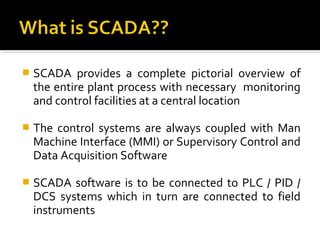

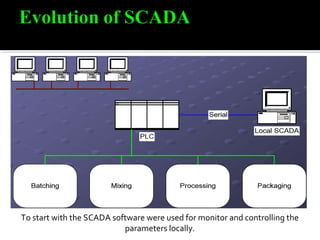

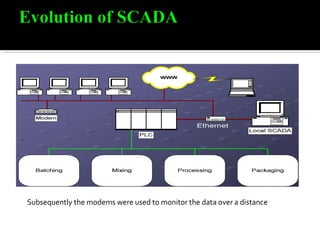

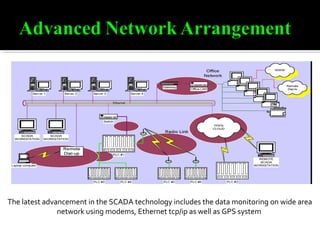

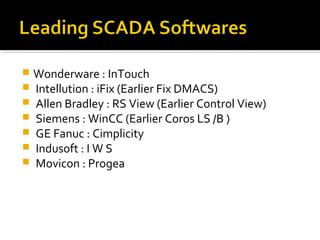

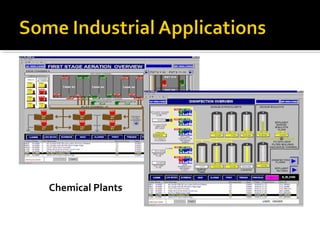

SCADA software provides centralized monitoring and control of industrial processes through dynamic process graphics, real-time trending, alarms, recipe management, security features, and connectivity to field devices and databases. It allows operators to monitor and control processes from remote locations through networking capabilities. SCADA has advanced from local to wide area monitoring using technologies like modems, Ethernet, and GPS. Common SCADA software packages include Wonderware InTouch, Intellution iFix, Allen Bradley RSView, Siemens WinCC, GE Fanuc Cimplicity, and Indusoft IWS. SCADA is widely used in industries like oil and gas, water and wastewater, manufacturing, and electrical power generation.