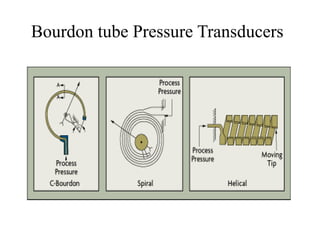

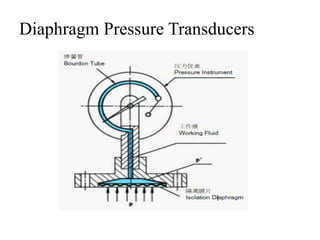

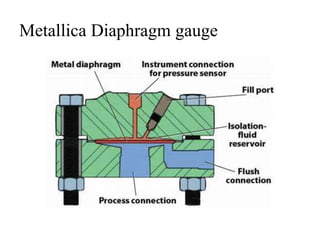

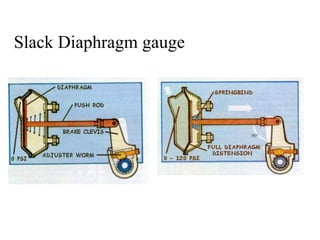

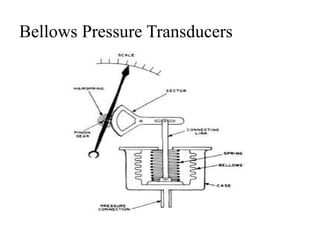

This document discusses elastic pressure transducers, which are mechanical transducers that convert one form of energy into another form that can be easily measured. There are several types of elastic pressure transducers, including Bourdon tube, diaphragm, and bellows transducers. Bourdon tube transducers are inexpensive with simple construction but are susceptible to shock and vibration. Diaphragm transducers have good linearity but lack vibration resistance and are difficult to repair. Bellows transducers can deliver high force but require temperature compensation and are unsuitable for high pressures.