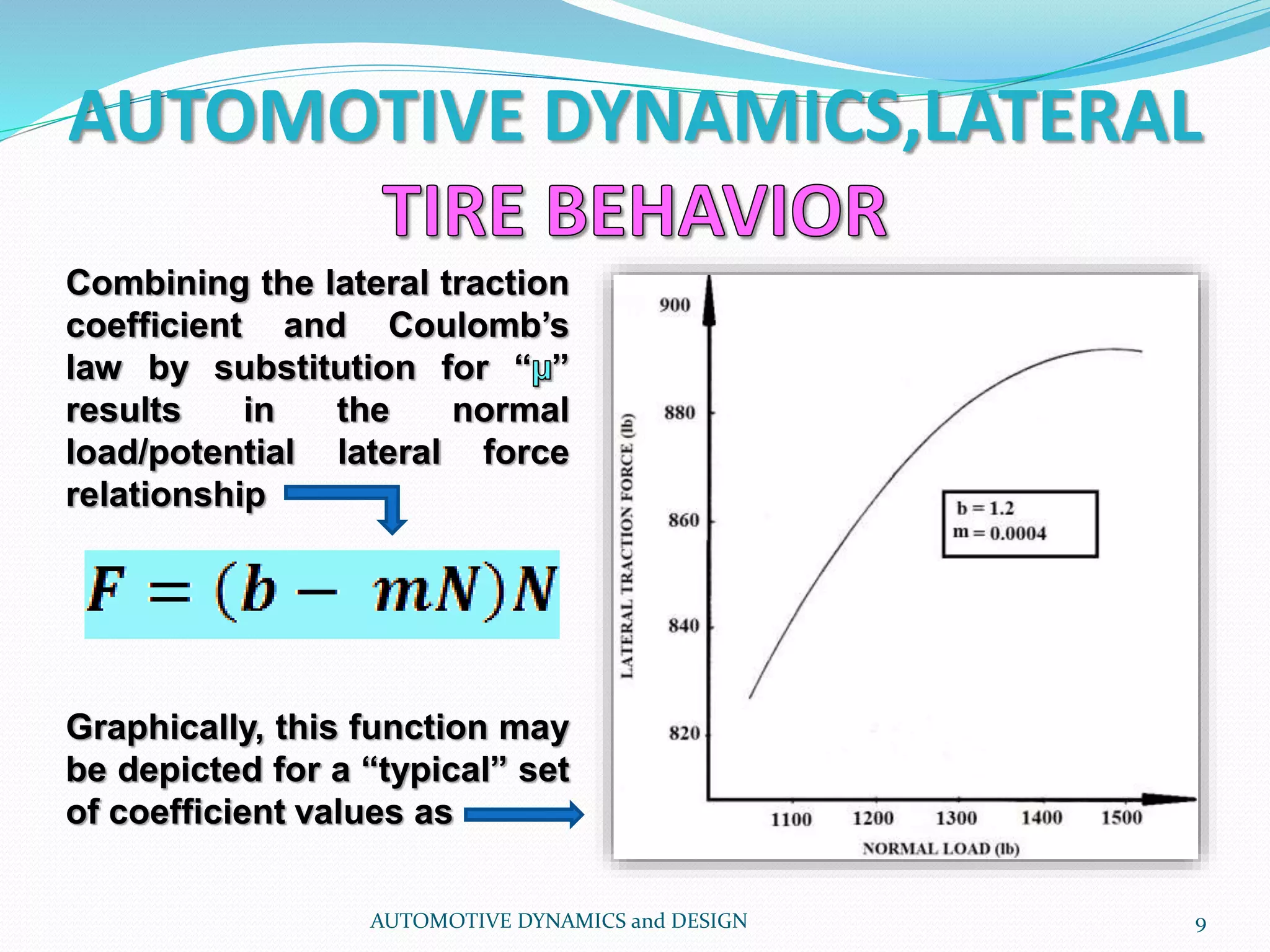

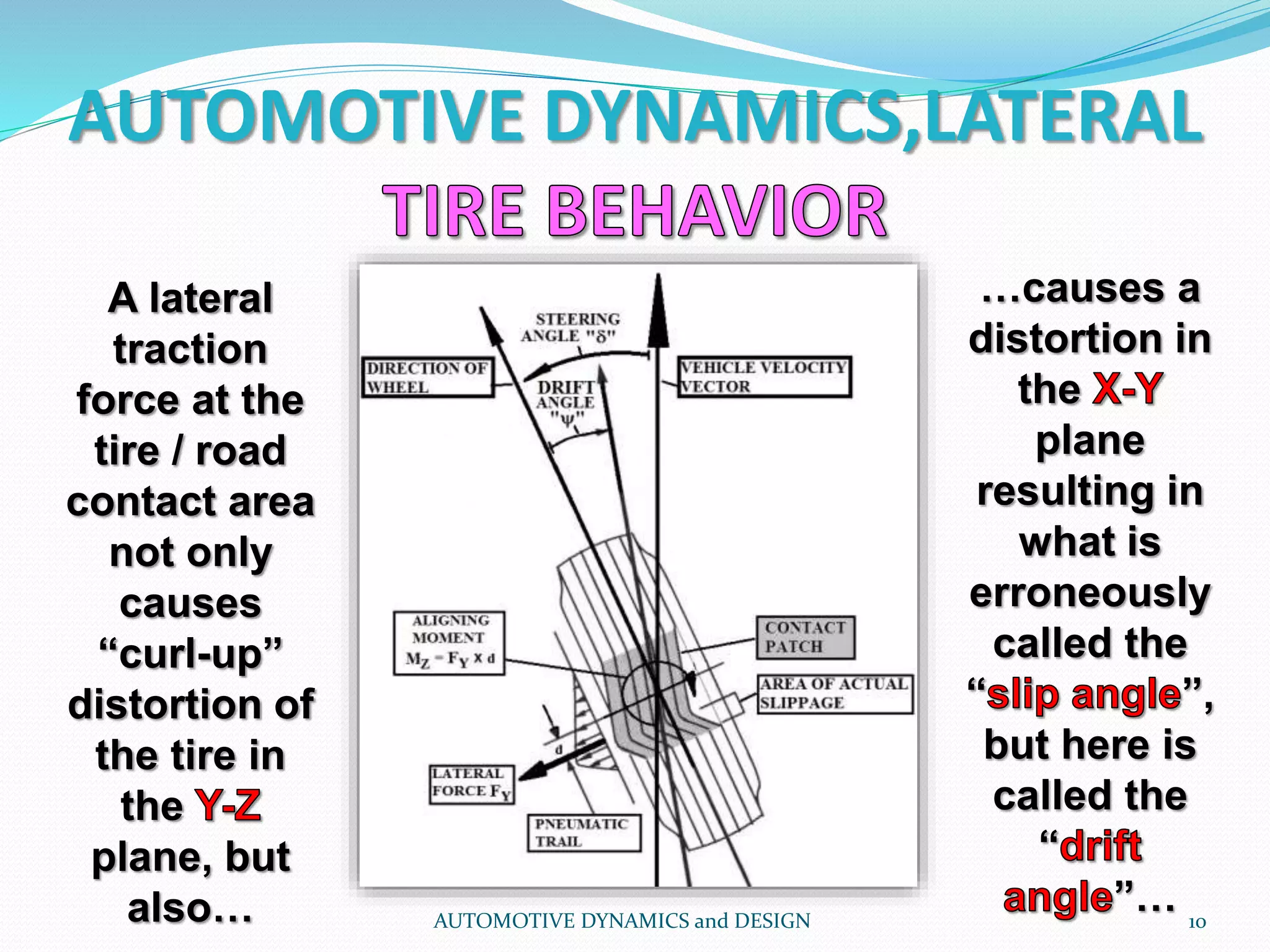

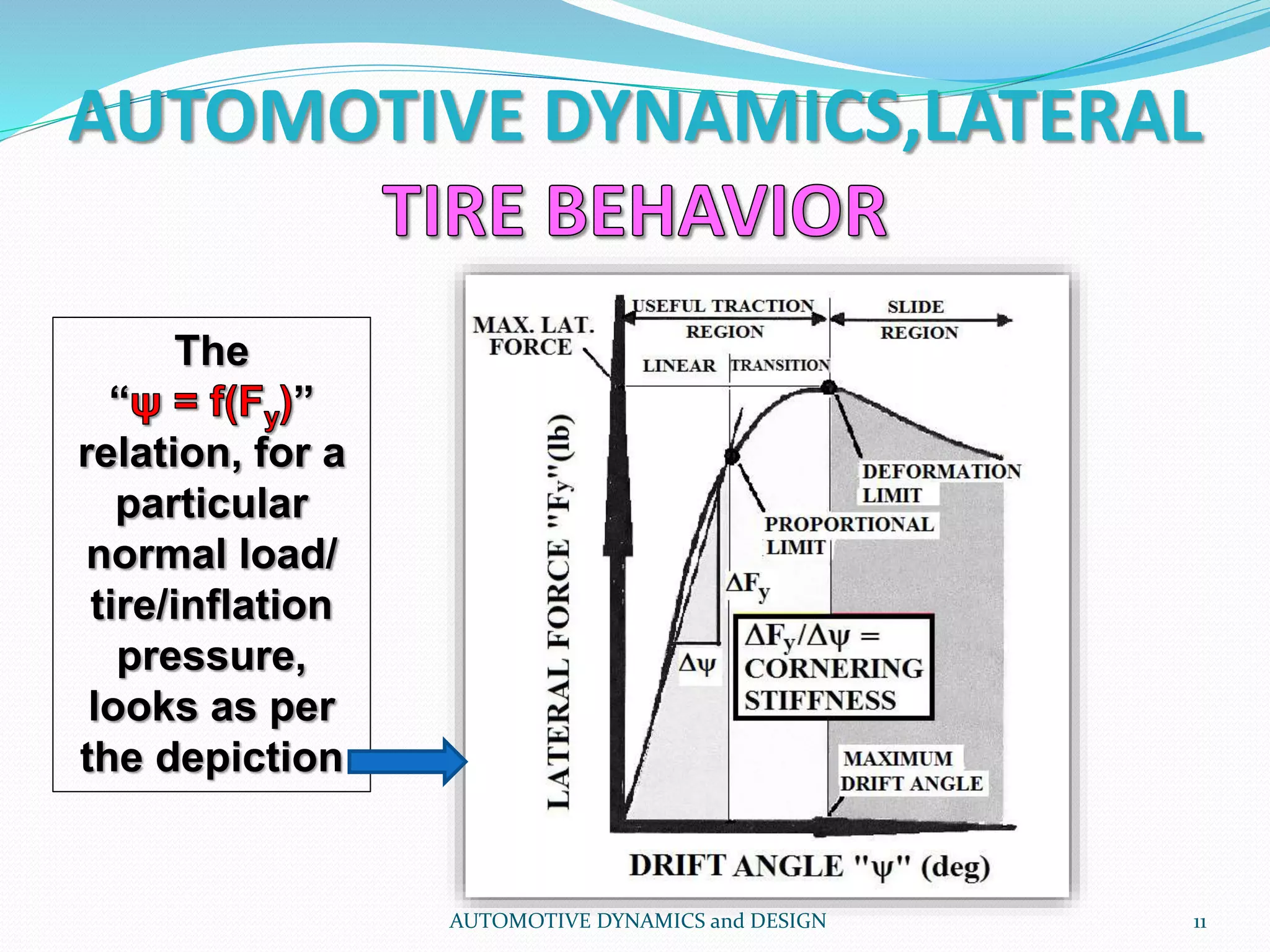

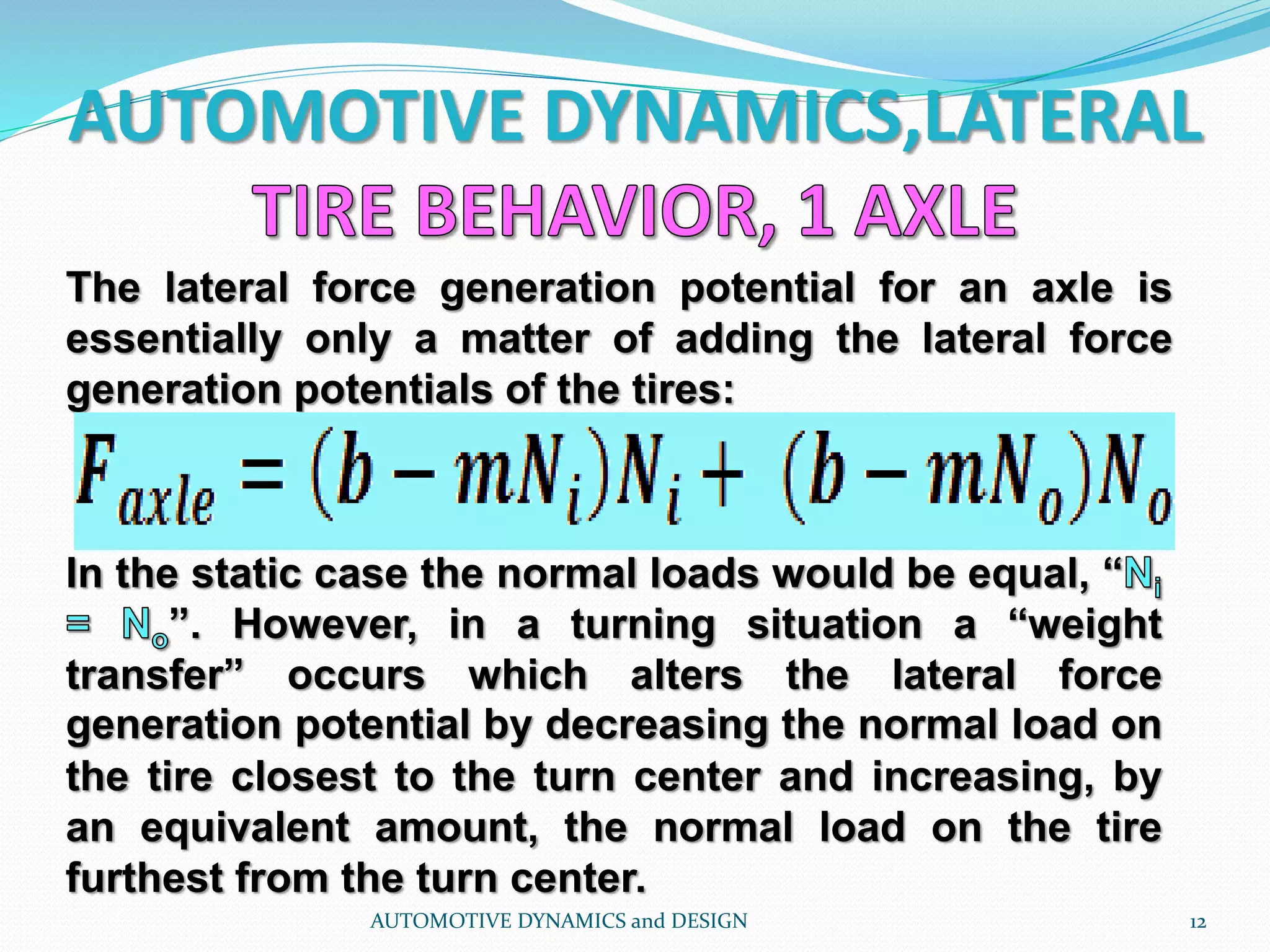

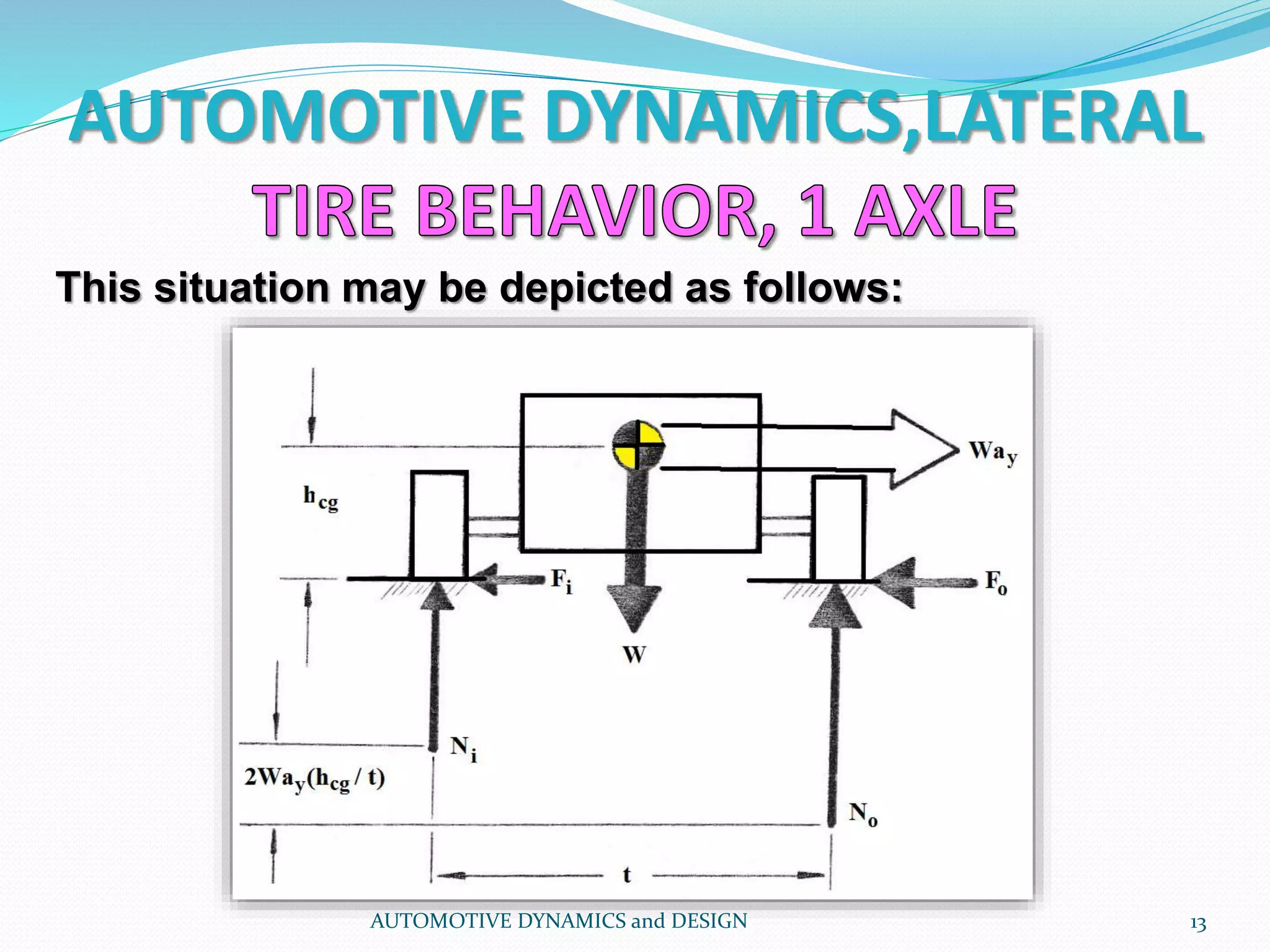

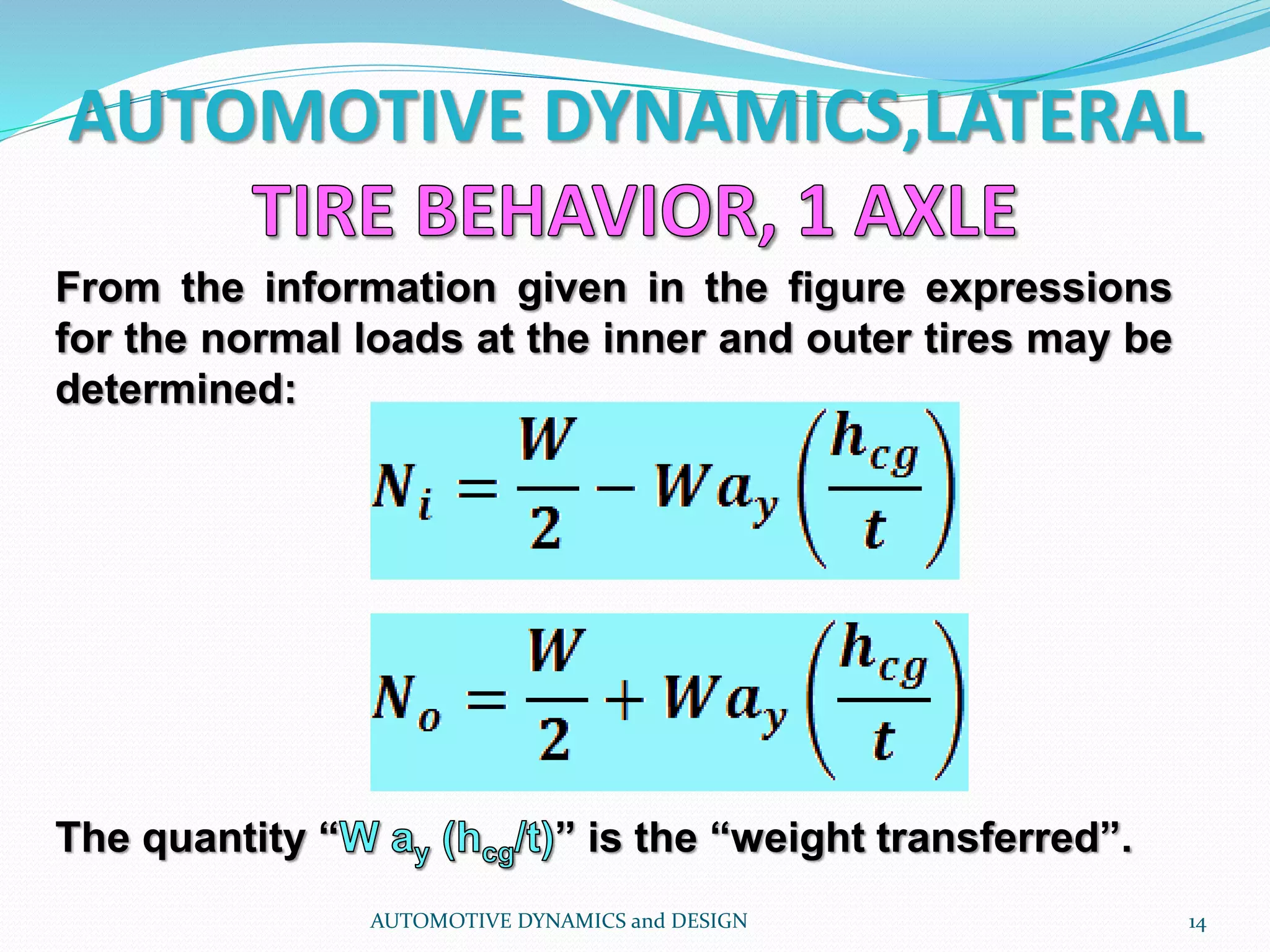

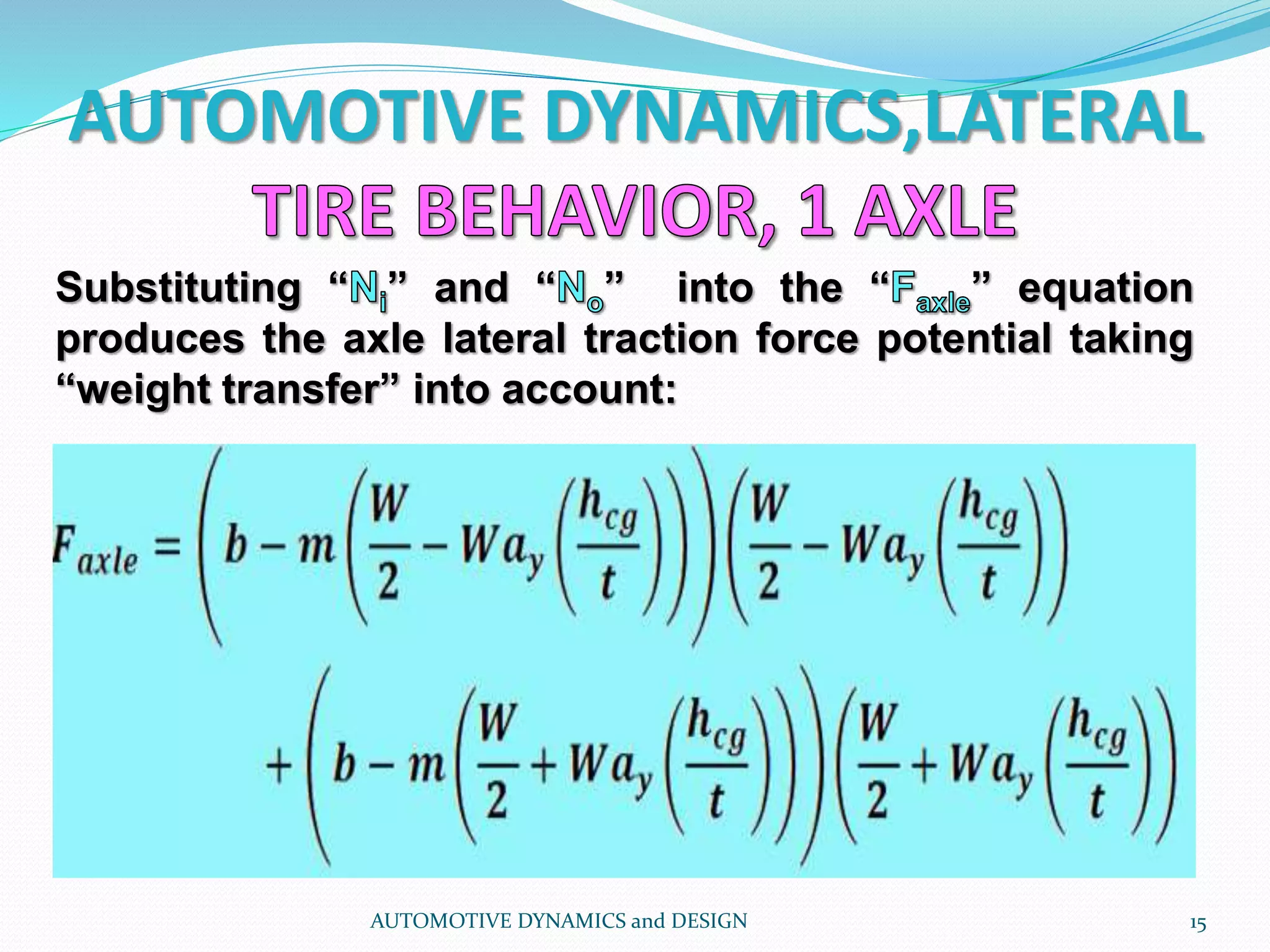

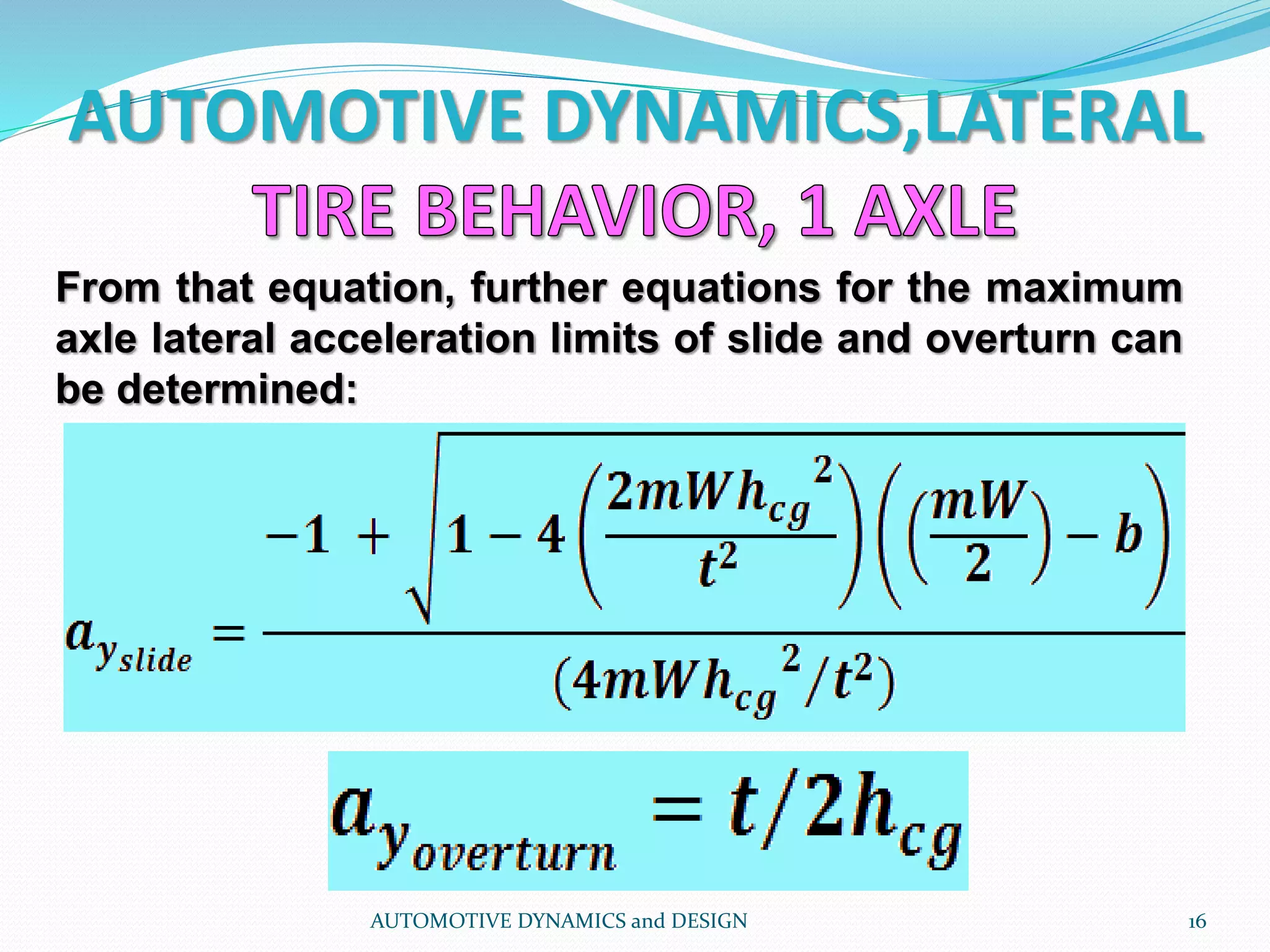

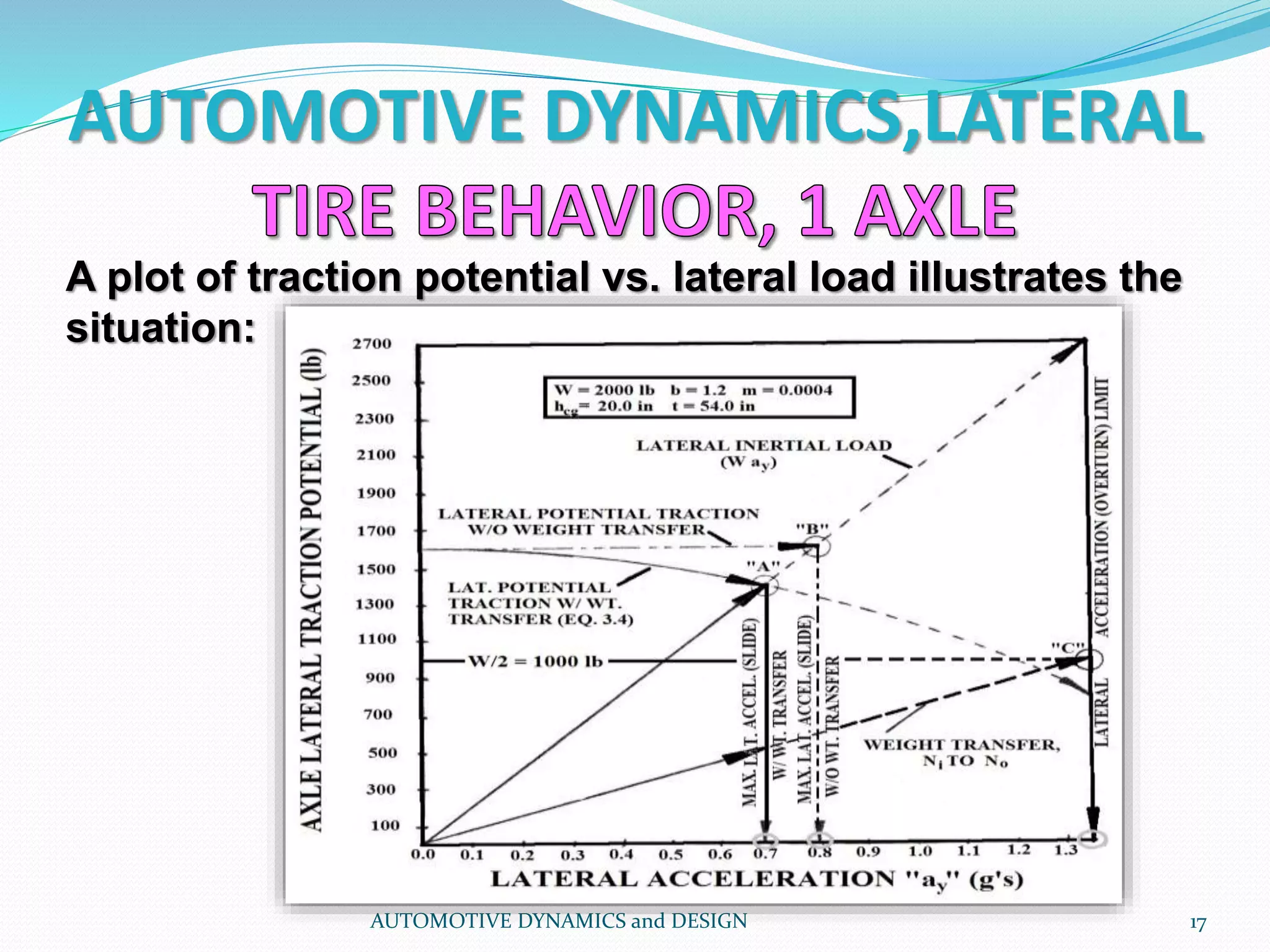

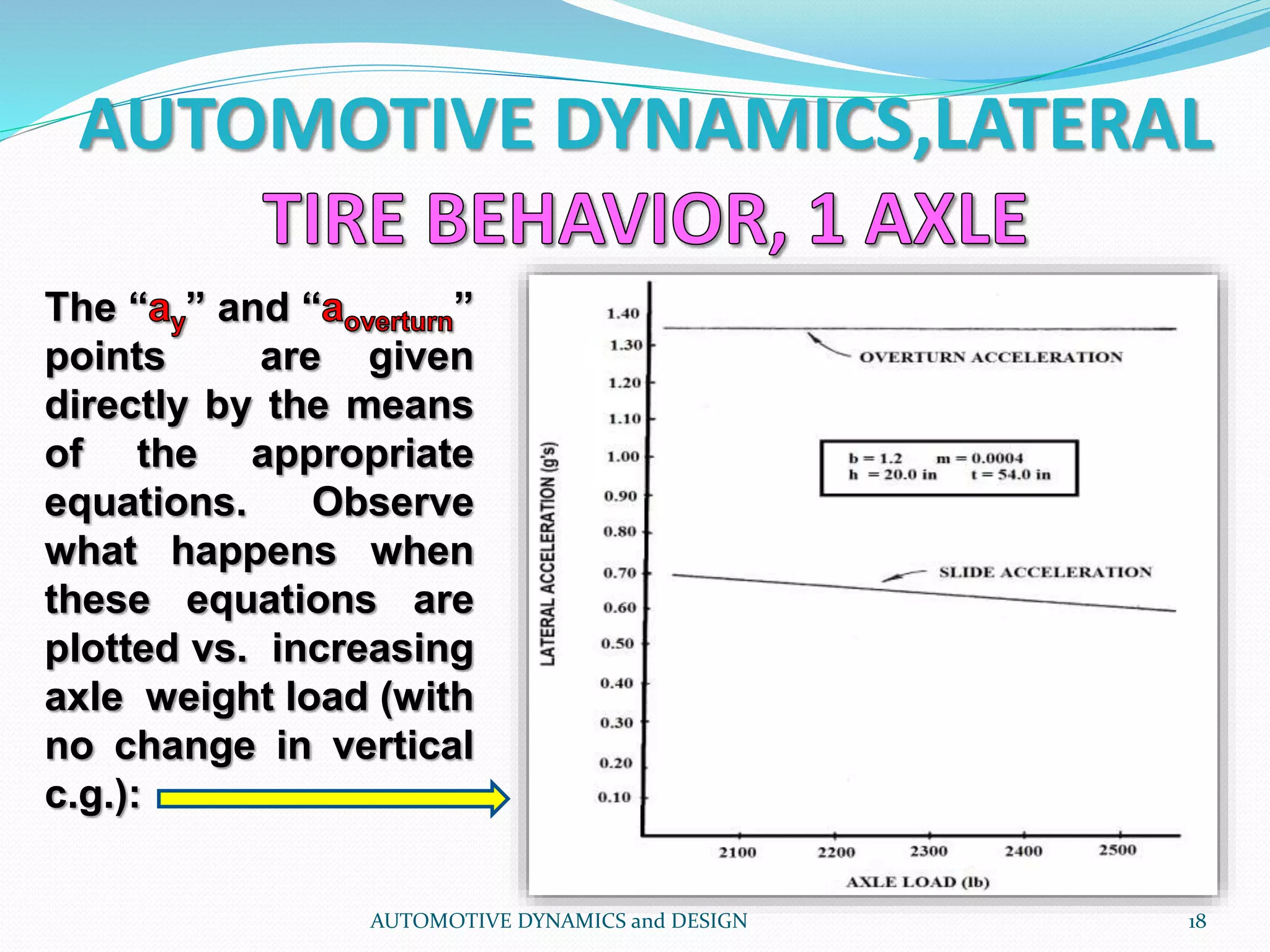

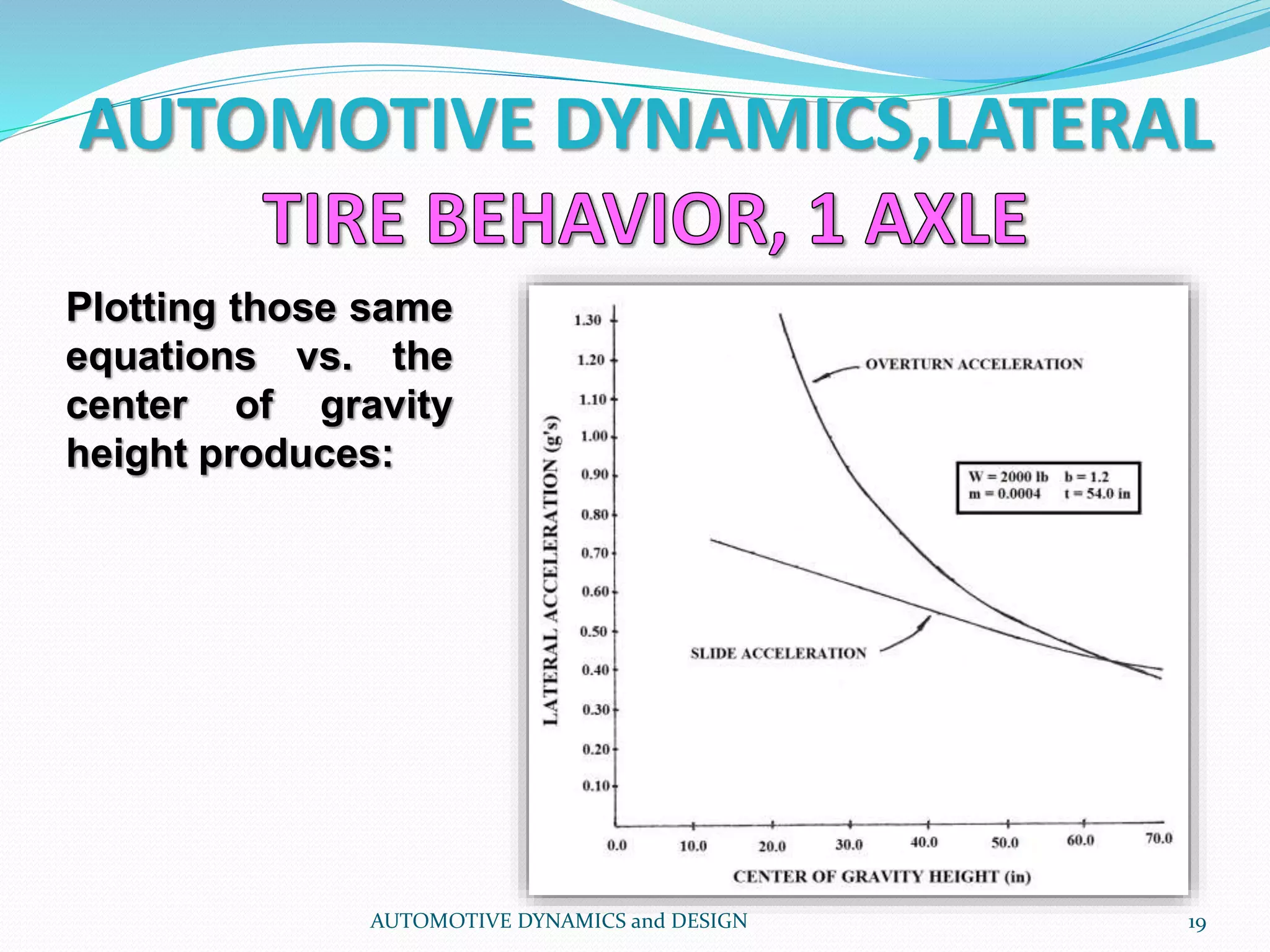

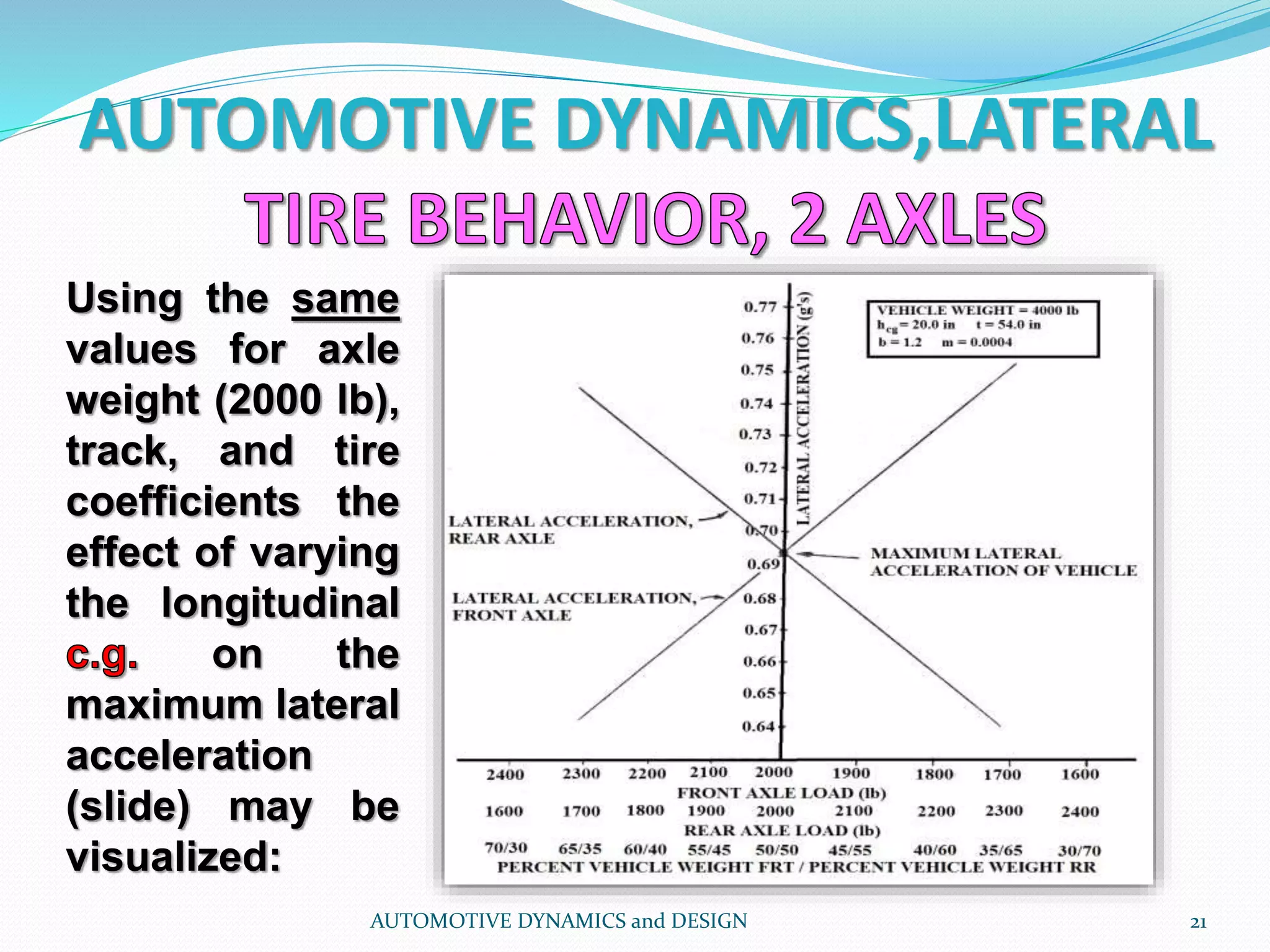

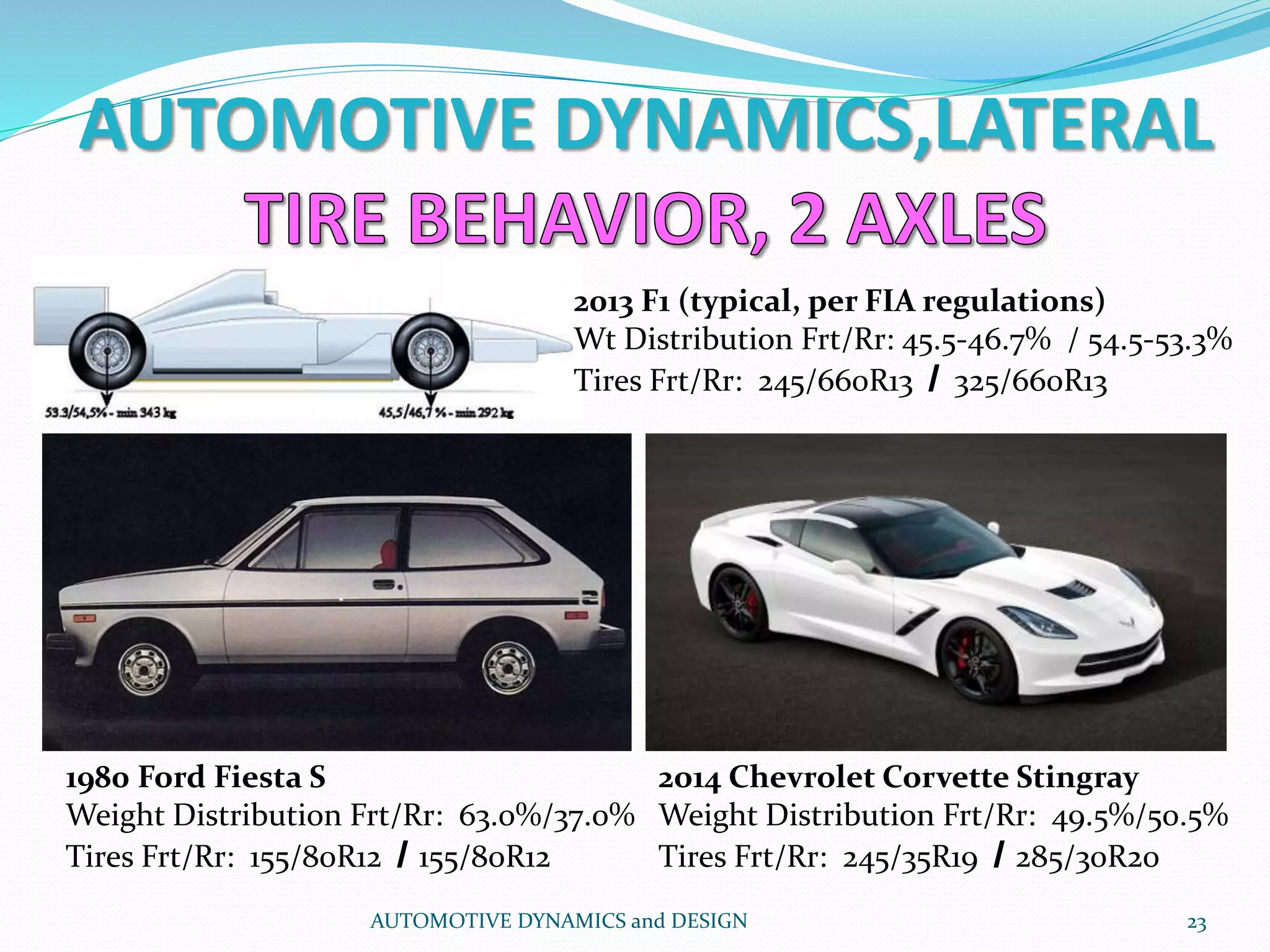

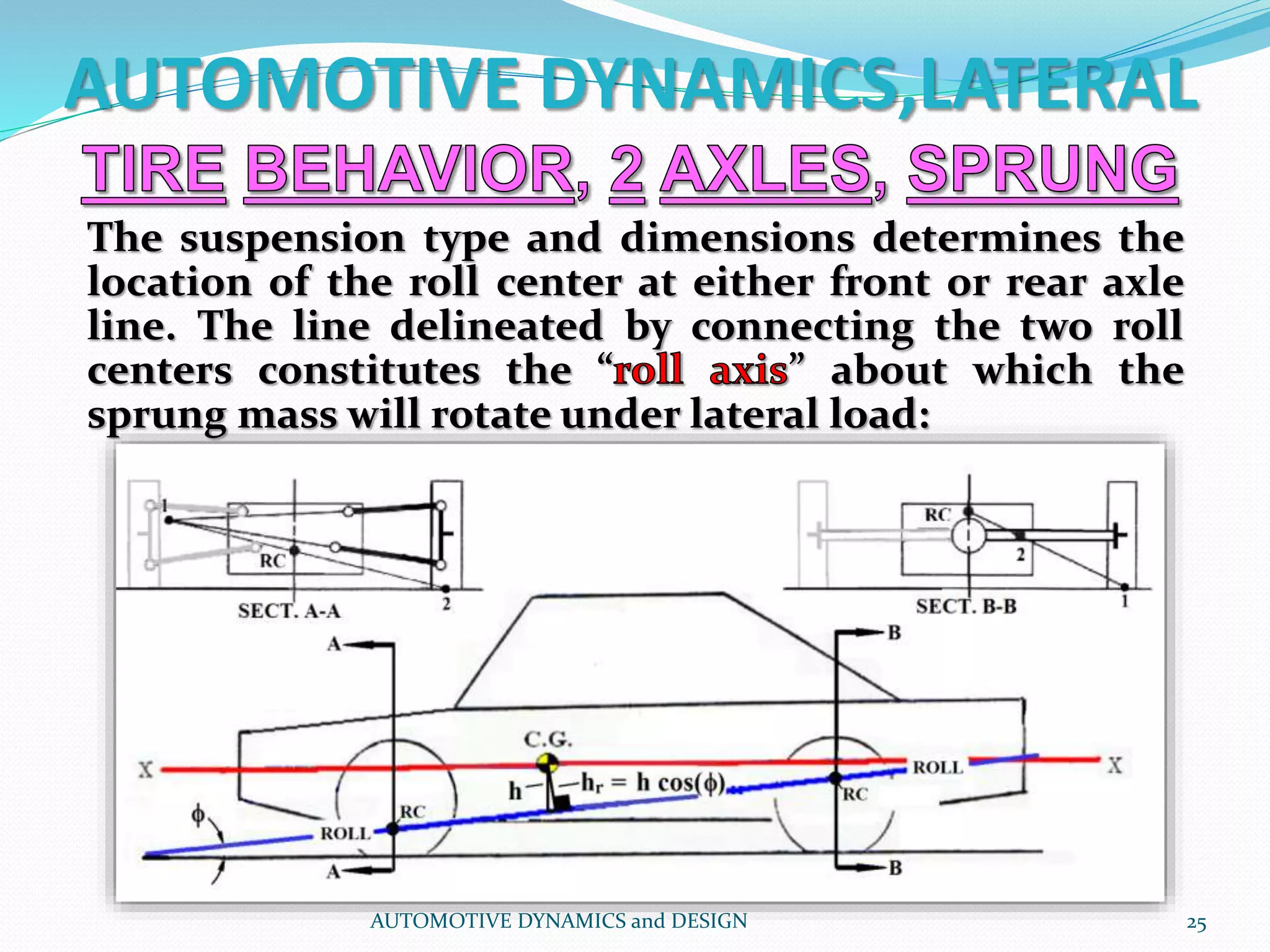

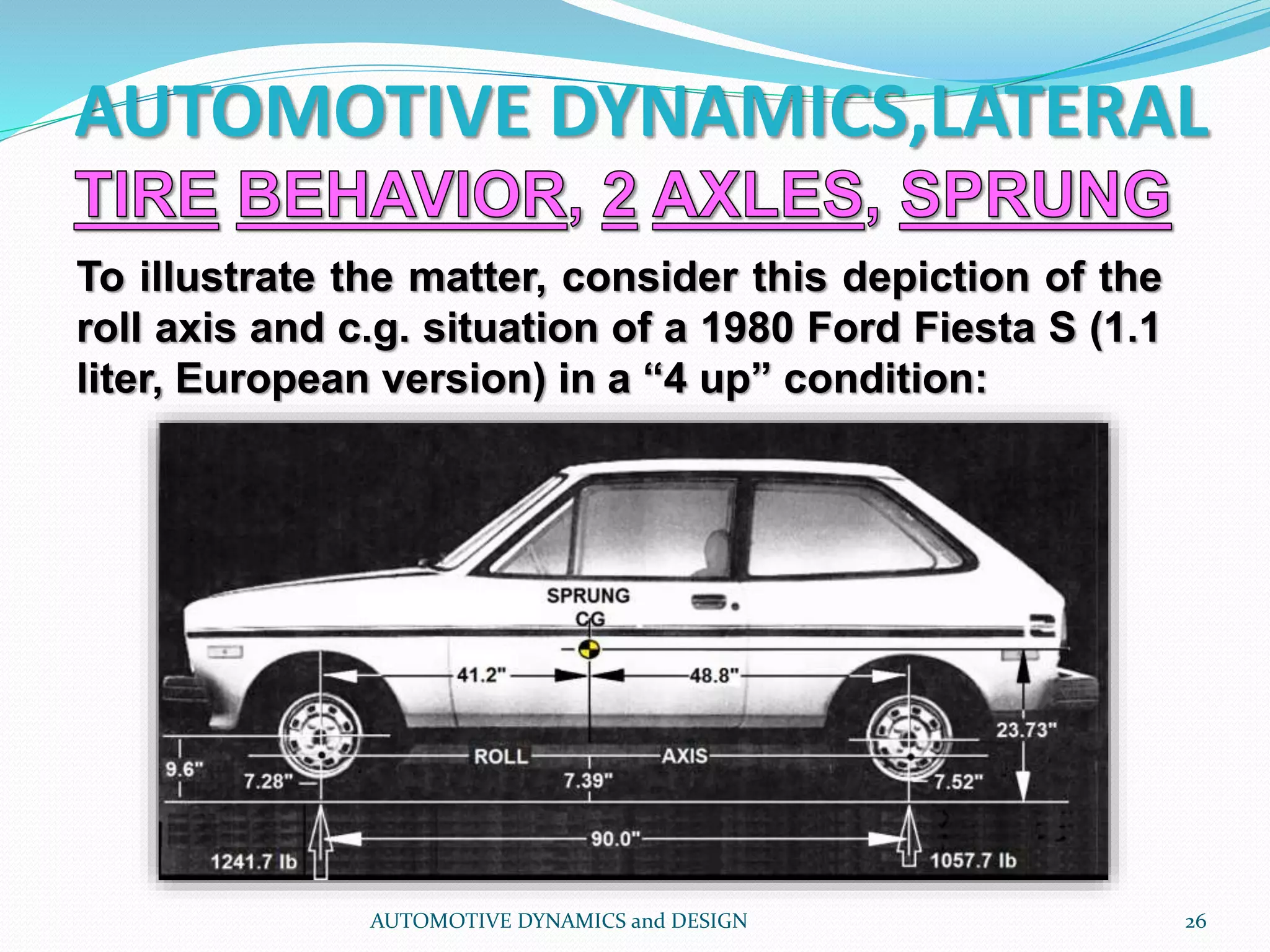

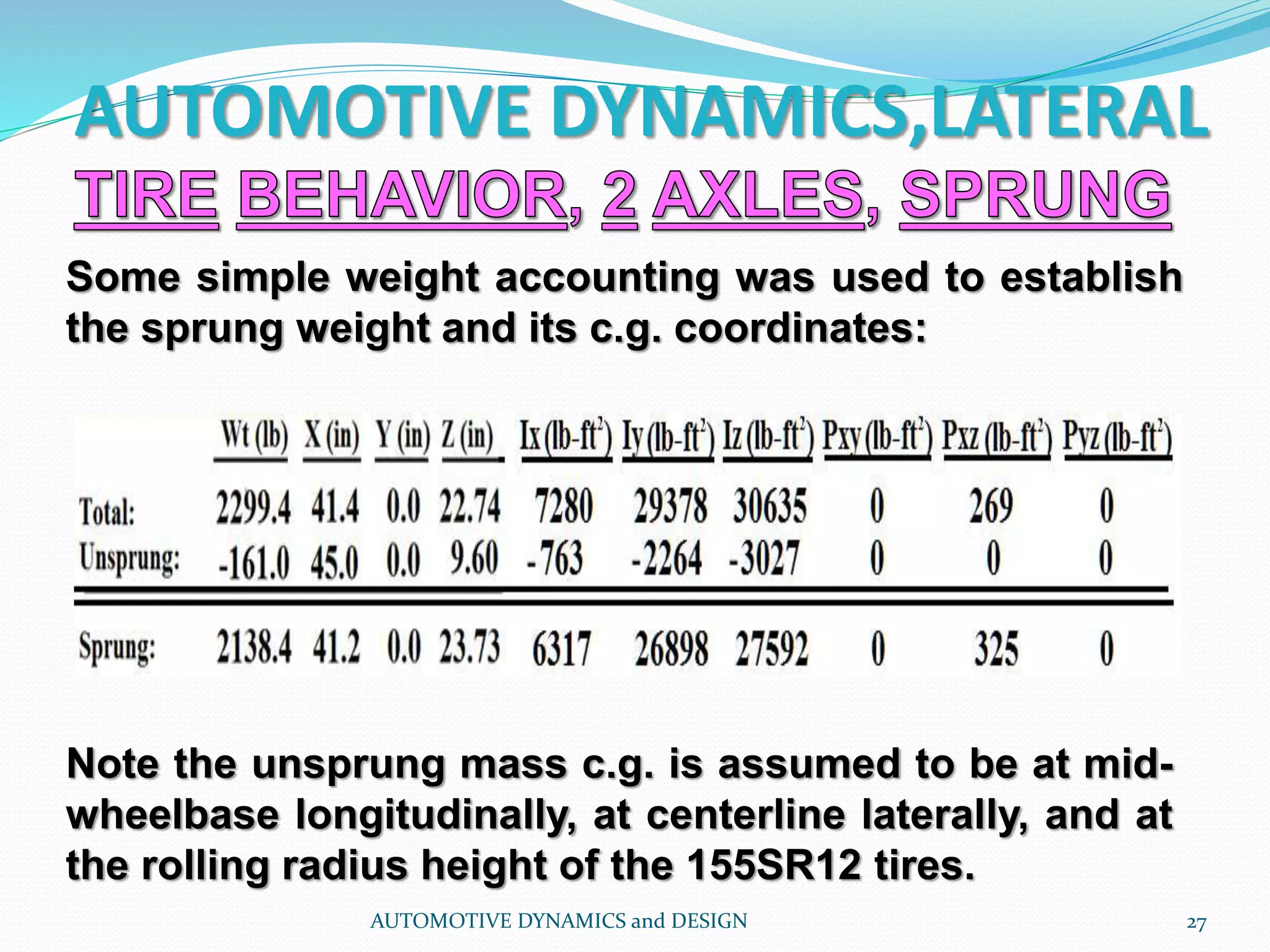

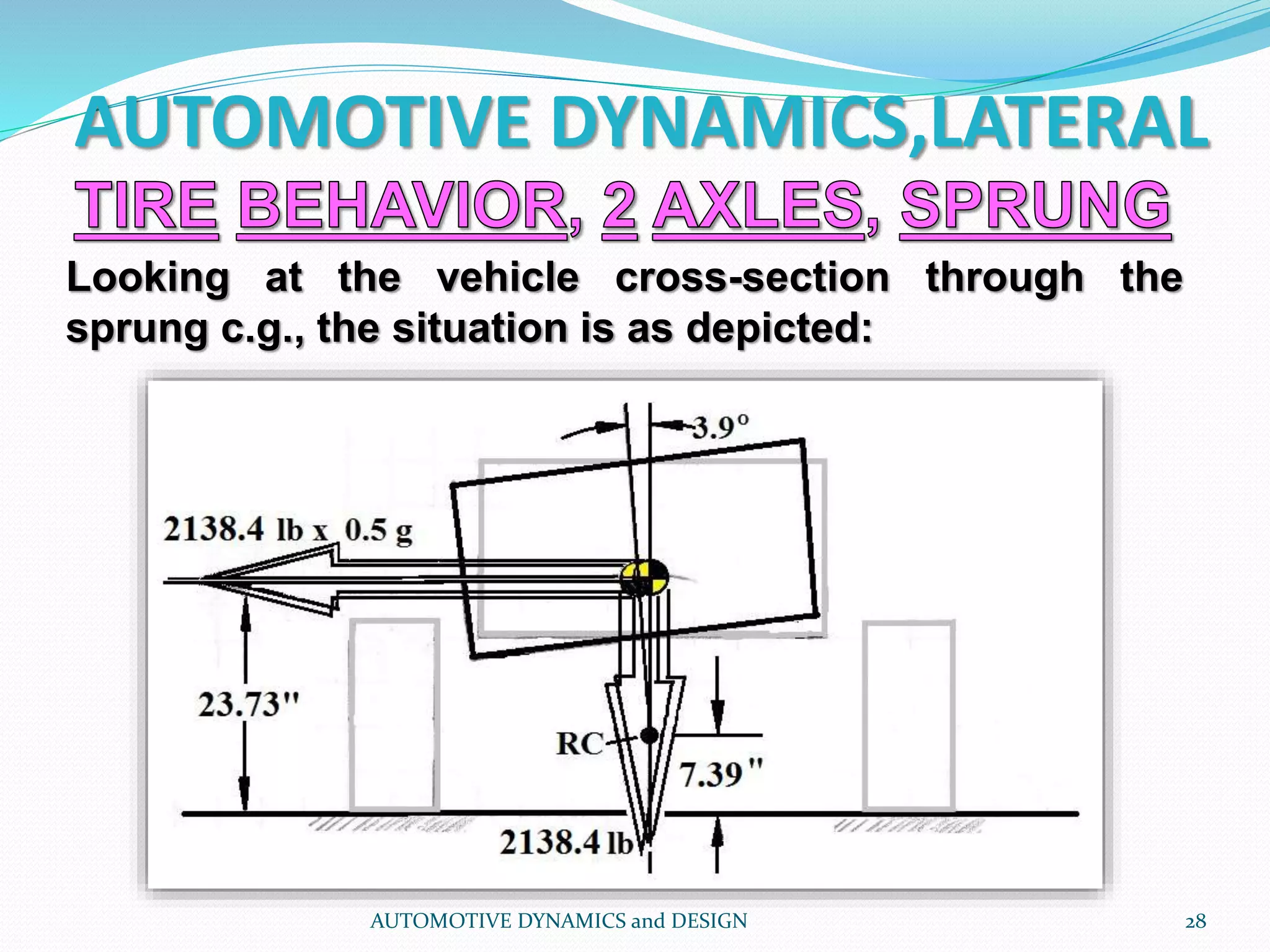

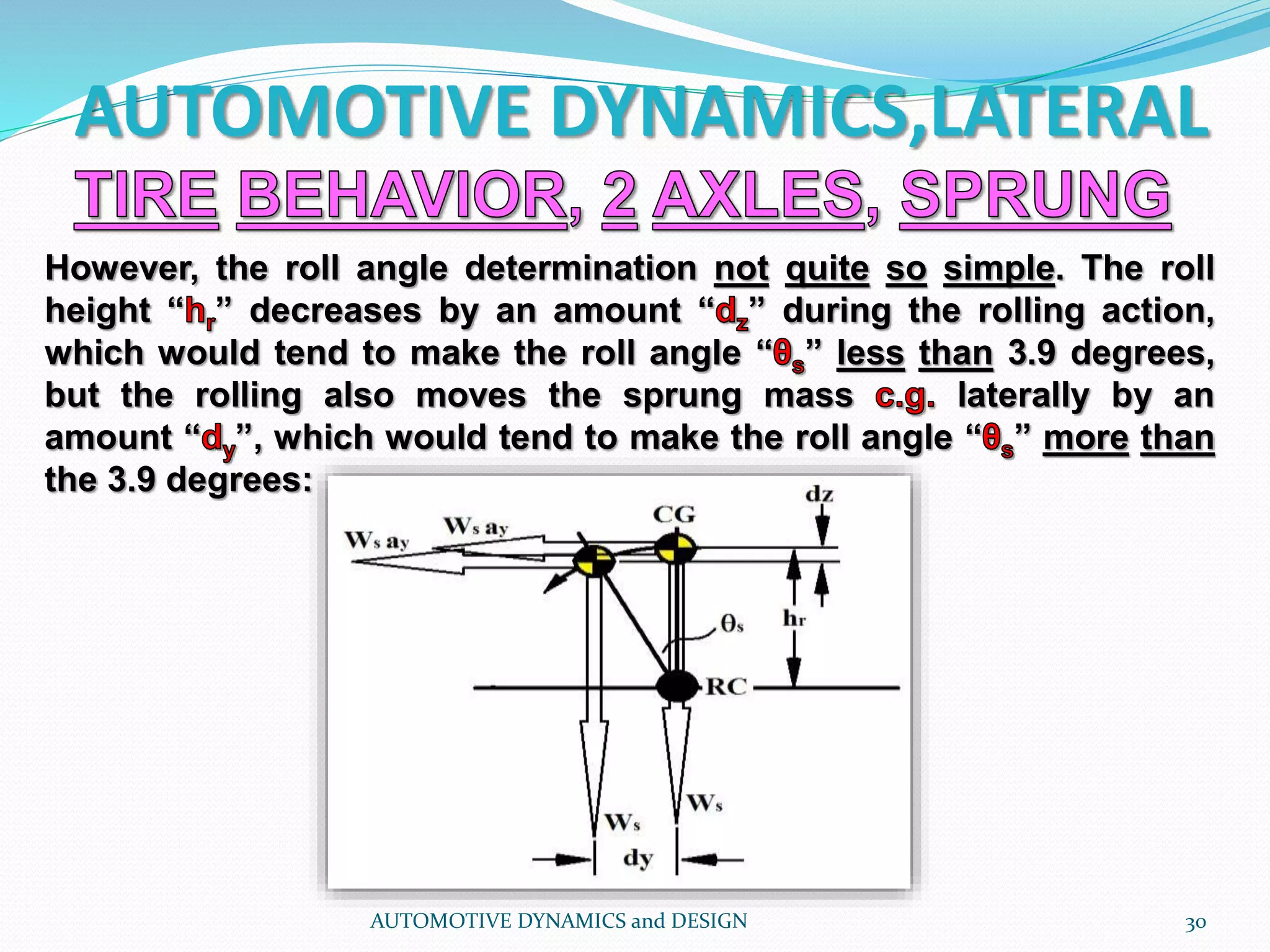

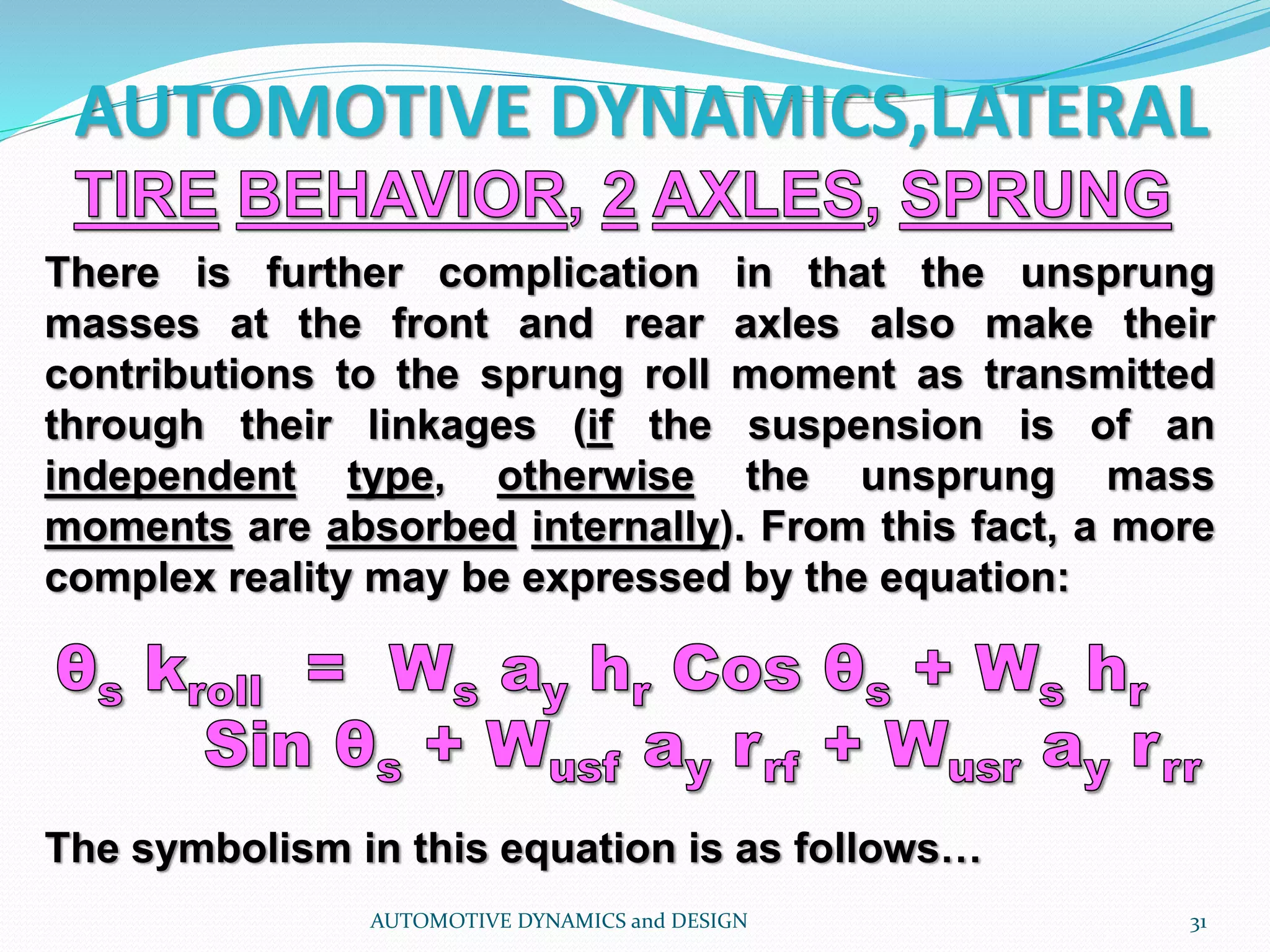

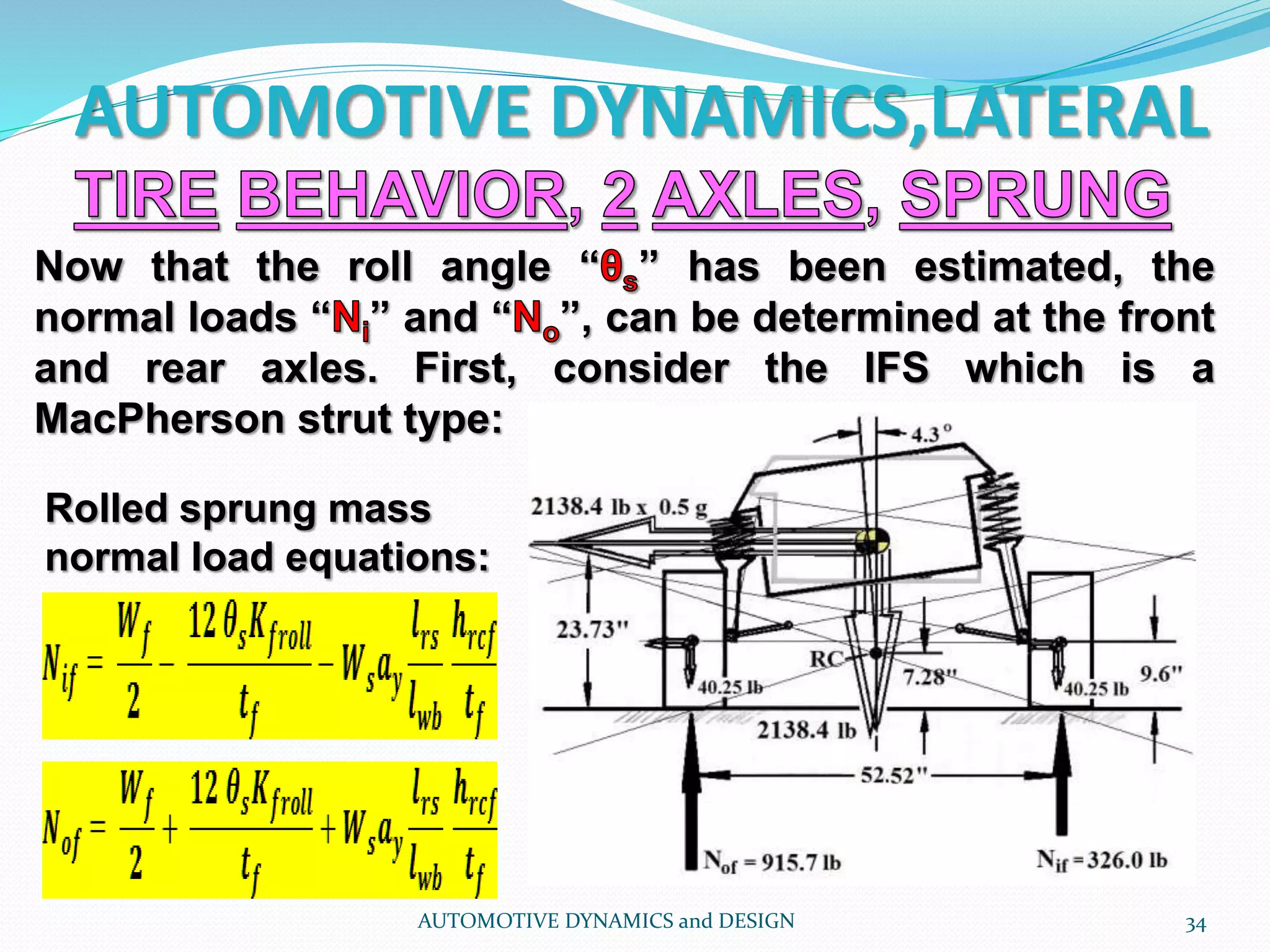

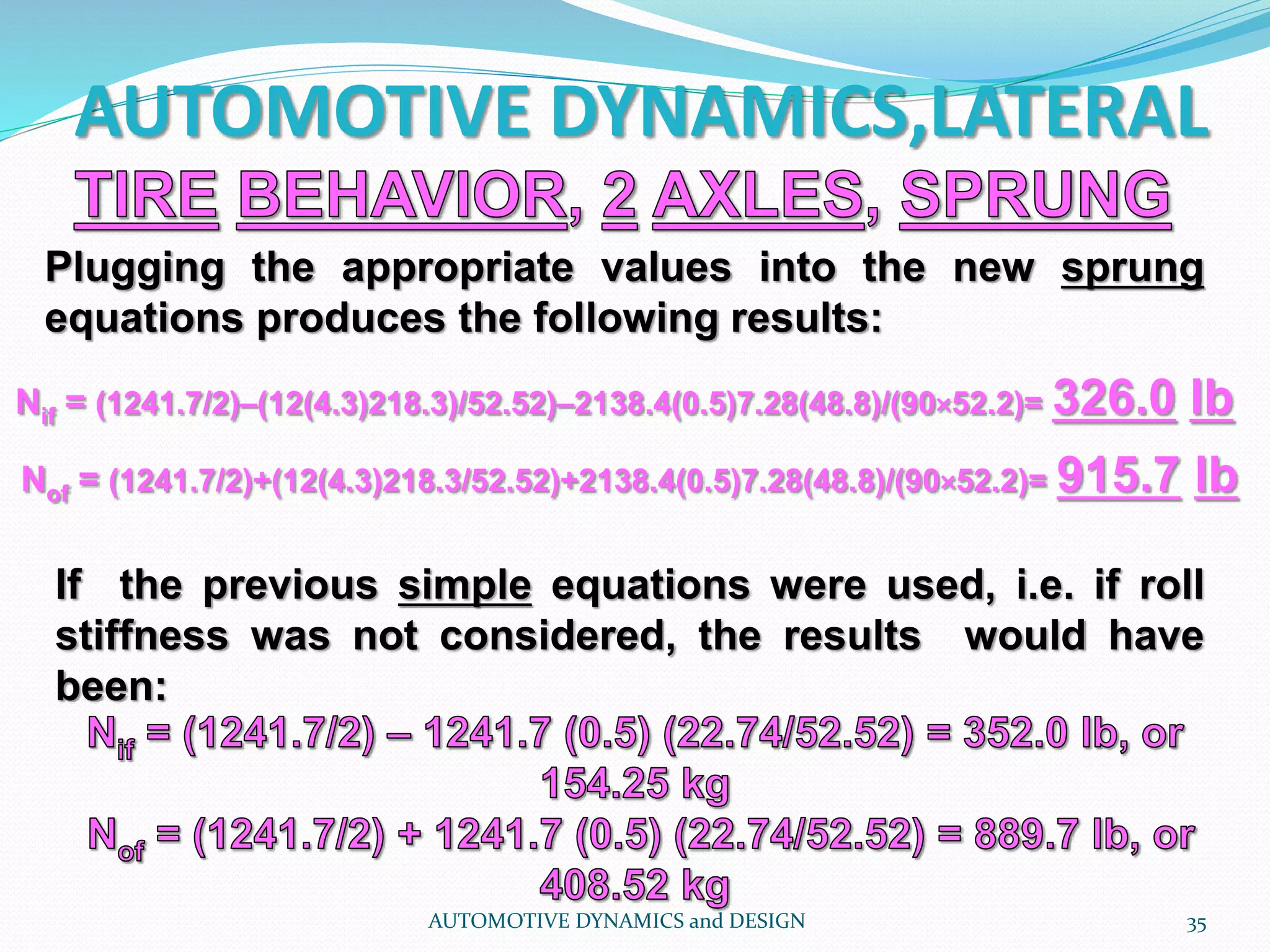

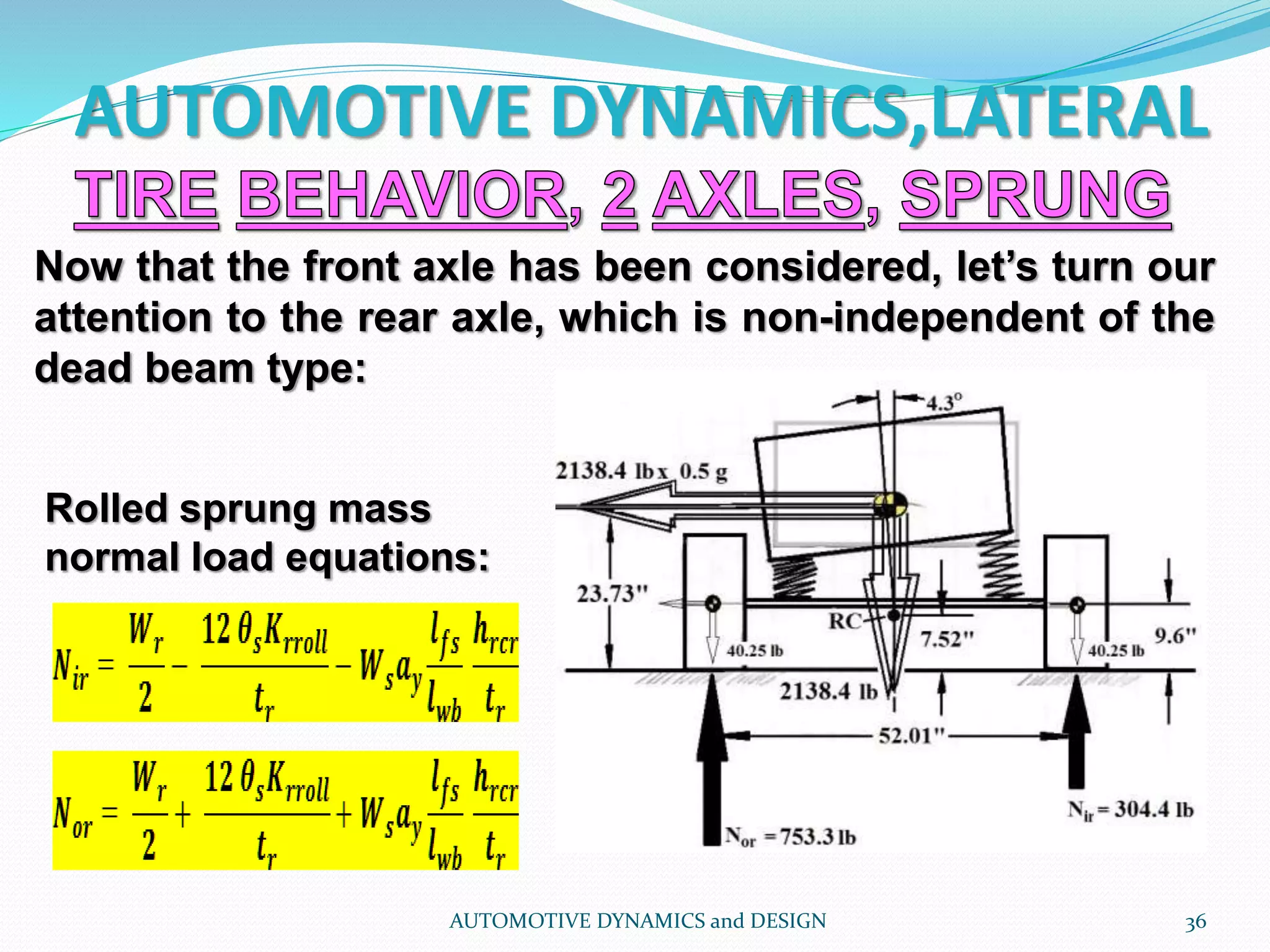

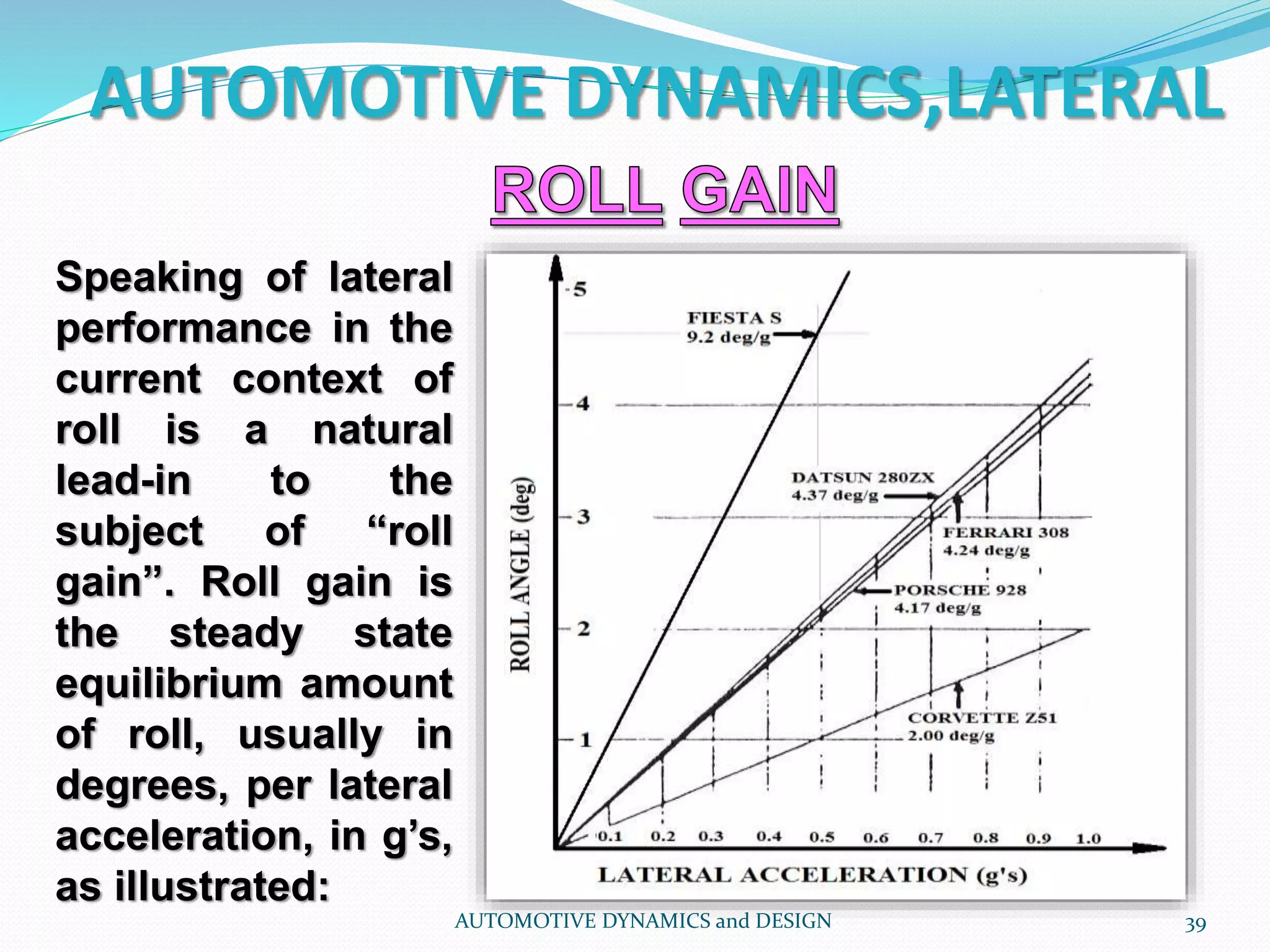

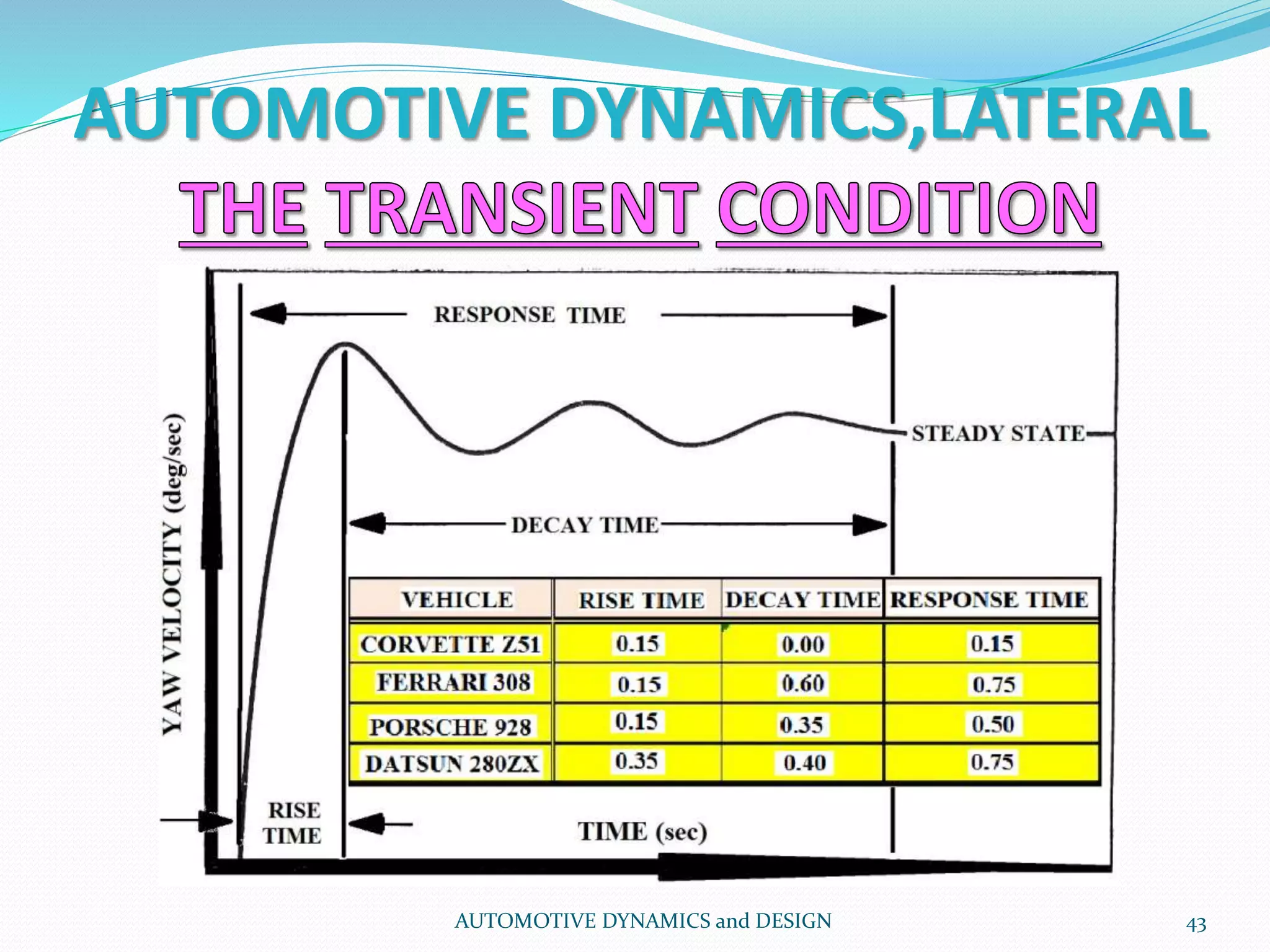

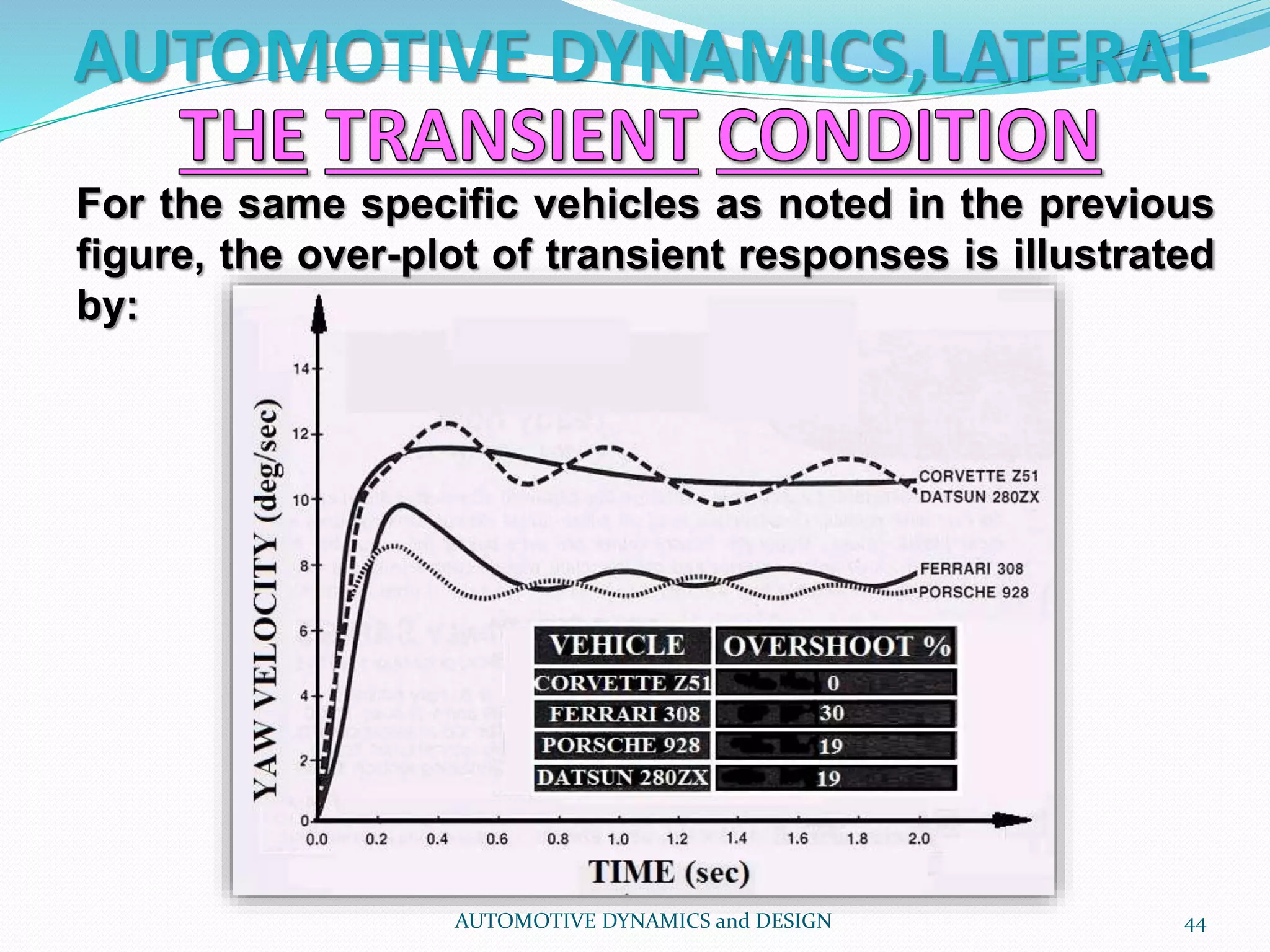

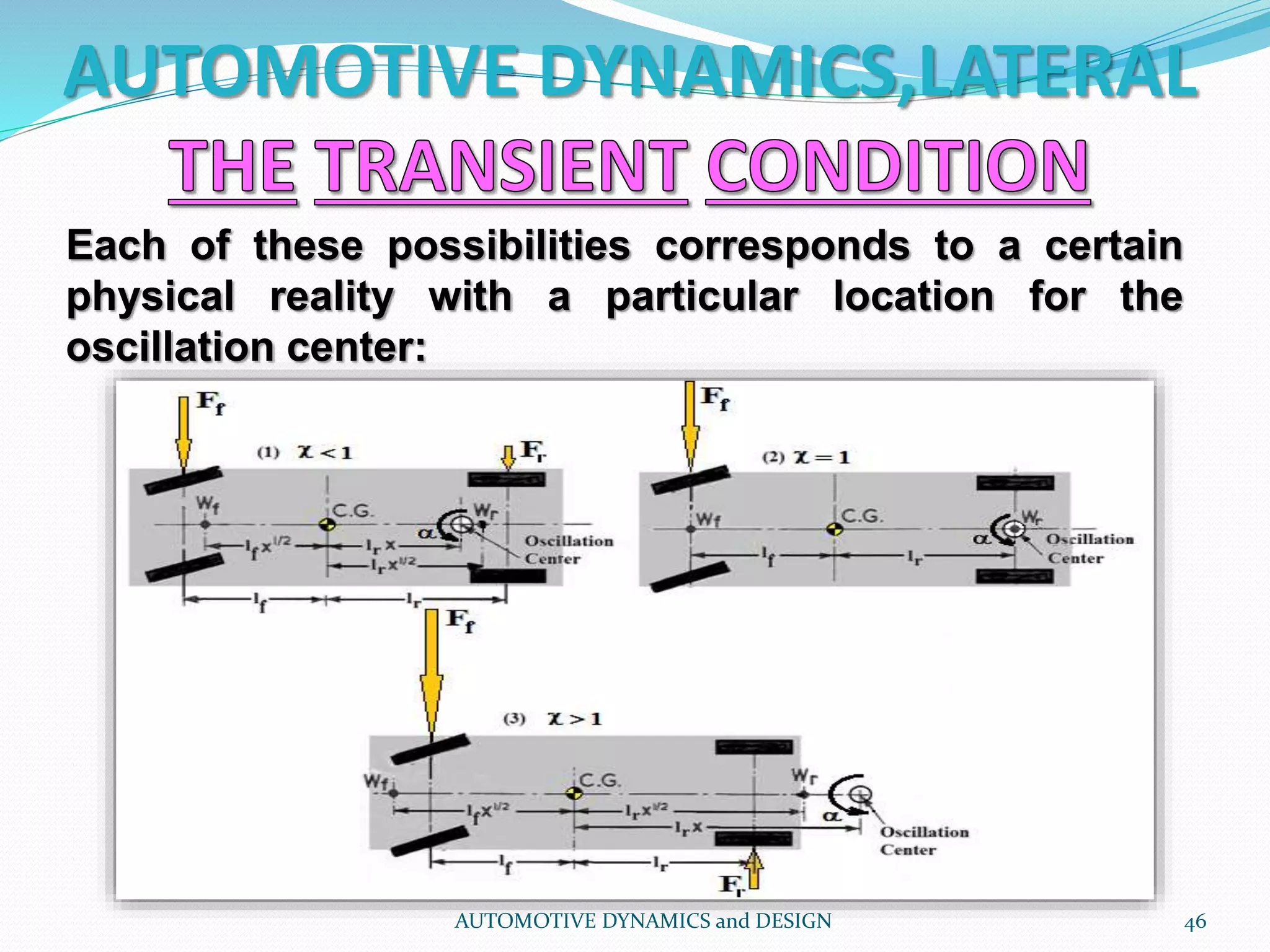

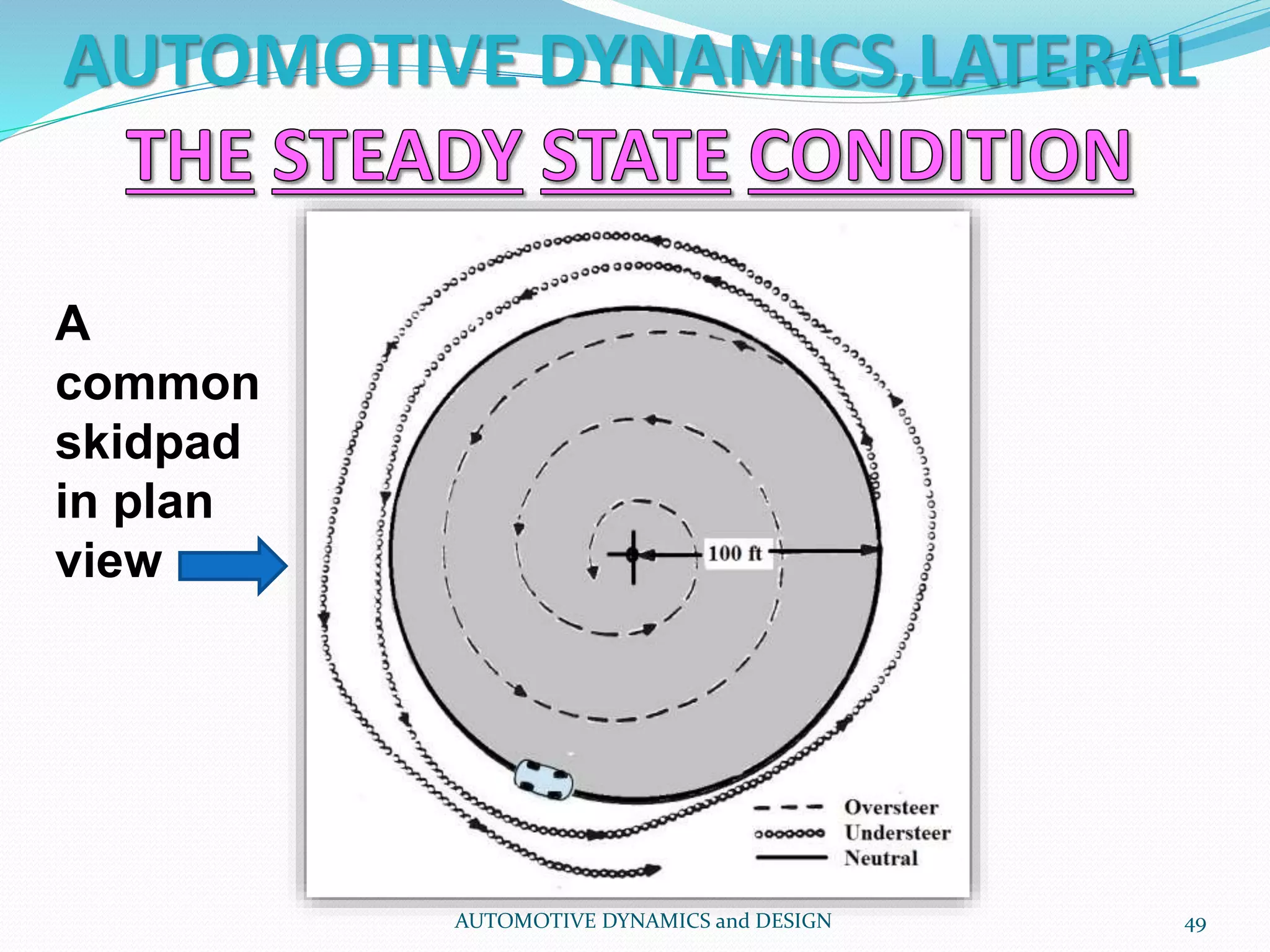

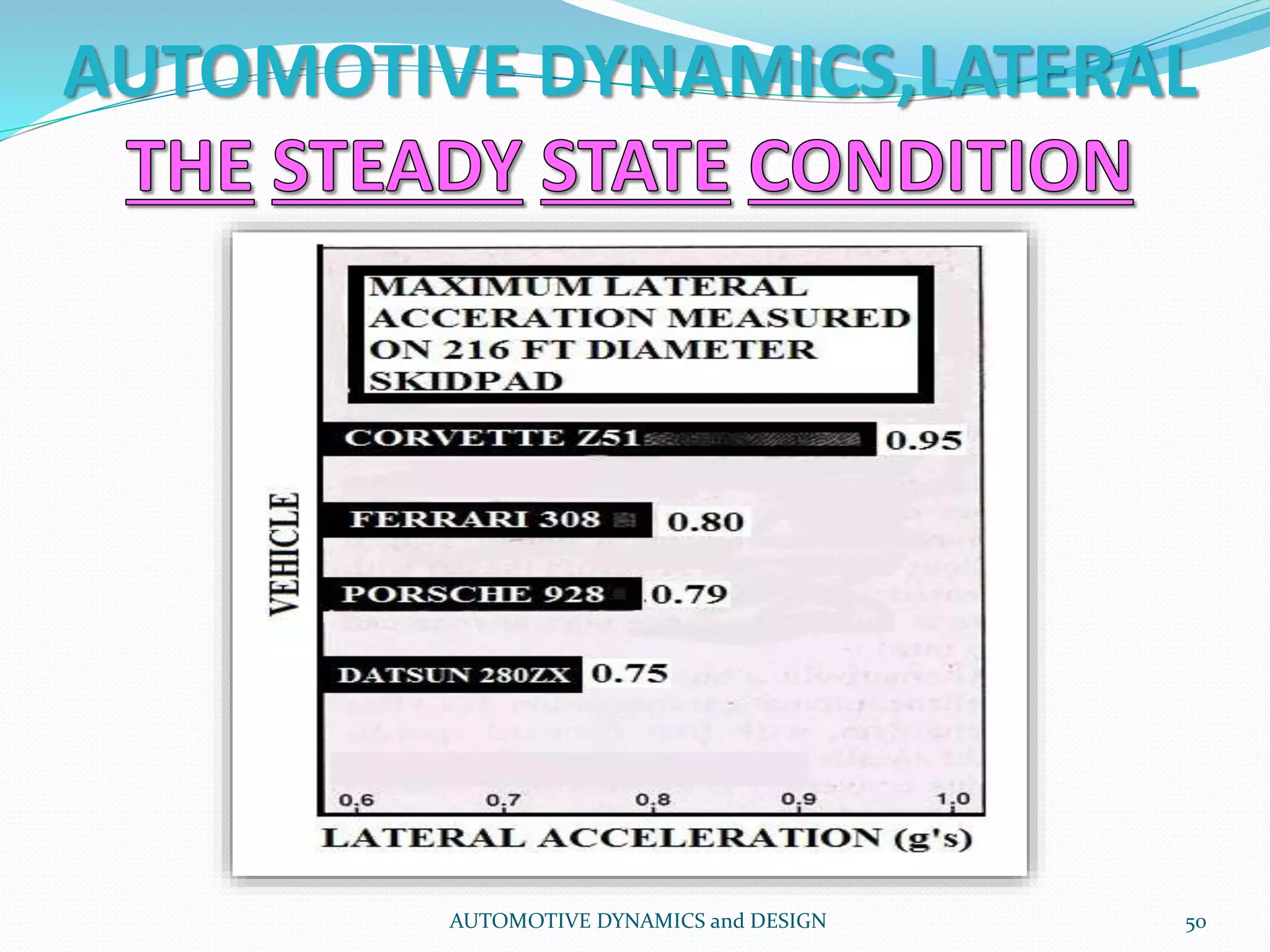

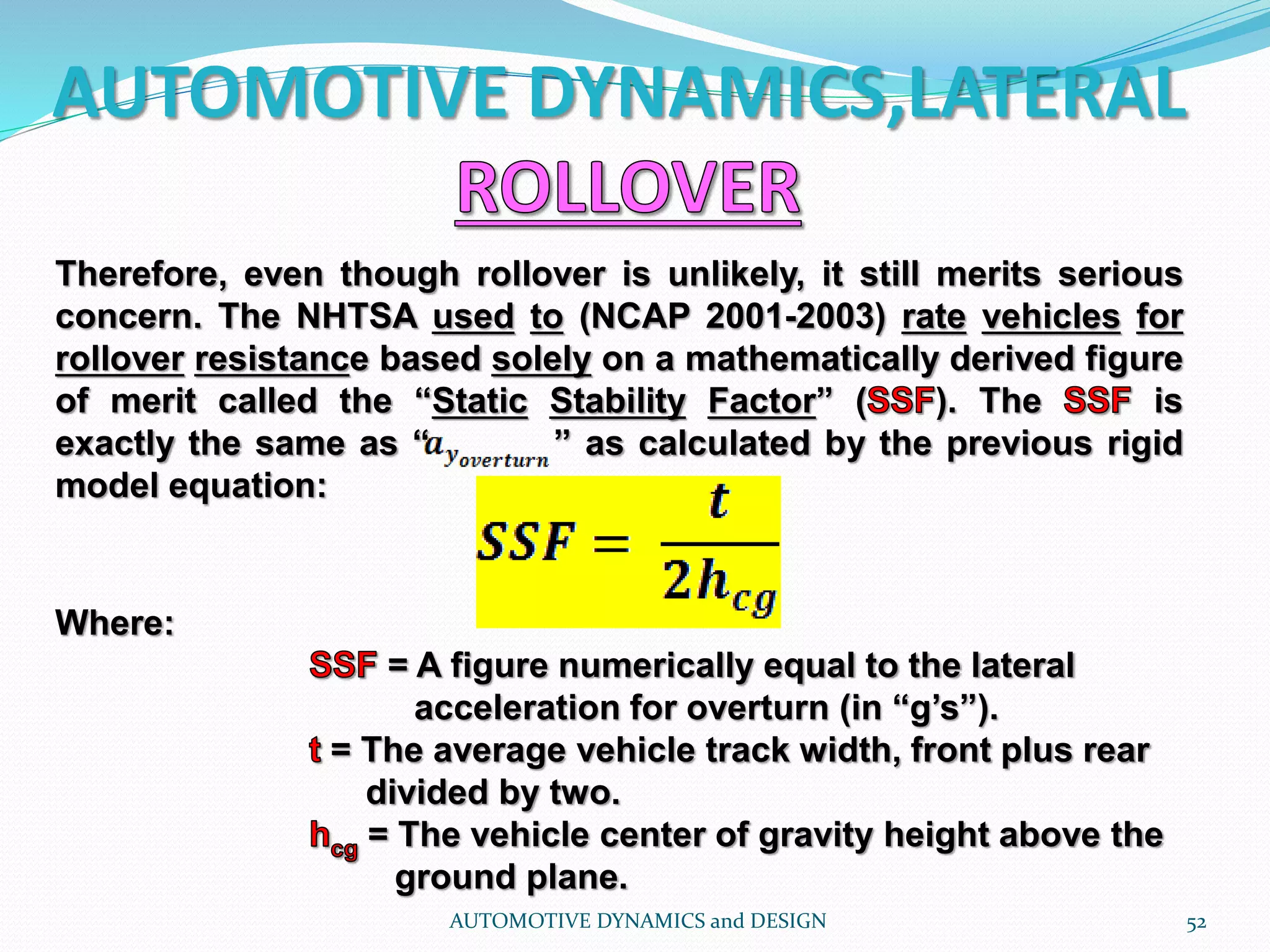

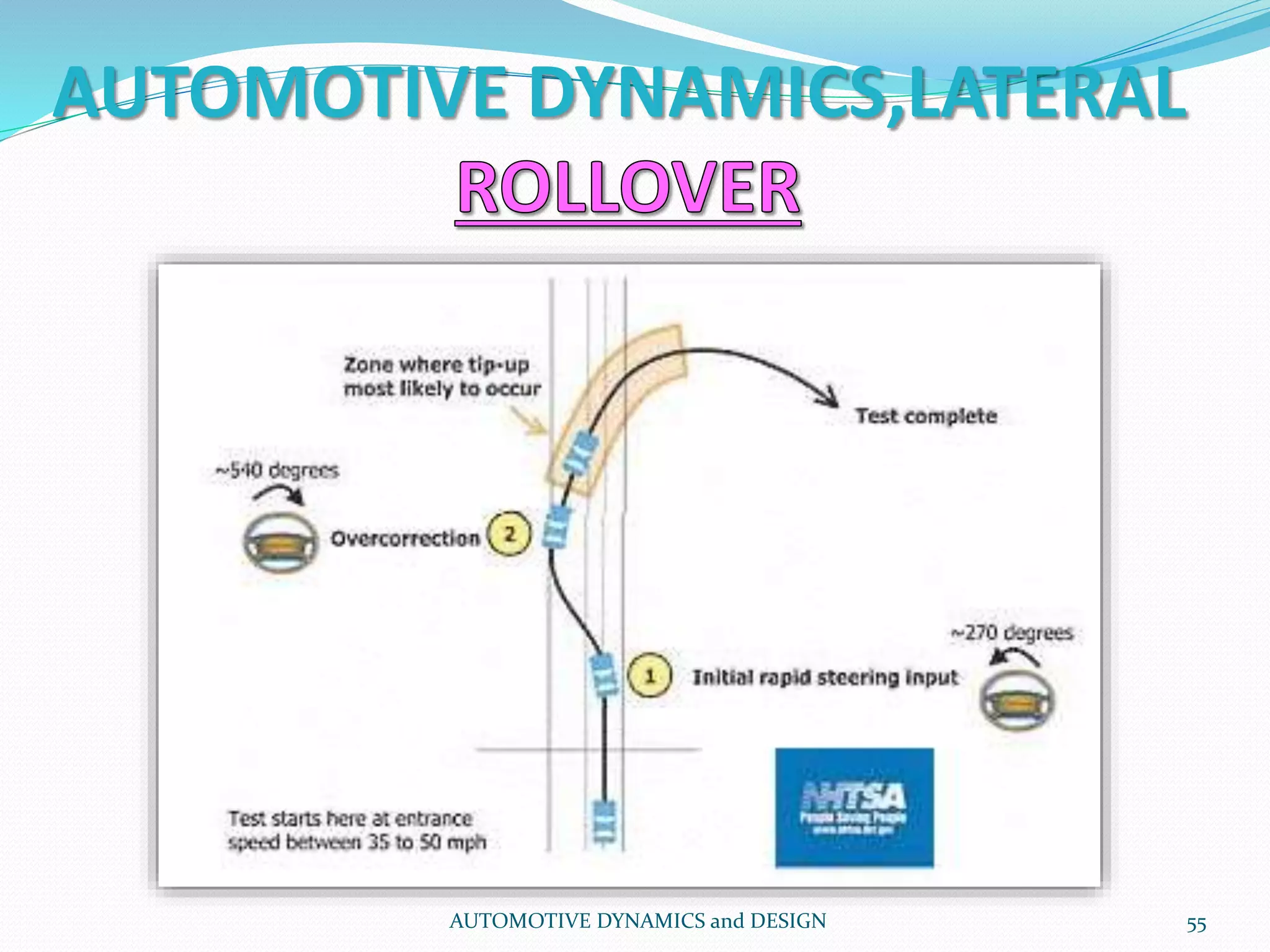

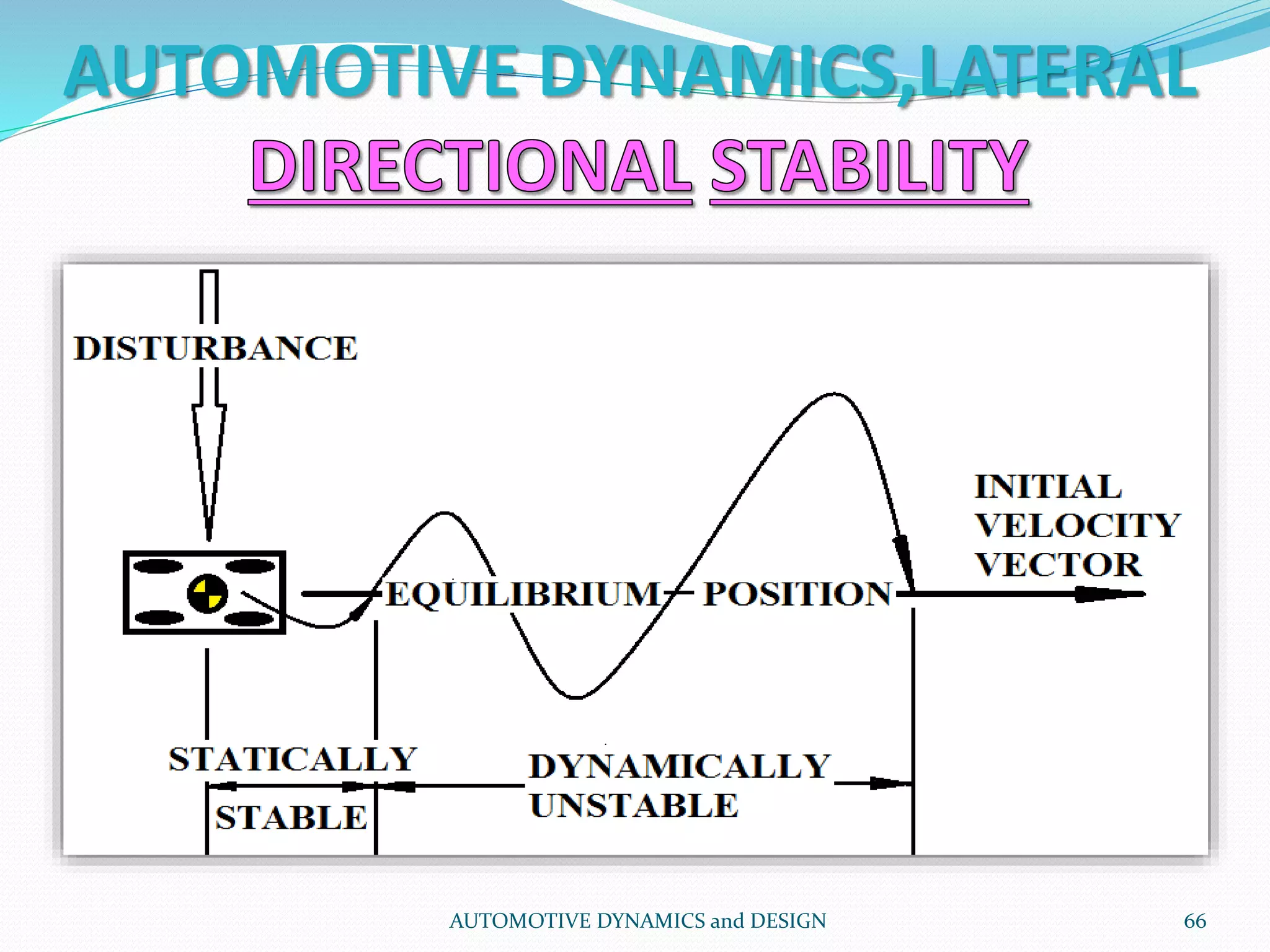

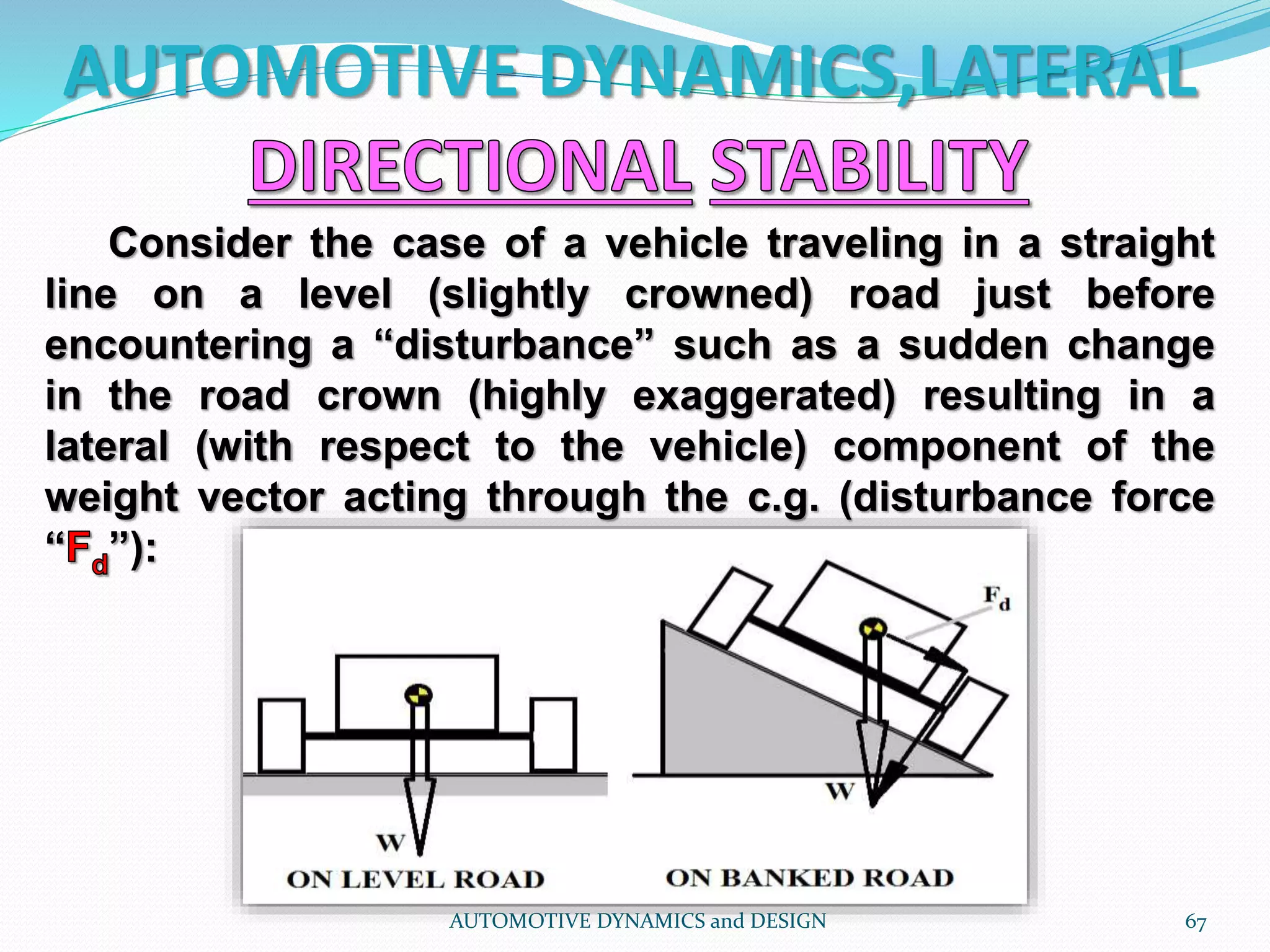

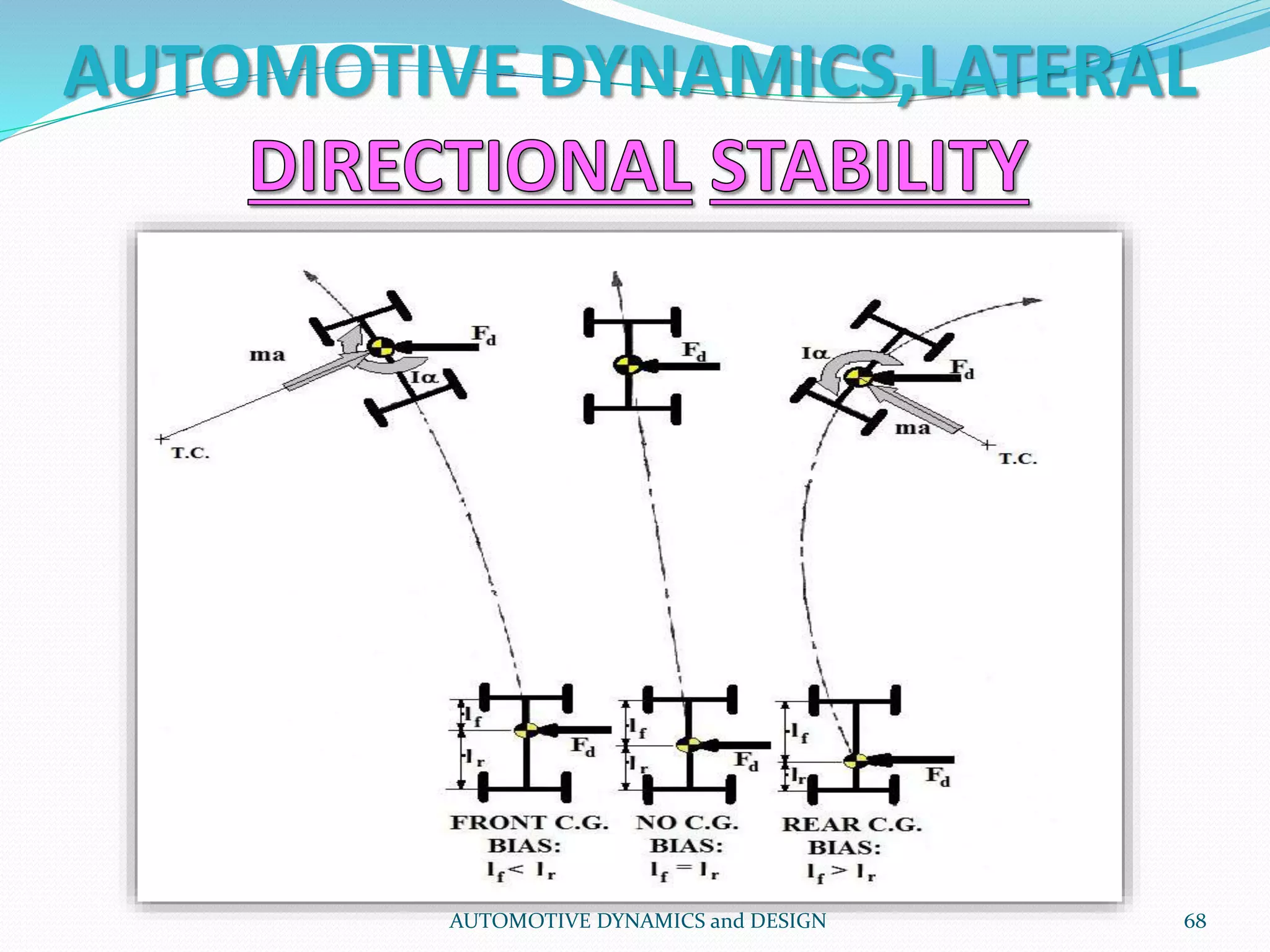

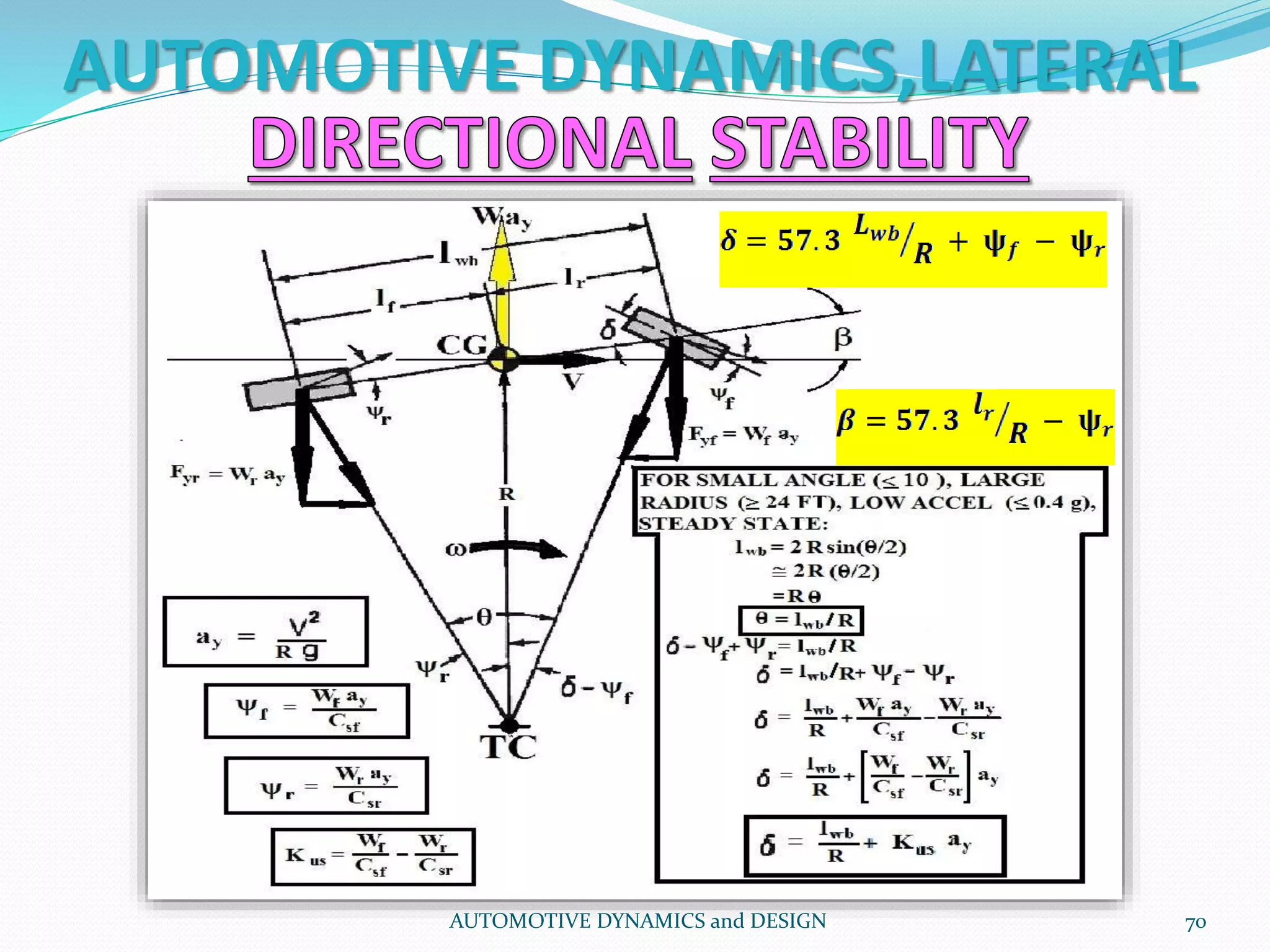

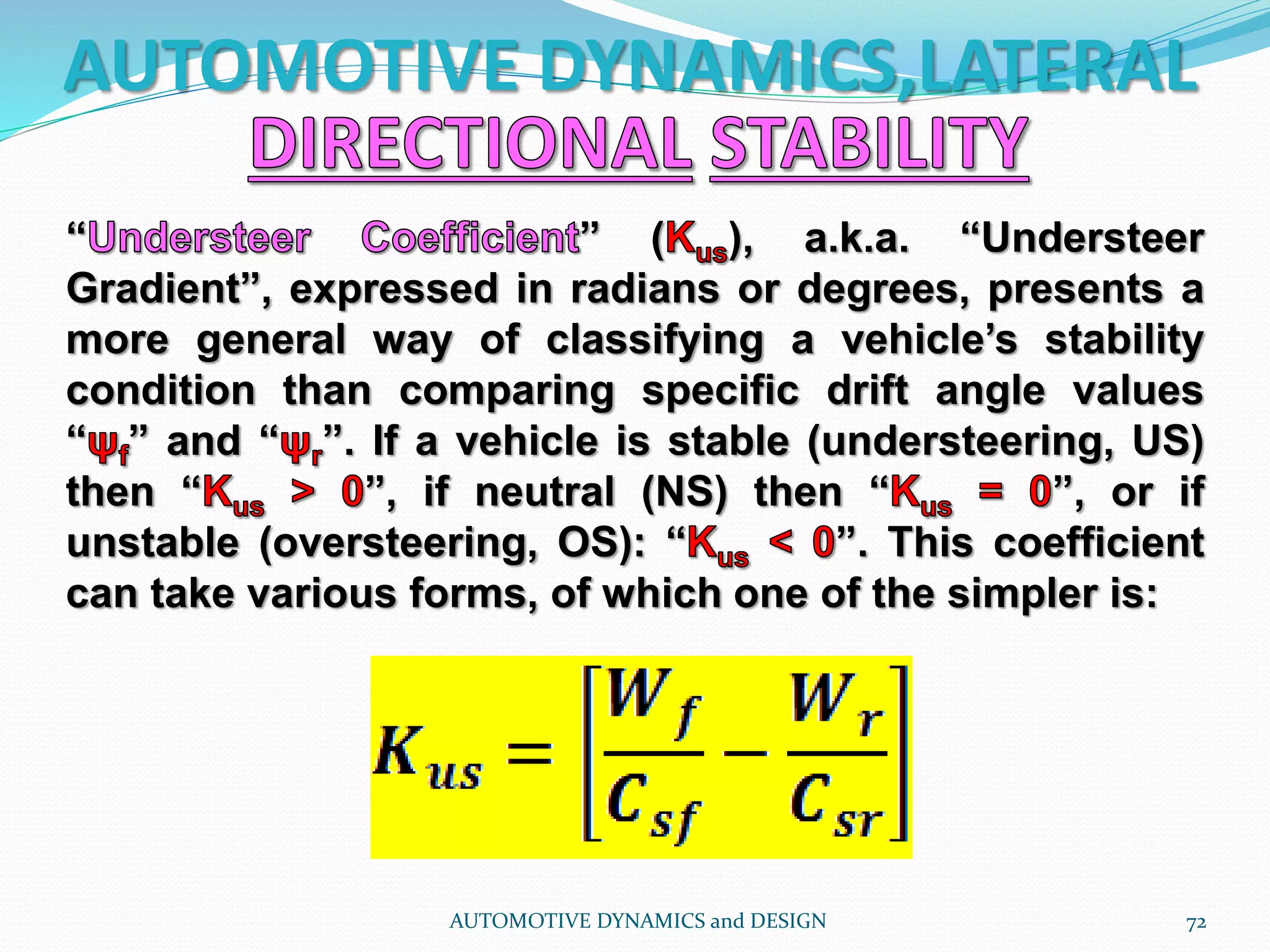

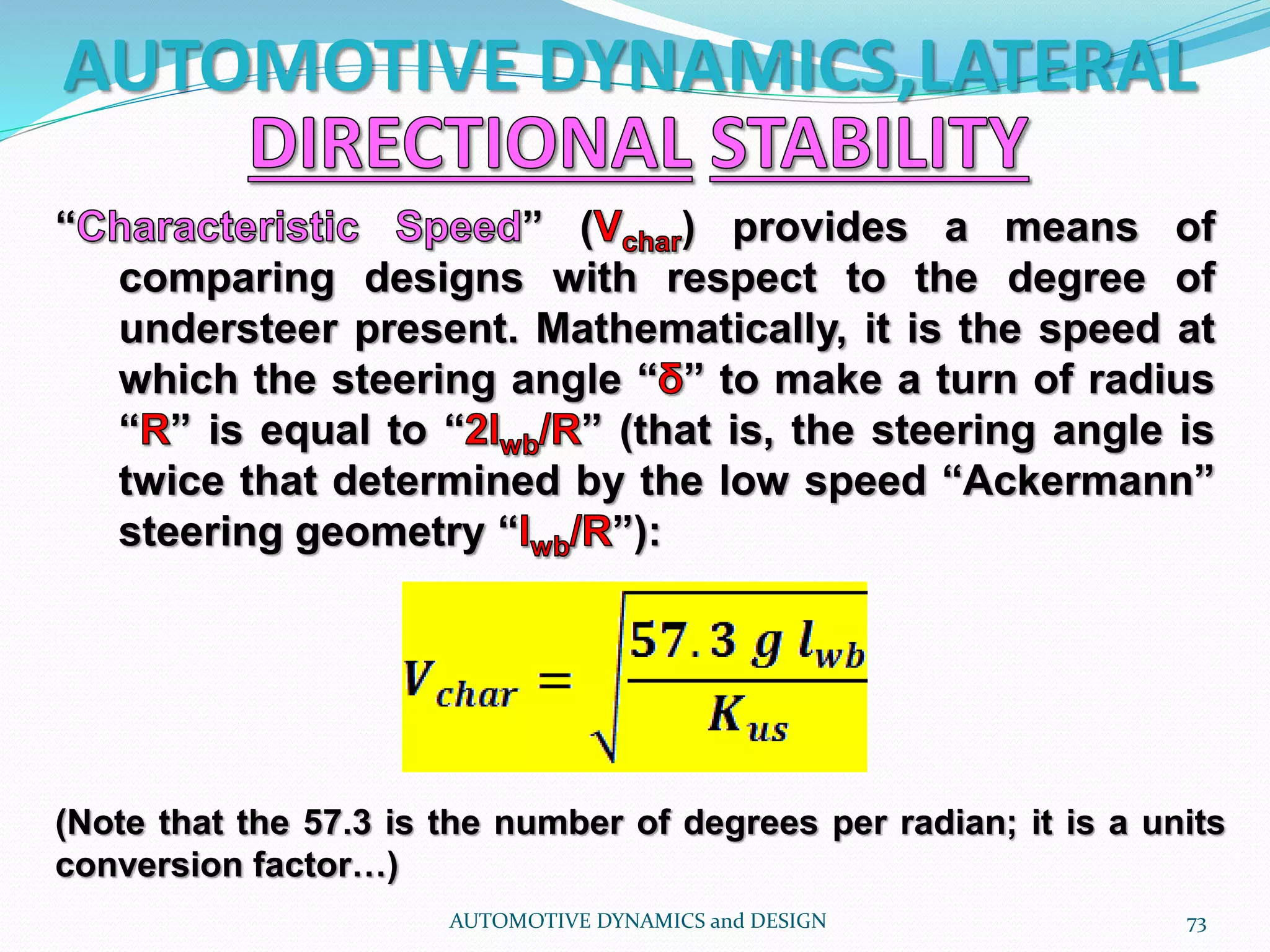

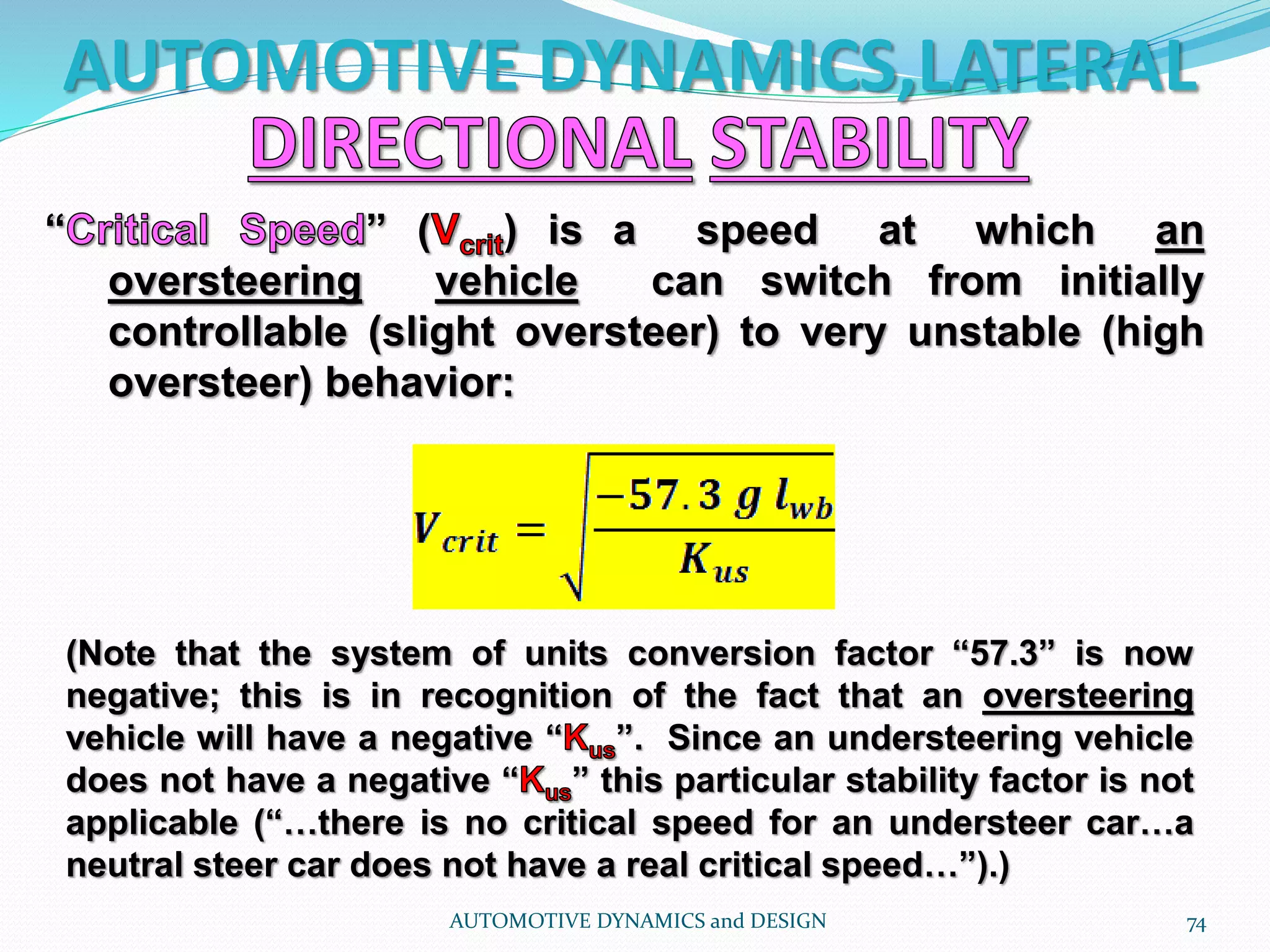

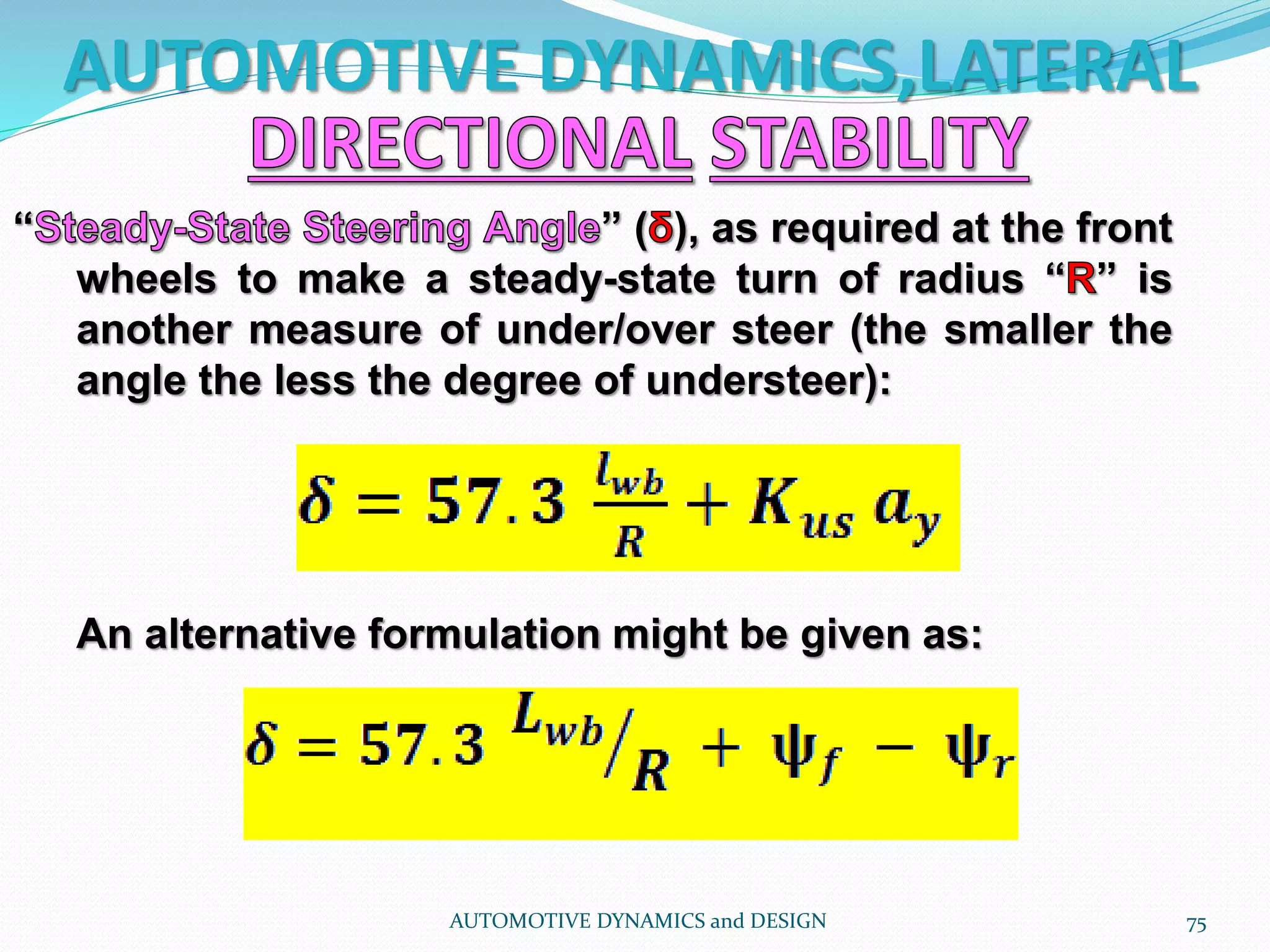

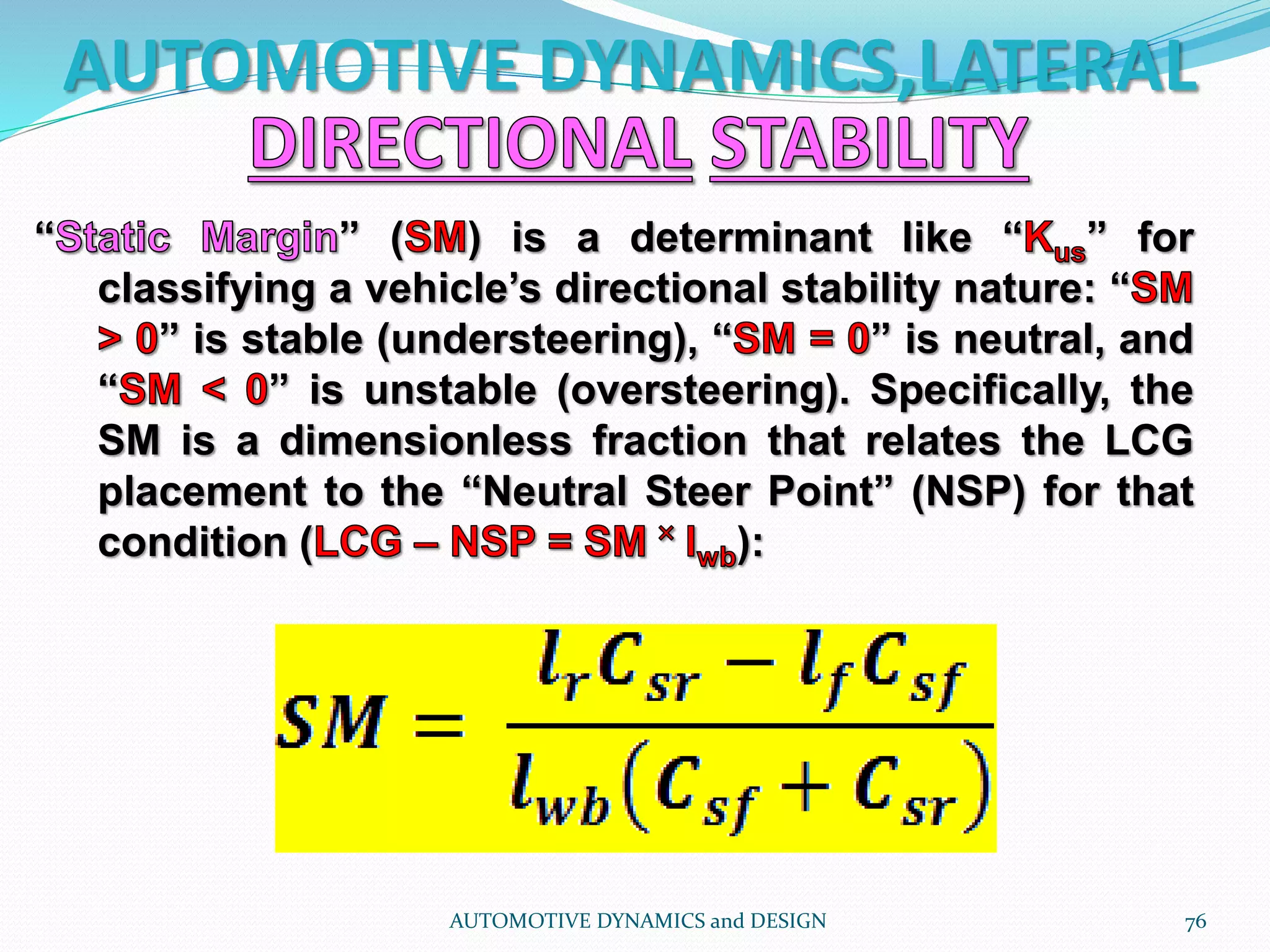

The document discusses the dynamics of automotive performance related to lateral motion, detailing aspects such as maneuverability, lateral acceleration, and rollover risk. It explains the complex relationships between forces and moments during steady-state turning and highlights the significance of factors like tire traction, weight transfer, and suspension effects in vehicle dynamics. The implications of these dynamics are illustrated through various equations and scenarios, ultimately emphasizing the importance of these factors in vehicle safety and performance.