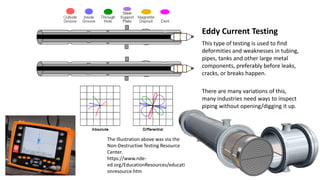

The document discusses the impact of digital maintenance and test equipment (M&TE) on industrial control system security, emphasizing the vulnerabilities introduced by modern digital technologies. It outlines how M&TE is essential for maintaining reliable industrial operations but highlights the potential for cyber interference due to insufficient security measures during firmware updates and equipment evaluations. The author provides insights into the risks associated with M&TE hacking and suggests security measures to mitigate these risks, particularly for high-consequence equipment.