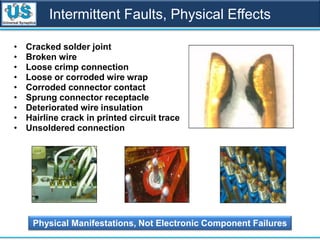

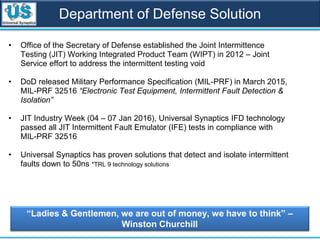

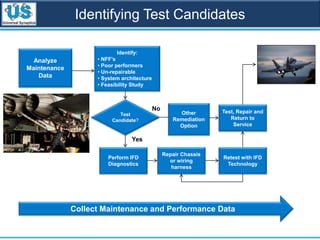

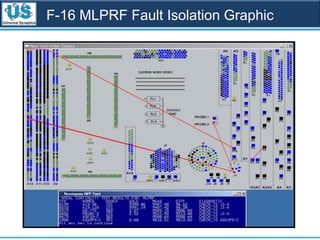

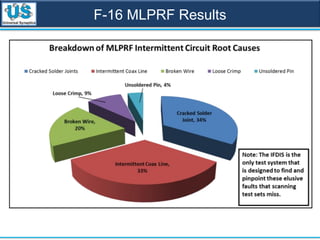

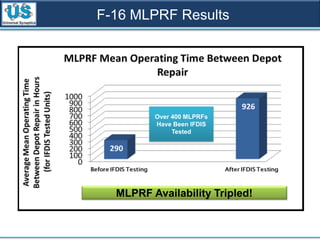

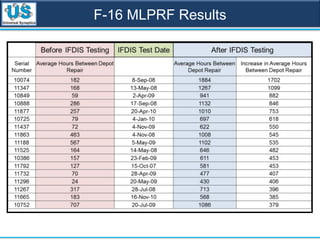

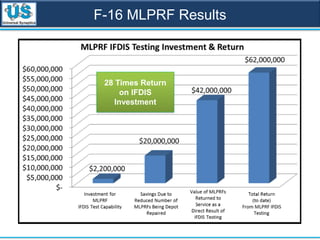

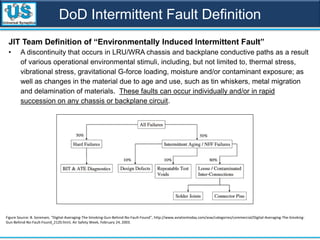

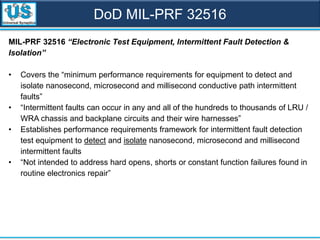

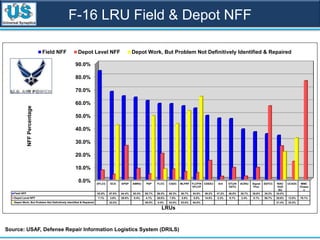

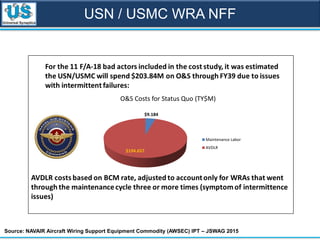

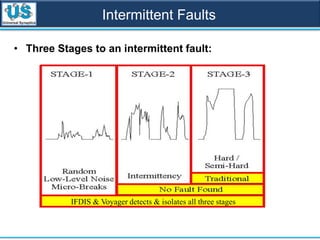

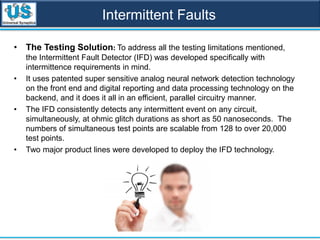

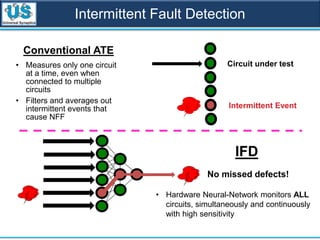

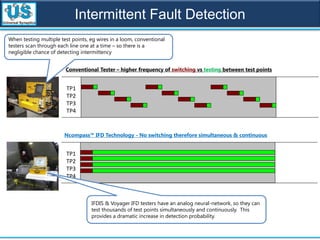

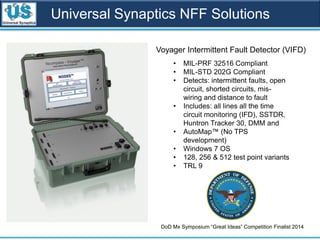

This document discusses how intermittent faults are a major cause of No Fault Found (NFF) issues for the Department of Defense, costing $2-10 billion annually. Conventional testing methods are unable to detect intermittent faults. Universal Synaptics has developed intermittent fault detection technologies, the Intermittent Fault Detection and Isolation System (IFDIS) and Voyager Intermittent Fault Detector, which can test all circuit lines simultaneously and continuously with high sensitivity, significantly reducing NFF rates and costs for the DoD.

![Universal Synaptics NFF Solutions

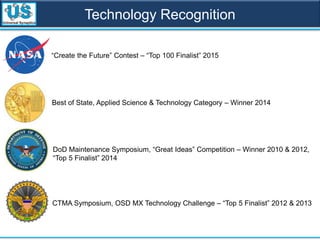

DoD Mx Symposium “Great Ideas”

Competition Winner 2010 & 2012

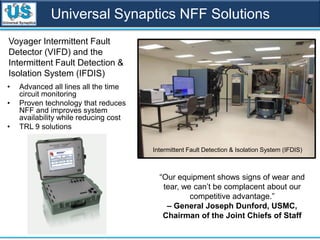

Intermittent Fault Detection & Isolation System (IFDIS)

• MIL-PRF 32516 Compliant

• Detects: intermittent faults,

open circuit, shorted circuits

and mis-wiring

• Includes: all lines all the time

circuit monitoring (IFD),

Picoscope, DMM and

• AutoMap™

• Windows 7 OS

• Expandable to over 20,000

test points

• TRL 9

IFDIS

"If we’re going to keep the advantage

that we’ve historically had then we need

to keep up [technologically].”

– Secretary of Defense Ash Carter](https://image.slidesharecdn.com/1330anderson-170618232828/85/1330-anderson-17-320.jpg)