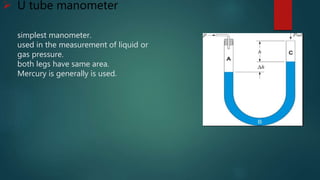

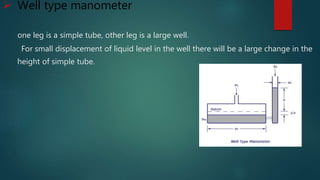

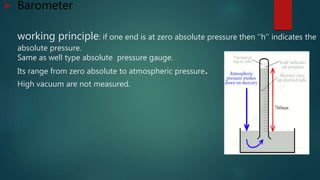

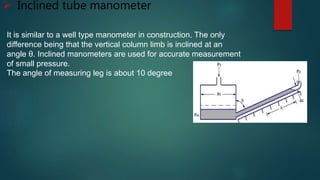

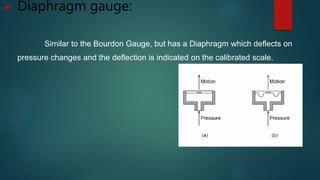

Hydrostatic devices use fluids to measure pressure and come in two types: manometers and mechanical gauges. Manometers measure pressure by comparing the height of a liquid column to the pressure of a fluid. Common manometers are U-tube, well, barometer, and inclined tube manometers. Mechanical gauges use a solid object like a tube, plate or diaphragm that deflects under pressure instead of a liquid column. Common mechanical gauges are Bourdon tubes, diaphragms, bellows, and pressure transducers, which convert pressure into electrical signals.