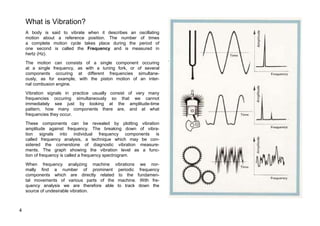

This document provides an introduction to vibration measurement, including:

- Why vibration is measured, where it comes from, and what vibration is

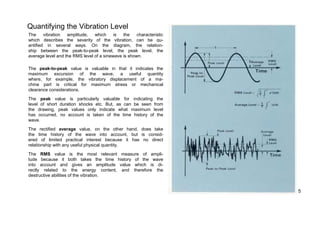

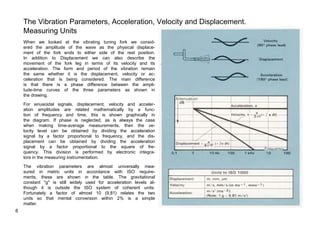

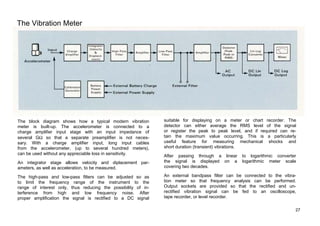

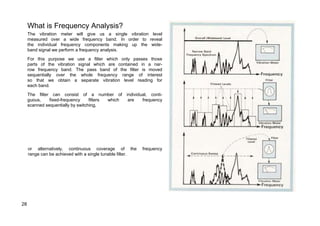

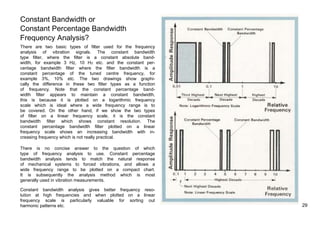

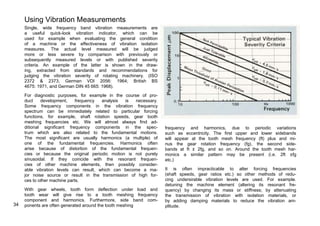

- How to quantify vibration levels using parameters like acceleration, velocity, and displacement

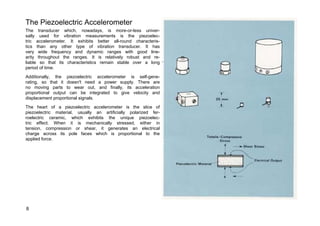

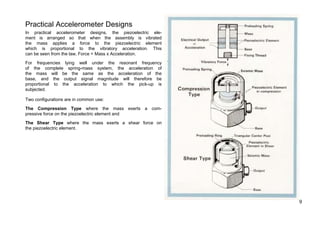

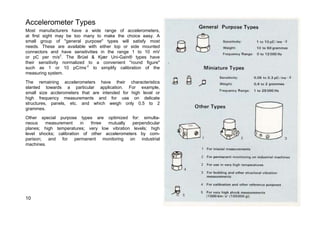

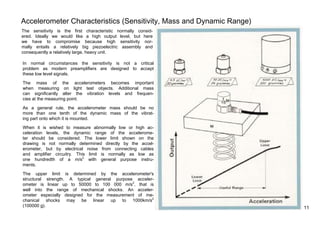

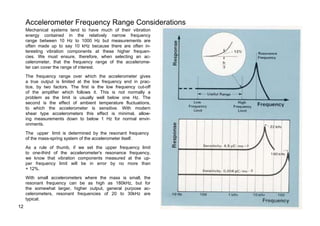

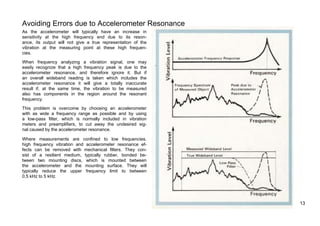

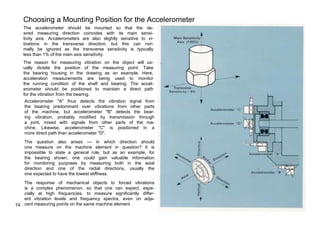

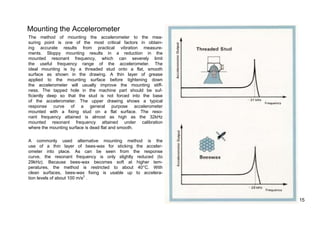

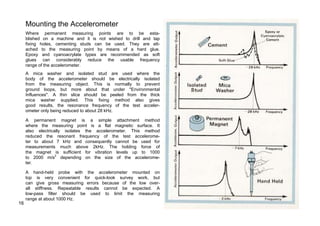

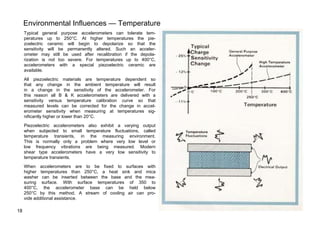

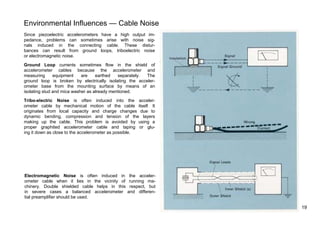

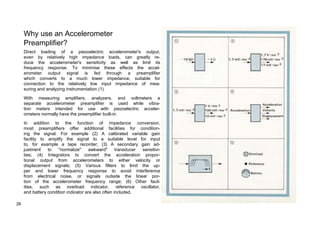

- Details on piezoelectric accelerometers, which are commonly used to measure vibration

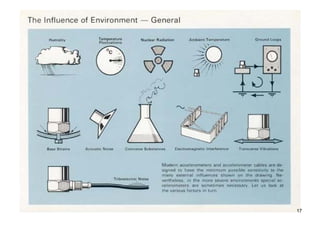

- Factors to consider when taking vibration measurements, like sensor mounting, environmental influences, and instrumentation