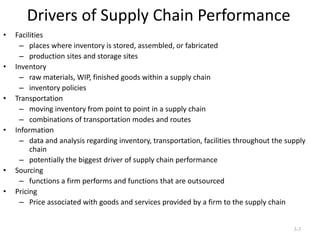

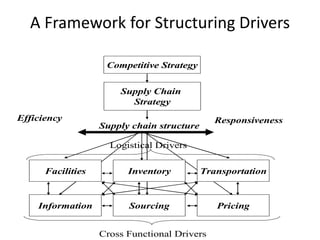

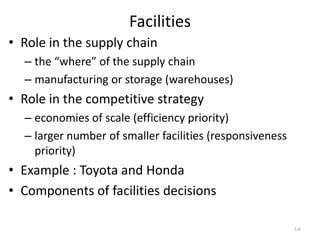

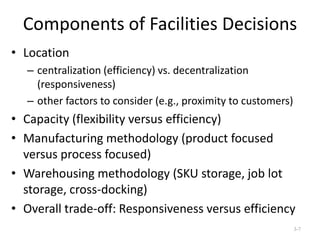

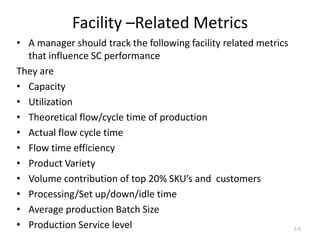

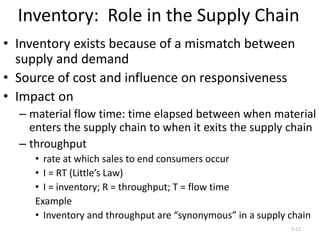

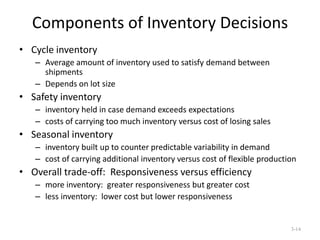

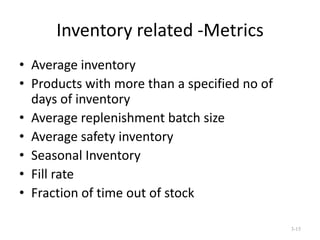

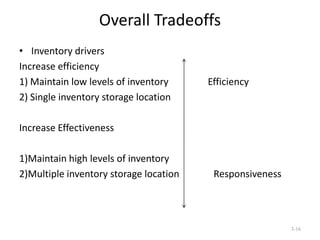

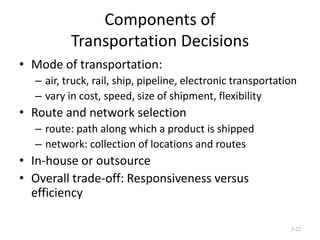

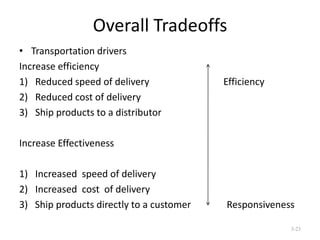

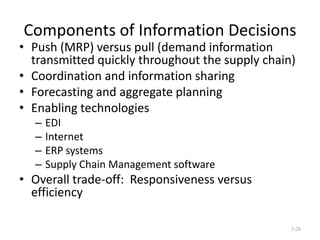

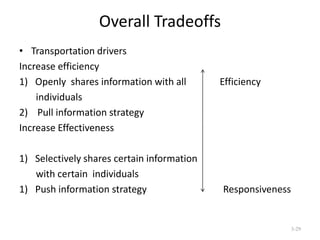

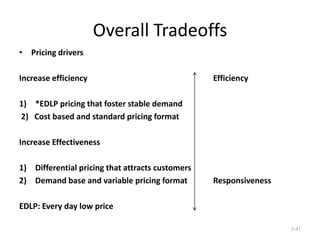

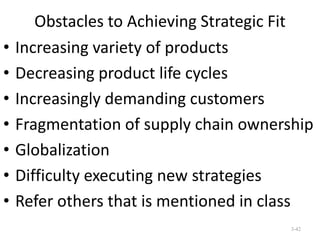

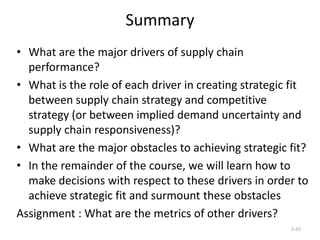

The document discusses the major drivers of supply chain performance - facilities, inventory, transportation, information, sourcing, and pricing. It explains the role of each driver in the supply chain and how firms can prioritize efficiency versus responsiveness through decisions about each driver. Achieving the right balance allows firms to create strategic fit between their supply chain and competitive strategy. However, obstacles like increasing product variety and demanding customers can make achieving fit difficult.