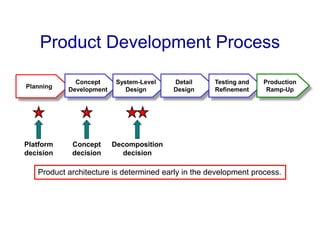

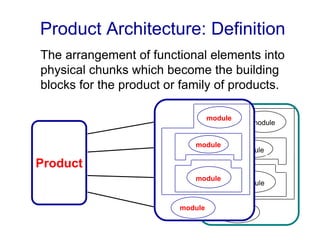

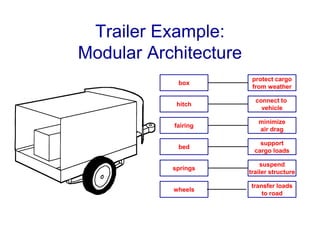

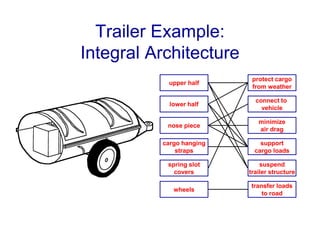

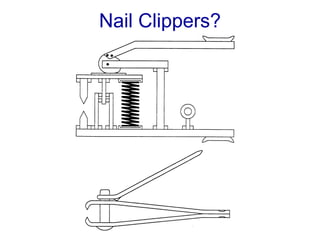

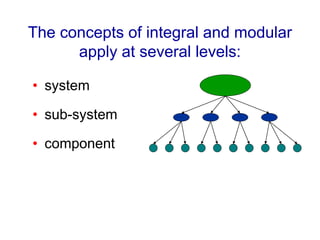

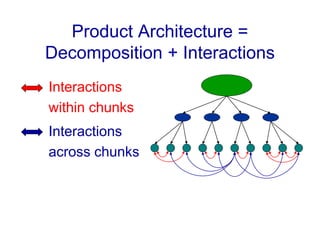

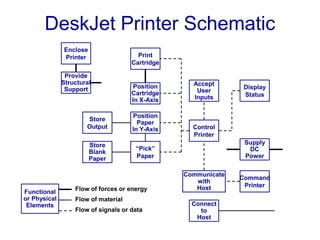

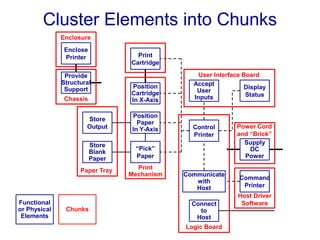

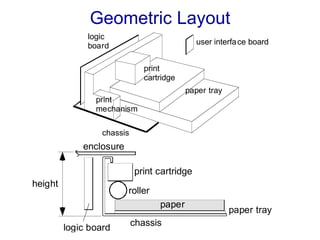

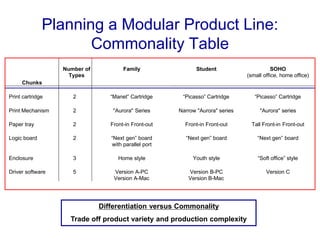

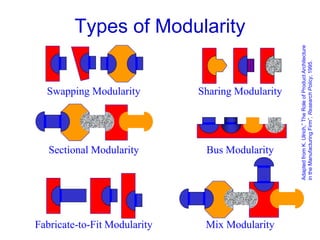

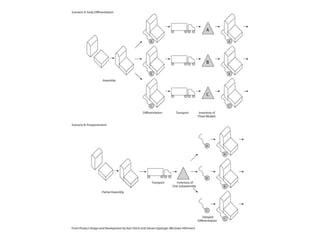

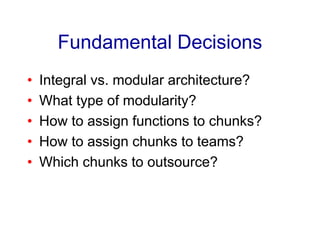

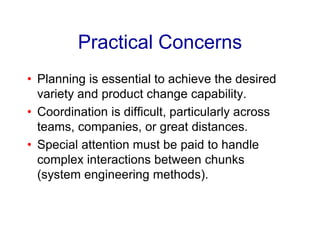

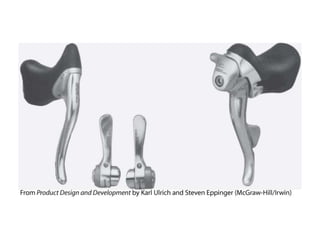

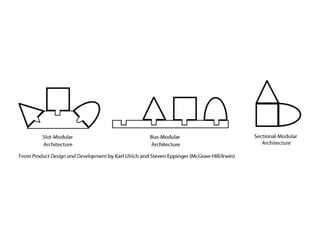

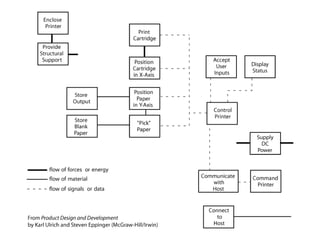

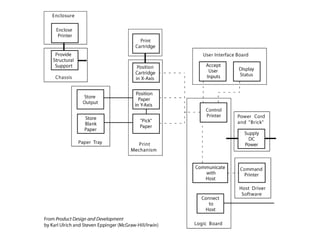

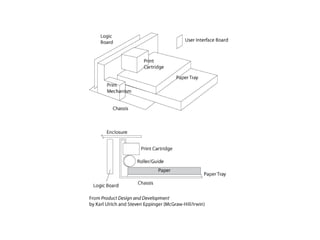

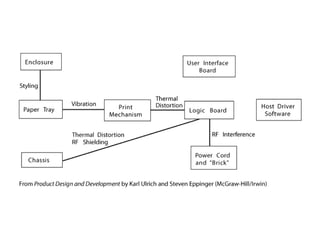

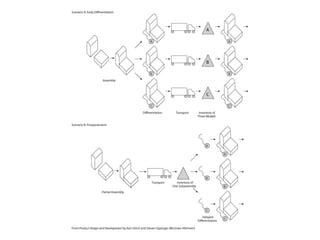

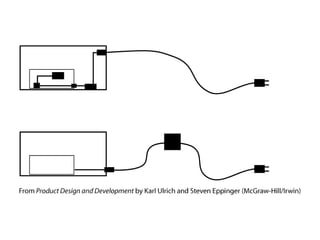

This document provides an overview of product architecture from Chapter 10 of the book Product Design and Development by Karl T. Ulrich and Steven D. Eppinger. It defines product architecture as the arrangement of functional elements into physical chunks that become building blocks for a product or product family. It discusses how to establish a modular architecture through decomposition and interaction mapping. Key decisions include choosing integral vs modular, the type of modularity, and assigning functions and teams to chunks. Product architecture determines ease of variety, modification, and costs.